Automobile hub diameter measuring and positioning conveying device and control method thereof

A technology for diameter measurement and automobile hubs, applied in the direction of measuring devices, conveyor control devices, conveyors, etc., can solve the problems of not being able to make full use of the internal space of solid melting furnaces, damage to the surface of hubs and roller tables, and complex mechanical mechanisms, etc., to achieve improvement Energy utilization and heat treatment efficiency, convenient arrangement and density, and simple control algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

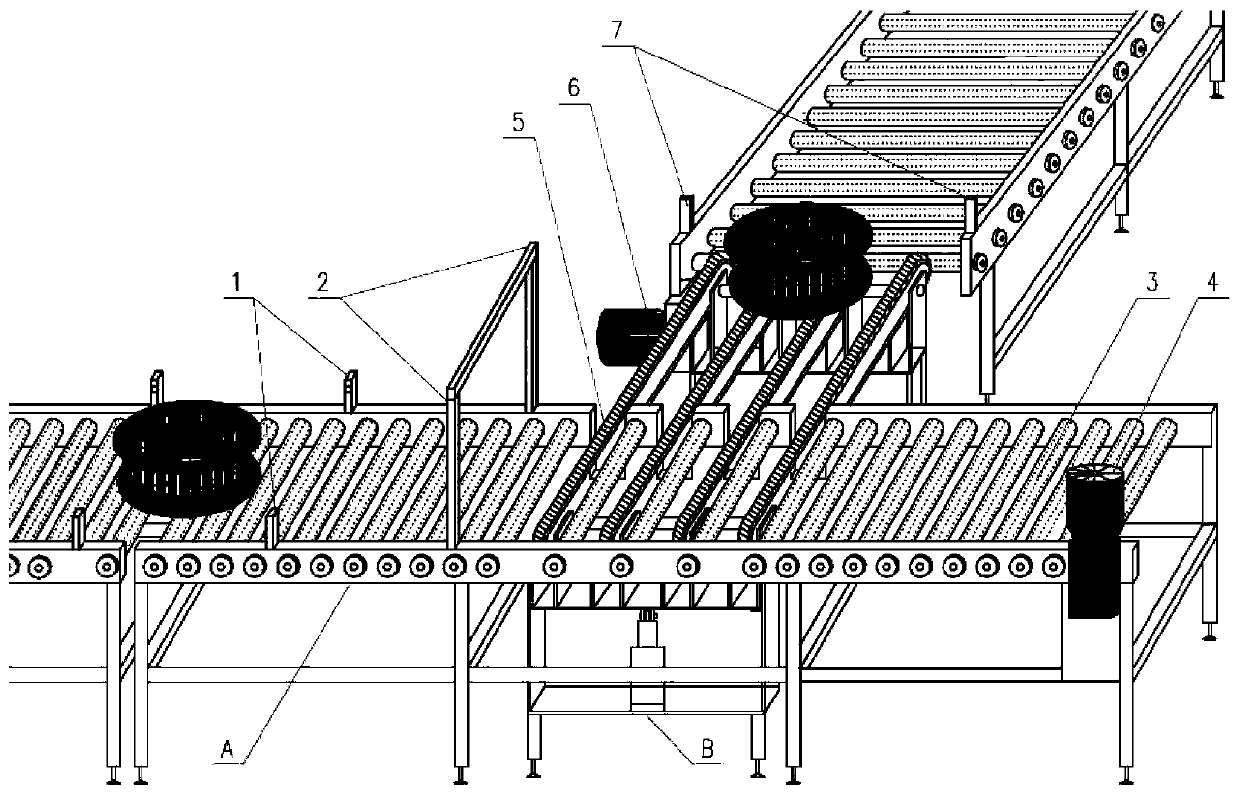

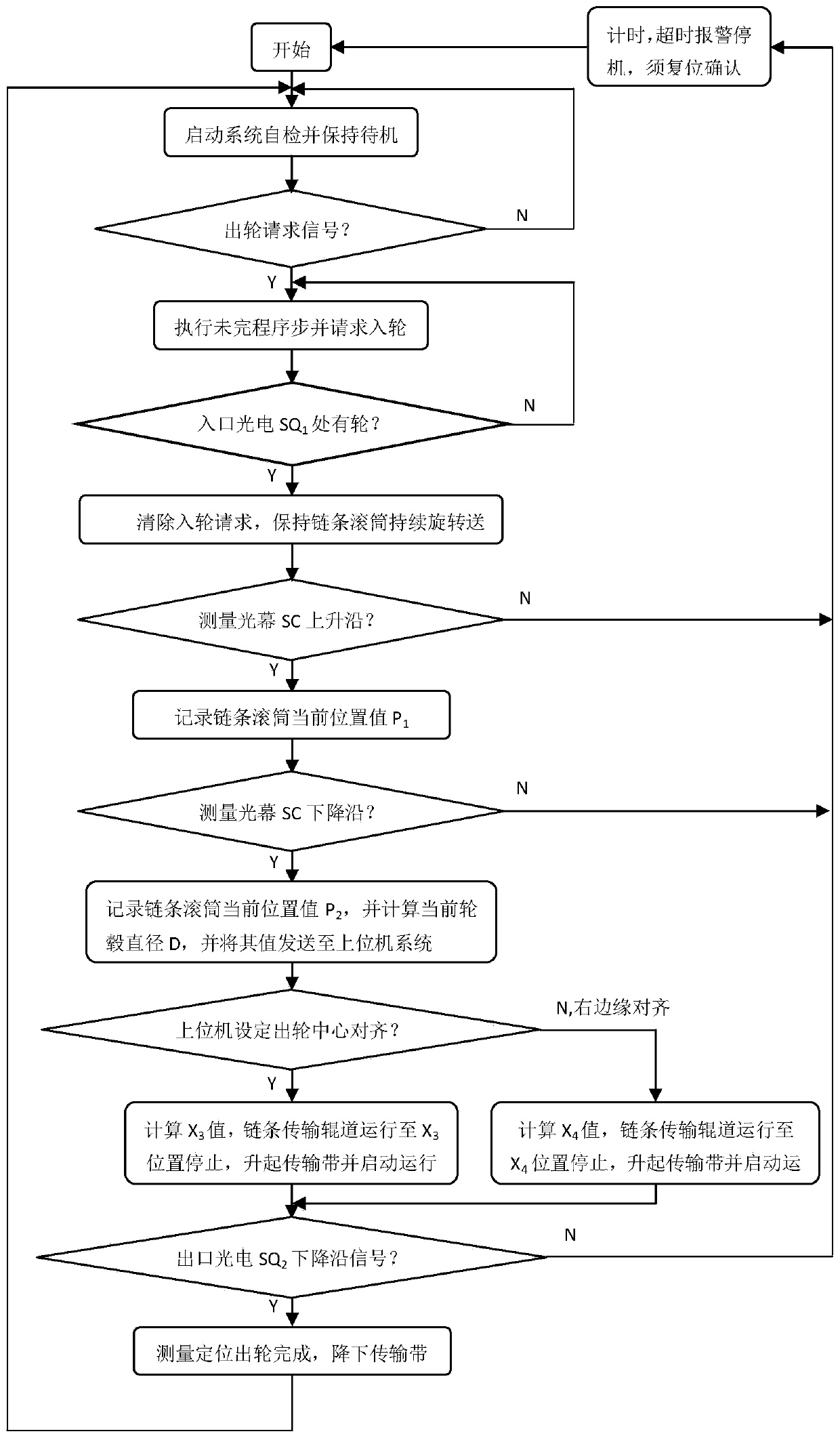

[0043] As a specific embodiment of the present invention, the lateral conveying device A includes a first variable frequency motor 4 that provides a driving force, a chain that transmits a driving force, and a roller 3 that carries a conveying hub; the first variable frequency motor 4 passes through a chain that transmits a driving force, Drive the rotation of the roller bearing the conveying hub, so that the hub moves laterally on the transverse conveying device;

[0044] The wheel hub longitudinal conveying device includes the second variable frequency motor 6 that provides the driving force, the belt 5 that transmits the driving force and carries the conveying wheel hub, and the lifting device that drives the belt to move up and down; the lifting device drives the belt that carries the conveying wheel hub to move up and down to realize the horizontal The hub on the conveying device is smoothly transferred to the longitudinal conveying belt; the second variable frequency moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com