Oil well online closure metering device

A technology of metering device and oil well, applied in the direction of measuring device, weighing, measurement, etc., can solve the problems of reduced work reliability, adverse effects of saving and emission reduction, large maintenance workload, etc. The effect of simple and reliable control and high working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

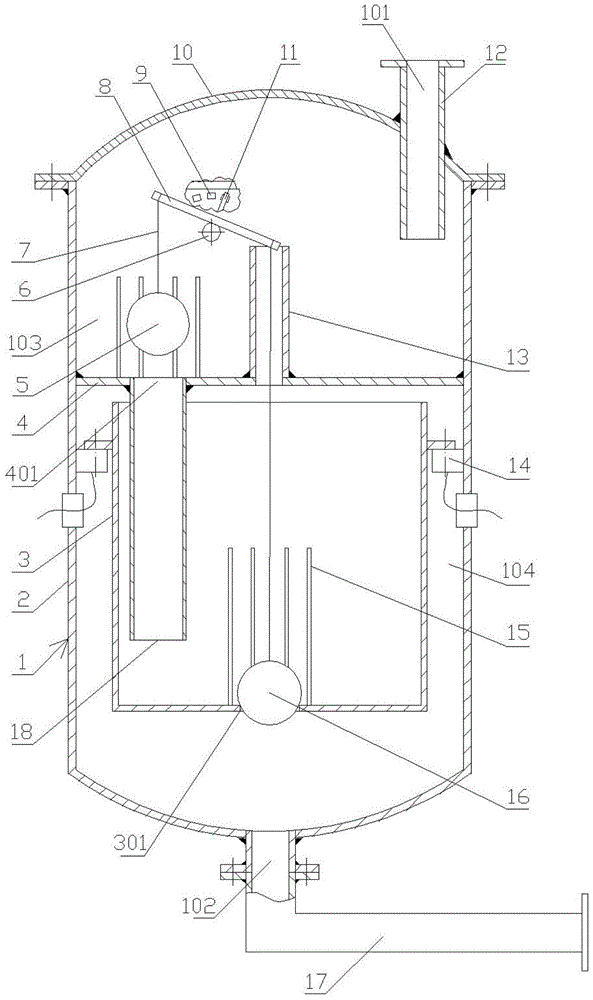

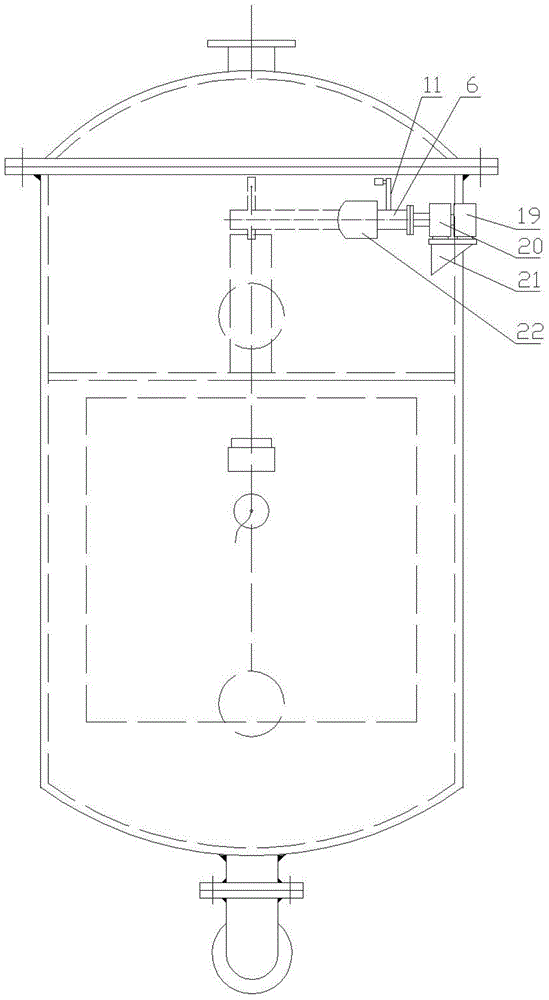

[0030] Such as Figure 1-Figure 3 As shown, an oil well online interception metering device related to the present invention includes a metering housing 1, and an oil inlet 101 and an oil outlet 102 are respectively provided at the upper and lower ends of the metering housing 1 . The metering housing 1 is formed by connecting a cylindrical housing main body 2 and an arc top cover 10 through flanges and bolts uniformly distributed around the circumference. The bottom surface of the housing main body 2 is arc-shaped, and the oil inlet 101 It is formed as an oil inlet pipe 12 vertically inserted into one side of the upper cover 10 . The oil outlet 102 at the lower end of the metering housing 1 is connected with an oil discharge pipe 17 through a flange.

[0031] A partition 4 is fixedly welded in the middle of the metering housing 1 , and the partition 4 divides the inner chamber of the metering housing 1 into upper and lower chambers, which are respectively the retention chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com