High-temperature ceramic pressure sensor for pressure test in high temperature environment and processing method thereof

A pressure sensor and pressure testing technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problems of power supply, signal circuit temperature rise, unstable mechanical properties, unstable electrical properties, etc., to achieve Solve the problem of thermal expansion mismatch, avoid high temperature problems, and achieve the effect of flatness and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

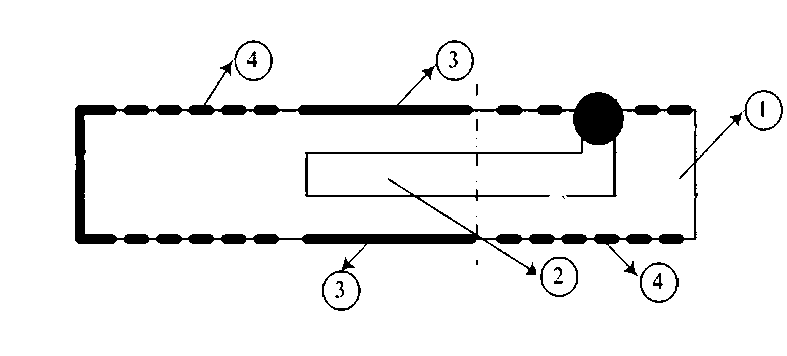

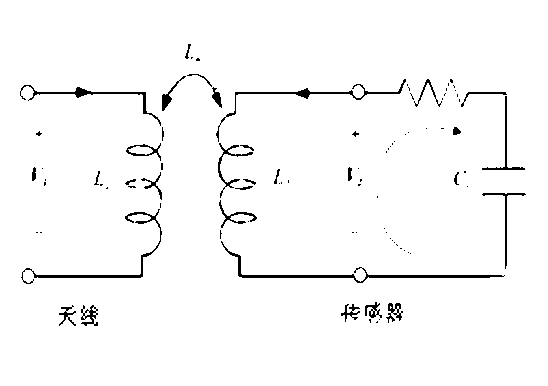

[0024] Such as figure 1 As shown, the high-temperature ceramic pressure sensor used for pressure testing in a high-temperature environment includes a pressure-sensitive ceramic part 1 for sensitive pressure changes. The pressure-sensitive ceramic part 1 is provided with a closed chamber 2, and the upper and lower planes of the pressure-sensitive ceramic part 1 are The upper area facing the airtight chamber 2 is a pressure sensitive area; the surface of the pressure sensitive area on the upper and lower planes of the pressure sensitive ceramic part 1 is respectively provided with an electrode layer 3, and the two electrode layers 3 form a capacitor; the upper and lower planes of the pressure sensitive ceramic part 1 The surface of the non-pressure sensitive area on the lower plane is provided with a planar spiral inductor 4, one end of the planar spiral inductor 4 is connected to the electrode layer 3 on the same surface, and one end is connected to the planar spiral inductor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com