Miniature mud floating electronic pressure gauge, its working method, and pressure measuring device

A floating, pressure gauge technology, applied to temperature devices, real-time measurement of downhole pressure, can solve problems such as E-MWD that cannot work stably, ordinary storage pressure gauges cannot recover data in time, etc., and achieves simple structure, low cost, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] All features disclosed in this specification, or all disclosed steps in a method or process, may be combined in any way except mutually exclusive features and / or steps.

[0035] Any feature disclosed in this specification (including any accompanying claims, abstract and drawings), unless expressly stated otherwise, may be replaced by other equivalent or alternative features serving a similar purpose. That is, unless expressly stated otherwise, each feature is but one example of a series of equivalent or similar features.

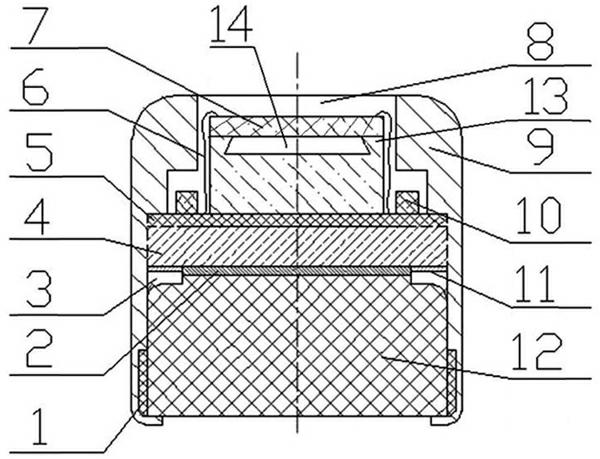

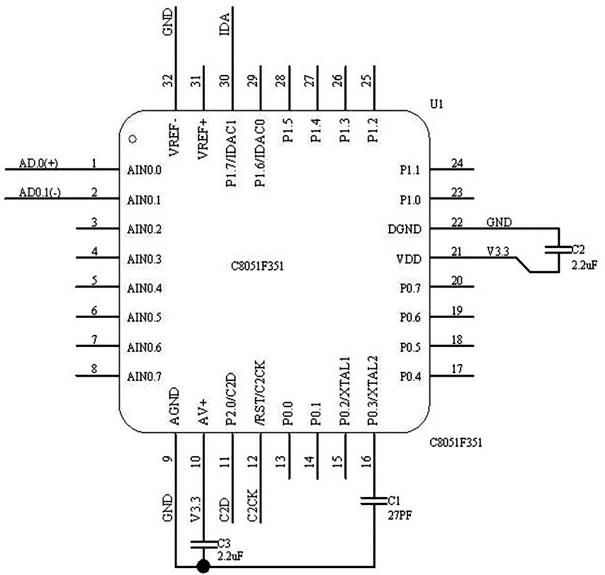

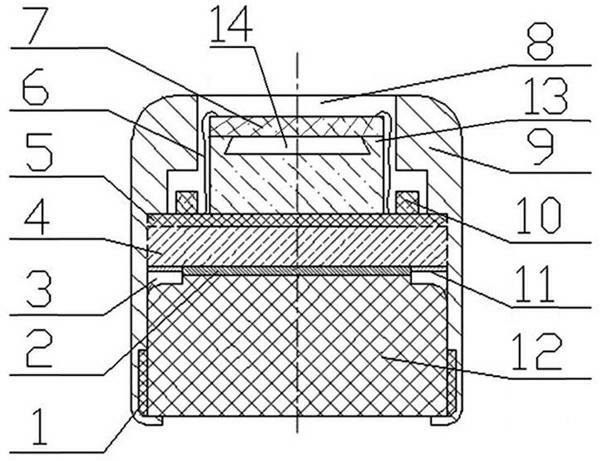

[0036] like figure 1 As shown, there are CR626 lithium manganese button battery 12, microcontroller 4, circuit board 5, connection block 13, pressure chip 7 stacked in sequence from bottom to top in aluminum alloy shell 9, and the negative electrode of the battery is connected to the negative electrode on the back of the microcontroller 4. 2, the single-chip microcomputer 4 is soldered to the circuit board 5, and the data read-write electrode 11 is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com