Automatic-inflation wheel side framework-type rotating joint assembly with air pipe for trailer tire

A rotary joint and automatic inflation technology, which is applied to tire inflation valves, tire parts, vehicle parts, etc., can solve the problems of low reliability, easy air leakage, and product dependence on imports, and achieve simple assembly structure and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Below in conjunction with accompanying drawing and example describe in detail:

[0068] 1. Overall

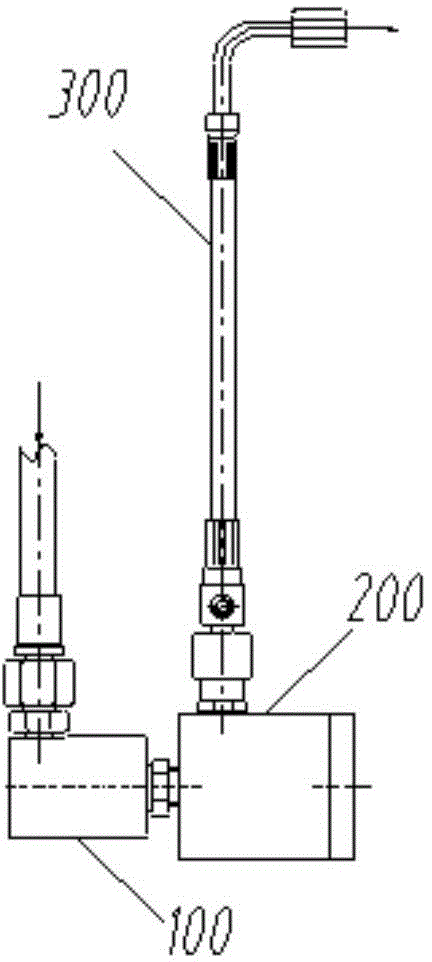

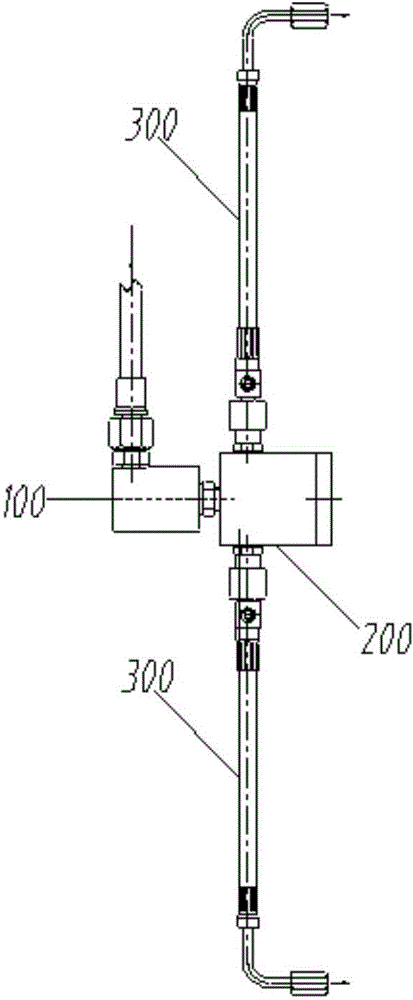

[0069] Such as figure 1 , 2 , the assembly includes a rotary joint subassembly 100, a mounting bracket subassembly 200 and a valve air pipe subassembly 300;

[0070] Its location and connection relationship are:

[0071] The rotary joint subassembly 100 is connected to the mounting bracket subassembly 200, and the valve air pipe subassembly 300 is connected to the mounting bracket subassembly 200;

[0072] The inner cavity of the swivel joint subassembly 100 and the valve trachea subassembly 300 forms a one-way air chamber.

[0073] The rotating part is connected to the rotating chamber, and the stationary part is connected to the static chamber. There is a complete gas channel between the two parts. The skeleton oil seal completes the air seal between the rotating part and the stationary part to prevent gas leakage.

[0074] 2. Functional components

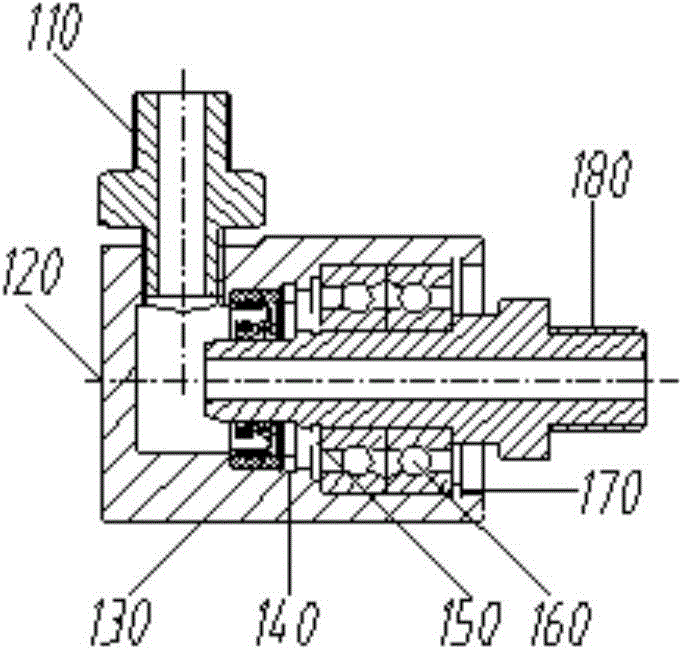

[0075] 1. Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com