Capacitive miniature tire pressure sensor

A pressure sensor, micro-tire technology, applied in tire measurement, tire parts, transportation and packaging, etc., can solve the problems of not meeting the new technology standards and requirements of energy saving and environmental protection, environmental pollution, and limited life, and achieve convenient The effect of collaborative work and information fusion, improved reliability and maintainability, and improved interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

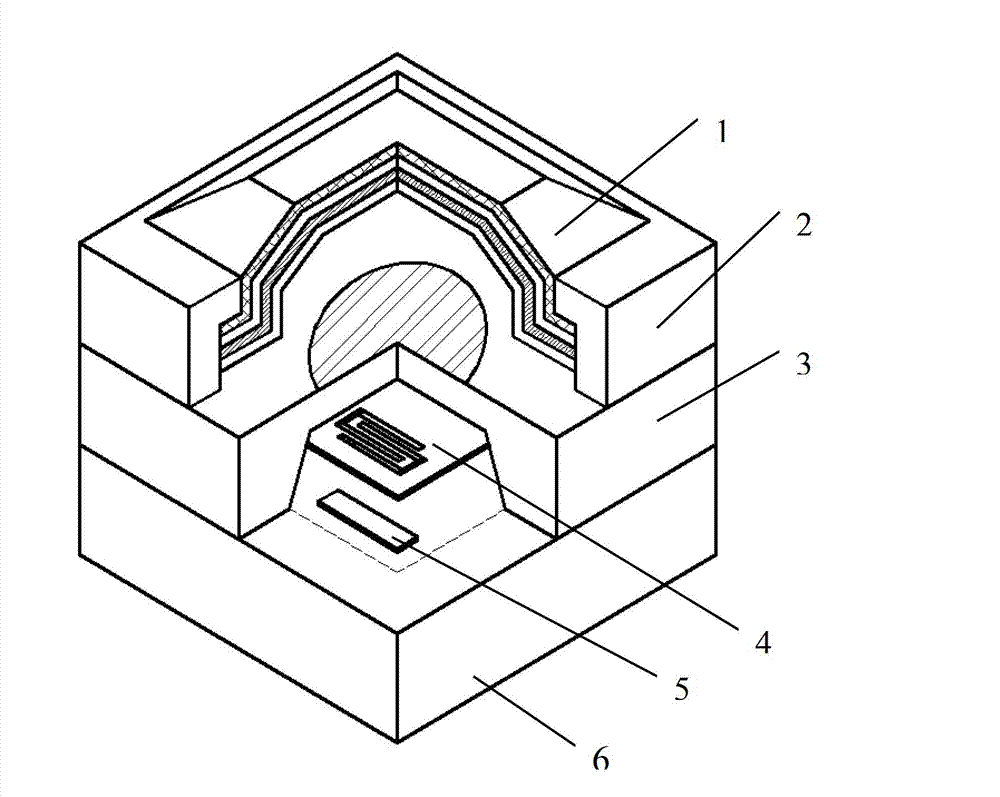

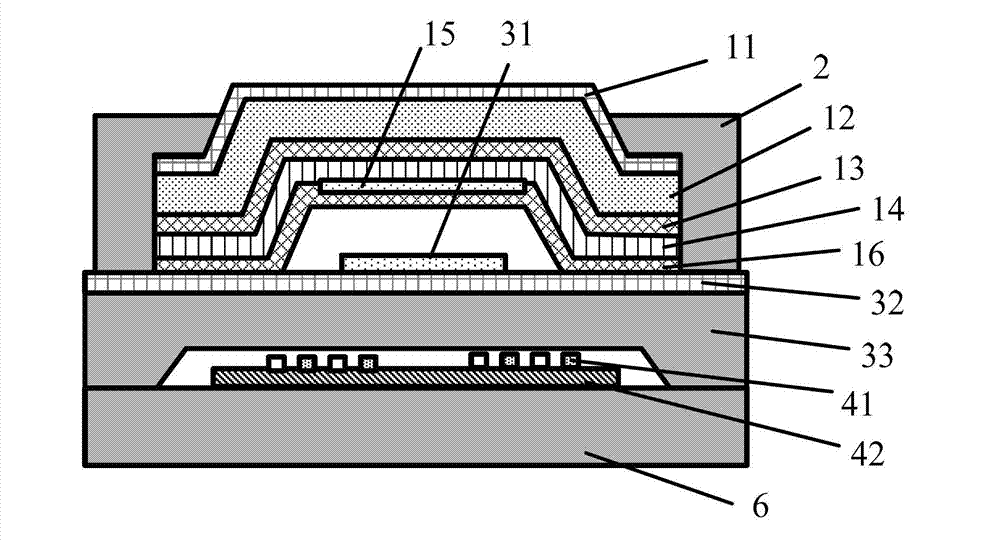

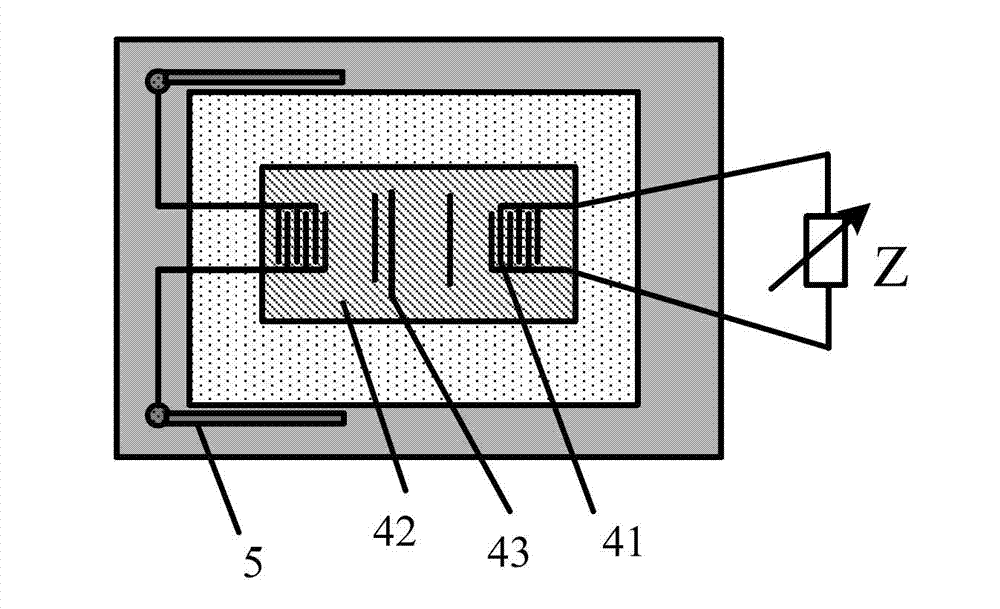

[0033] see Figure 1 to Figure 4, the present invention is a capacitive miniature tire pressure monitoring sensor, which can be implanted into the tire to work. The sensor has a three-layer plate structure, and the upper plate is made with an outwardly convex multi-layer composite elastic film, which is used to be sensitive to external pressure. Capacitive electrodes are fabricated on the multi-layer film and the support plate for pressure measurement. A wireless communication antenna and a surface acoustic wave device are integrated on the bottom floor, and the two together complete energy coupling and information transmission. After the external signal is coupled into the antenna, an oscillation effect is generated in the surface acoustic device to obtain the working energy required by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com