High precision coal seam gas pressure recorder

A technology of coal seam gas pressure and recorder, which is applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of no data storage, over-limit alarm curve drawing, accuracy can not meet requirements, low data reliability, etc. Effects of manual intervention, high precision, reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

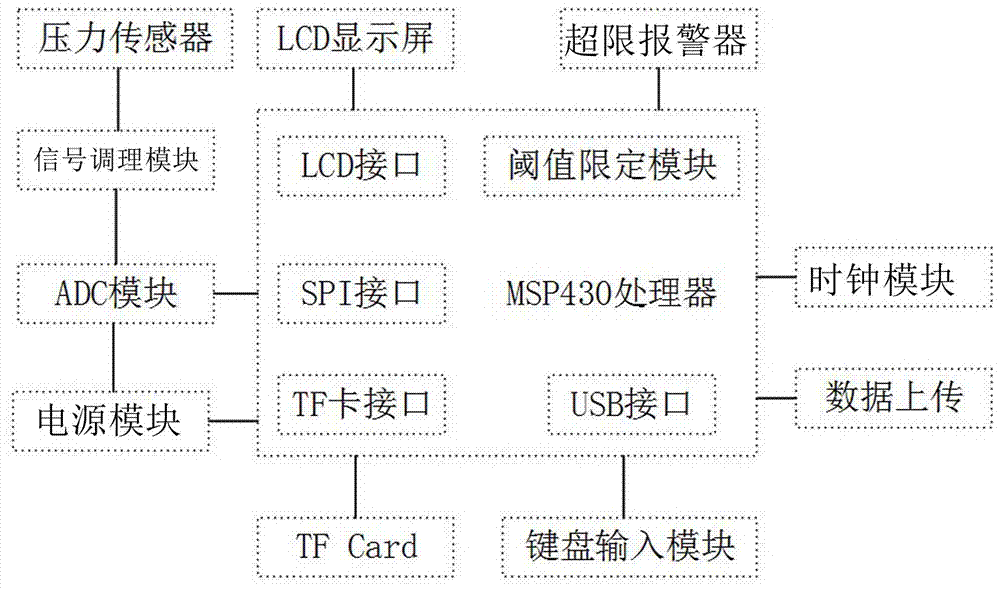

[0020] Such as figure 1 As shown, a high-precision coal seam gas pressure recorder, a main control module, a pressure sensor, a signal conditioning module, an ADC module, a power supply module, an LCD display module, an overrun alarm, a keyboard input module, a TF Card module and a clock module; The pressure sensor, signal conditioning module, ADC module, and power module are connected in sequence; the ADC module is connected to the SPI interface of the main control module; the power module is also connected to the main control module; the LCD display module is connected to the LCD interface of the main control module; the TF Card module It is connected with the TF card interface of the main control module, the keyboard input module is connected with the USB interface of the main control module, and the main control module is also connected with an overrun alarm and a system clock.

[0021] The main control module is a processor based on MSP430.

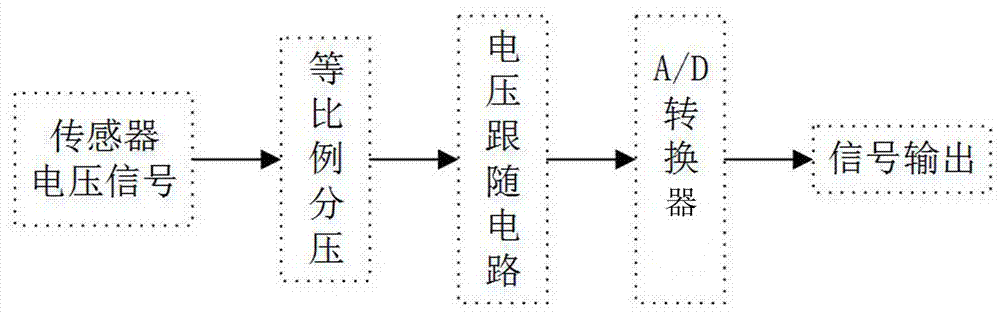

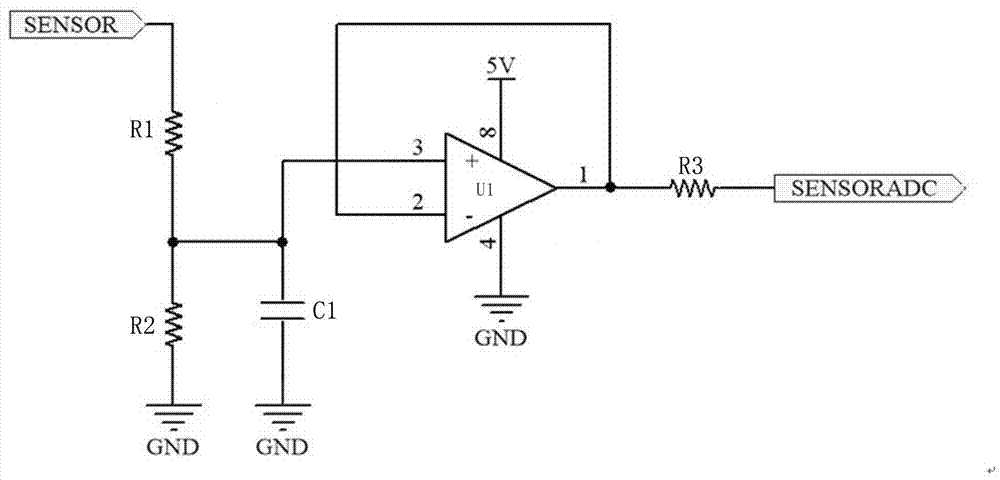

[0022] Such as figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com