Carbon particle dispersion and method for producing same

A manufacturing method and technology of dispersion liquid, which are applied in the preparation/purification of carbon, conductive materials dispersed in non-conductive inorganic materials, fibrous fillers, etc. As well as mechanical properties and other issues, to achieve the effect of good electrical conductivity and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

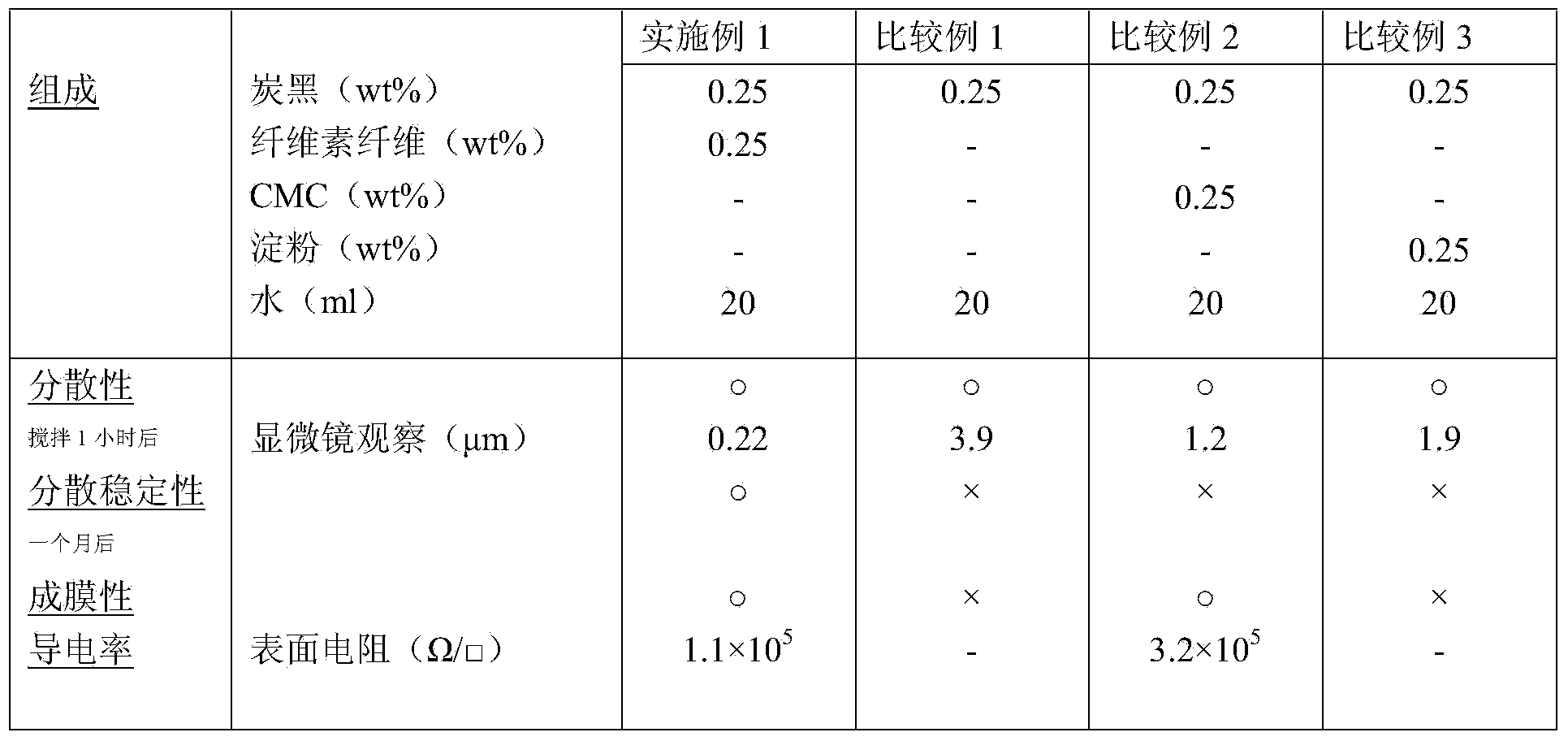

Embodiment 1

[0075] Cellulose to which carboxyl groups were imparted by TEMPO oxidation treatment (carboxyl group content: 1.8 mmol / g) was prepared. The pH was adjusted to 10 using 1N sodium hydroxide while adding ion-exchanged water so that the total concentration of solid content as cellulose was 1%. These were processed with a stirrer (Osaka Chemical, absolute mill, 14000 rpm) for 1 hour to prepare a prepared liquid containing cellulose fibers. The obtained cellulose had a fiber width of 3 nm and a fiber length of 1.6 μm. 5 ml of the prepared liquid, 50 mg of carbon black, and 15 ml of ion-exchanged water were mixed and stirred with a stand mixer to prepare a carbon black dispersion. After stirring for one hour, the dispersion was allowed to stand. The dispersibility after the dispersion of carbon black proceeded for one hour and the dispersion stability after standing for one month were observed. Furthermore, 2 ml of the dispersion after dispersing for one hour was dropped onto a gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com