Novel transmissible pressure and differential pressure transmitter for measuring pressure of ultrahigh temperature medium

A differential pressure transmitter, medium pressure technology, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of poor liquid fluidity, affecting the pressure transmission speed in the stainless steel capillary, and functional damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

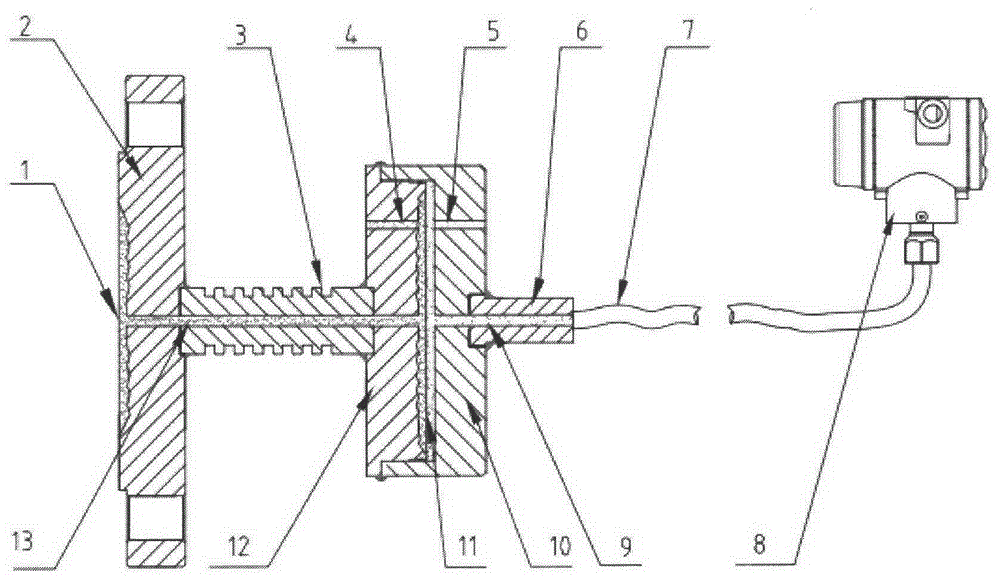

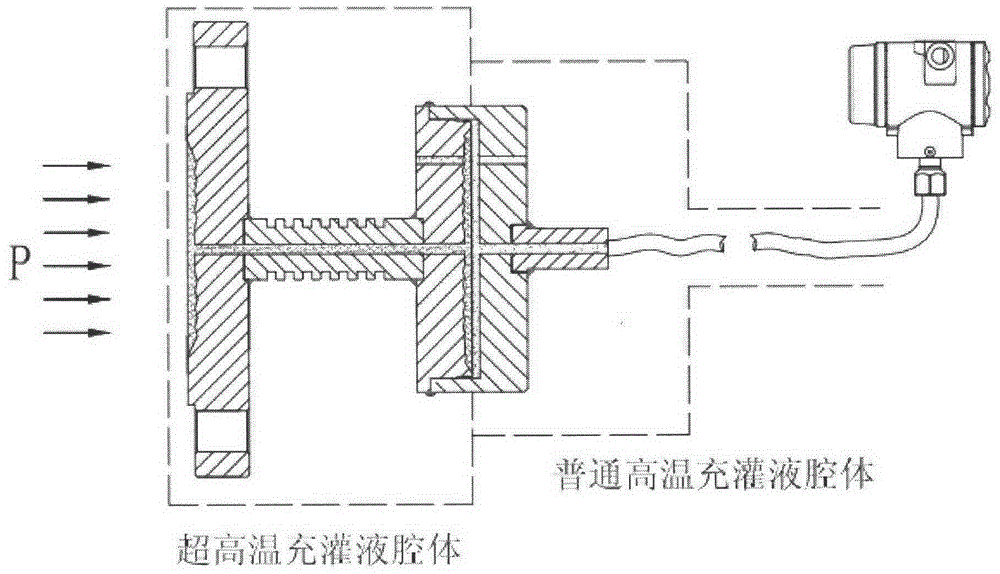

[0010] exist figure 1 Among them, the two outer ends of the connecting flange (2) and the isolating flange (12) are respectively arranged with the measuring diaphragm (1) and the isolating diaphragm (11), and the heat sink (3) is welded and connected between the connecting flange (2) and the isolating flange (12). Between the flanges (12), through the ultra-high temperature filling hole (4) on the isolation flange (12), inject an appropriate amount of ultra-high temperature resistant high-viscosity high-temperature filling liquid (13) and then seal it, forming an ultra-high temperature filling hole (4). Fill the liquid cavity. Weld and connect the mating flange (10), capillary joint (6), stainless steel capillary (7) and pressure, differential pressure transmitter body (8) in sequence, and then assemble and weld with the isolation flange (12), and then in the matching method The high-temperature filling hole (5) on the blue is injected with a low-viscosity high-temperature fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com