Patents

Literature

35results about How to "Realize pressure measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

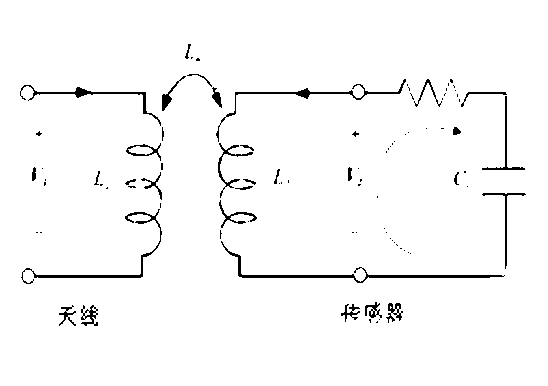

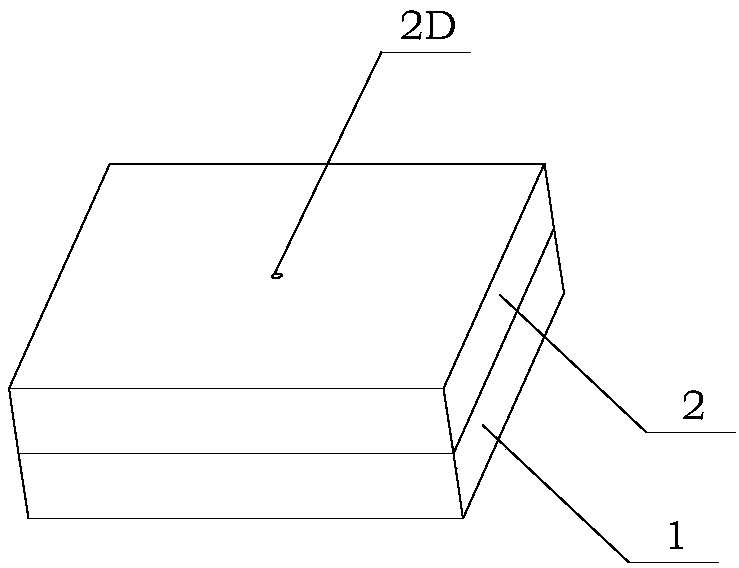

High-temperature ceramic pressure sensor for pressure test in high temperature environment and processing method thereof

ActiveCN103017945ARealize pressure measurementAvoid high temperature problemsFluid pressure measurement by electric/magnetic elementsForce measurementCapacitancePressure sense

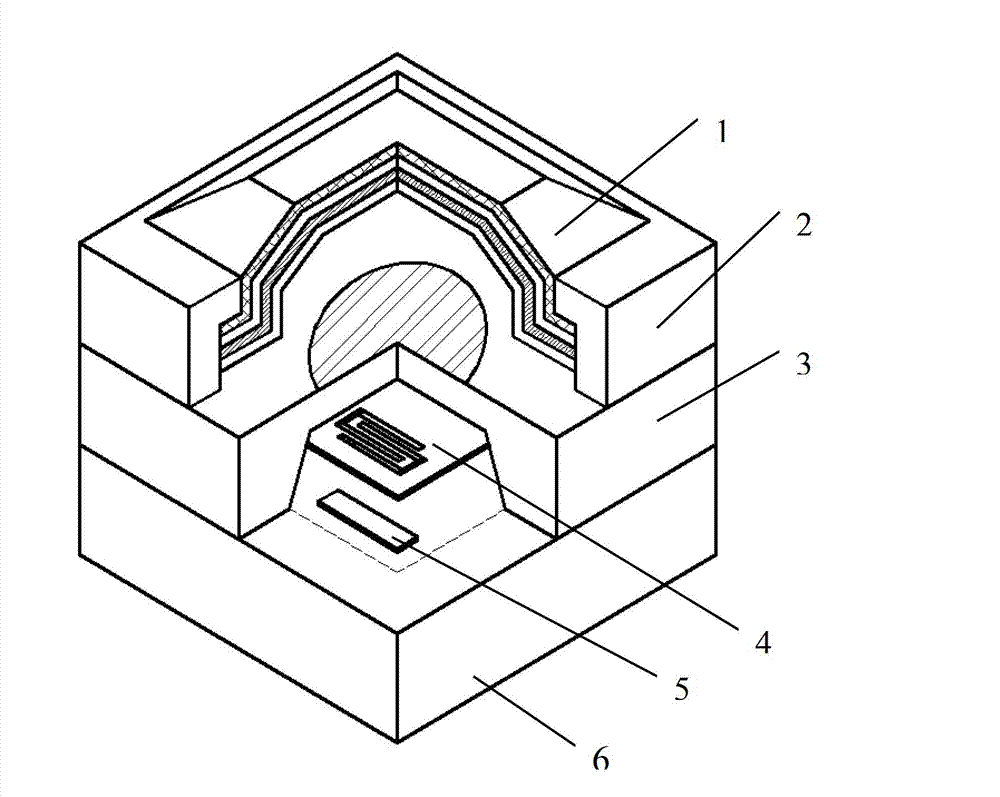

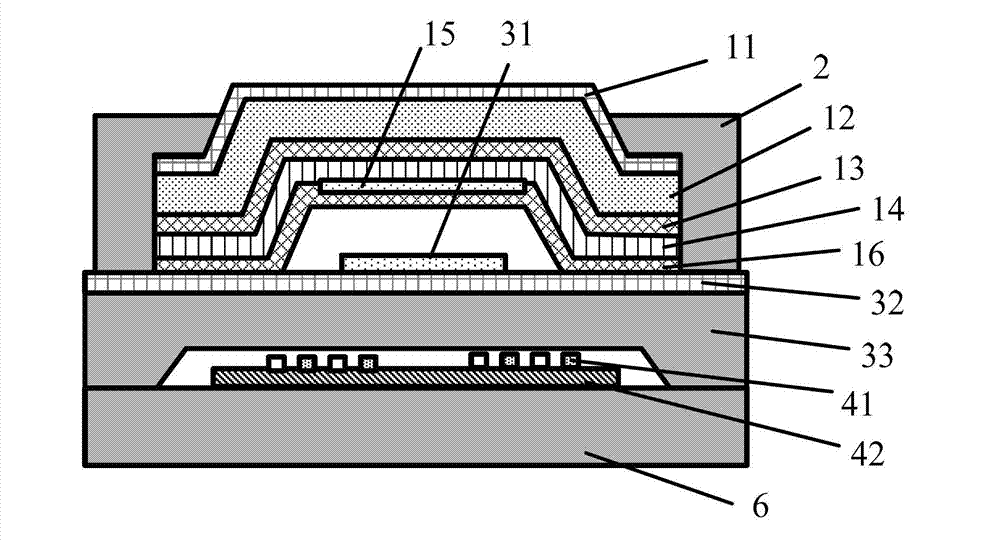

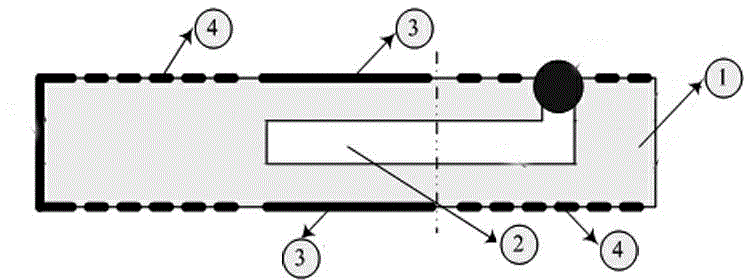

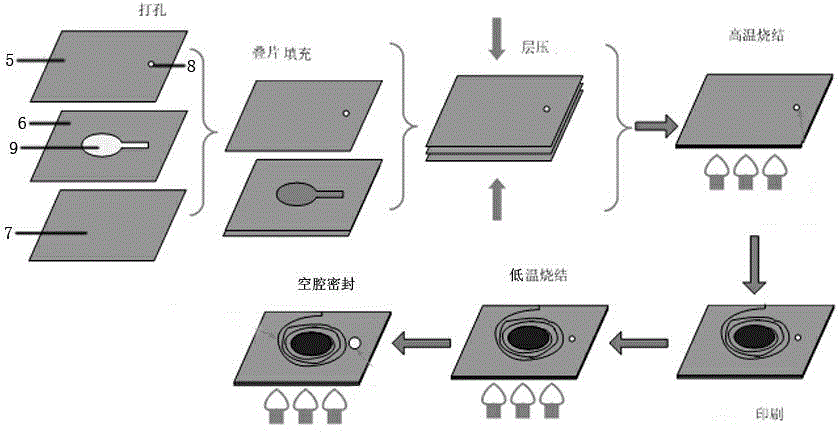

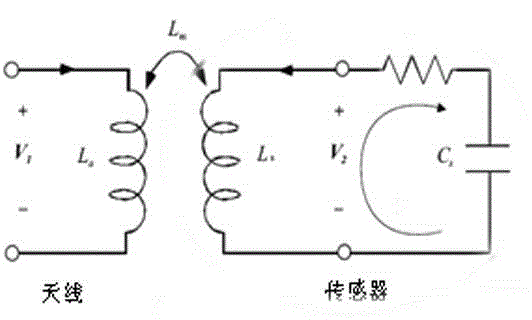

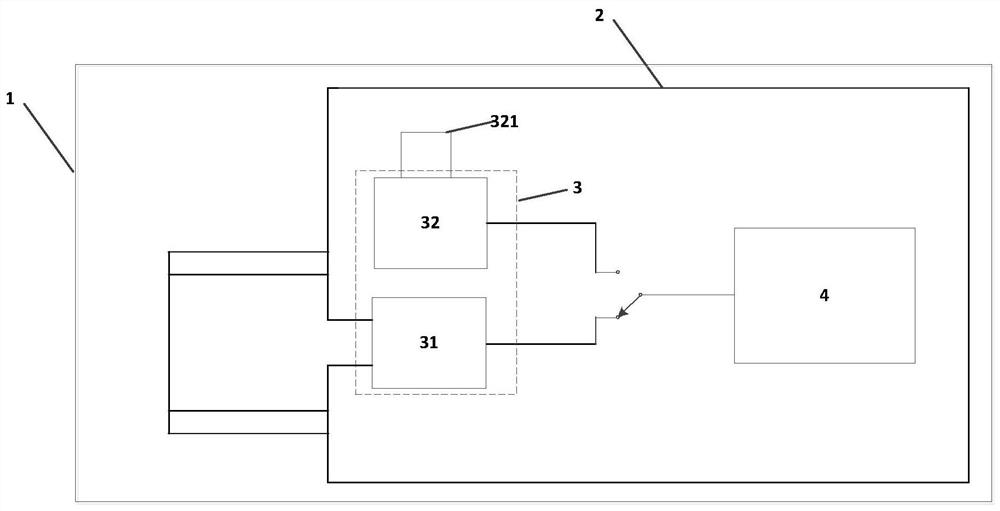

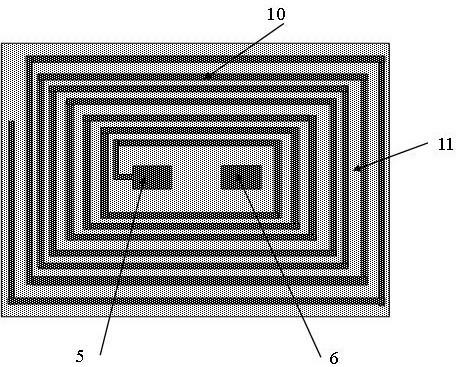

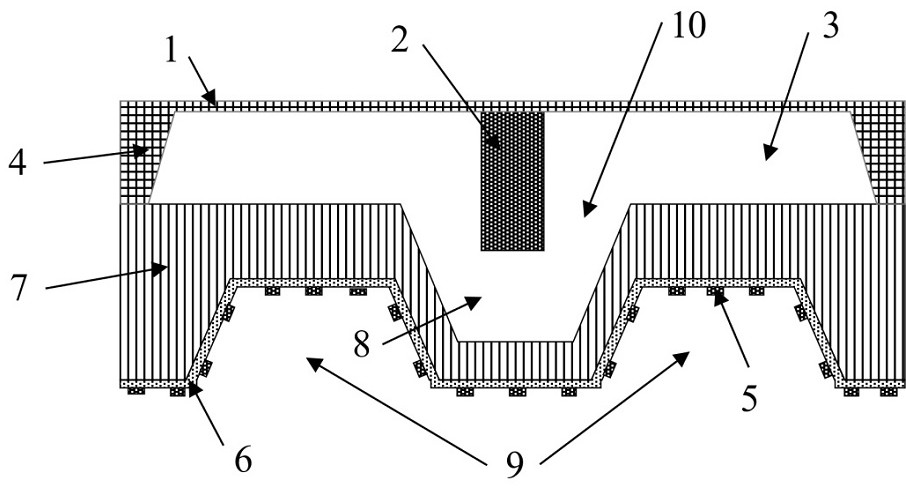

The invention relates to the field of a pressure sensor, particularly a high-temperature ceramic pressure sensor for a pressure test in a high temperature environment and a processing method of the high-temperature ceramic pressure sensor. The effective pressure test can be implemented in a special high temperature environment for a long time. The high-temperature ceramic pressure sensor comprises a pressure sensing ceramic element, wherein a closed chamber is arranged inside the pressure sensing ceramic element; the upper and lower planes of the pressure sensing ceramic element are respectively provided with an electrode layer and a planar spiral inductor; the two electrode layers form a capacitor; and the capacitor is connected in series with the two planar spiral inductors to form an LC loop. The processing steps are as follows: a, curtain coating; b, punching; c, stacking and filling; d, laminating and thermal cutting; e, high-temperature sintering; f, printing and low-temperature sintering; and g, cavity sealing. The sensor and the method disclosed by the invention can design and realize a concrete structure of sensitive elements of the sensor at a totally new angle; the structure is ingenious and reasonable; and a passive wireless high-temperature ceramic pressure sensor for the detection in a noncontact wireless manner based on an LC resonance theory is realized, so that the pressure test can be performed for a long time at a high temperature higher than 300 DEG C.

Owner:ZHONGBEI UNIV

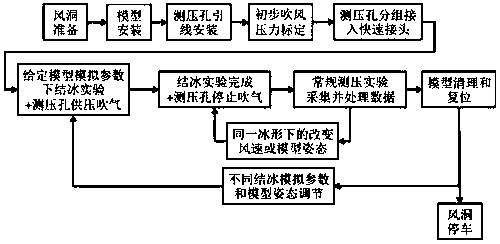

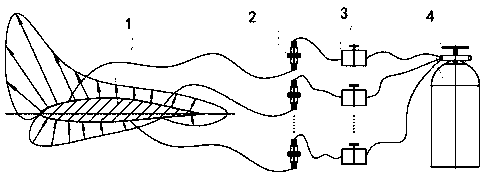

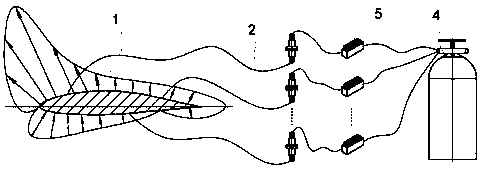

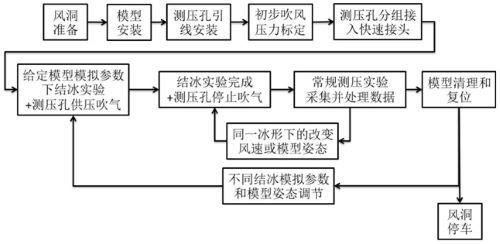

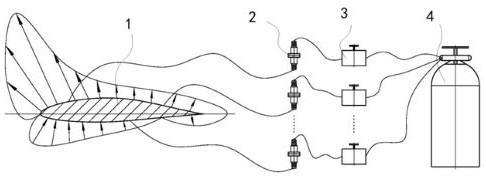

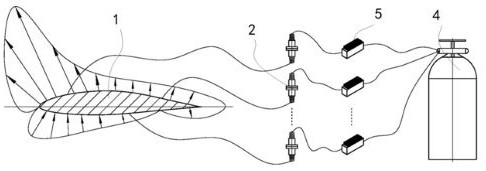

Icing wind tunnel pressure measurement test method

ActiveCN111238759AGuaranteed accuracySolve the difficulties that cannot be stress testedAerodynamic testingEngineeringIce formation

The invention discloses an icing wind tunnel pressure measurement test method. The method is based on an existing icing wind tunnel model icing test. The method comprises: establishing a wind tunnel test method integrating a model icing test and an ice-shaped aerodynamic influence evaluation test, improving the accuracy of a test result is improved while the aerodynamic test efficiency, firstly, installing a pressure measurement model according to a conventional pressure measurement test method, and connecting a pressure measurement hole to a scanning valve quick connector through a pressure measurement hose; calibrating and grouping the pressure values of the pressure measuring holes under different speed pressures; when a cloud-containing pneumatic test is carried out, using an externalair source for supplying pressure and blowing air to the pressure measuring hole; after the outer surface of the model is frozen, closing the pressure measuring hole for air supply, performing a pressure measuring test with an ice shape according to a conventional method, and finally obtaining the aerodynamic characteristics of the ice-shape-containing model. According to the invention, the problem that the pressure measurement test cannot be carried out on the model pressure measurement hole of the icing wind tunnel in a cloud state is solved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

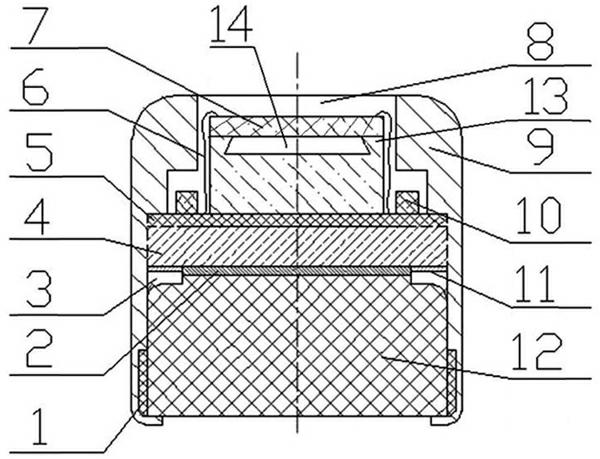

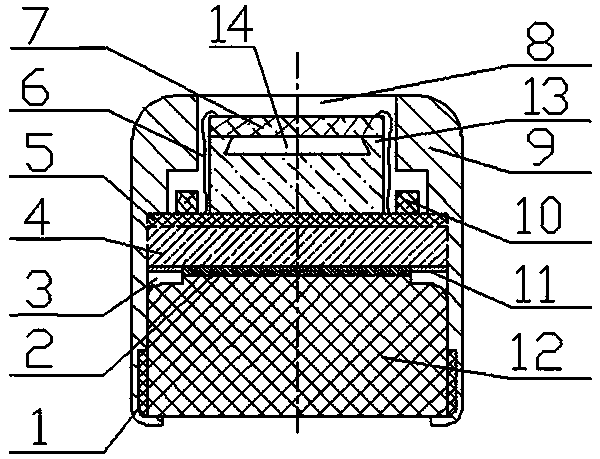

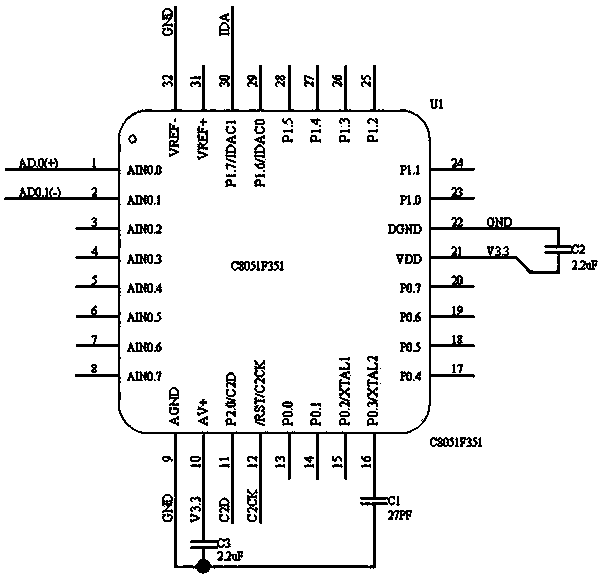

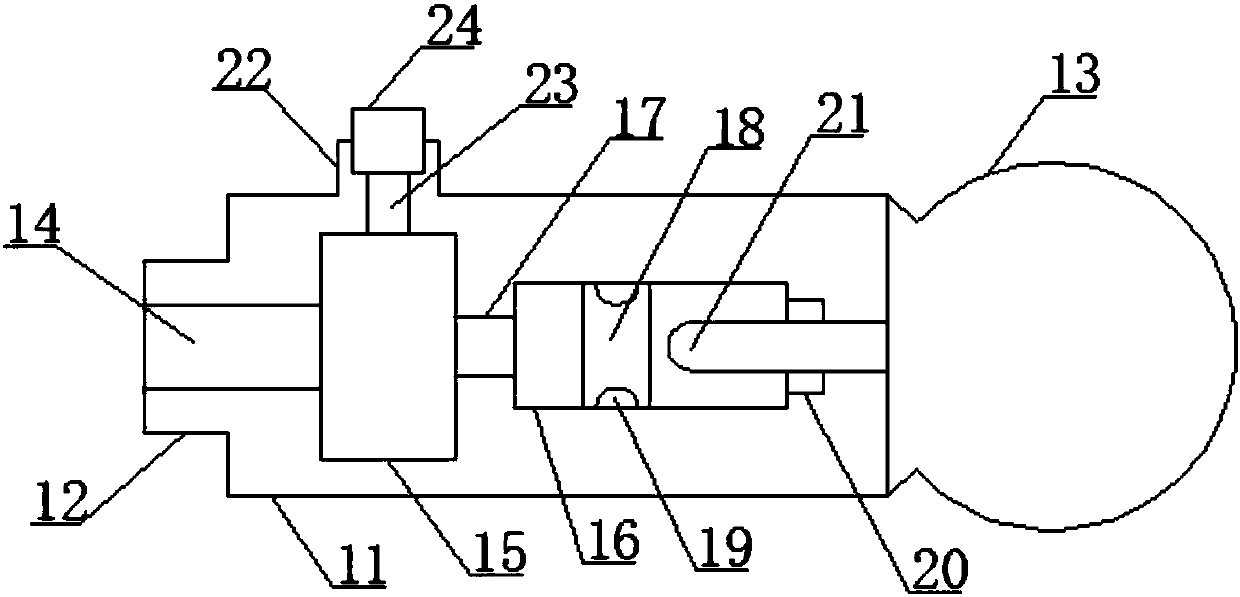

Miniature mud floating electronic pressure gauge, its working method, and pressure measuring device

The invention discloses a micro mud floating electronic pressure gauge, a working method thereof, and a pressure measurement device, relates to the field of oil and gas extraction, and aims to provide a device for measuring underground pressure and temperature in the mud drilling process in real time, and a working method thereof. The technical key point is that: a button cell, a singlechip with acquisition software, a circuit board, a connection block, and a pressure chip are stacked in a shell sequentially from bottom to top; the shell is a cylindrical shell of which the upper and lower ends are provided with openings, and the interior and the exterior of the shell are isolated by isolation protective adhesive; the pressure gauge acquires temperature and pressure information intermittently under a well; and the pressure measurement device comprises the pressure gauge, a data loading system, and a pressure and temperature calibrating device. The pressure gauge is as small as drill cuttings, so the pressure gauge can float in mud and move along with mud, measure pressure timely and recover data, and does not influence the drill construction.

Owner:CHENGDU HAOHAN WELL COMPLETION & LOGGING SCI & TECH

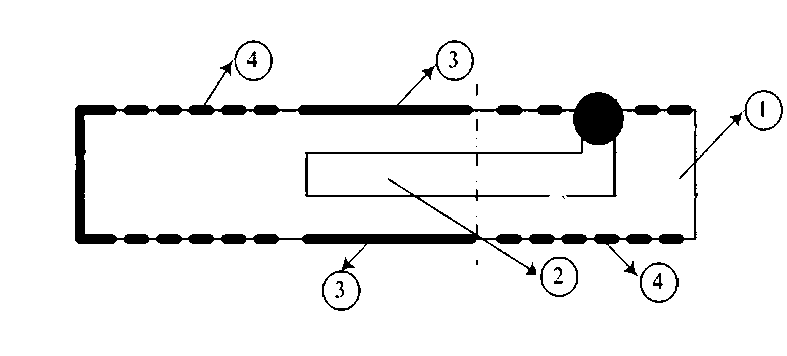

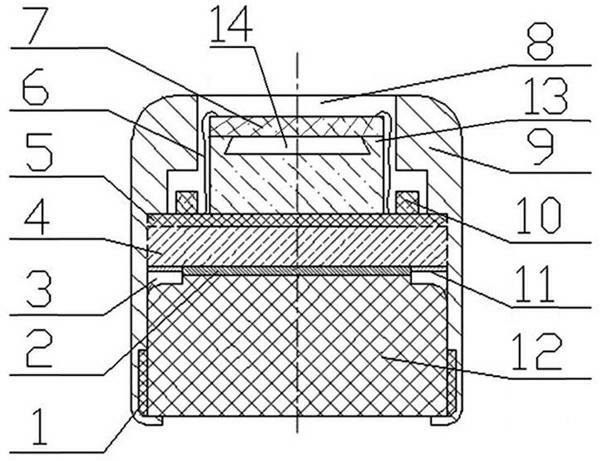

Capacitive miniature tire pressure sensor

The invention discloses a capacitive miniature tire pressure sensor. The capacitive miniature tire pressure sensor comprises an upper plate, a supporting plate and a lower base plate, a multi-layer compound film sensitive to pressure is installed on the upper plate, a capacitive upper pole plate is installed in the multi-layer compound film; the upper surface of the supporting plate is provided with a capacitive lower pole plate, and detection capacitance is formed by the capacitive upper pole plate and the capacitive lower pole plate; and the lower base plate is provided with a surface acoustic wave component and a miniature antenna which is connected with the surface acoustic wave component in coupled mode, and the surface acoustic wave component comprises piezoelectric materials and two groups of interdigital electrodes, wherein one group of interdigital electrodes are connected with the miniature antenna, and the other group of interdigital electrodes are respectively connected with the capacitive upper pole plate and the capacitive lower pole plate. The capacitive miniature tire pressure sensor can be embedded inside a tire to work, achieves measurement and result transfer of tire pressure in passive and wireless mode, and has the advantages of being small in size, light in weight, low in cost, and free of maintenance.

Owner:XI AN JIAOTONG UNIV

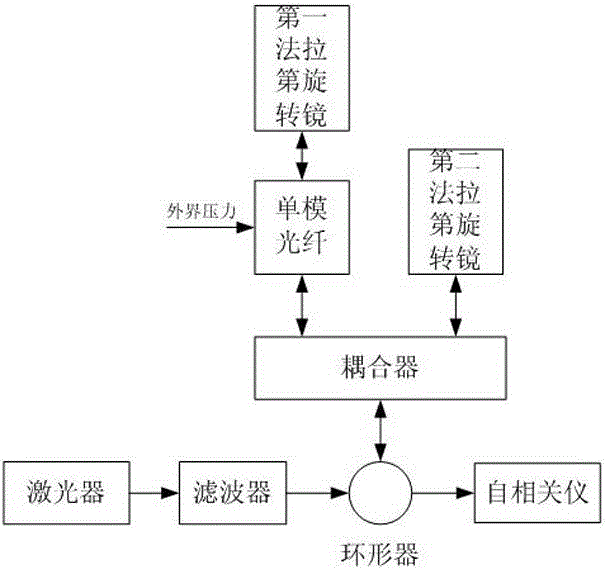

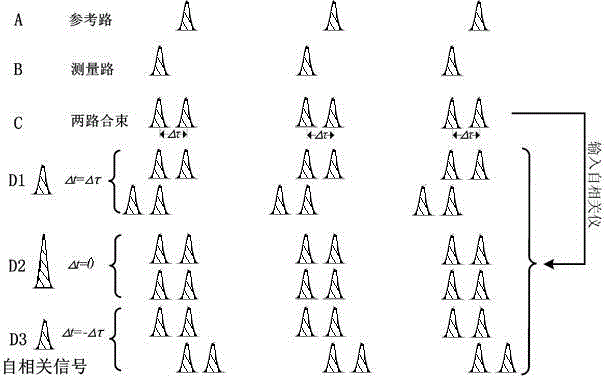

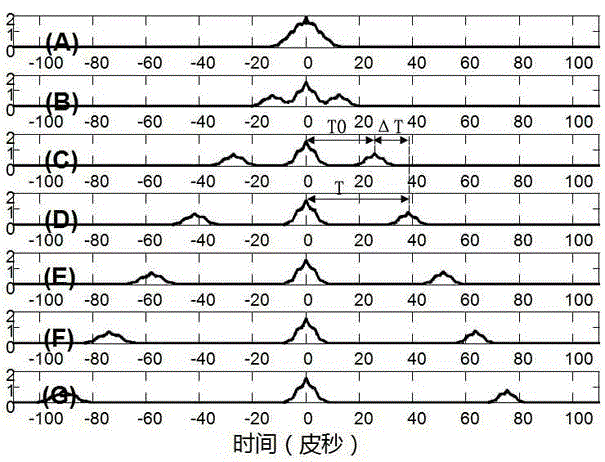

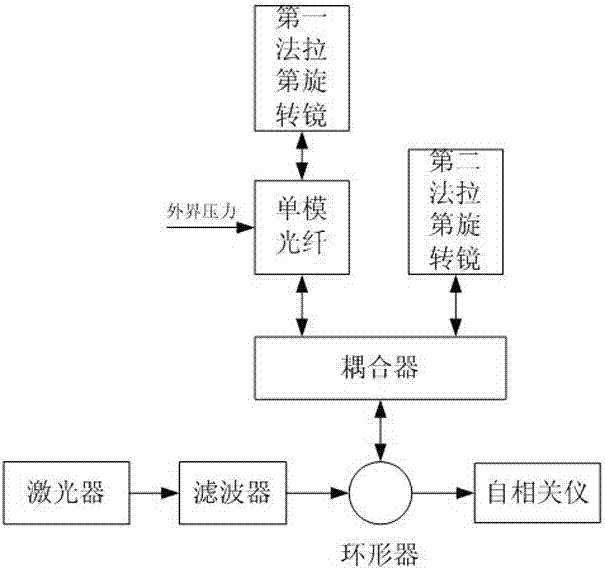

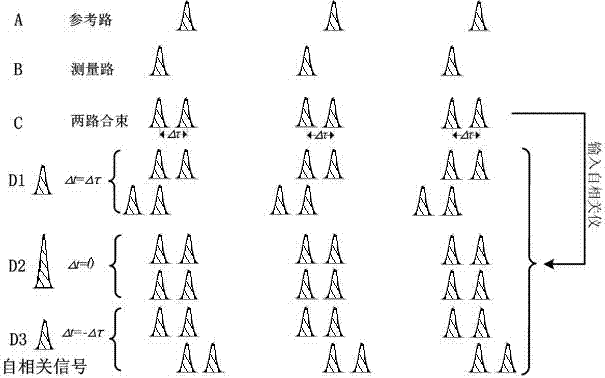

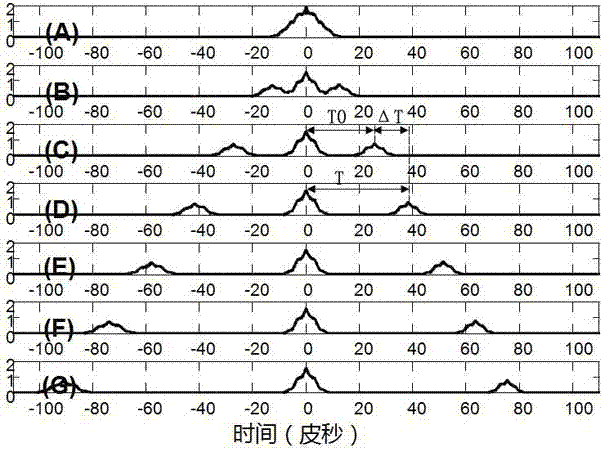

Optical fiber pressure sensing measurement method and device

InactiveCN104458080ASimple structureEasy to operateForce measurement by measuring optical property variationRapid change measurementEngineeringOptical pathlength

The invention relates to the technical field of high-precision optical fiber pressure sensing, in particular to an optical fiber pressure sensing measurement method and device. The optical fiber pressure sensing measurement method and device solve the technical problems in the prior art and are simple in structure and high in measurement accuracy. When outside pressure is applied to an optical fiber serving as a detector, the optical path for optical pulses to transmit in the optical fiber changes, the change of the optical path is measured in real time through an autocorrelator, and therefore the pressure applied to the optical fiber can be obtained. According to the method and device, laser beams are output through a pulse laser; the beams output from the laser are divided into two paths of optical signals after passing through a filter, a circulator and a coupler, one path of optical signals are measurement path optical signals, the other path of optical signals are reference path optical signals, and an outside pressure value is obtained according to the formula in the specification by measuring whether outside pressure exists or not and measuring the interval delta T and T of the autocorrelator.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

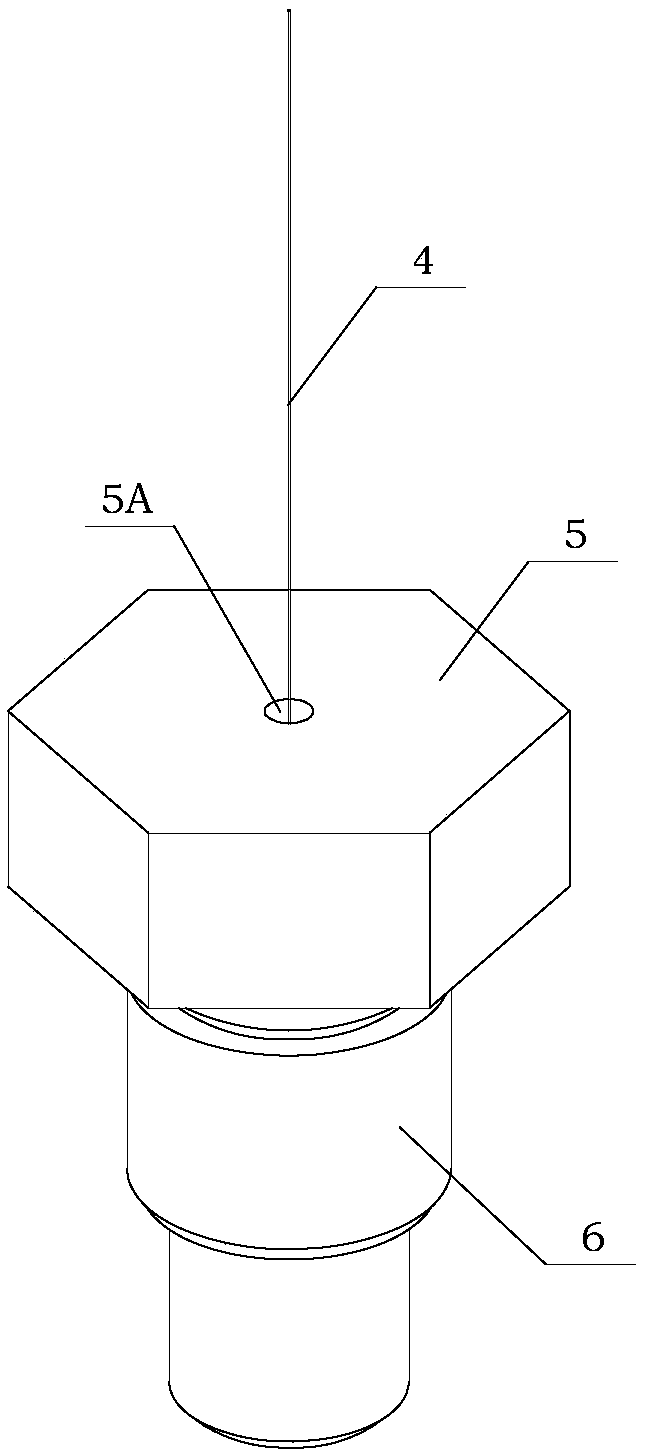

Absolute pressure fiber fabry-perot silicon carbide heat-resistant aviation pressure sensor

ActiveCN108760148ARealize pressure measurementAvoid failureRapid change measurementFiberDynamic pressure

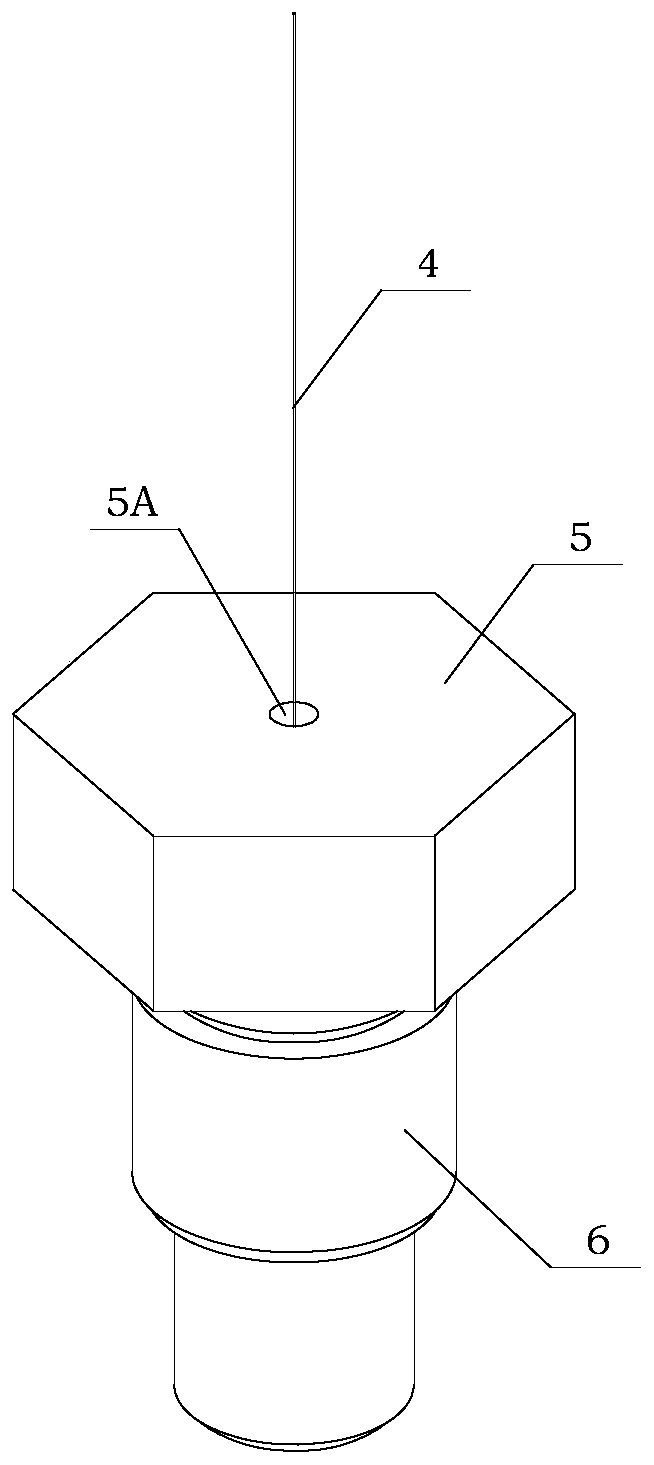

The present invention discloses an absolute pressure fiber fabry-perot silicon carbide heat-resistant aviation pressure sensor. A sensing head in the sensor employs a total SiC structure of a siliconcarbide sensing mebrane and a silicon carbide substrate to achieve vacuum fabry-perot cavity structure through direct binding; the sensor provided by the invention comprises a silicon carbide sensingmebrane, a silicon carbide substrate, optical fibers, a molybdenum package seat and a molybdenum package body; the SiC sensing mebrane and the SiC substrate are installed below a zirconium oxide substrate, one end of the optical fibers is bonded on the SiC substrate, the zirconium oxide substrate is installed in a countersunk head cavity of the molybdenum package seat, and the molybdenum package body is in threaded connection with the lower portion of the molybdenum package seat; and the other end of the optical fibers passes through a B center through hole on the molybdenum package seat. Theabsolute pressure fiber fabry-perot silicon carbide heat-resistant aviation pressure sensor is suitable for the in-situ real-time measurement of the aviation engine high-temperature dynamic pressure and flow field features, and is miniaturized, high in precision and resistant to electromagnetic interference.

Owner:BEIHANG UNIV +2

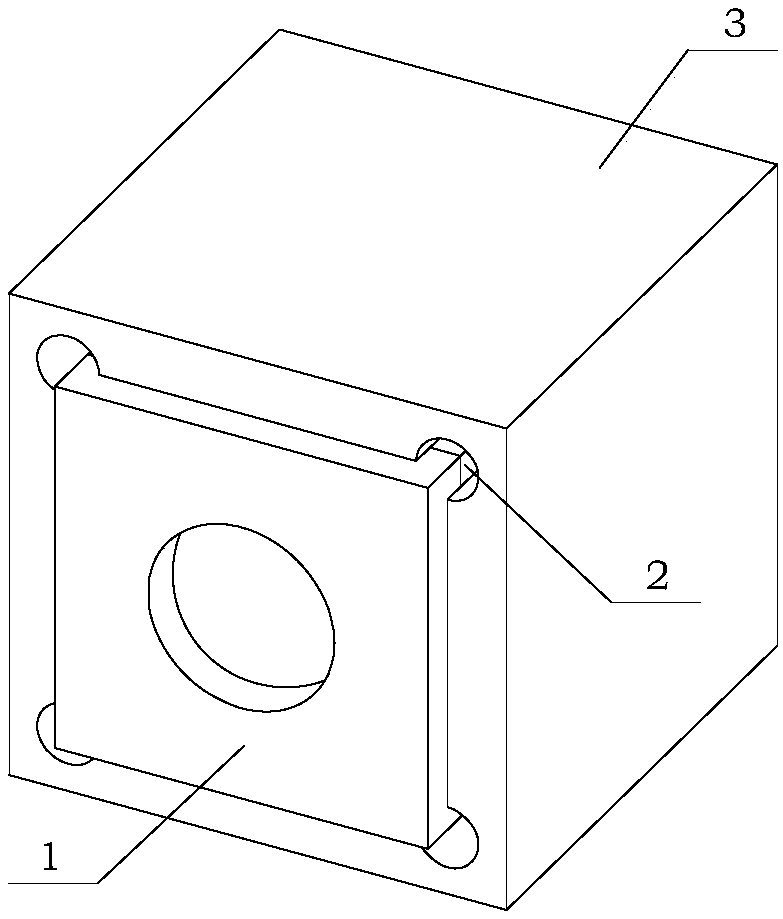

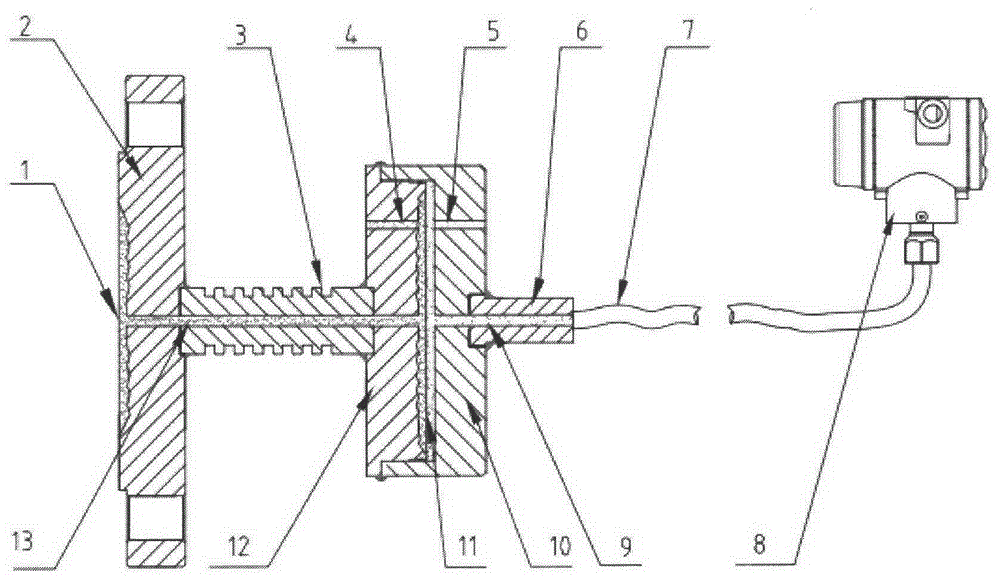

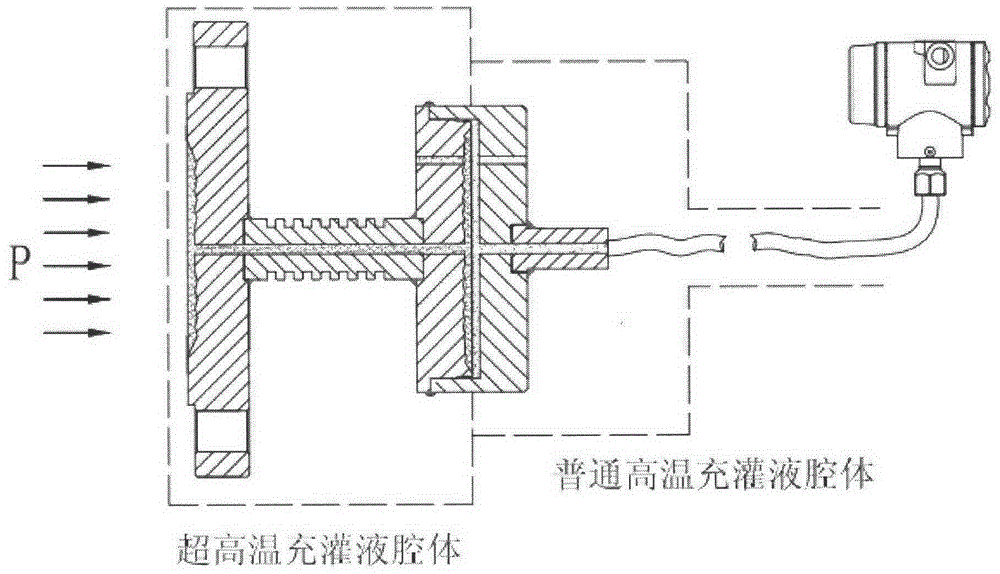

Remote transmission module and remote transmission pressure transmitter having same

PendingCN108760137ARealize pressure measurementSafe and stable jobFluid pressure measurement using elastically-deformable gaugesMarine engineeringTantalum

The present invention provides a remote transmission module used for a remote transmission pressure transmitter. The remote transmission module comprises a remote transmission part and a tantalum mebrane (6), a tetrafluorohydrazine sleeve (2) and a tetrafluorohydrazine cover (4) coating the outer surface of the remote transmission part, and a fluororubber seal ring configured to seal the tantalummebrane (6), the tetrafluorohydrazine sleeve (2) and the tetrafluorohydrazine cover (4). The present invention further provides a remote transmission pressure transmitter having the remote transmission module. Compared to an original a remote transmission pressure transmitter made of tantalum materials. The remote transmission pressure transmitter reduces the production and usage cost and ensure the long-term, stable and safe work of an instrument.

Owner:浙江洛丁森智能科技有限公司

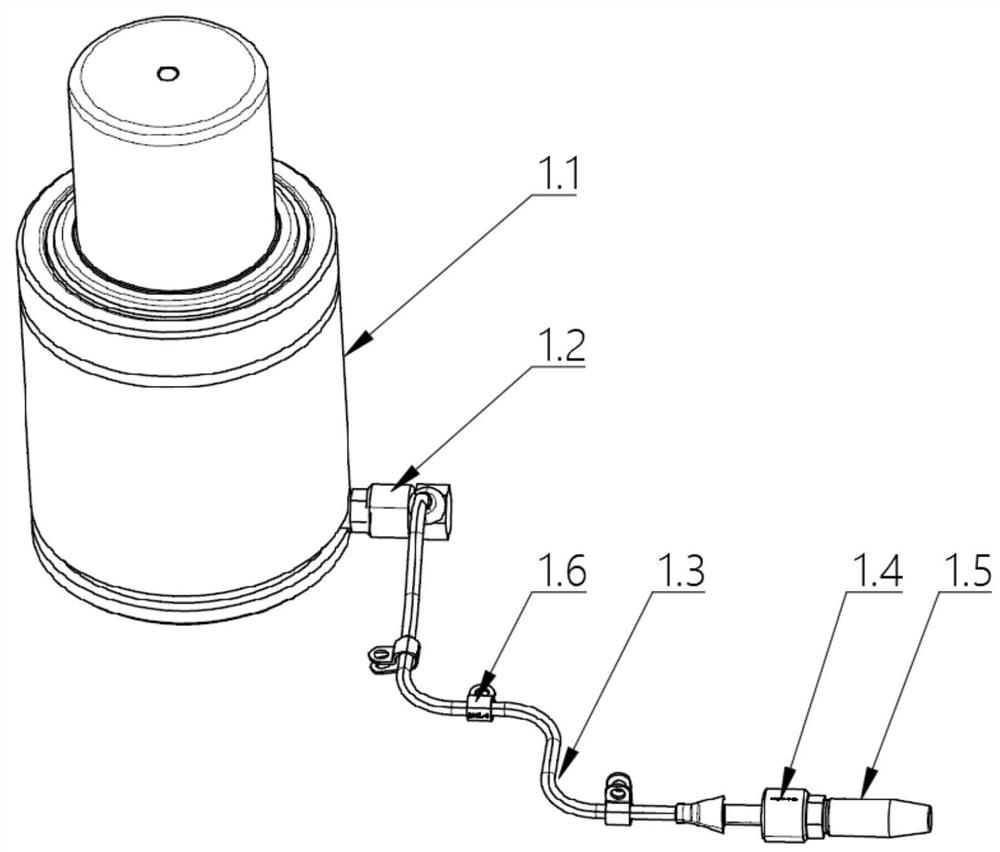

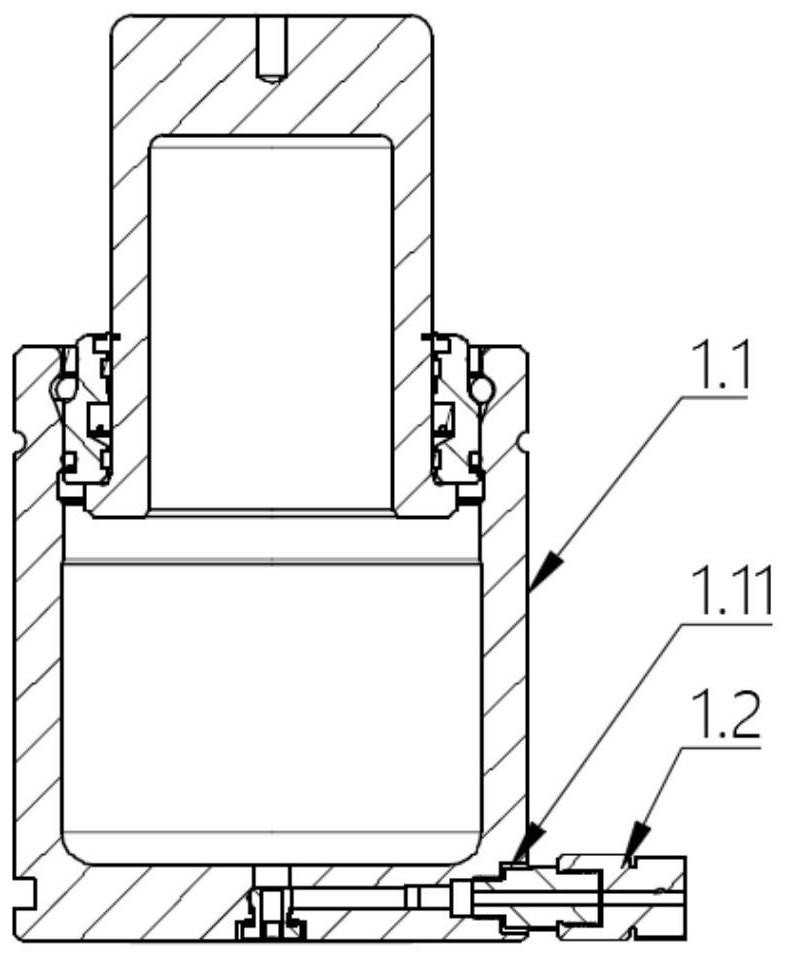

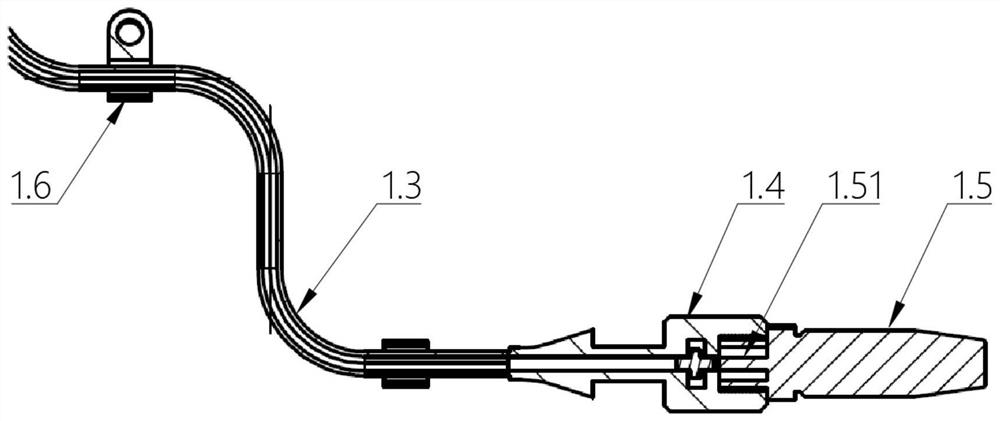

Nitrogen spring with self-induction monitoring function and pressure monitoring system thereof

PendingCN111795099AAvoid stabilityMinimized installation sizeSpringsGas based dampersThermodynamicsNitrogen gas

The invention discloses a nitrogen spring with a self-induction monitoring function. The nitrogen spring comprises a nitrogen spring body and a self-induction assembly, wherein an inflation connectoris arranged on the nitrogen spring body, the self-induction assembly comprises an adapter, a hose, an inflation one-way valve and a wireless pressure sensor with a wireless signal transmitter, whereinone end of the adapter is connected with the inflation connector of the nitrogen spring body, the other end of the adapter is connected with one end of the hose, the other end of the hose is connected with the gas outlet end of the inflation one-way valve, and a one-way valve connector is arranged on the wireless pressure sensor and connected with the inflation end of the inflation one-way valve.The invention further provides a nitrogen spring pressure monitoring system, and the nitrogen spring pressure monitoring system comprises a signal receiving assembly and at least one nitrogen spring.According to the nitrogen spring with the self-induction monitoring function and the pressure monitoring system thereof, a pressure value and a pressure change condition of the nitrogen springs can be checked in real time, and the nitrogen springs to be damaged can be conveniently found in advance.

Owner:武汉科尔精密科技有限公司

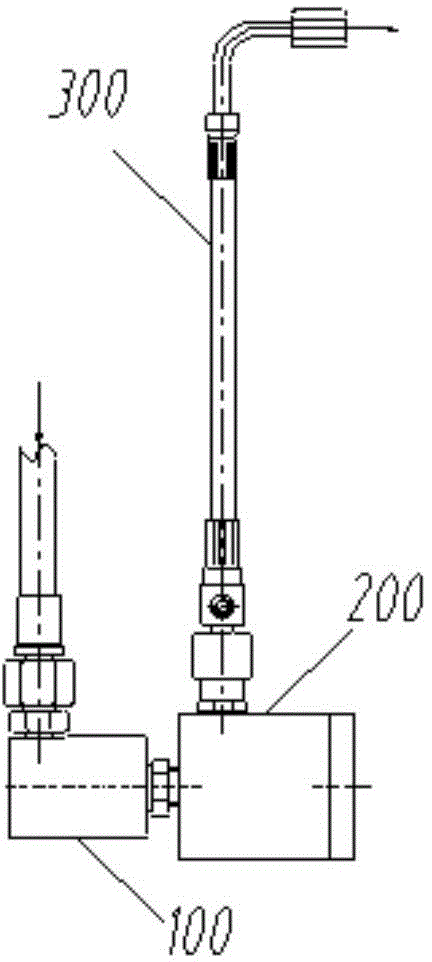

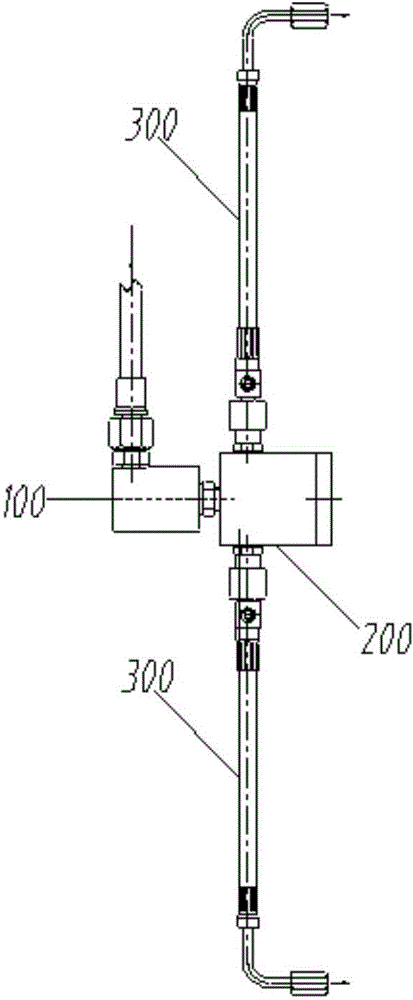

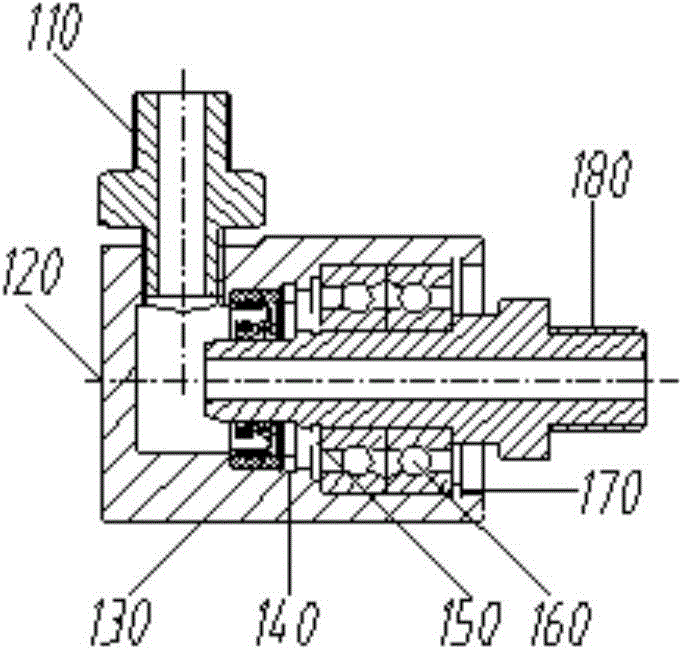

Automatic-inflation wheel side framework-type rotating joint assembly with air pipe for trailer tire

InactiveCN104129242AAssembly structure is simpleEasy to operateTyre-inflating valvesPneumatic pressureEngineering

The invention discloses an automatic-inflation wheel side framework-type rotating joint assembly with an air pipe for a trailer tire, and relates to a vehicle tire inflation technology. The assembly is characterized in that a rotating joint sub-assembly (100) is connected with a mounting bracket sub-assembly (200), and a tire valve air pipe sub-assembly (300) is connected with the mounting bracket sub-assembly (200); a one-way ventilating air chamber is formed by the rotating joint sub-assembly (100) and an inner cavity of the tire valve air pipe sub-assembly (300); a rotating part is connected with a rotating cavity, a stationary part is connected with a stationary cavity, and an integrated air channel is arranged between the rotating part and the stationary part; and a framework oil seal completes the air channel seal of the rotating part and the stationary part, air leakage is avoided. The automatic-inflation wheel side framework-type rotating joint assembly has the advantages of simple structure and convenient operation, installation and maintenance for a driver. Air inflation can be completed under the condition of air pressure supply, pressure measuring can be completed by manual operation, and the air channel of a tire and the assembly ventilates in a one-way manner.

Owner:湖北军缔悍隆科技发展有限公司

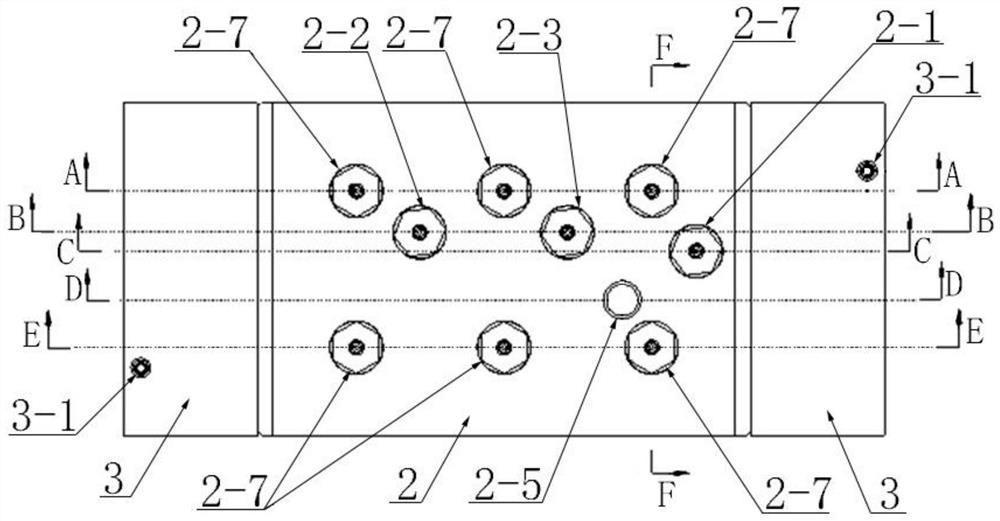

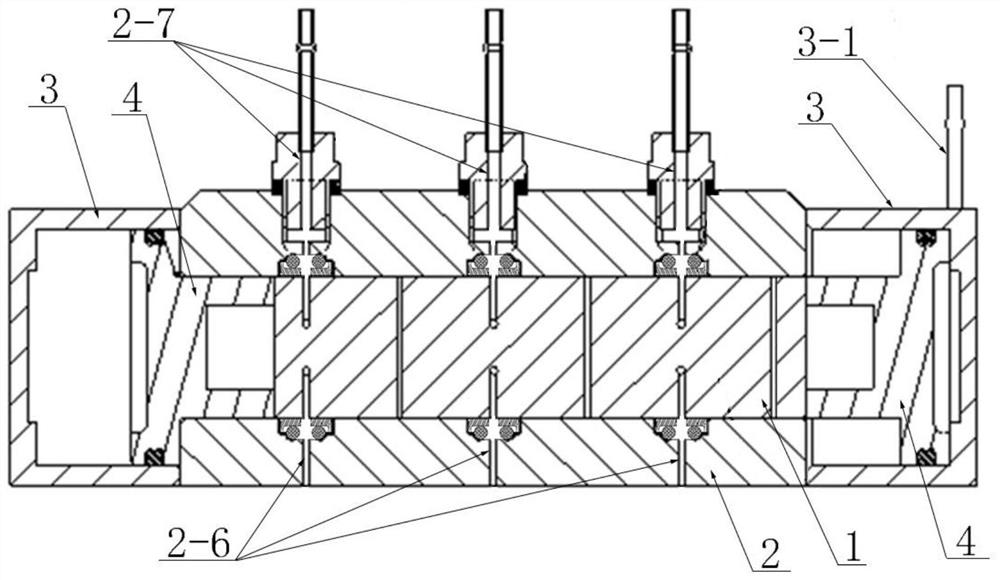

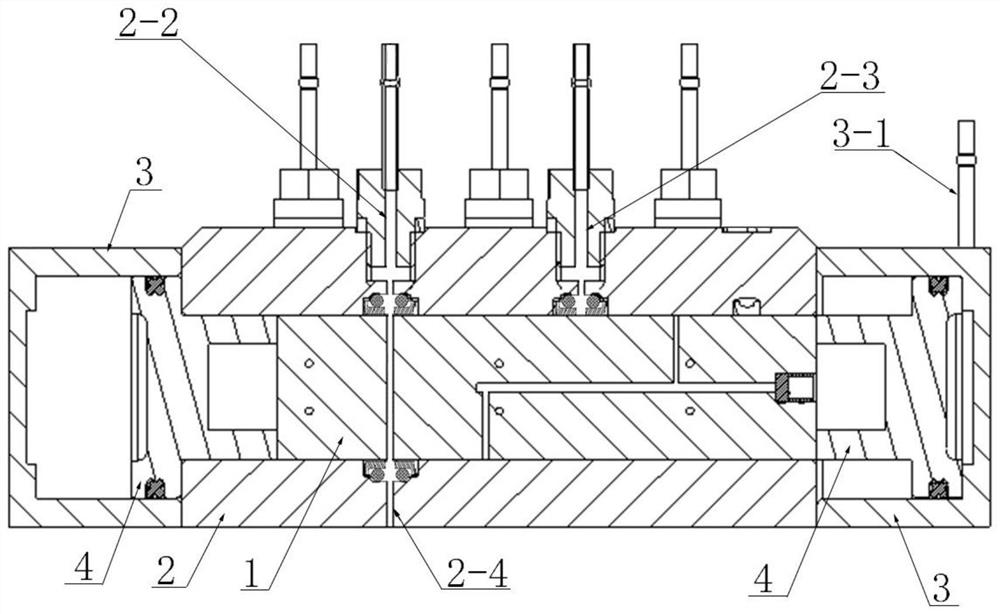

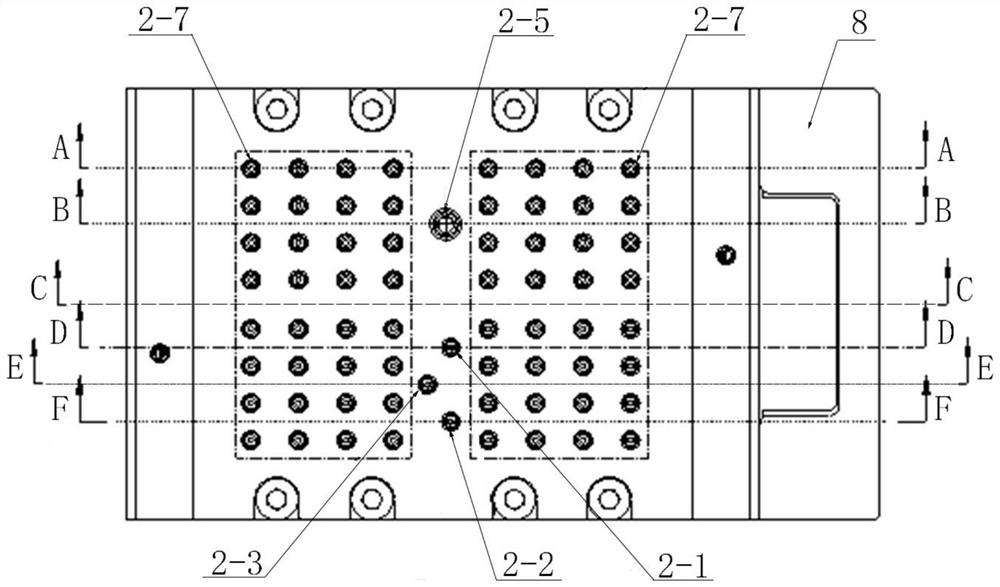

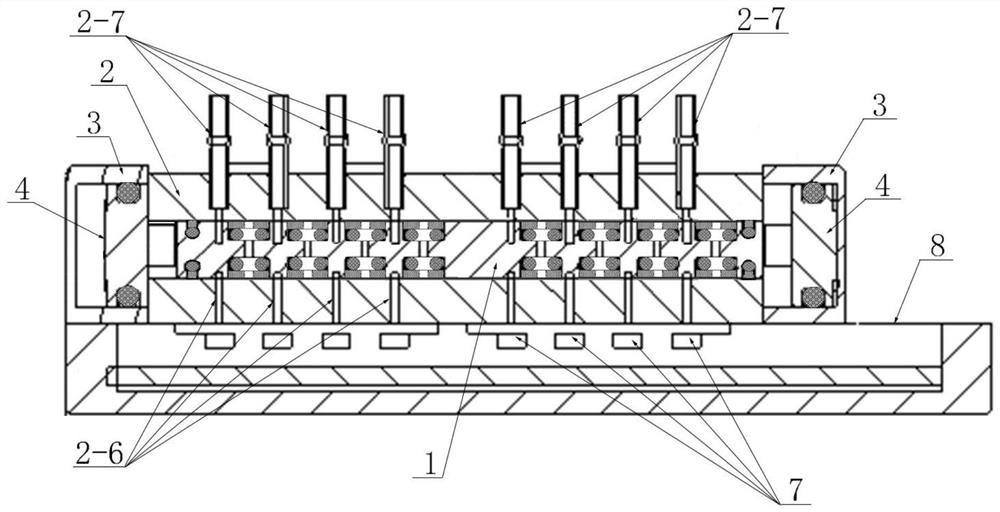

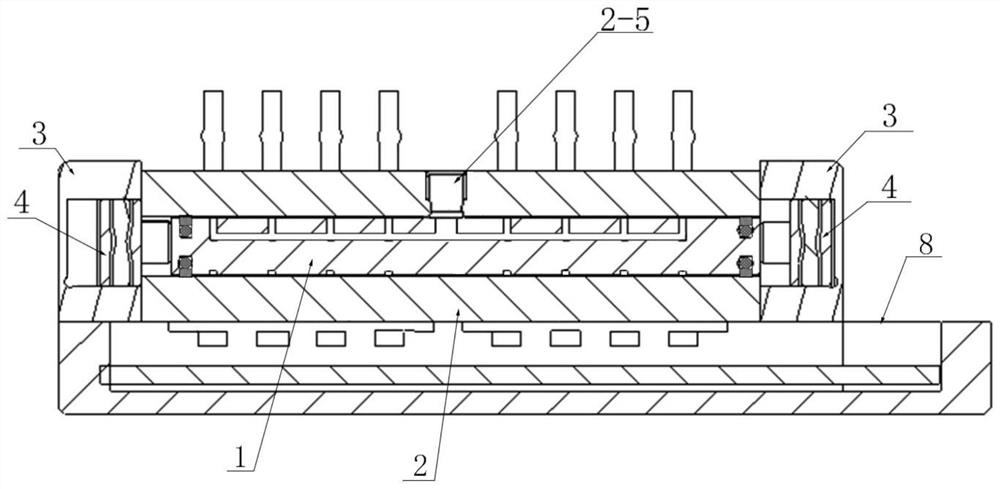

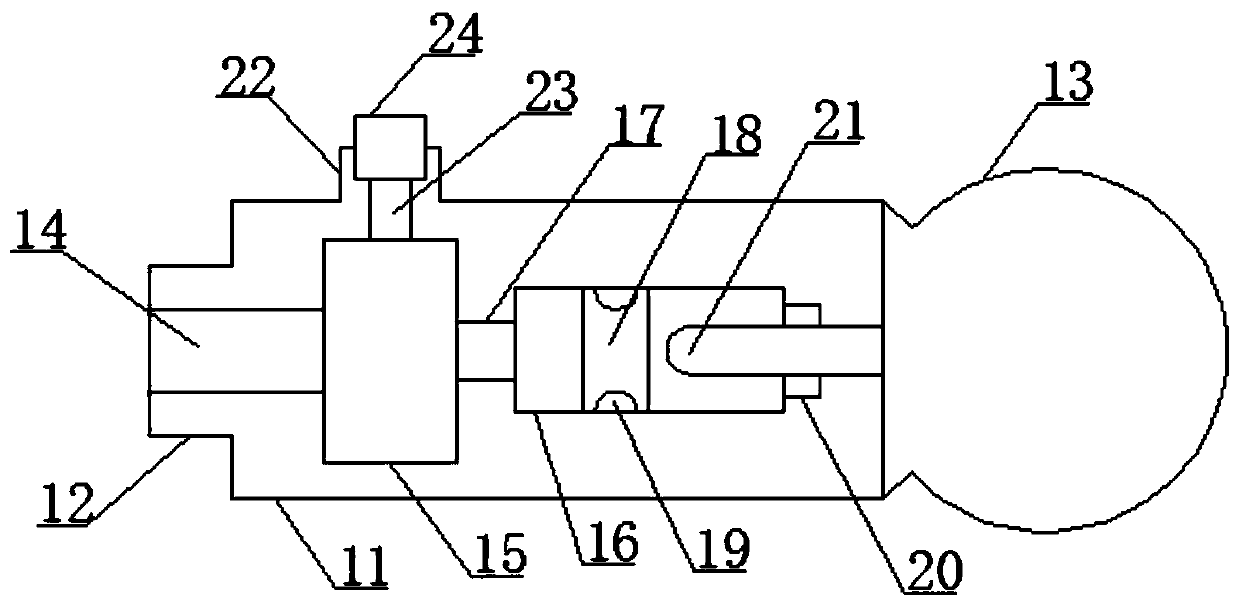

Pneumatic type multifunctional pressure scanning valve

ActiveCN113513615AConducive to miniaturization designReduce manufacturing costMultiple way valvesControl systemEngineering

The invention provides a pneumatic type multifunctional pressure scanning valve. The pneumatic type multifunctional pressure scanning valve comprises a valve shuttle, a valve body and a power assembly, the valve shuttle linearly slides in the valve body through the power assembly, a middle pipeline a and a middle pipeline b are arranged in the valve shuttle, and a calibration air source pipeline, a detected air source pipeline and a pressure sensor pressure measuring end pipeline are arranged in the valve body. The valve shuttle reaches the first valve position under the action of the power assembly, and the calibration air source pipeline and the pressure sensor pressure measuring end pipeline communicate through a middle pipeline a. The valve shuttle reaches the second valve position under the action of the power assembly, and the detected air source pipeline communicates with the pressure sensor pressure measuring end pipeline through a middle pipeline b. According to the pressure scanning valve, the working modes can be simply and rapidly switched, a tedious switching control system and various valves are not needed, and miniaturization design of the pressure scanning valve is better facilitated.

Owner:四川天利科技有限责任公司

Miniature pressure scanning valve

PendingCN113252237AConducive to miniaturization designReduce manufacturing costFluid pressure measurementControl systemEngineering

The invention provides a miniature pressure scanning valve which comprises a valve shuttle, a valve body and a power assembly, wherein the valve shuttle linearly slides in the valve body through the power assembly, a middle pipeline e and a middle pipeline b are arranged in the valve shuttle, and a purging gas source pipeline, a detected gas source pipeline and a pressure sensor pressure measuring end pipeline are arranged in the valve body; the valve shuttle reaches the first valve position under the action of the power assembly, and the purging gas source pipeline and the detected gas source pipeline are communicated through the middle pipeline e; and the valve shuttle reaches the second valve position under the action of the power assembly, and the detected gas source pipeline is communicated with the pressure measuring end pipeline of the pressure sensor through the middle pipeline b. According to the pressure scanning valve, the working modes can be simply and rapidly switched, a tedious switching control system and various valves are not needed, and miniaturization design of the pressure scanning valve is better facilitated.

Owner:四川天利科技有限责任公司

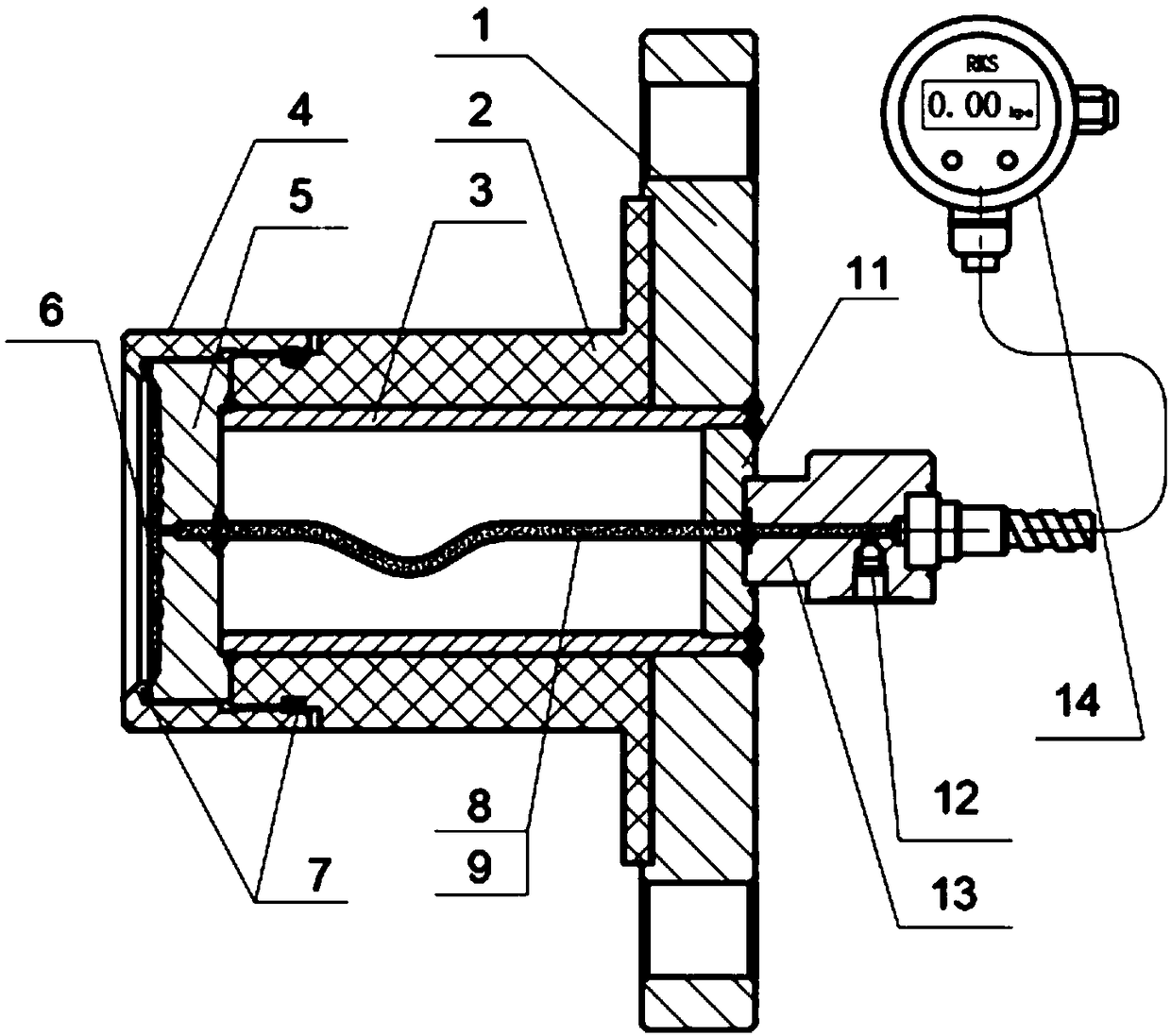

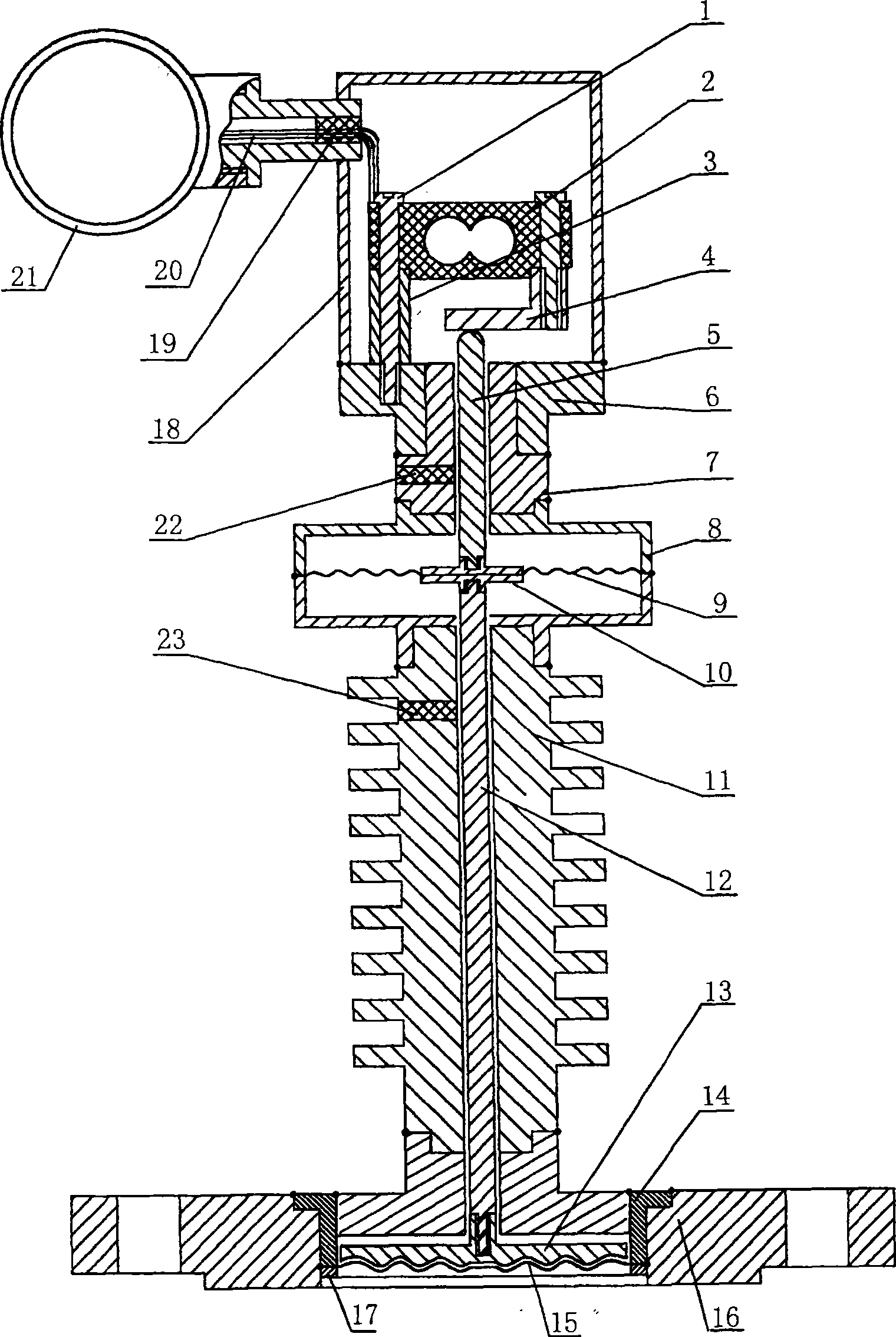

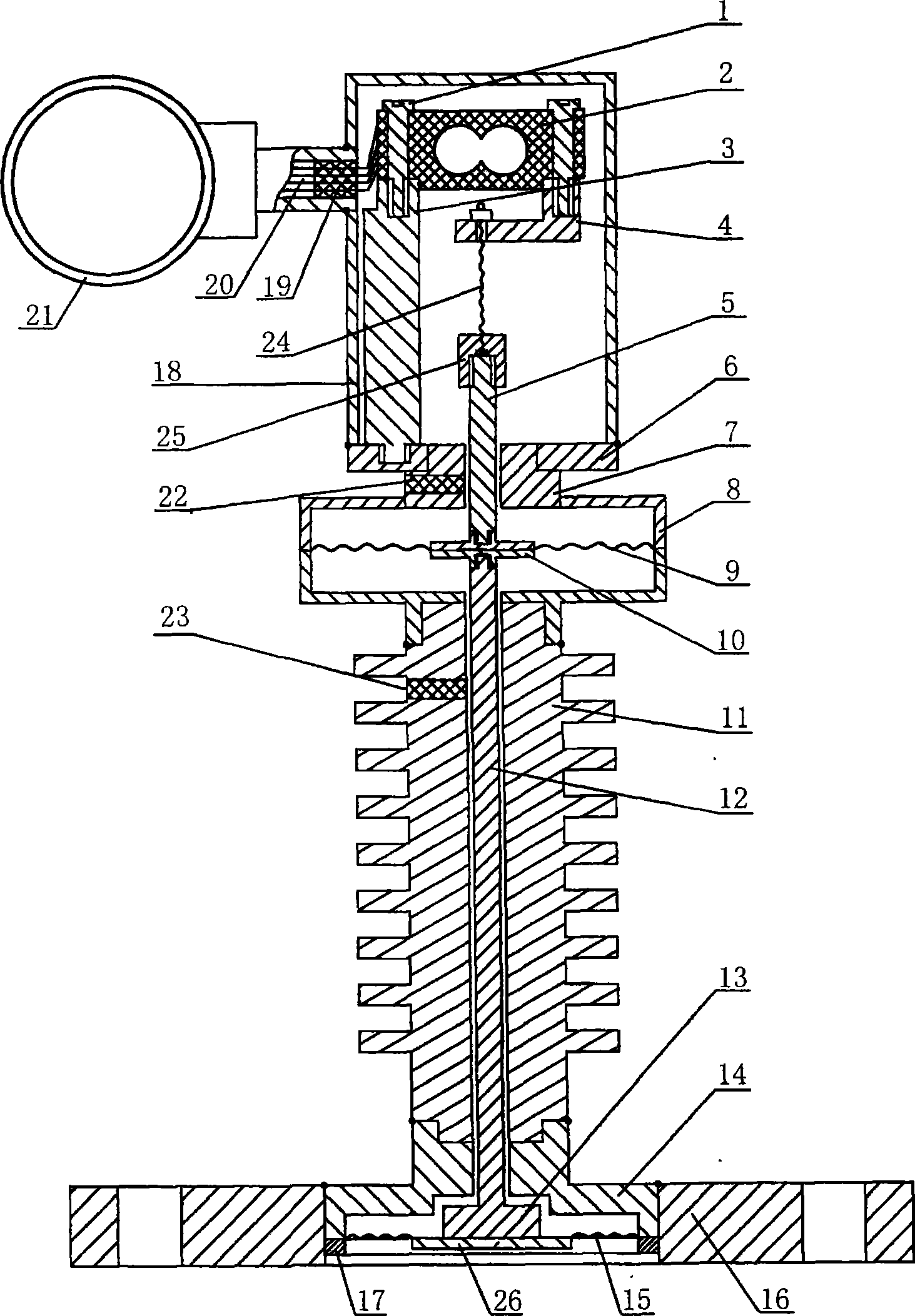

Pressure sensor/converter for converting force to pressure

InactiveCN100494939CEasy to manufactureLow costFluid pressure measurement using elastically-deformable gaugesForce measurementManufacturing cost reductionTransducer

A pressure sensor / transducer for transforming pressure to force contains force sensor and connecting element assembled by connecting module. Its technical features are: stressed block of connecting element is assembled on force sensor. Upper stress bar connecting with stressed block is jointed with lower vector bar by connecting hard-core and does advance and return movement along the internal cavity, which holds the two bars. Compressed aneroid of connecting element is fixed in adapting flange. Pressed body connecting the bottom end of lower vector bar is packaged in compressed aneroid by at least one corrugated diaphragm. It has more rational structural design and takes full advantages of sensor characteristics including simple construction, low cost and high precision etc. It can transform pressure to force in cooperation with connecting element, use force sensor with one measuring range to measure pressure with multi-range and complete measurement of plus-minus pressure under both high and low temperature, which reduce cost, improve measuring precision and extend application range greatly.

Owner:SHENYANG SENSOR TECH INST

High-temperature ceramic pressure sensor for pressure test in high temperature environment and processing method thereof

ActiveCN103017945BRealize pressure measurementAvoid high temperature problemsFluid pressure measurement by electric/magnetic elementsForce measurementCapacitancePressure sense

Owner:ZHONGBEI UNIV

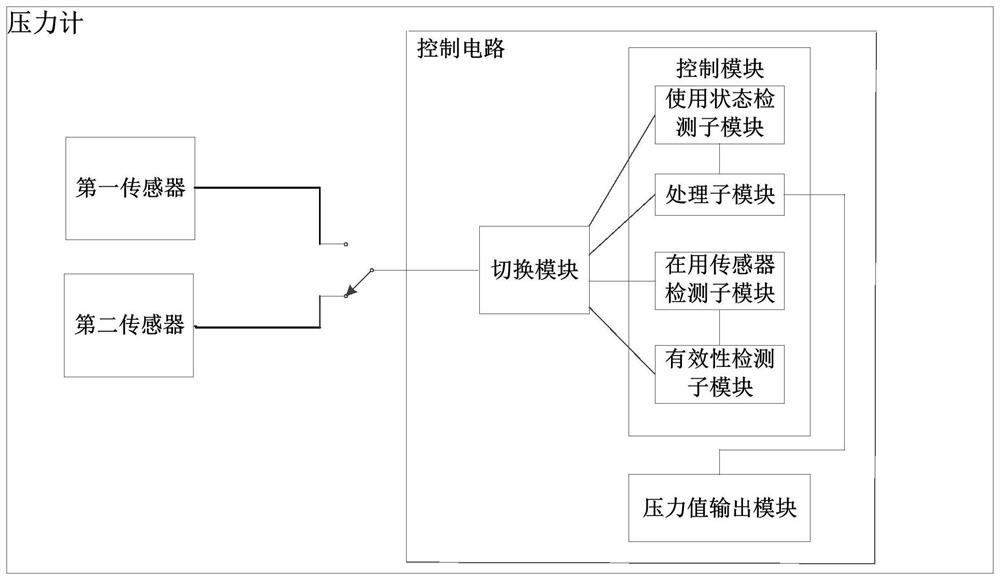

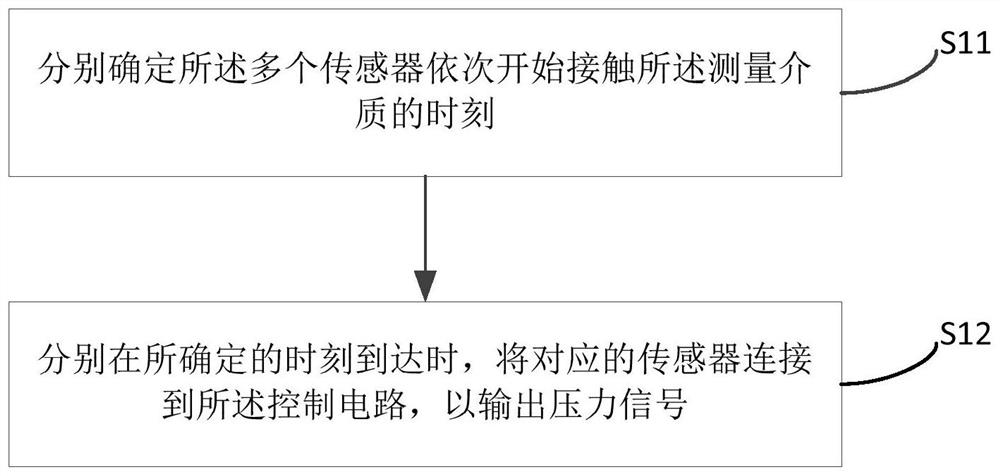

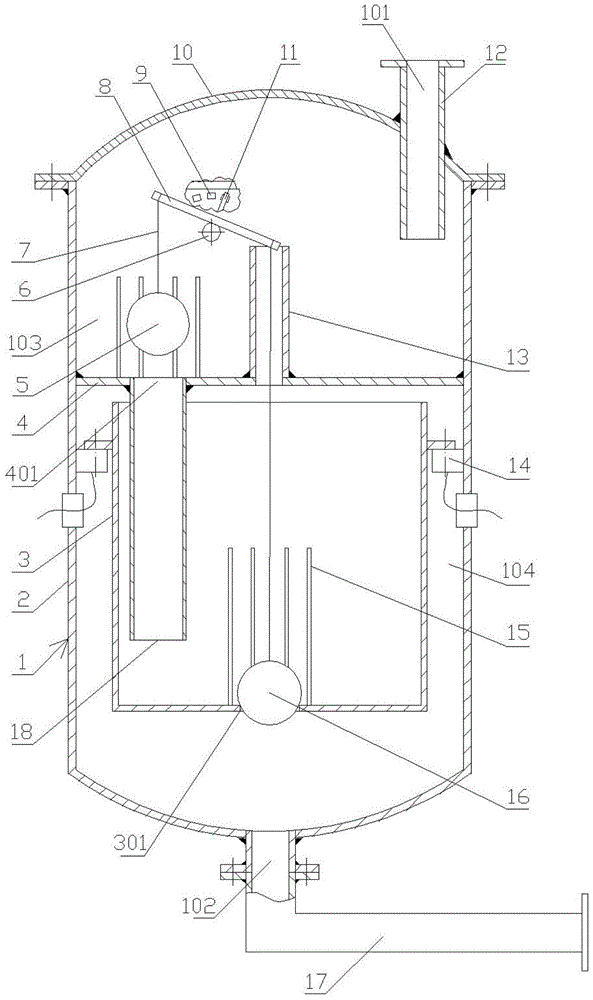

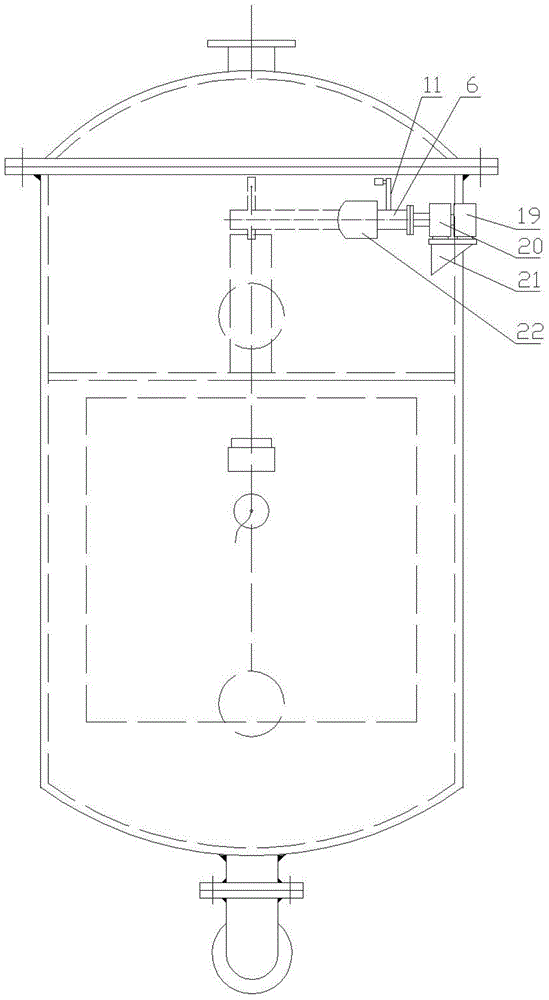

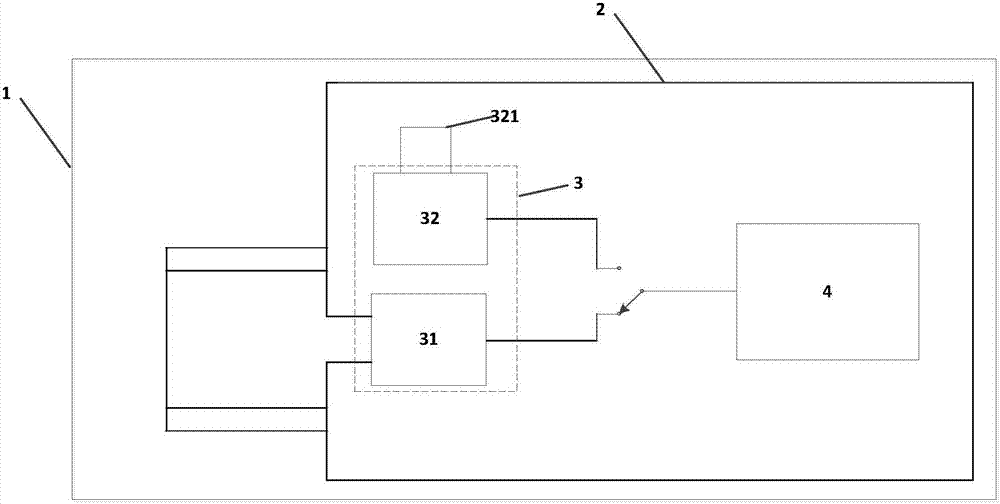

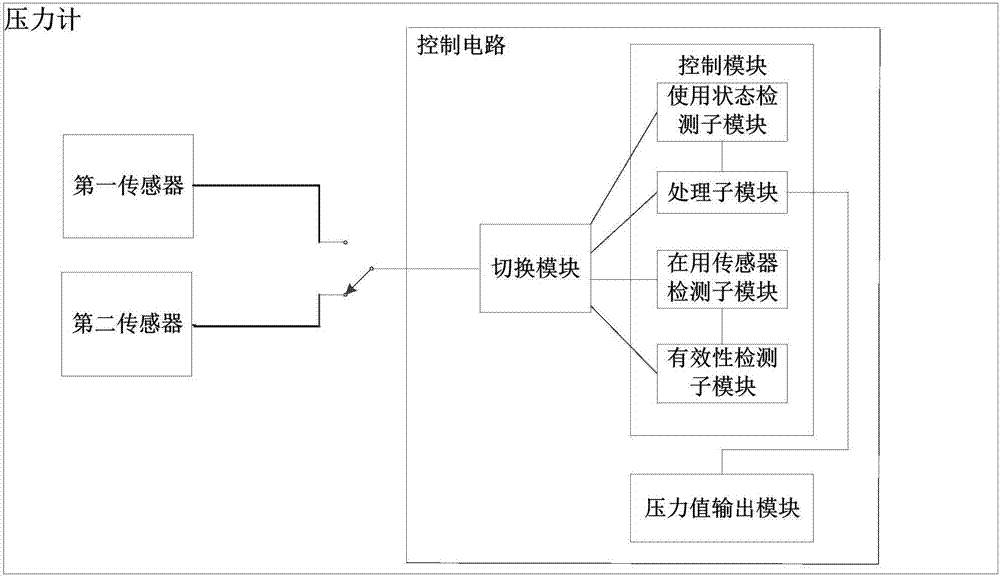

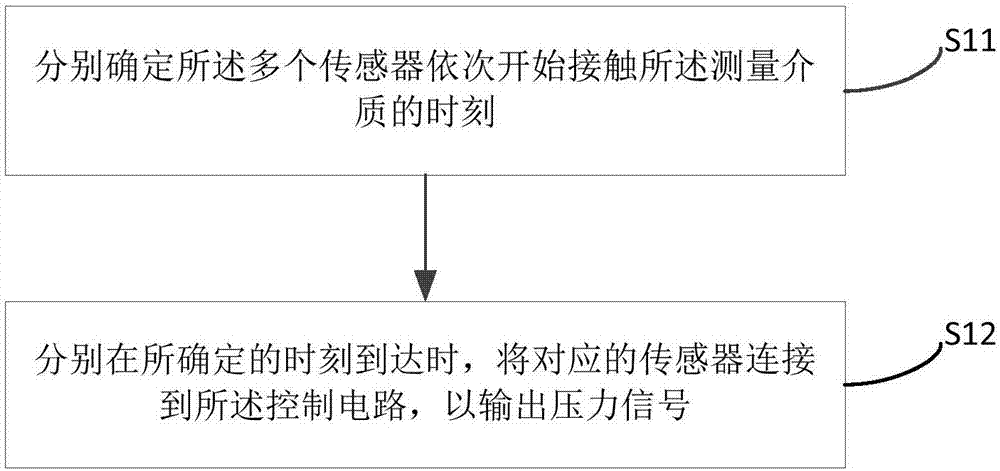

Manometer and method for measuring pressure

ActiveCN108007636BUnlimited calibration cycleRealize pressure measurementFluid pressure measurementEngineeringControl circuit

The present invention discloses a pressure gauge and a method for measurement of pressure. The pressure gauge comprises a body, and a plurality of pressure sensors and a control circuit which are arranged in the body. The pressure sensors can contact measurement medium in order and can be correspondingly connected with the control circuit in order to output pressure signals. The pressure gauge isemployed to connect the pressure sensors with the control circuit in order to output the pressure signals, and the pressure sensors included in the pressure gauge can continuously work. The method isnot limited to the calibration cycle of one sensor, and therefore pressure measurement with a calibration cycle being longer than the calibration cycle of one sensor is achieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Oil well online closure metering device

ActiveCN104596624BHigh measurement accuracyAccurate measurement excludesSurveyWeighing apparatus for materials with special property/formElectricityLoad cell

The invention discloses an oil well on-line flow closure metering device. The oil well on-line flow closure metering device comprises a metering shell, wherein an oil inlet and an oil outlet are formed in the upper end and the lower end of the metering shell respectively, a separating plate is arranged in the middle of the interior of the metering shell, and an inner cavity of the metering shell is divided by the separating plate into a preservation cavity and a metering cavity; an overflow pipe and a metering inlet are arranged on the separating plate, and the preservation cavity and the metering cavity are communicated through the overflow pipe and the metering inlet; a weighing hopper is supported in the metering cavity through weighing sensors, an upper opening of the weighing hopper is opened, and is correspondingly communicated with the metering inlet, and a metering outlet is formed in the bottom surface of the weighing hopper; a control device comprises two gravity valves, wherein the gravity valves are arranged in a hanging mode, and correspond to the metering inlet and the metering outlet respectively; the control device is electrically connected with the weighing sensors, and is used for executing alternate control over opening and closing movement of the metering inlet and the metering outlet according to data measured by the weighing sensors. The oil well on-line flow closure metering device has the advantages that metering accuracy is high, the oil well on-line flow closure metering device does not need to be attended by workers, the liquid production capacity can be metered in real time, manual metering can be replaced, pressure-bearing metering can be achieved, working reliability is high, and the service life is long.

Owner:盘锦晨宇石油工程有限公司

Micro mud floating electronic pressure gauge, working method thereof, and pressure measurement device

ActiveCN102287184BDoes not affect drilling constructionSimple structureSurveyMeasurement deviceWell drilling

Owner:CHENGDU HAOHAN WELL COMPLETION & LOGGING SCI & TECH

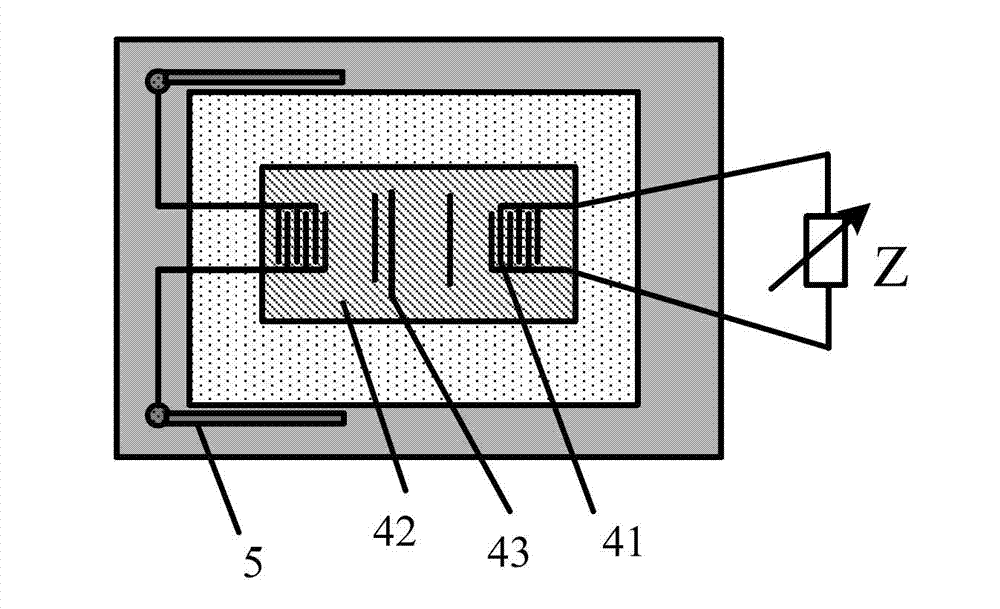

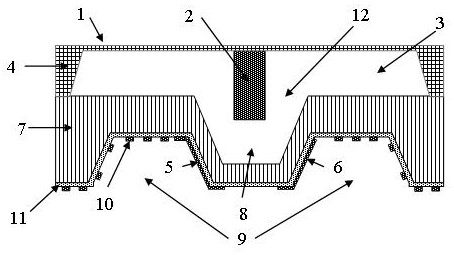

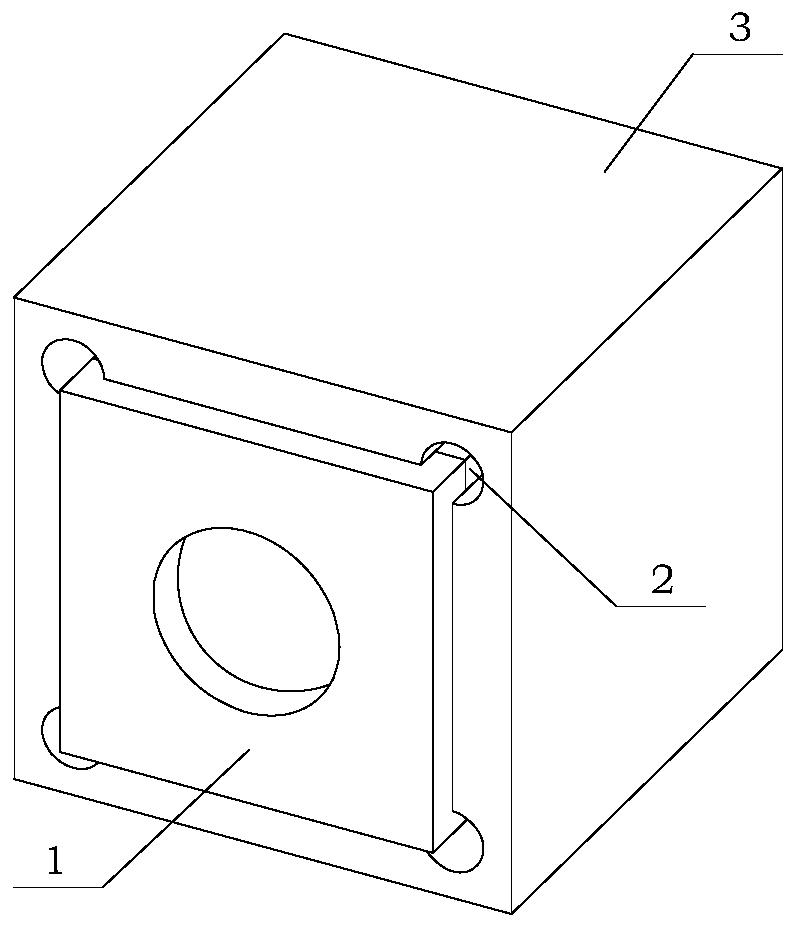

A kind of LC composite mems pressure sensor and preparation method thereof

ActiveCN112683427BImprove reliabilitySimple preparation processForce measurementMems pressure sensorEngineering

The present invention proposes an LC composite MEMS pressure sensor and a preparation method thereof. The pressure sensor includes: a stacked first substrate and a second substrate; a pressure sensitive film arranged on the upper surface of the first substrate; a groove, arranged on the lower surface of the first substrate, opposite to the pressure sensitive film; an LC sensitive body, arranged on the lower surface of the pressure sensitive film, located in the first groove; the second a groove, arranged on the upper surface of the second substrate, forming a vacuum chamber with the first groove; a third groove, arranged on the lower surface of the second substrate surrounding and spaced apart from the second groove Surface: an inductor coil layer, disposed on the bottom surface of the third groove and a side wall away from the second groove. Under the action of environmental pressure, both L and C of the sensor will change, and the change trend is the same, so it has high sensitivity.

Owner:NANJING GAOHUA TECH

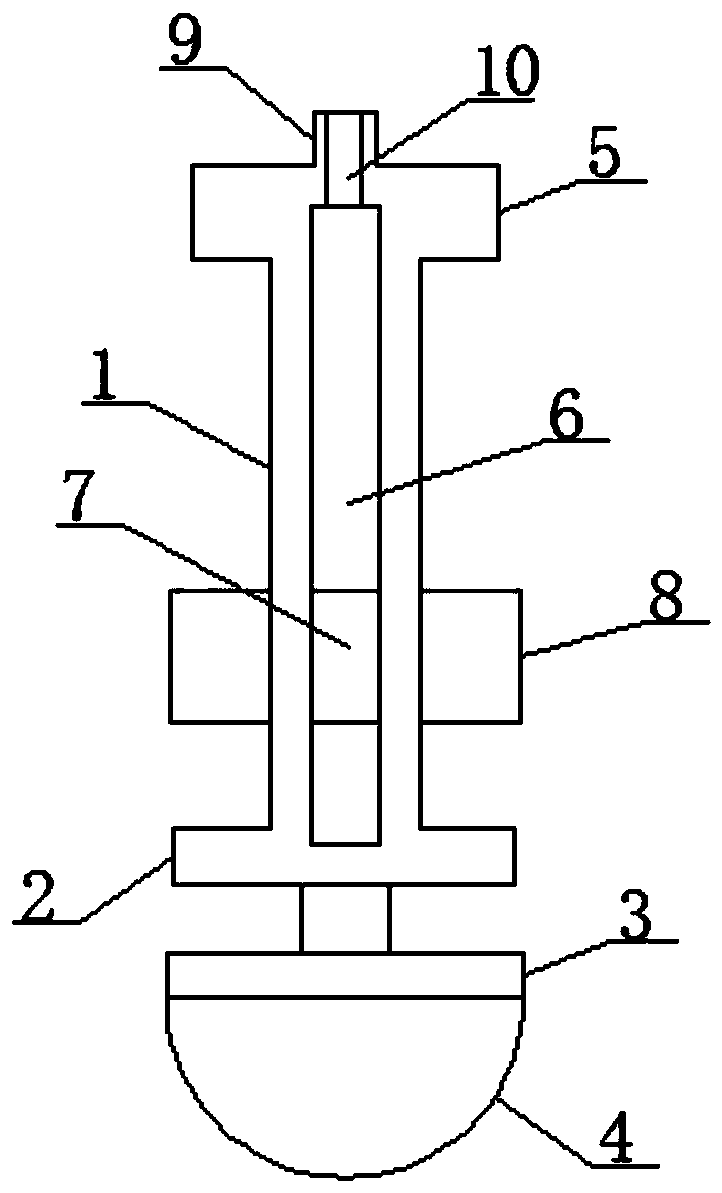

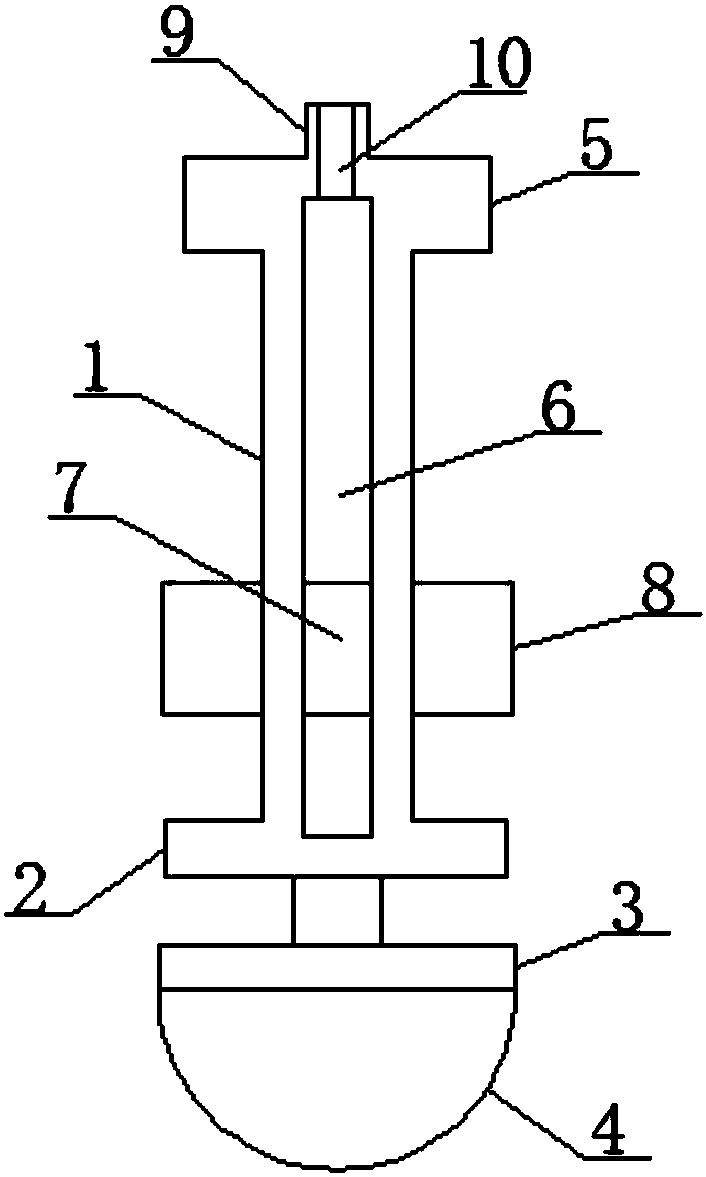

A liquid pressure demonstrator for high school physics teaching

ActiveCN107767745BRealize pressure measurementPracticalEducational modelsEngineeringPressure measurement

The invention discloses a liquid pressure intensity demonstrator for high school physics teaching. The demonstrator comprises a liquid penetrating part and a pressure intensity measurement part, wherein the liquid penetrating part comprises a main hollow column-shaped column body, the bottom of the main hollow column-shaped column body is provided with a bottom connecting plate structure which isstructurally integrated with the bottom, the bottom of the bottom connecting plate structure is provided with a connecting rod, the bottom of the connecting rod is provided with a gravity hemispheroid, the top of the main hollow column-shaped column body is provided with a top limiting plate structure which is structurally integrated with the top, and the center of the main hollow column-shaped column body is provided with a hollow mobile space. According to the demonstrator, equivalent replacement is utilized, the pressure intensity values of liquid at different depths are determined througha difference between a known air pressure value and a current air pressure value, in addition, the device can be connected with air pipelines with different lengths, the pressure intensity measurementof liquid with a relatively great depth is changed and realized, moreover, the interior of the device does not come into contact with liquid, so that the service life of the device is prolonged, andthe practicability is strong.

Owner:瑞安市华嘉机械制造有限公司

An absolute pressure fiber-optic silicon carbide high temperature resistant aviation pressure sensor

ActiveCN108760148BRealize pressure measurementAvoid failureRapid change measurementCarbide siliconAviation

The present invention discloses an absolute pressure fiber fabry-perot silicon carbide heat-resistant aviation pressure sensor. A sensing head in the sensor employs a total SiC structure of a siliconcarbide sensing mebrane and a silicon carbide substrate to achieve vacuum fabry-perot cavity structure through direct binding; the sensor provided by the invention comprises a silicon carbide sensingmebrane, a silicon carbide substrate, optical fibers, a molybdenum package seat and a molybdenum package body; the SiC sensing mebrane and the SiC substrate are installed below a zirconium oxide substrate, one end of the optical fibers is bonded on the SiC substrate, the zirconium oxide substrate is installed in a countersunk head cavity of the molybdenum package seat, and the molybdenum package body is in threaded connection with the lower portion of the molybdenum package seat; and the other end of the optical fibers passes through a B center through hole on the molybdenum package seat. Theabsolute pressure fiber fabry-perot silicon carbide heat-resistant aviation pressure sensor is suitable for the in-situ real-time measurement of the aviation engine high-temperature dynamic pressure and flow field features, and is miniaturized, high in precision and resistant to electromagnetic interference.

Owner:BEIHANG UNIV +2

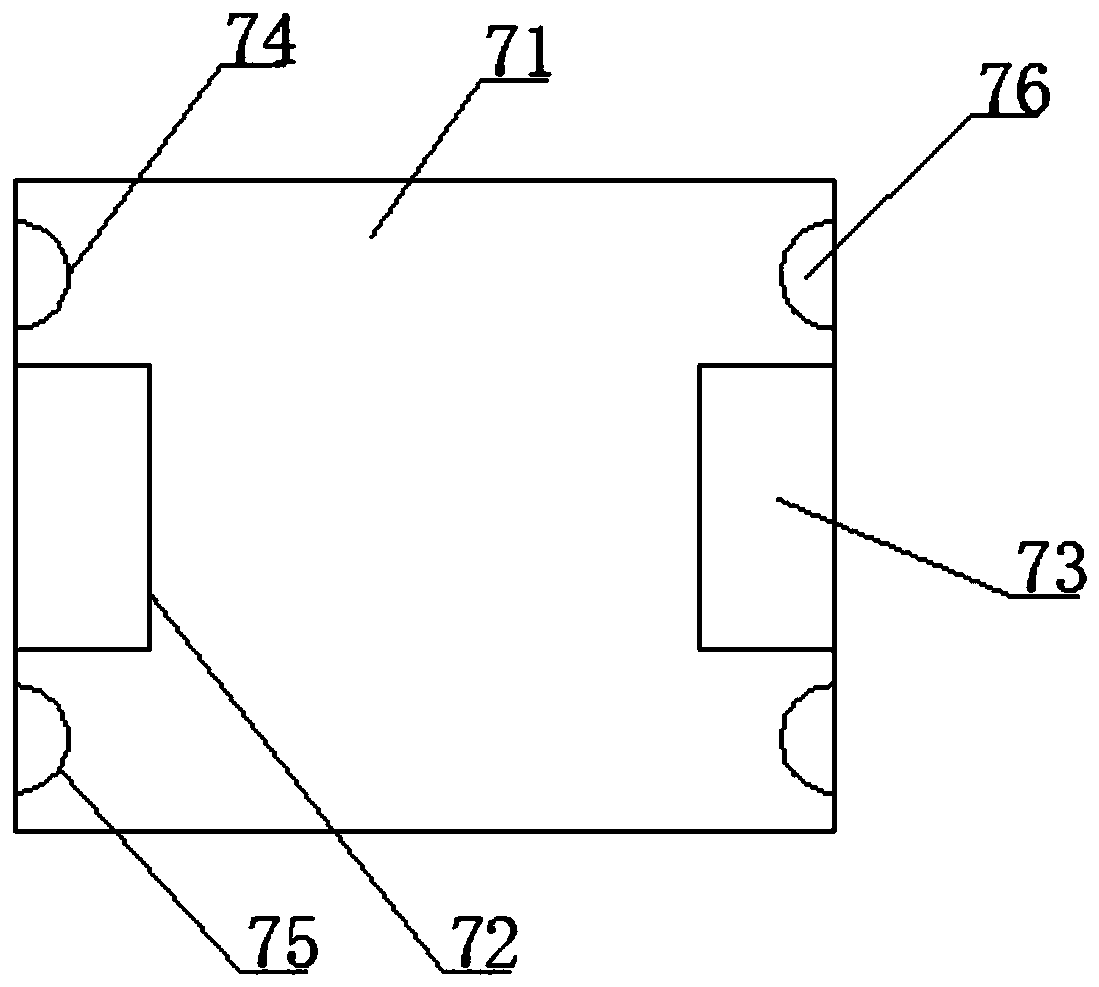

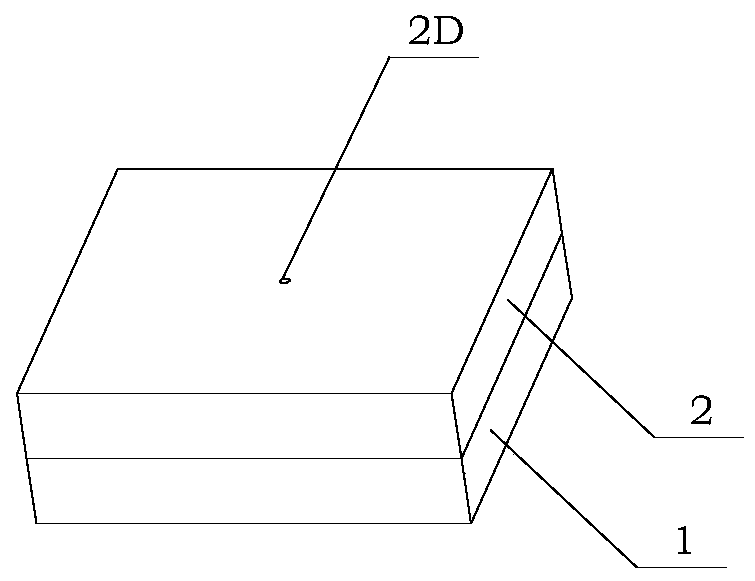

A kind of MEMS inductive pressure sensor and preparation method thereof

The present invention provides a MEMS inductive pressure sensor and a preparation method thereof. The pressure sensor comprises: a stacked first substrate and a second substrate; a pressure sensitive film arranged on the upper surface of the first substrate; a first substrate a groove, arranged on the lower surface of the first substrate, opposite to the pressure-sensitive film; a ferromagnetic core, arranged on the lower surface of the pressure-sensitive film, located in the first groove; a second groove a groove, arranged on the upper surface of the second substrate, and forming a vacuum cavity with the first groove; a third groove, arranged on the lower surface of the second substrate around and spaced from the second groove ; The inductor coil layer is arranged on the lower surface of the second substrate. The sensor has simple structure, excellent linearity, high sensitivity, small temperature drift and wide application scenarios.

Owner:NANJING GAOHUA TECH

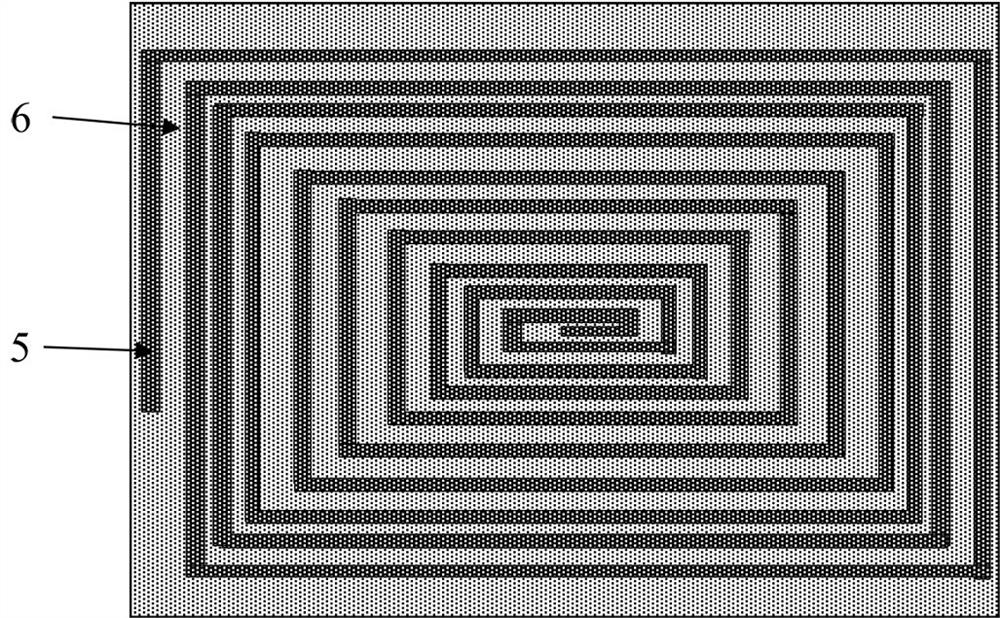

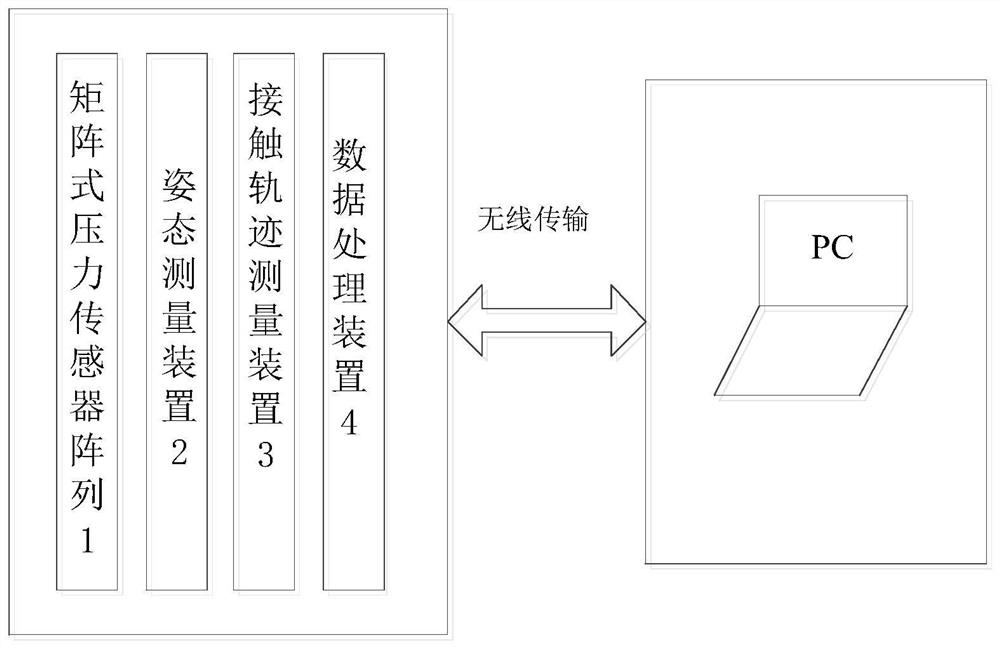

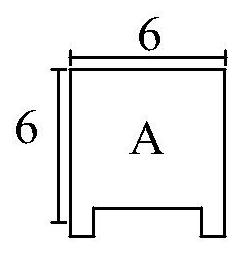

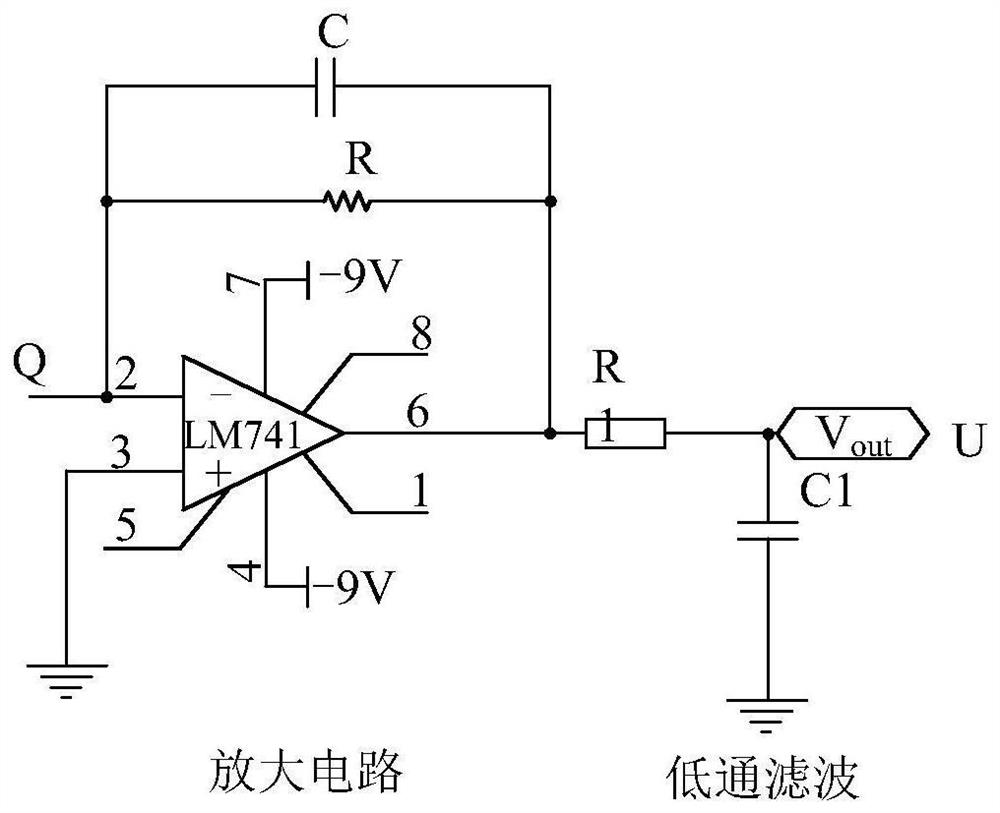

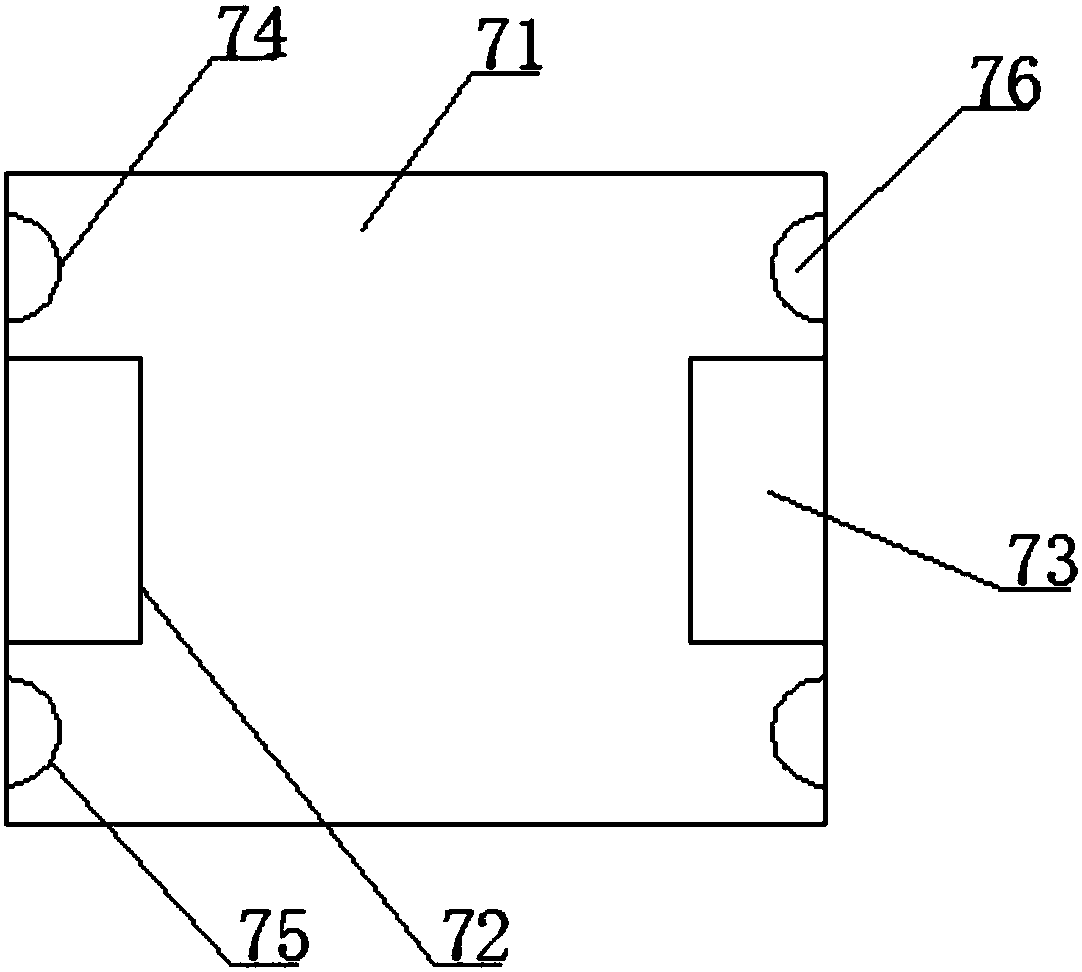

Knee joint multi-parameter measuring system based on total knee arthroplasty

PendingCN113925493ARealize pressure measurementDiagnostic recording/measuringSensorsPressure sensor arrayKnee joint replacement

The invention discloses a knee joint multi-parameter measuring system based on total knee arthroplasty. The system comprises a matrix type pressure sensor array which is used for being placed on a lower limb osteotomy plane of a knee joint of a patient in an operation process of a doctor to obtain a pressure signal, a posture measuring device which is used for being placed on the lower limb osteotomy plane of the knee joint of the patient in the operation process of the doctor to obtain posture signals of the lower limb, a contact type track measuring device which is used for being placed on the lower limb osteotomy plane of the knee joint of the patient in the operation process of the doctor to obtain related motion track data, and a data processing device, wherein the data measured by the matrix type pressure sensor array, the posture measuring device and the contact type track measuring device is sent to the data processing device, a tibia spacer is temporarily replaced in the operation process, the tibia spacer is taken out after the pressure and the posture are balanced, and a proper tibia spacer is placed in the tibia spacer. The problem that gap balance is difficult to accurately grasp in the existing artificial total knee joint replacement process is solved.

Owner:BEIJING YIMAI MEDICAL TECH CO LTD +1

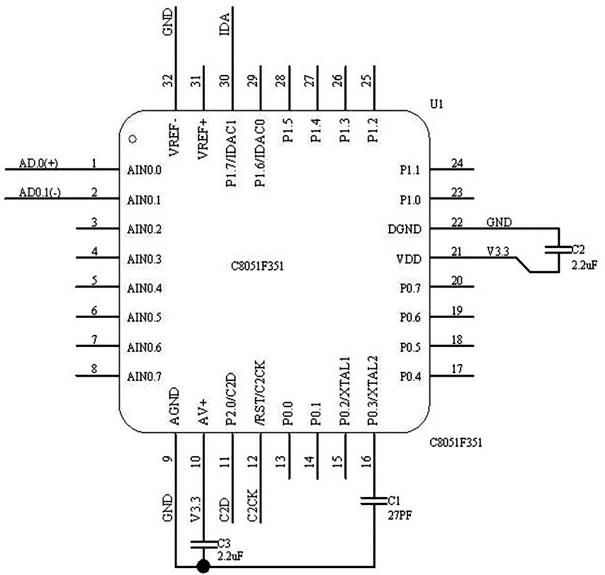

High precision coal seam gas pressure recorder

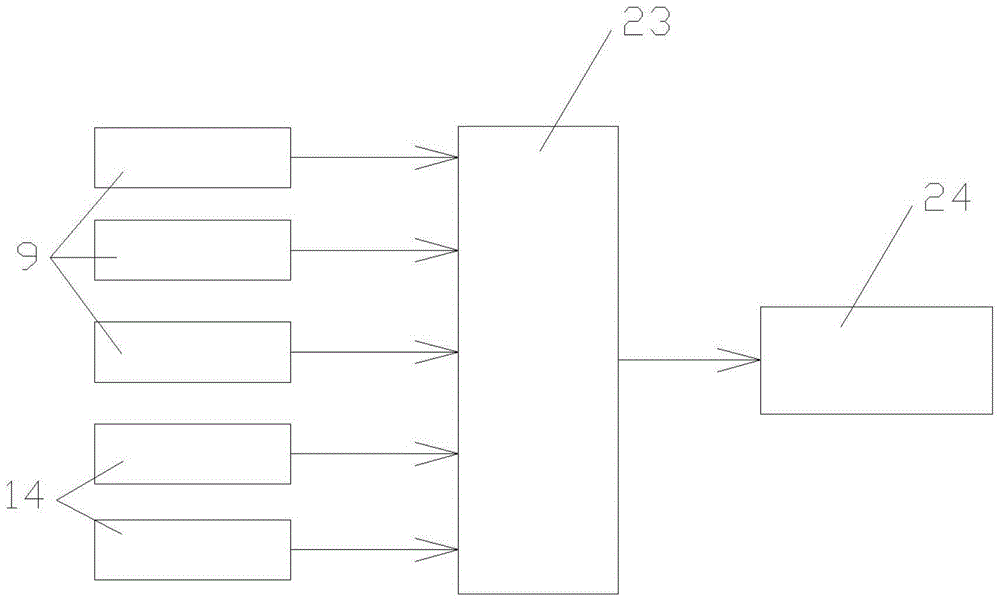

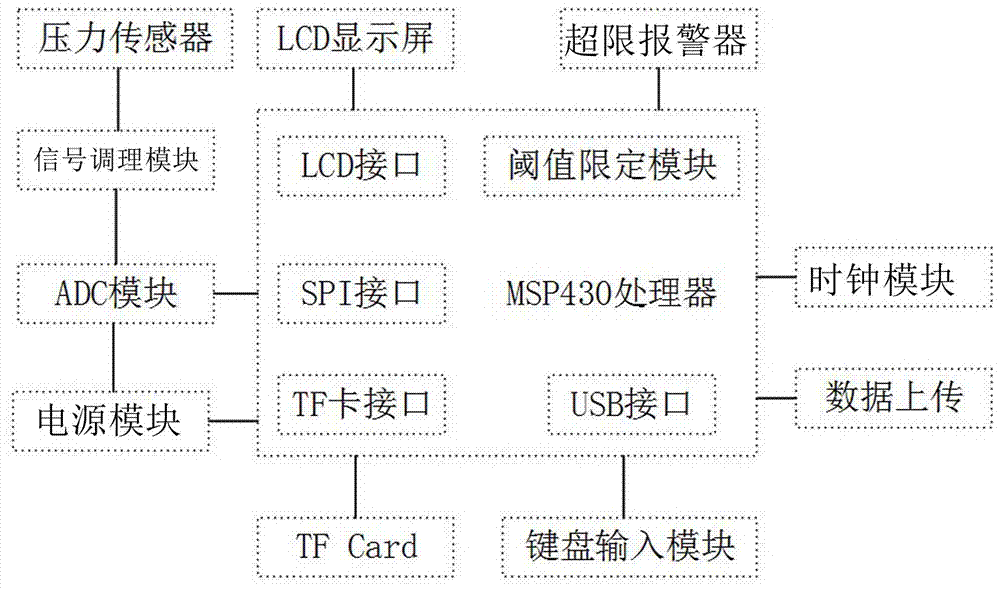

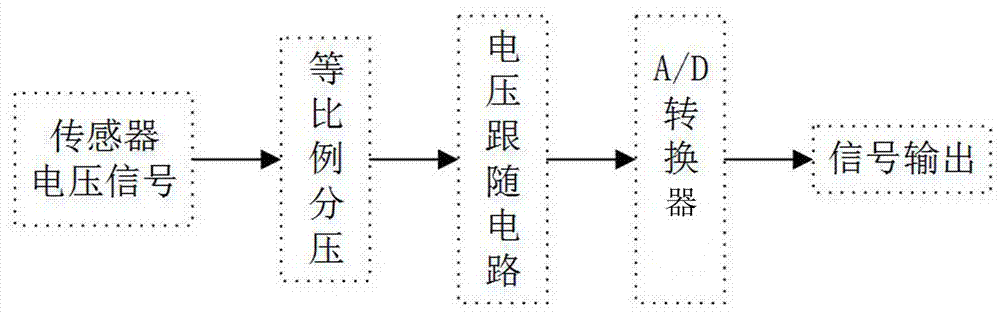

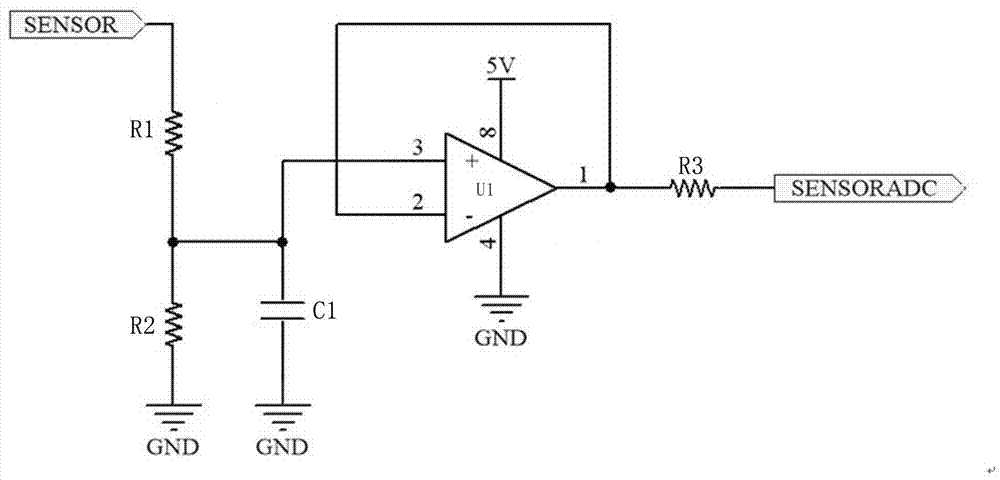

InactiveCN107328516AHigh precisionImprove reliabilityFluid pressure measurementSignal conditioningUSB

The invention discloses a high precision coal seam gas pressure recorder which comprises a main control module, a pressure sensor, a signal conditioning module, an ADC module, a power supply module, an LCD display module, an overrun alarm, a keyboard input module, a TF card module and a clock Module. The pressure sensor, the signal conditioning module, the ADC module and the power supply module are connected in turn. The ADC module is connected with the SPI interface of the main control module. The power supply module is connected with the main control module. The LCD display module is connected with the LCD interface of the main control module. The TF card module is connected with the TF card interface of the main control module. The keyboard input module is connected with the USB interface of the main control module. The main control module is connected with the overrun alarm and the system clock. The recorder has the advantages of high accuracy, high reliability and high efficiency, and can record the pressure of a coal seam gas in real time.

Owner:GUILIN UNIV OF ELECTRONIC TECH

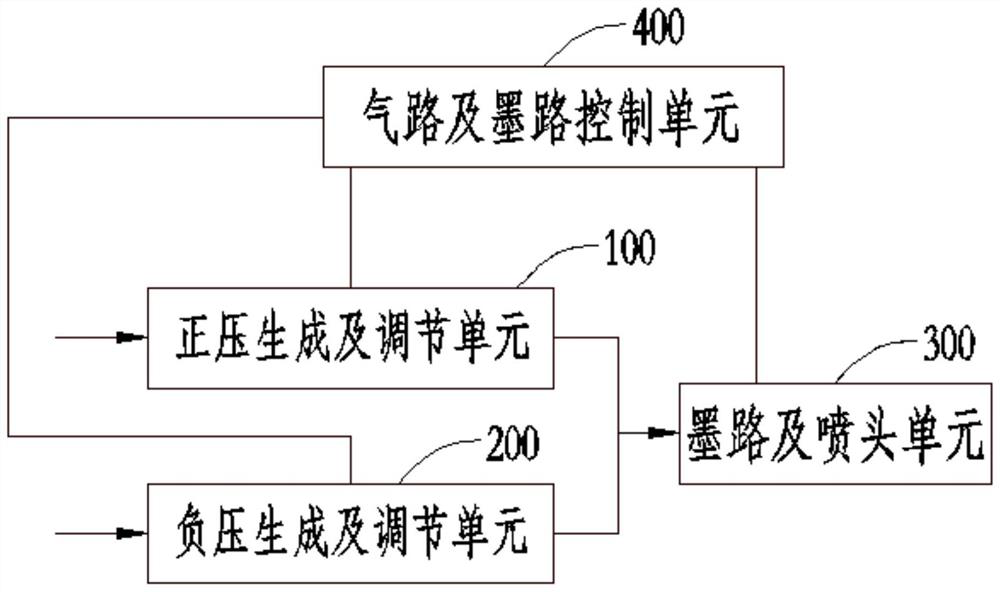

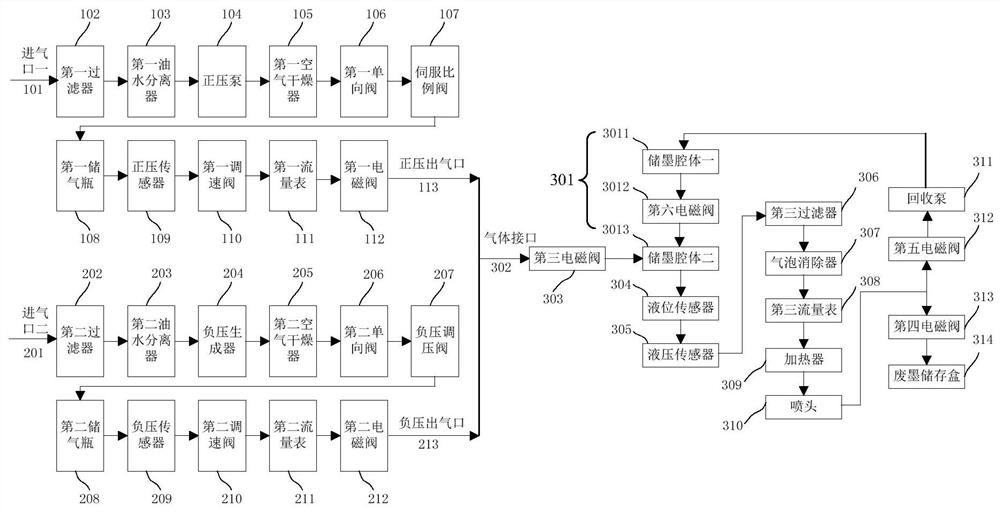

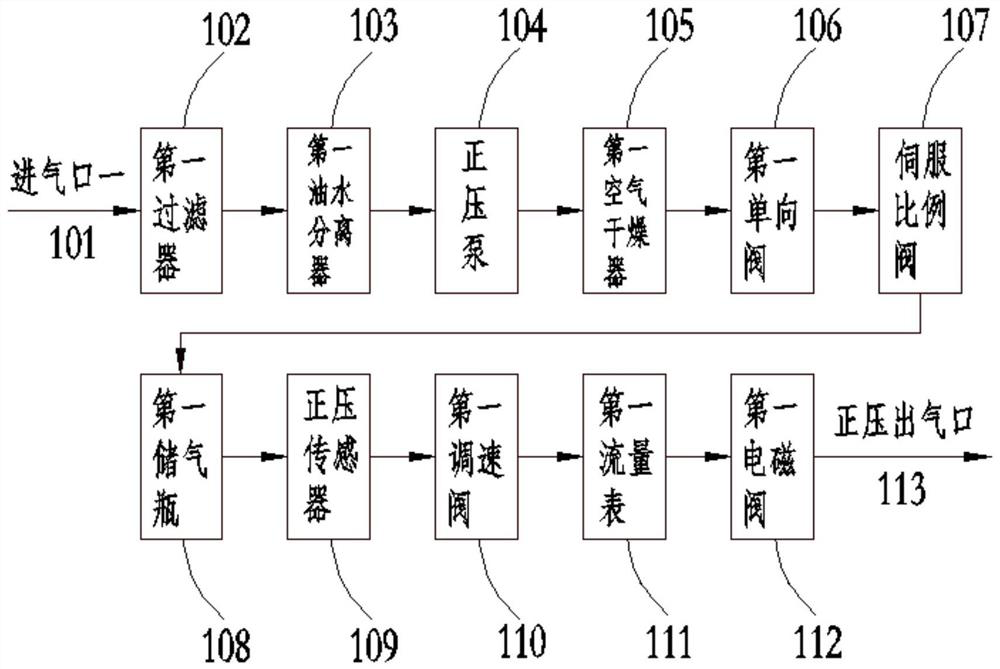

A multi-nozzle ink path air pressure control system for inkjet printing and its application

The invention belongs to the technical field related to inkjet printing, and specifically discloses an inkjet printing multi-nozzle ink path air pressure control system and its application, which includes a positive pressure generation and adjustment unit, a negative pressure generation and adjustment unit, an ink path and a nozzle unit And the air circuit and ink circuit control unit, the positive pressure generation and adjustment unit and the negative pressure generation and adjustment unit are respectively connected with the ink circuit and the nozzle unit, and are used to provide positive pressure gas and negative pressure gas for the ink circuit and the nozzle unit , the gas circuit and the ink circuit control unit are respectively connected with the positive pressure generation and adjustment unit, the negative pressure generation and adjustment unit, the ink circuit and the nozzle unit, and are used to coordinate and control these three units to pass the positive and negative pressure gas The control realizes high-precision inkjet printing. The invention can realize functions such as ink supply and pressure of ink or solution in the ink path, jet printing, low-frequency jet, nozzle cleaning, ink recovery, etc., and has the advantages of compact structure, stable pressure, easy manipulation, high precision and high degree of automation.

Owner:武汉国创科光电装备有限公司

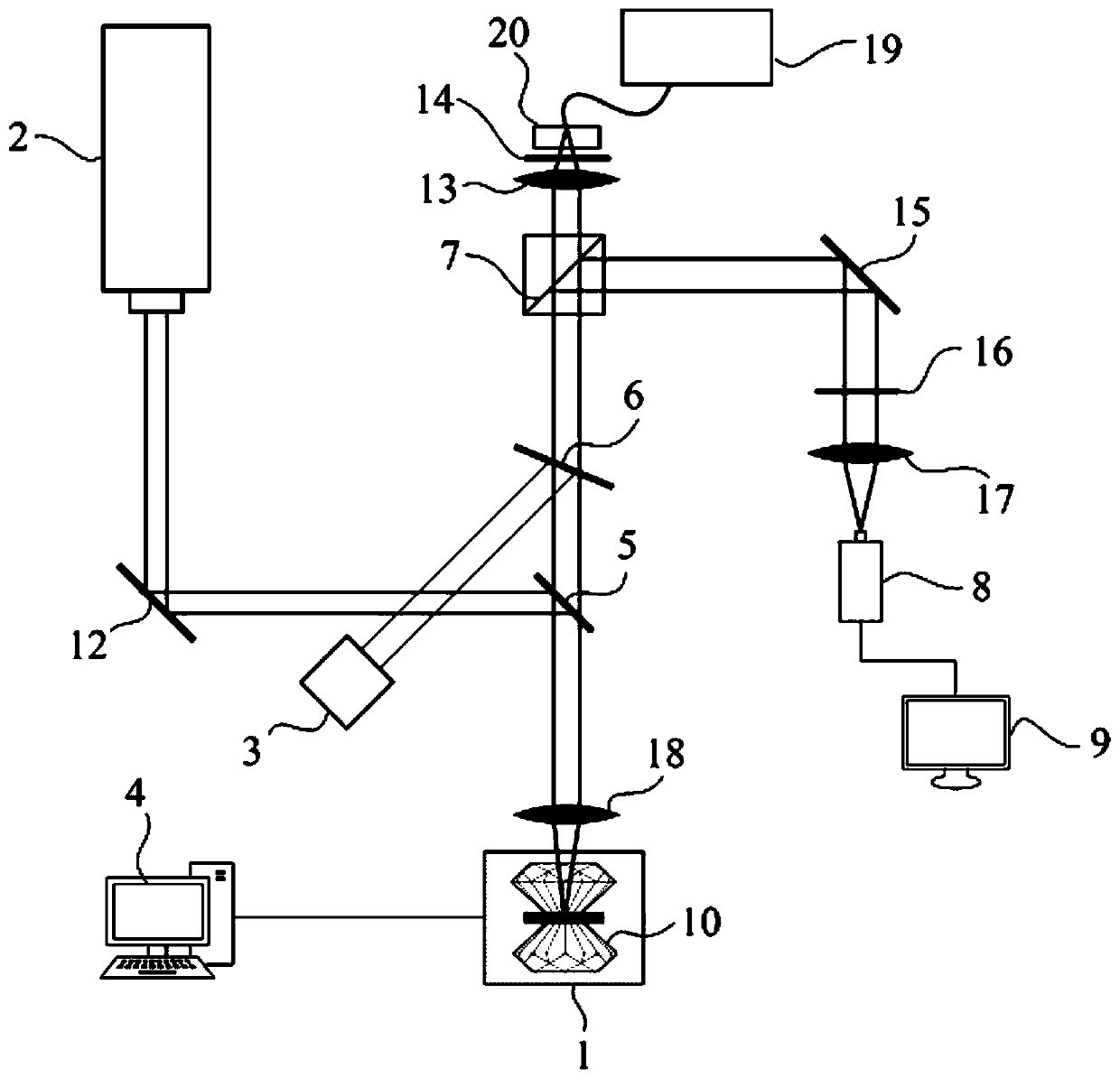

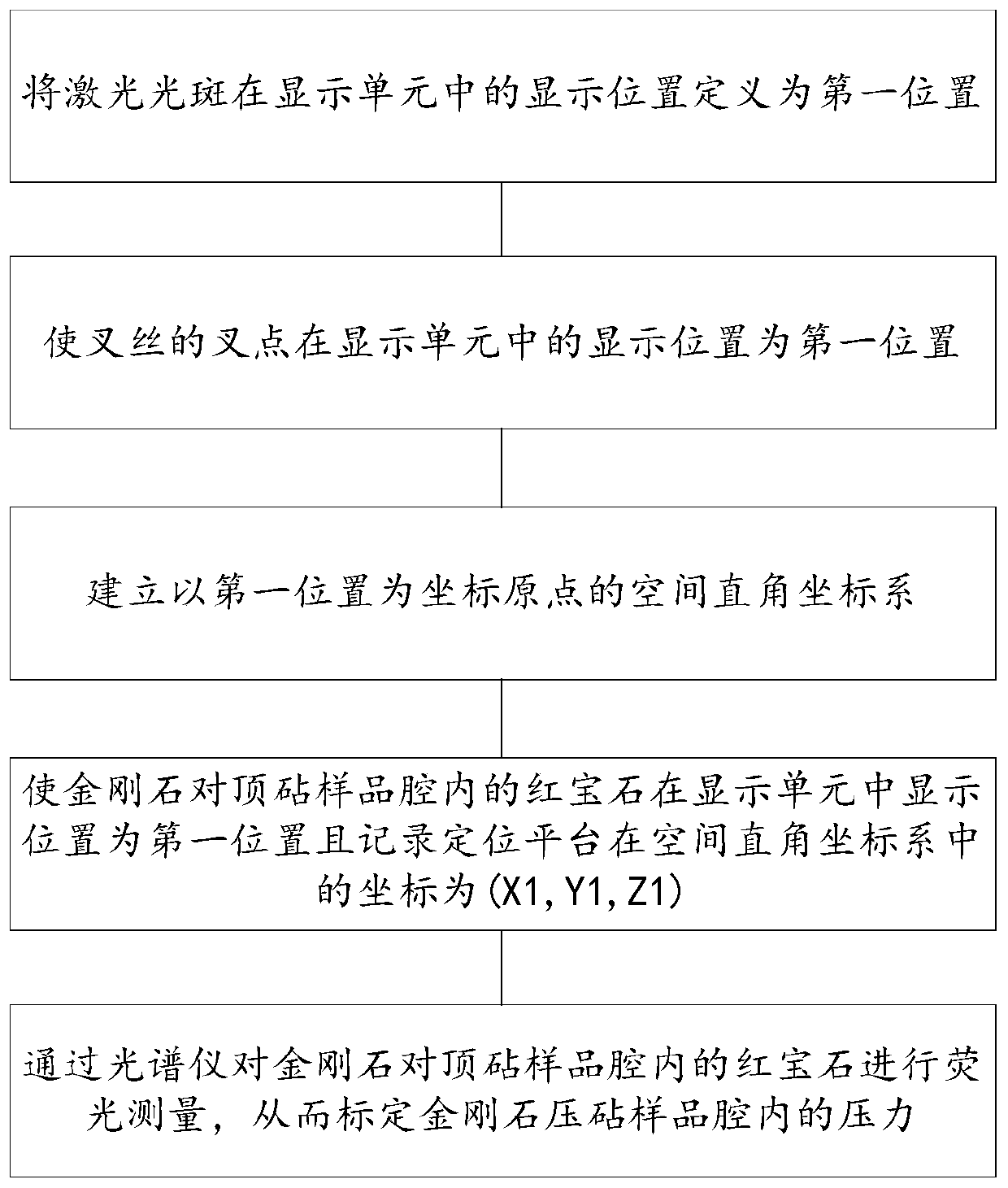

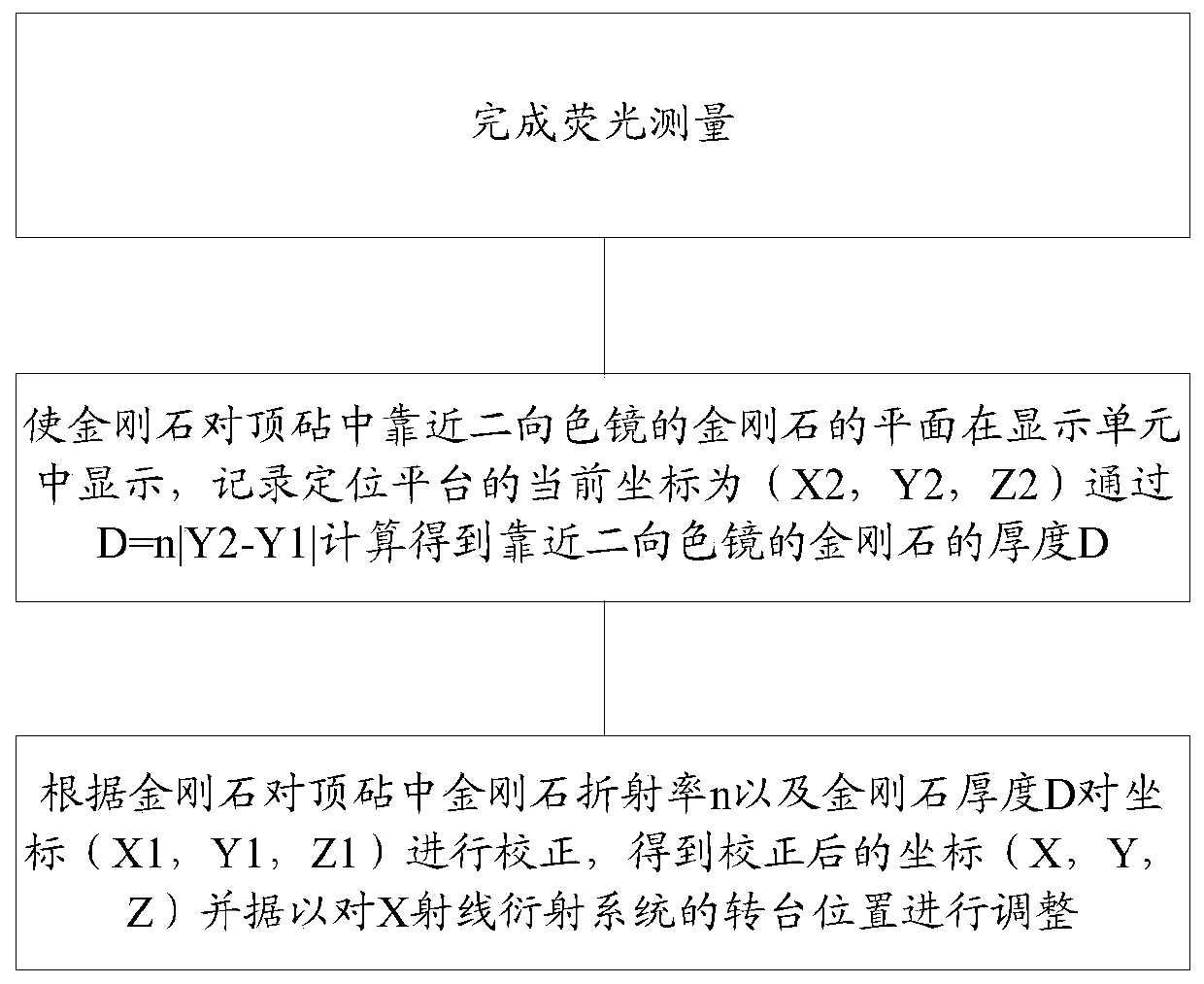

Optical system pre-positioning method

InactiveCN106525884BAchieve pre-positioningRealize pressure measurementMaterial analysis using wave/particle radiationForce measurement by measuring optical property variationBeam splitterFluorescence

The invention provides an optical system and a fluorescence measurement and pre-positioning method thereof. The optical system comprises a positioning platform, a laser source, an illuminating light source, a control unit, a dichroscope, a semi-reflection mirror, a beam splitter, an image pickup unit and a display unit. The method comprises the following steps: positioning a first position by laser, wherein the display position of the cross point of cross hairs in the display unit is the first position; placing a diamond anvil cell on a positioning platform; moving the positioning platform so that the display position of ruby in a diamond anvil cell sample cavity in the display unit is the first position to finish fluorescence measurement; recording the coordinates of the positioning platform; and finally, correcting the recorded coordinates according to the diamond refractive index in the diamond anvil cell. In the invention, pressure measurement and pre-positioning of the diamond anvil cell sample cavity can be realized, the calibration of pressure of the sample cavity depending on a Raman spectral system is avoided, and the positioning time of a diamond anvil cell sample cavity experiment by an X-ray diffraction system is shortened.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

Novel transmissible pressure and differential pressure transmitter for measuring pressure of ultrahigh temperature medium

ActiveCN103017974BRealize pressure measurementFluid pressure measurementPressure transmissionDifferential pressure

Owner:SHANGHAI ROCKSENSOR AUTOMATION

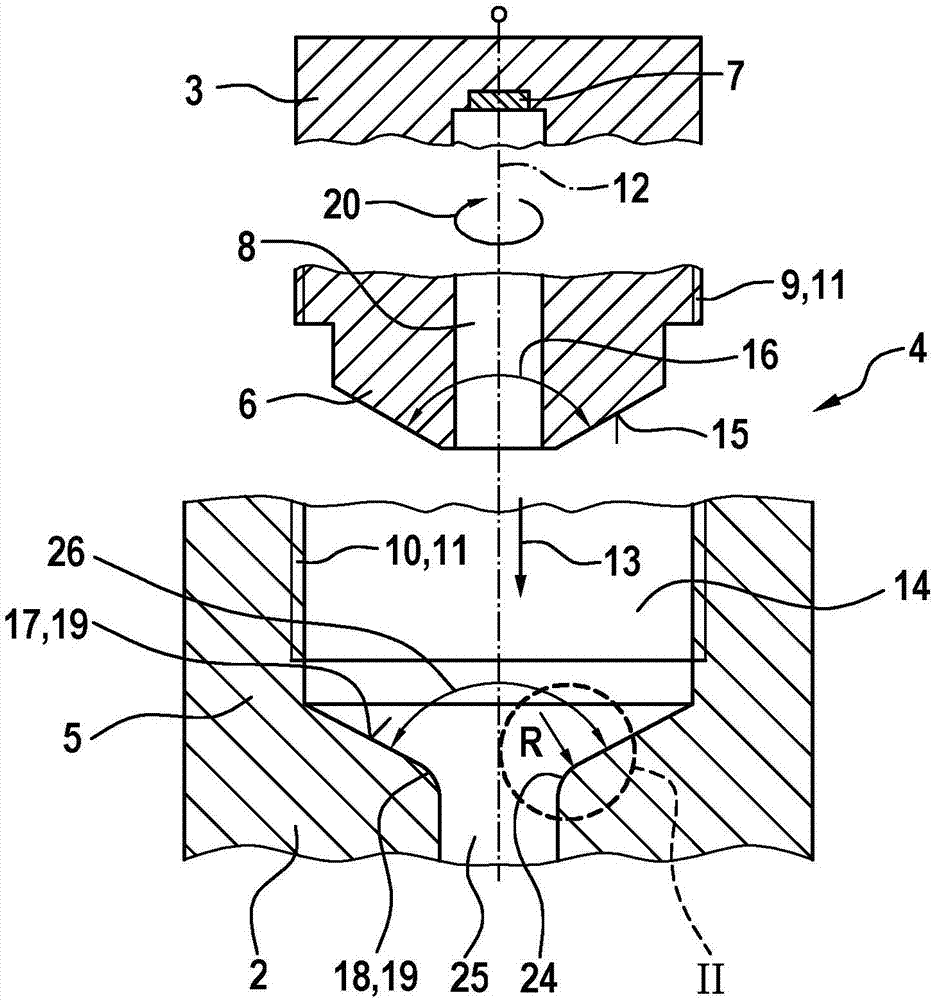

Device of fuel injection system and metal-to-metal sealing connection arrangement

ActiveCN107110087AReduce usageRealize the sealing functionMachines/enginesSpecial fuel injection apparatusMetalFuel injection

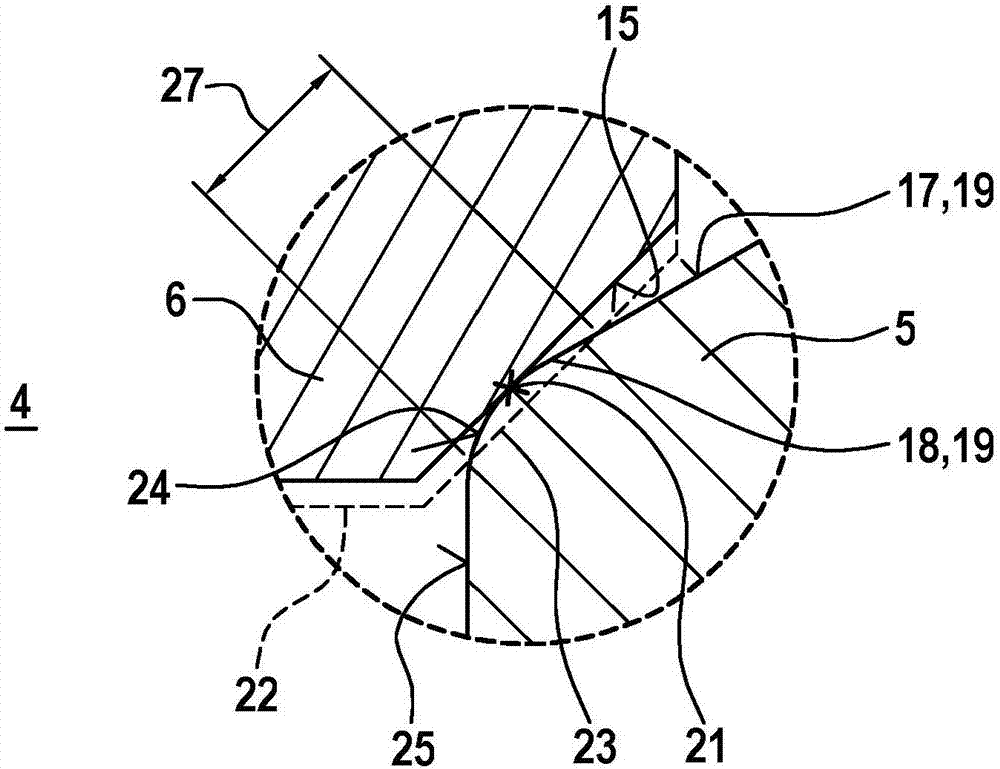

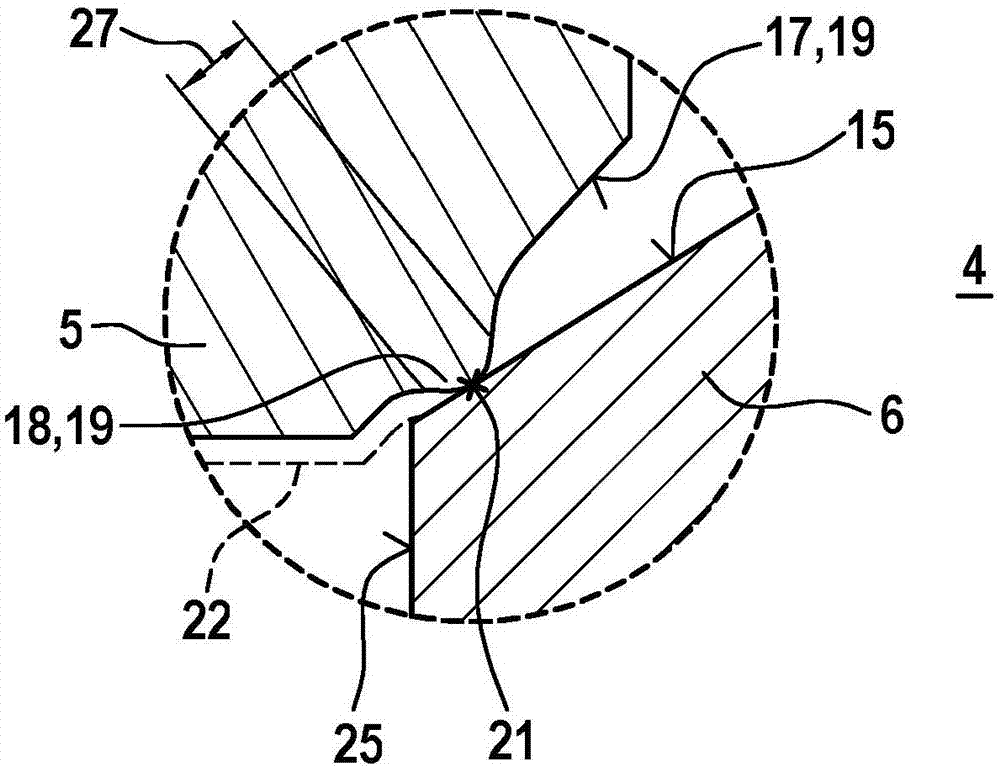

A device (1) of a fuel injection system has a fuel-conducting component (2) and a connecting part (3). A metal-to-metal sealing connection arrangement (4) is provided which comprises a first metal connection partner (6) and a second metal connection partner (5). The metal connection partners (5, 6) can be connected to each another with respect to an axis (12), with a conical sealing surface (15) on the first connection partner (6) and a sealing contour (19) matching the conical sealing surface (15) of the first connection partner (6) on the second connection partner (5). The sealing contour (19) of the second connection partner (5) has, in an initial state, a circumferential elevation (18) around the axis (14), said elevation facing the conical sealing surface (15) of the first sealing partner (6), wherein the sealing contour (19) of the second connection partner (5) is configured such that, with the screwing of the first connection partner (6) to the second connection partner (5), the circumferential elevation (18) of the second connection partner (5) is at least partially plastically deformed, in order to form a metal-to-metal seal between the conical sealing surface (15) of the first connection partner (6) and the elevation (18) of the second connection partner (5) that is deformed in the screwed state.

Owner:ROBERT BOSCH GMBH

An icing wind tunnel pressure measurement test method

ActiveCN111238759BGuaranteed accuracySolve the difficulties that cannot be stress testedAerodynamic testingIce formationGas supply

The invention discloses an icing wind tunnel pressure measurement test method. On the basis of the existing icing wind tunnel model icing test, a wind tunnel that integrates the model icing test and the ice shape aerodynamic impact evaluation test is established. The hole test method will help improve the efficiency of the pneumatic test and improve the accuracy of the test results. First, install the pressure measurement model according to the conventional pressure measurement test method, and connect the pressure measurement hole to the quick connector of the scanning valve through the pressure measurement hose; then Calibrate and group the pressure values of the pressure measuring holes at different speeds and pressures; when carrying out the aerodynamic test with clouds and fog, the pressure measuring holes are supplied with air from an external air source; after the surface of the model freezes, the air supply to the pressure measuring holes is closed, The pressure measurement test with the ice shape is carried out according to the conventional method, and finally the aerodynamic characteristics of the model with the ice shape are obtained; the invention solves the problem that the pressure measurement hole of the model pressure measurement hole of the icing wind tunnel cannot be carried out in the cloud and fog state.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

Pressure gauge and method for measurement of pressure

ActiveCN108007636AUnlimited calibration cycleRealize pressure measurementFluid pressure measurementEngineeringControl circuit

The present invention discloses a pressure gauge and a method for measurement of pressure. The pressure gauge comprises a body, and a plurality of pressure sensors and a control circuit which are arranged in the body. The pressure sensors can contact measurement medium in order and can be correspondingly connected with the control circuit in order to output pressure signals. The pressure gauge isemployed to connect the pressure sensors with the control circuit in order to output the pressure signals, and the pressure sensors included in the pressure gauge can continuously work. The method isnot limited to the calibration cycle of one sensor, and therefore pressure measurement with a calibration cycle being longer than the calibration cycle of one sensor is achieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Liquid pressure intensity demonstrator for high school physics teaching

ActiveCN107767745ARealize pressure measurementPracticalEducational modelsEngineeringGravitational force

The invention discloses a liquid pressure intensity demonstrator for high school physics teaching. The demonstrator comprises a liquid penetrating part and a pressure intensity measurement part, wherein the liquid penetrating part comprises a main hollow column-shaped column body, the bottom of the main hollow column-shaped column body is provided with a bottom connecting plate structure which isstructurally integrated with the bottom, the bottom of the bottom connecting plate structure is provided with a connecting rod, the bottom of the connecting rod is provided with a gravity hemispheroid, the top of the main hollow column-shaped column body is provided with a top limiting plate structure which is structurally integrated with the top, and the center of the main hollow column-shaped column body is provided with a hollow mobile space. According to the demonstrator, equivalent replacement is utilized, the pressure intensity values of liquid at different depths are determined througha difference between a known air pressure value and a current air pressure value, in addition, the device can be connected with air pipelines with different lengths, the pressure intensity measurementof liquid with a relatively great depth is changed and realized, moreover, the interior of the device does not come into contact with liquid, so that the service life of the device is prolonged, andthe practicability is strong.

Owner:瑞安市华嘉机械制造有限公司

Optical fiber pressure sensor measurement method and device

InactiveCN104458080BSimple structureEasy to operateForce measurement by measuring optical property variationRapid change measurementPressure senseLight beam

The invention relates to the technical field of high-precision optical fiber pressure sensing, in particular to an optical fiber pressure sensing measurement method and device. The optical fiber pressure sensing measurement method and device solve the technical problems in the prior art and are simple in structure and high in measurement accuracy. When outside pressure is applied to an optical fiber serving as a detector, the optical path for optical pulses to transmit in the optical fiber changes, the change of the optical path is measured in real time through an autocorrelator, and therefore the pressure applied to the optical fiber can be obtained. According to the method and device, laser beams are output through a pulse laser; the beams output from the laser are divided into two paths of optical signals after passing through a filter, a circulator and a coupler, one path of optical signals are measurement path optical signals, the other path of optical signals are reference path optical signals, and an outside pressure value is obtained according to the formula in the specification by measuring whether outside pressure exists or not and measuring the interval delta T and T of the autocorrelator.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com