Pressure gauge and method for measurement of pressure

A pressure gauge and pressure value technology, applied in the field of measurement and testing, can solve the problems of limited calibration period of the method of measuring pressure, low reliability of the measurement result of the pressure gauge, and inability to guarantee the reliability of the measurement result of the pressure gauge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

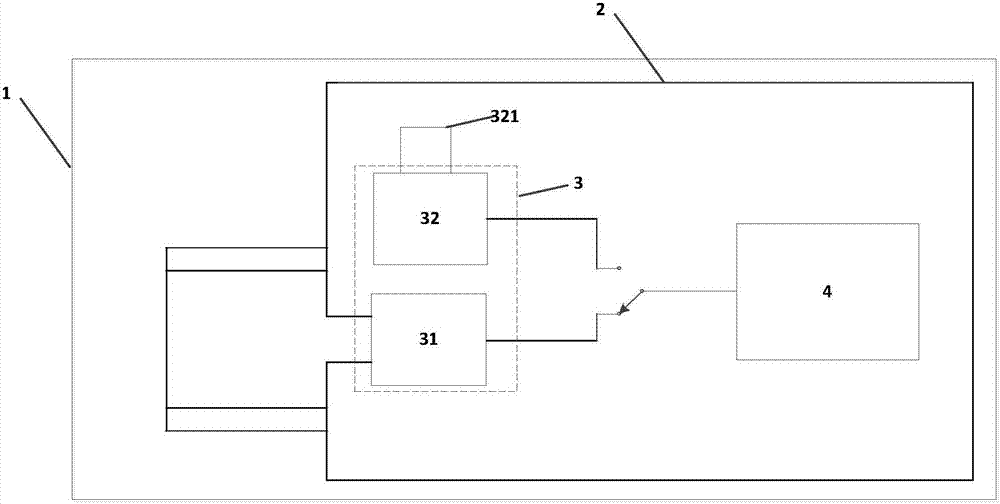

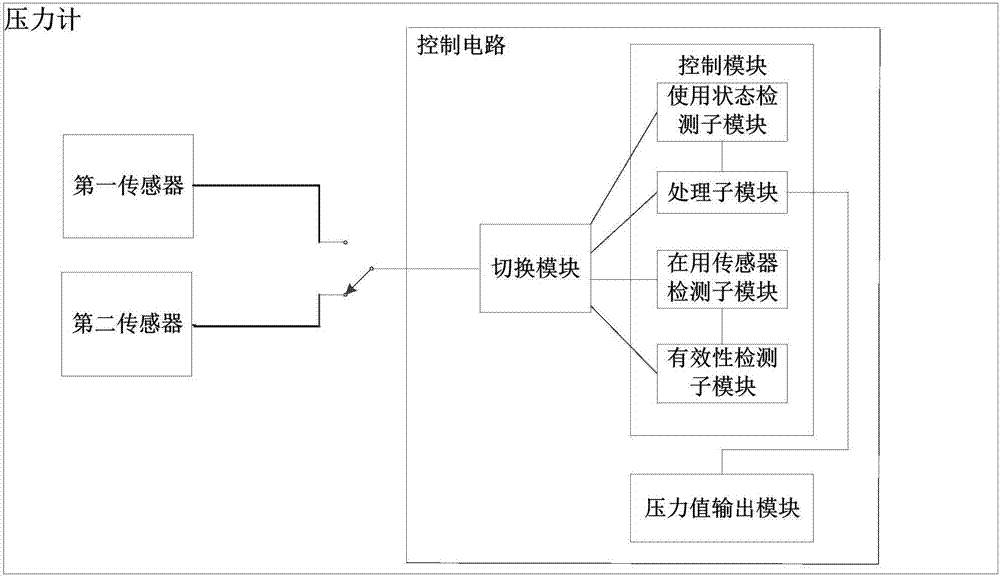

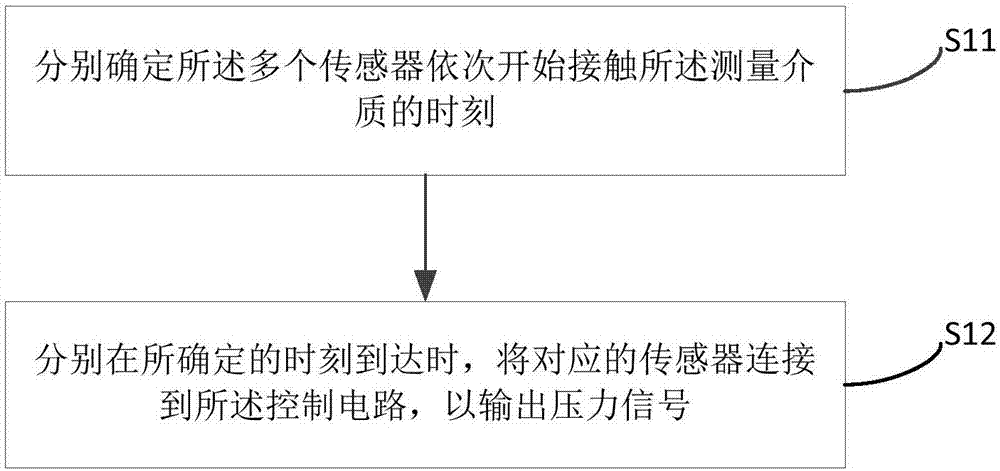

[0051] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0052]In the related technology, the pressure gauge includes a pressure sensor. After the measuring personnel place the pressure gauge downhole, the pressure sensor contacts the measurement medium, thus bears the pressure exerted by the measurement medium on the pressure sensor, and the pressure sensor senses the pressure signal. After the pressure signal is processed, it is converted into a pressure value and output to the user. That is to say, the pressure signal sensed by the pressure sensor is accurate by default. However, as the usage time increases, the errors caused by the pressure sensor itself (for example: errors caused by zero point drift and tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com