An absolute pressure fiber-optic silicon carbide high temperature resistant aviation pressure sensor

A Faper silicon carbide and pressure sensor technology, which is applied in the field of absolute pressure fiber Faber silicon carbide high temperature resistant pressure sensor and aviation pressure sensor manufacturing. The effect of low characteristics, fast response speed and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

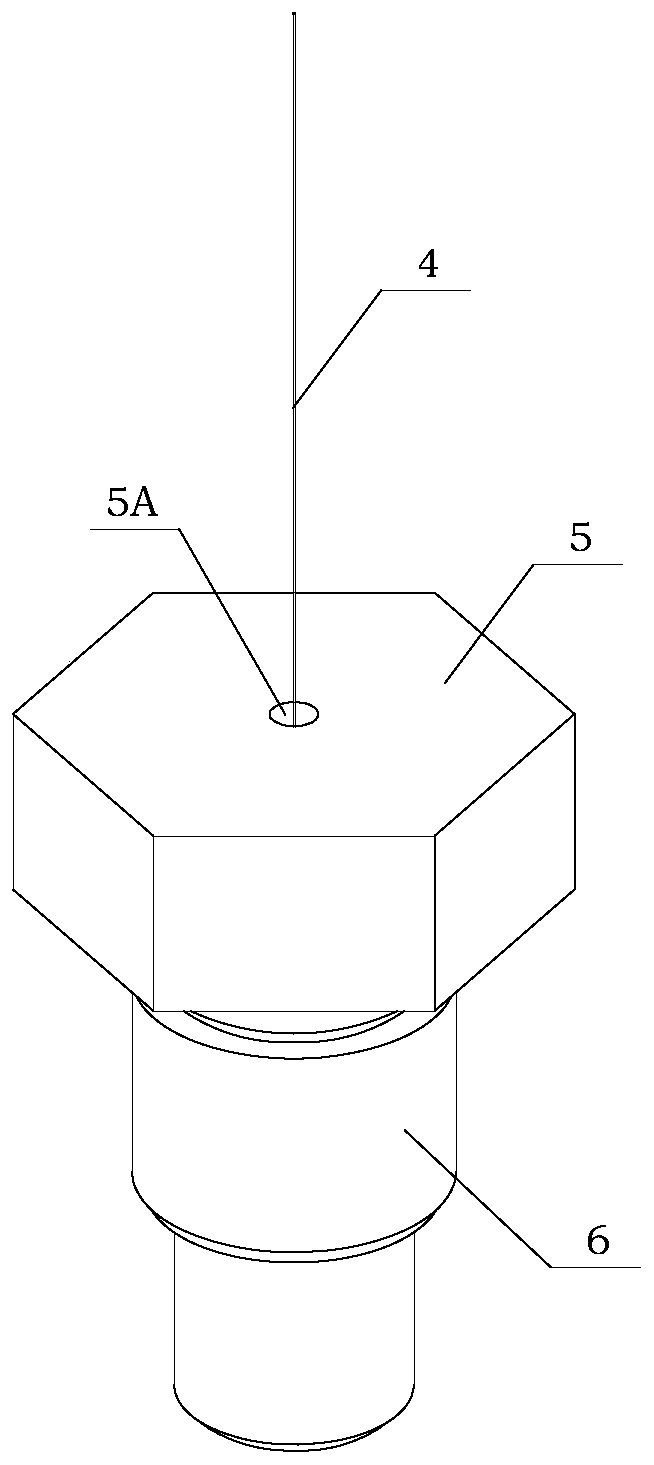

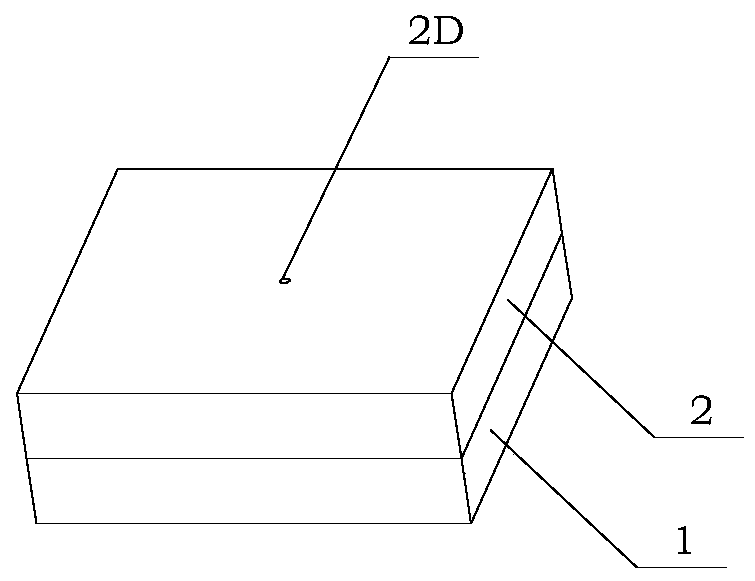

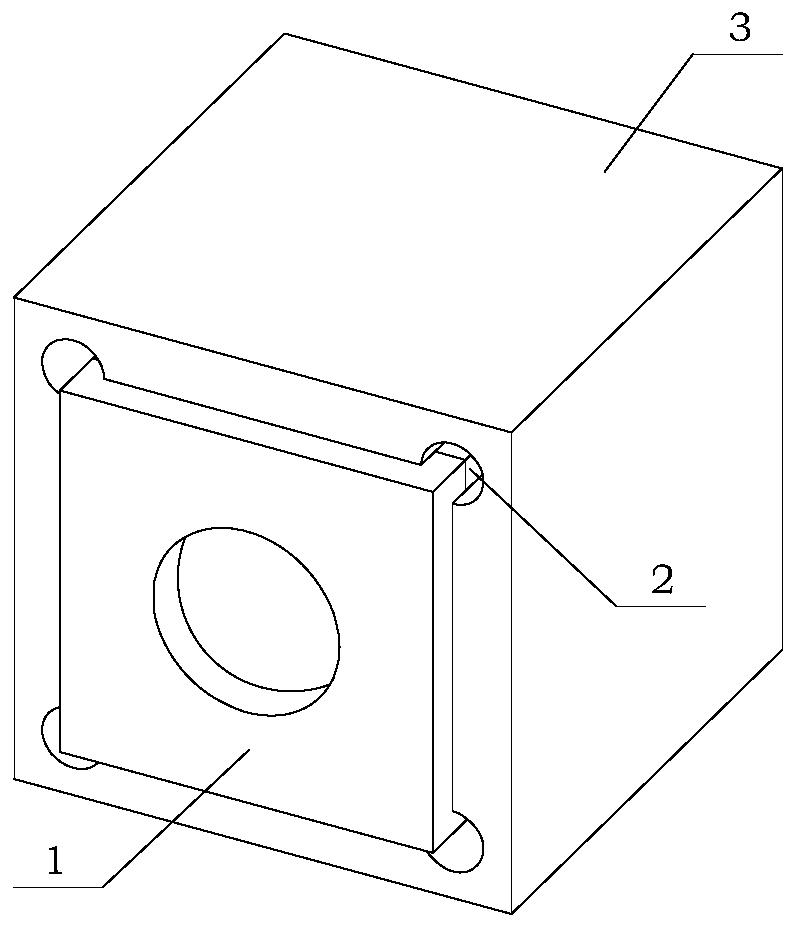

[0104] The full SiC structure sensing head designed by the present invention is applied to the measurement of dynamic pressure and flow field characteristics in the high-temperature area of the aero-engine. In order to be installed with the devices in the high-temperature area of the aero-engine, a molybdenum package seat 5 and a molybdenum package body are specially designed. 6. The SiC sensing diaphragm 1 and SiC substrate 2 are installed under the zirconia base 3, one end of the sapphire optical fiber 4 is bonded to the SiC substrate 2, and the zirconia base 3 is installed in the countersunk cavity 5C of the molybdenum package base 5 Among them, a molybdenum package body 6 is threadedly connected to the bottom of the molybdenum package base 5;

[0105] According to the sensor obtained in Example 1, the pressure measurement is carried out in a high-temperature environment. The ambient temperature is 1000 ° C, the measurement range is 0-1 MPa, and the Fappon cavity length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com