Patents

Literature

41 results about "Tetrafluorohydrazine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetrafluorohydrazine or dinitrogen tetrafluoride, N₂F₄, is a colourless, reactive inorganic gas. It is a fluorinated analog of hydrazine. It is a highly hazardous chemical that explodes in the presence of organic materials.

Catalyst for preparing 1,3,3,3-tetrafluorohydrazine propylene from 1,1,1,3,3-perfluoropropane

ActiveCN106902849AIncrease costLow costPreparation by hydrogen halide split-offPhysical/chemical process catalystsMole ratioTetrafluorohydrazine

The invention discloses a catalyst for preparing 1,3,3,3-tetrafluorohydrazine propylene from 1,1,1,3,3-perfluoropropane. The composition is MxOy / AlF3, wherein a carrier AlF3 is an active carrier which is of an alpha phase structure, has the specific surface area greater than 150 m<2>.g<-1> and has the aperture distribution concentrated at 15 to 40 nm; MxOy is one of MgO, Fe2O3, Co2O3 or CuO; the mole ratio of MxOy to AlF4 is 1: (5 to 50). A preparation method of the catalyst comprises the following steps: carrying soluble salt of any element of Mg, Fe, Co or Cu through active alpha-phase AlF3 which has a large specific surface area and a mesoporous structure and serves as the carrier via an equivalent immersion method, and preparing the catalyst through drying and high temperature roasting. The catalyst disclosed by the invention is excellent in performance; in a preparation process, no expensive noble metal compounds are needed, the cost is low, and the activity is high; during reaction at 280 DEG C, the conversion ratio of the 1,1,1,3,3-perfluoropropane is 70 percent or above, and the catalyst is long in service life and can stably work for 360 hours; meanwhile, no diluting gas is fed in the reaction process, and the catalyst has industrial application value.

Owner:XIAN MODERN CHEM RES INST

Polyimide material and preparation method thereof

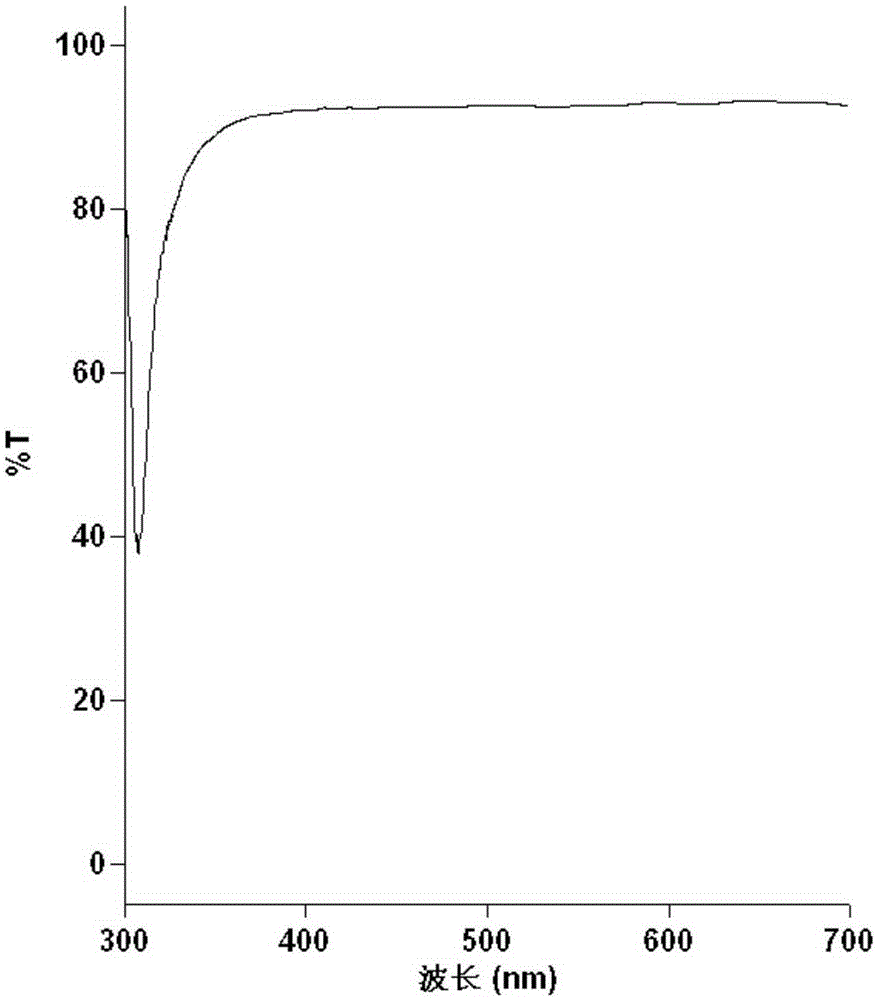

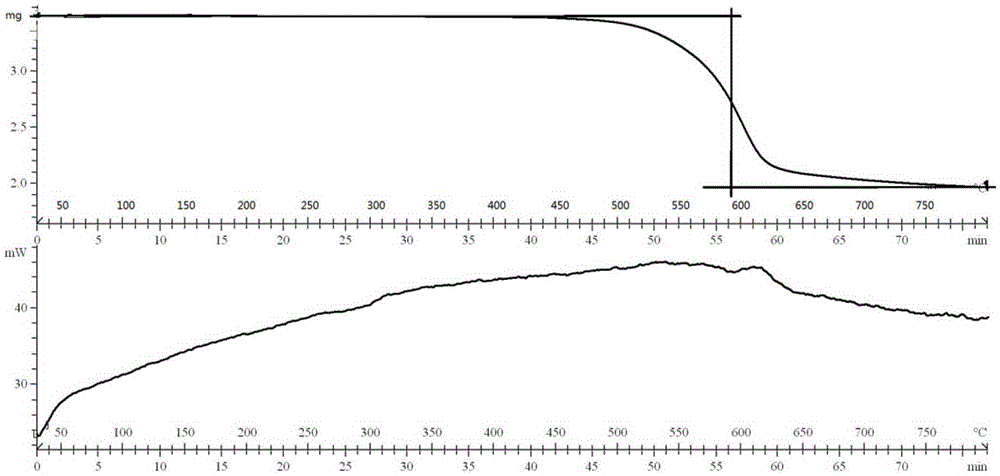

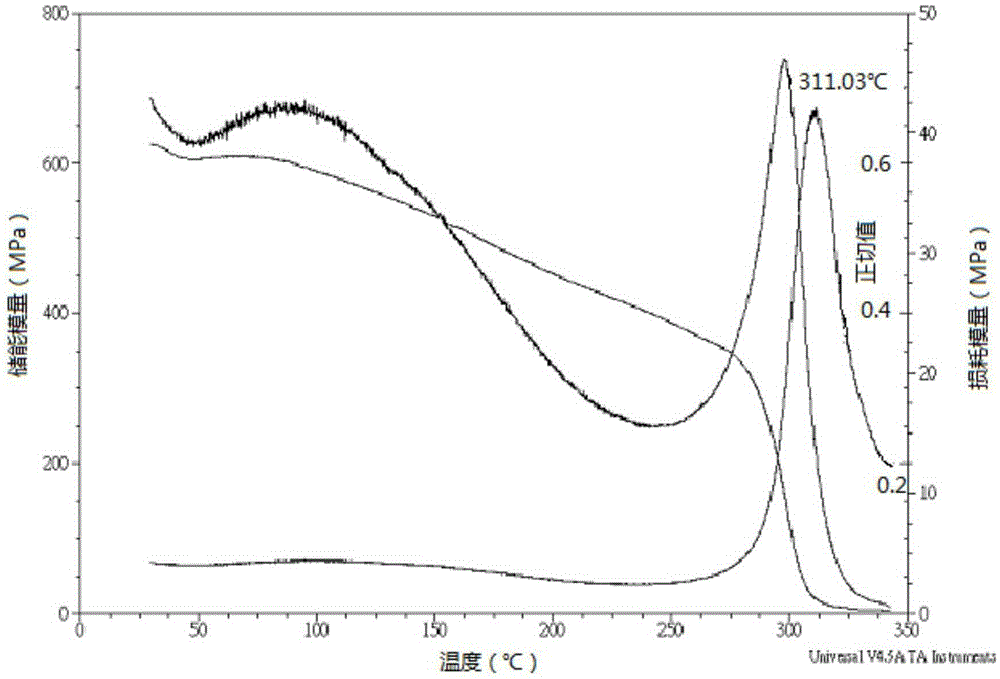

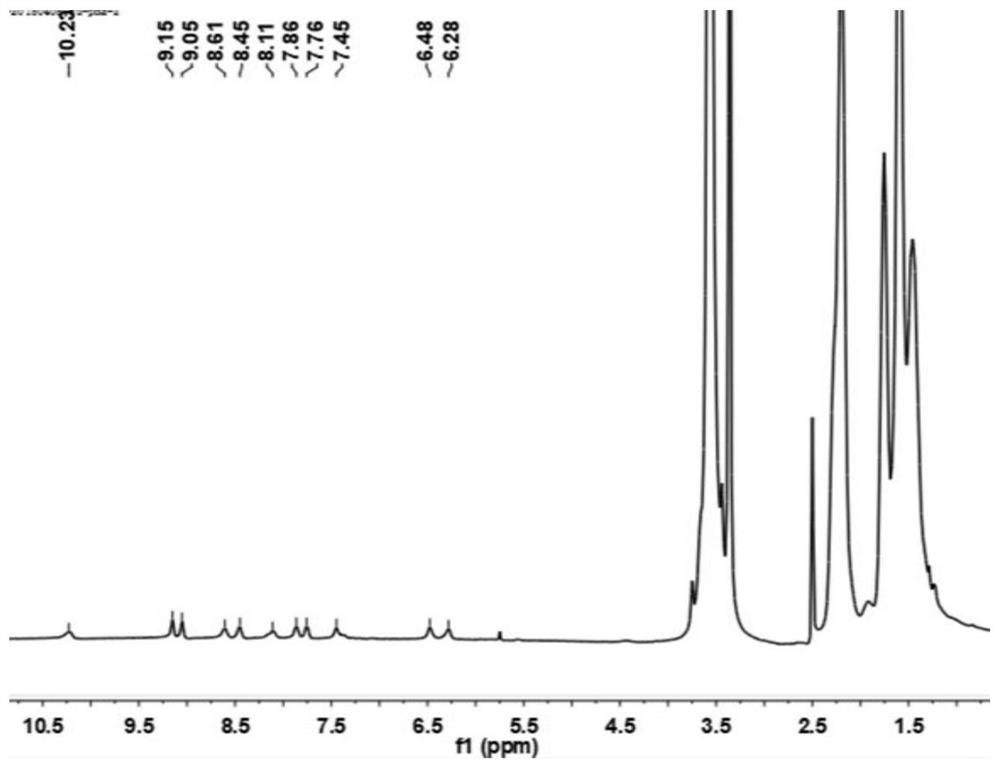

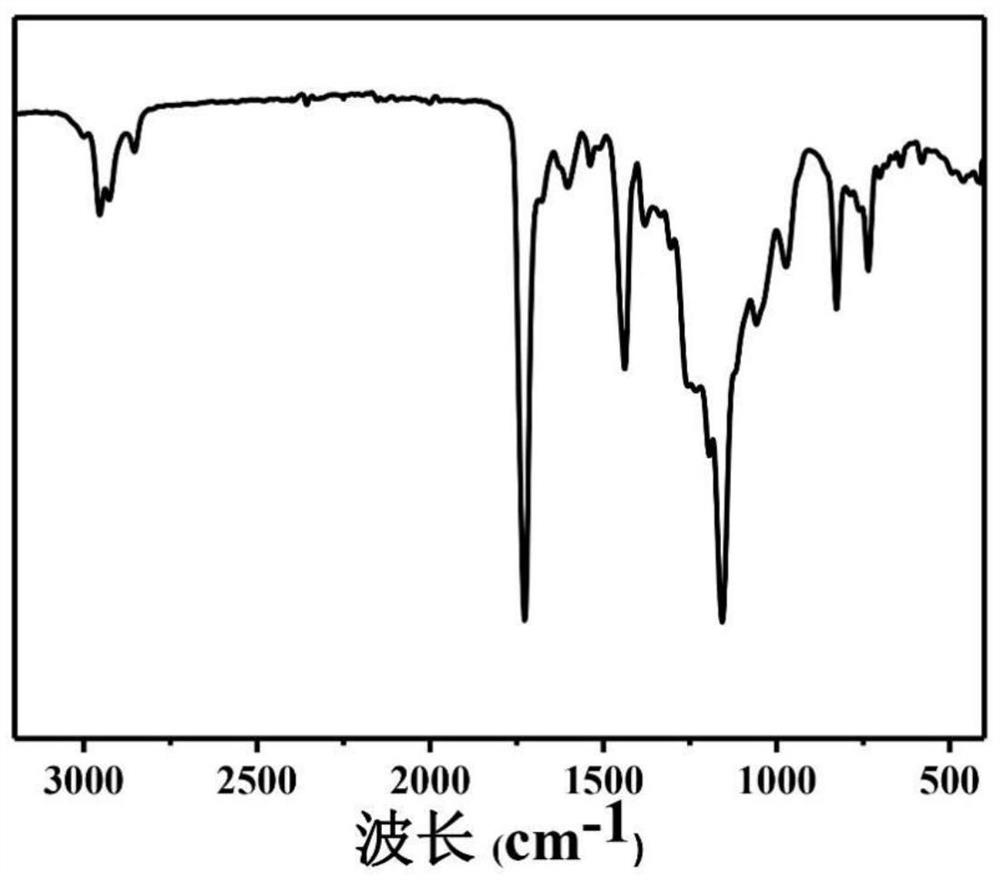

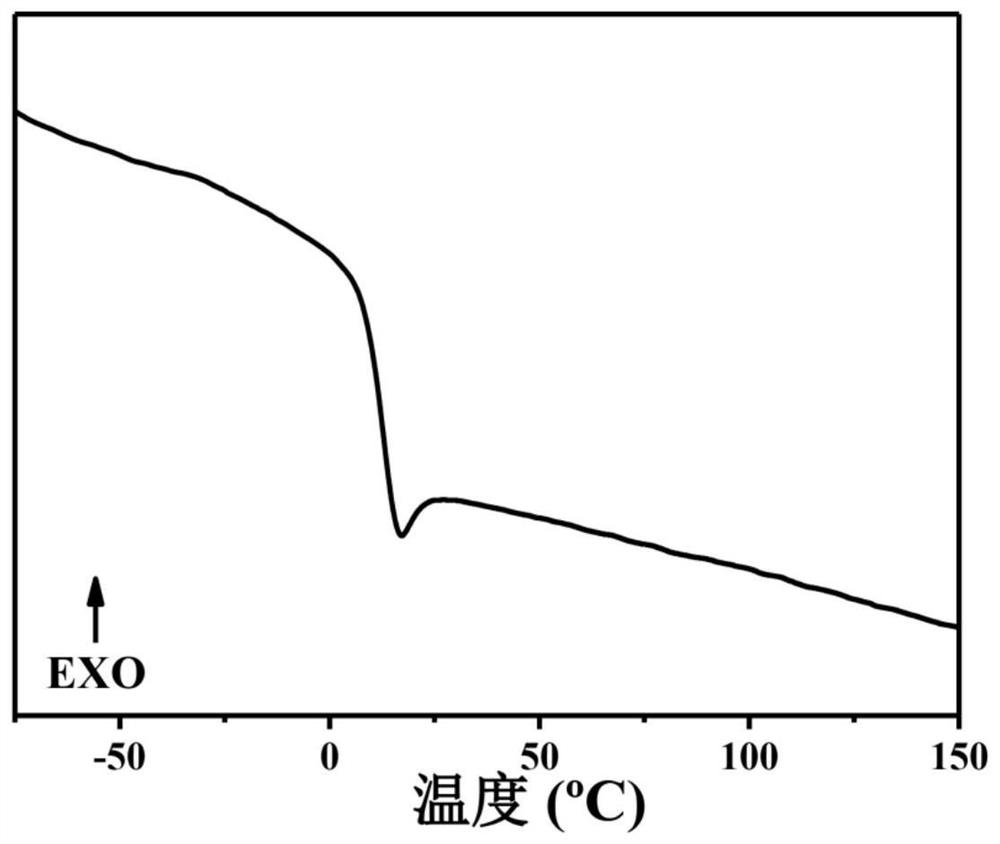

The invention relates to a polyimide material and a preparation method thereof. The polyimide material comprises diamine monomers, namely 2-(3,5-diaminophenyl)-4 and 5,6,7-(tetrafluorohydrazine isoindoline)-1,3-diketone. The preparation method comprises the steps of mixing the monomers and other aromatic diamines containing strong electron withdrawing groups, and then, reacting the mixture and fatty acid dianhydride to obtain polyimide. Fluorine atoms and the strong electron withdrawing groups are introduced to the structures of the diamine monomers, and meanwhile the diamines containing the strong electron withdrawing groups and the fatty acid dianhydride are used as polymerization monomers, so that the formation of intramolecular / intermolecular charge transfer complexes (CTC) is further inhibited, and the transparency of the polyimide is remarkably improved. The polyimide material prepared by using the preparation method has the advantages of high transparency, high glass transition temperature and favorable solubility and heat resistance and the like and has a wide application prospect in the relevant fields of flexible transparent substrates, flat panel displays and the like.

Owner:VALIANT CO LTD

System and method for producing refined sulfuric acid through pyrite acid manufacturing system

The invention discloses a system and method for producing refined sulfuric acid through a pyrite acid manufacturing system, and relates to the technical field of chemical engineering. The system for producing the refined sulfuric acid comprises a refined acid tower; a first smoke discharging port is connected to the upper end of the refined acid tower in a penetrating mode; a smoke feeding port isinstalled in one side of the lower end of the refined acid tower; a smoke feeding pipe is connected to one end of the smoke feeding port in a penetrating mode; and a gas valve A for controlling the feeding quantity of sulfur trioxide smoke is installed between the smoke feeding port and the smoke feeding pipe. According to the design, refined acid overflowing parts are lined with tetrafluorohydrazine, so that iron dissolved in acid is reduced; deionized water is adopted to adjust the concentration of the refined acid; dried air is utilized for air stripping of dissociative sulfur dioxide dissolved in the refined acid; the concentration of the dissociative sulfur dioxide in the acid is lowered; and the problem that in traditional pyrite acid manufacturing production, the content of industrial sulfuric acid impurities is relatively high, and particularly iron ions and the dissociative dioxide exceed a standard, so that the refined acid quality requirements cannot be achieved, and the economic value is reduced is solved.

Owner:ZHAOYUAN ZHAOJIN JINHE TECH

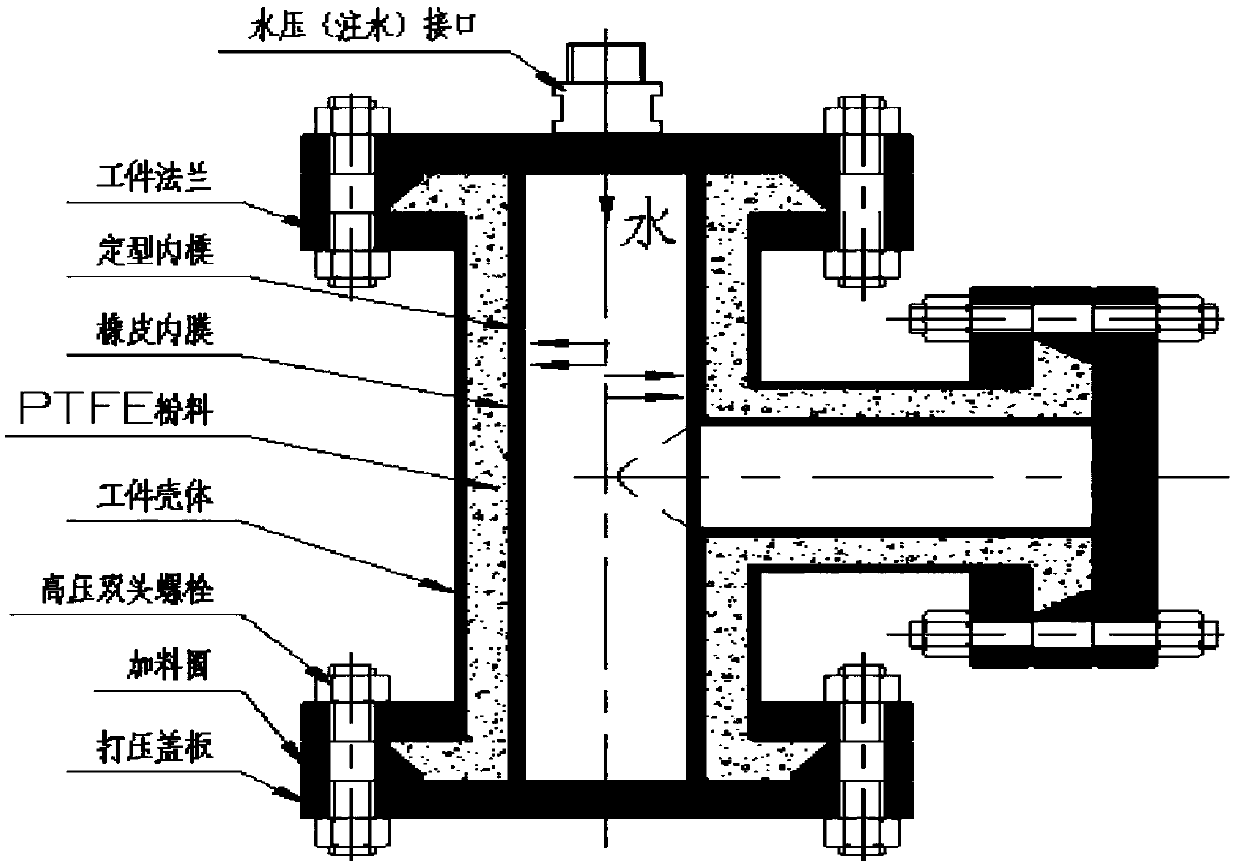

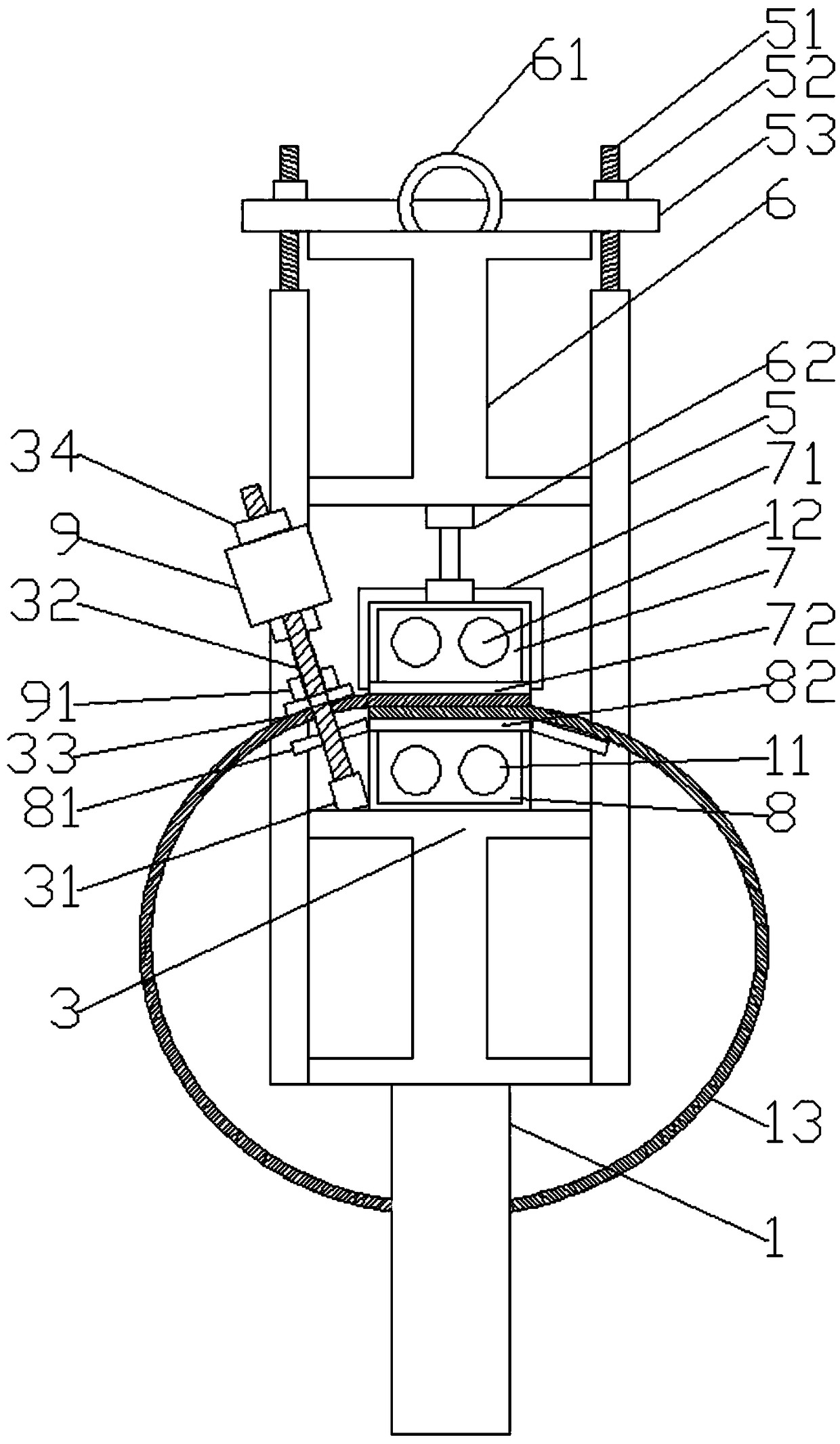

Steel lining tetrafluorohydrazine cage hoop equal steel compound technology

PendingCN109648768ASolve sheddingSolve the problem of bulging and suckingCorrosion preventionPipe protection against corrosion/incrustationCorrosion resistantMetal

The invention belongs to technical field of steel lining tetrafluorohydrazine cage hoop equal steel compound technologies, and particularly discloses a steel lining tetrafluorohydrazine cage hoop equal steel compound technology. For solving the problems of PTFE lining layer falling, bulking and dented suction and expansion deformation in the prior art, the technology comprises the following technological steps that die pressing is carried out, a workpiece shell is pressurized and filled with water through a water pressure connector, and the pressure is made to reach a set highest value and kept for 3-4h; filler is expanded, and tetrafluorohydrazine powder is injected into a gap in S6; sintering is carried out, and furnace charging and sintering are carried out; preheating is carried out for 6h in a furnace; a tetrafluorohydrazine layer and a metal part reach the synchronous thermal change coefficient, the temperature is gradually increased, the temperature increasing process is slowlycarried out in order, finally, the temperature reaches 385 DEG C, heat preservation is carried out for 6h, then, the temperature is slowly decreased in a grading mode, and the whole sintering processspends 36h. Steel lining tetrafluorohydrazine cage hoop pipeline equipment manufactured through the equal steel compound technology is good in corrosion resistance effect, good in compound effect, free of automatic falling, and free of bulking and dented suction and expansion deformation

Owner:江苏宣臻防腐工程有限公司

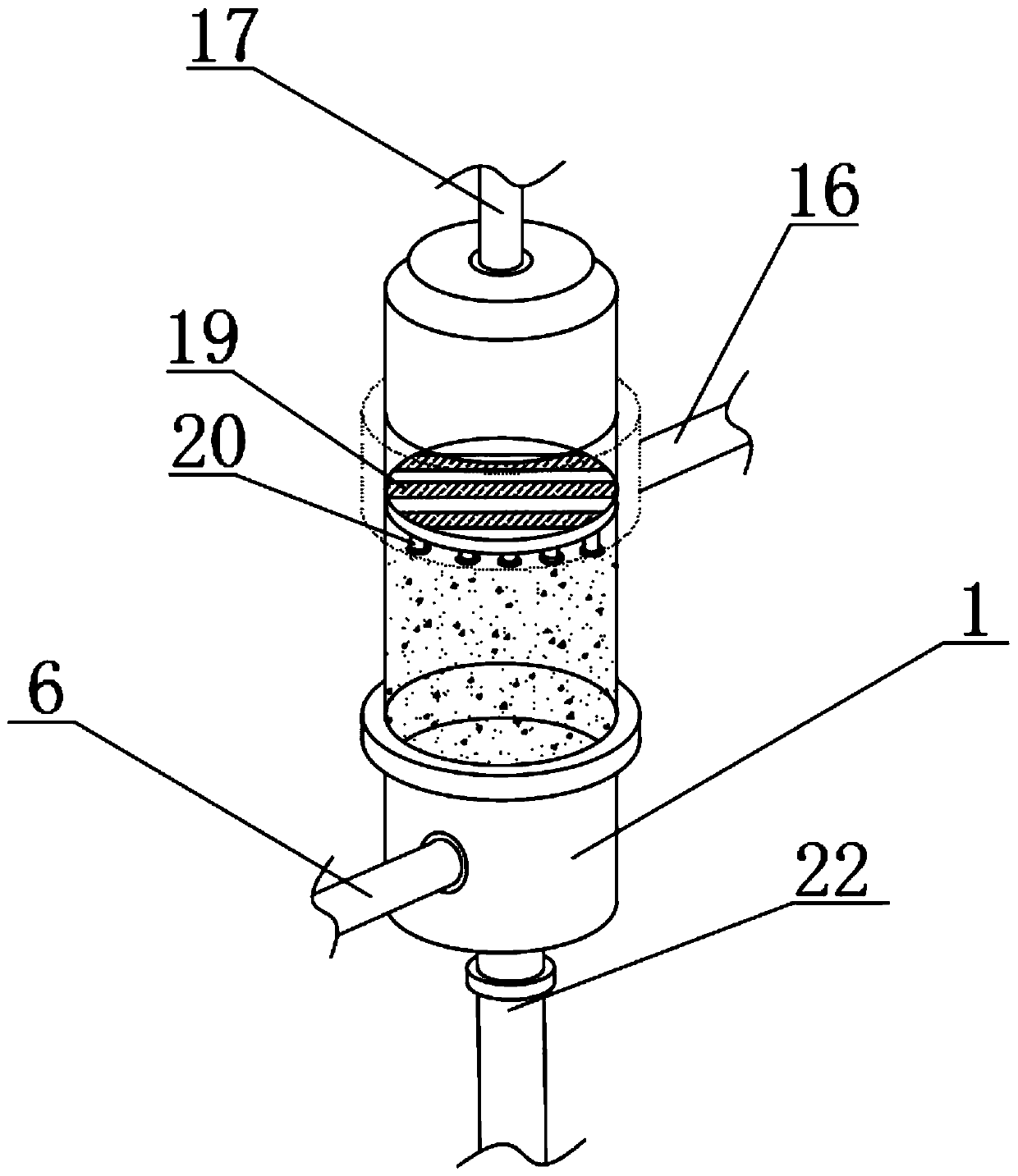

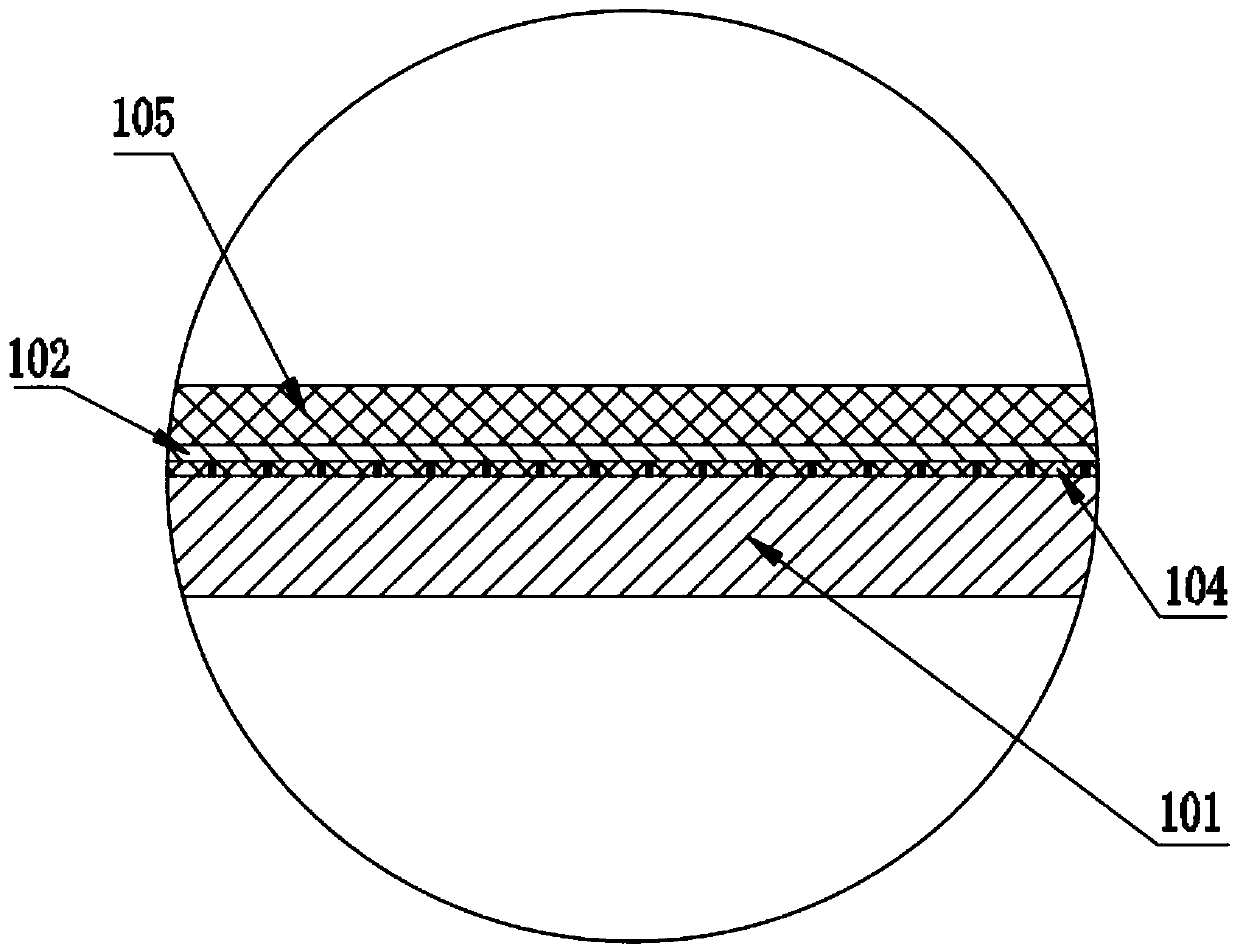

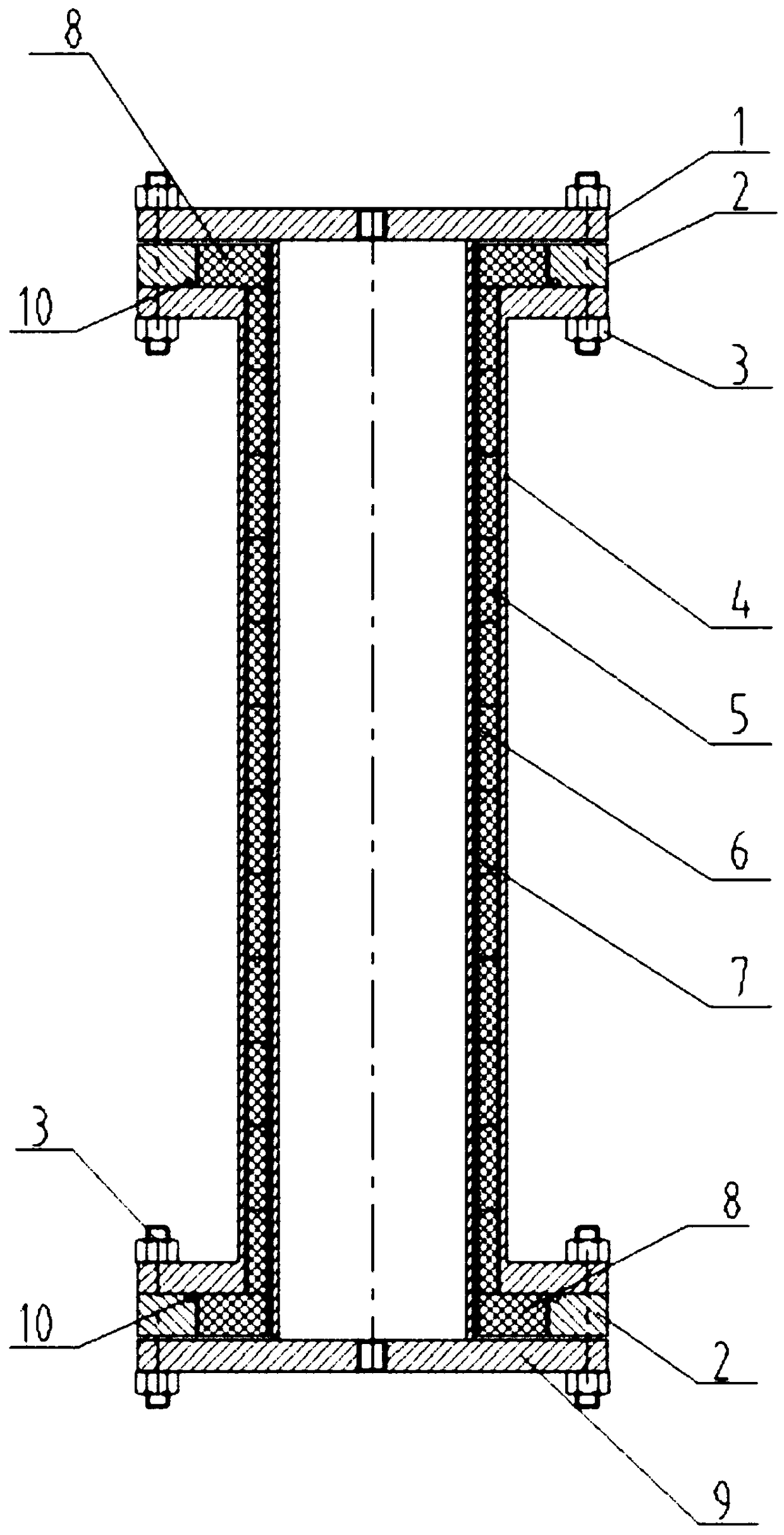

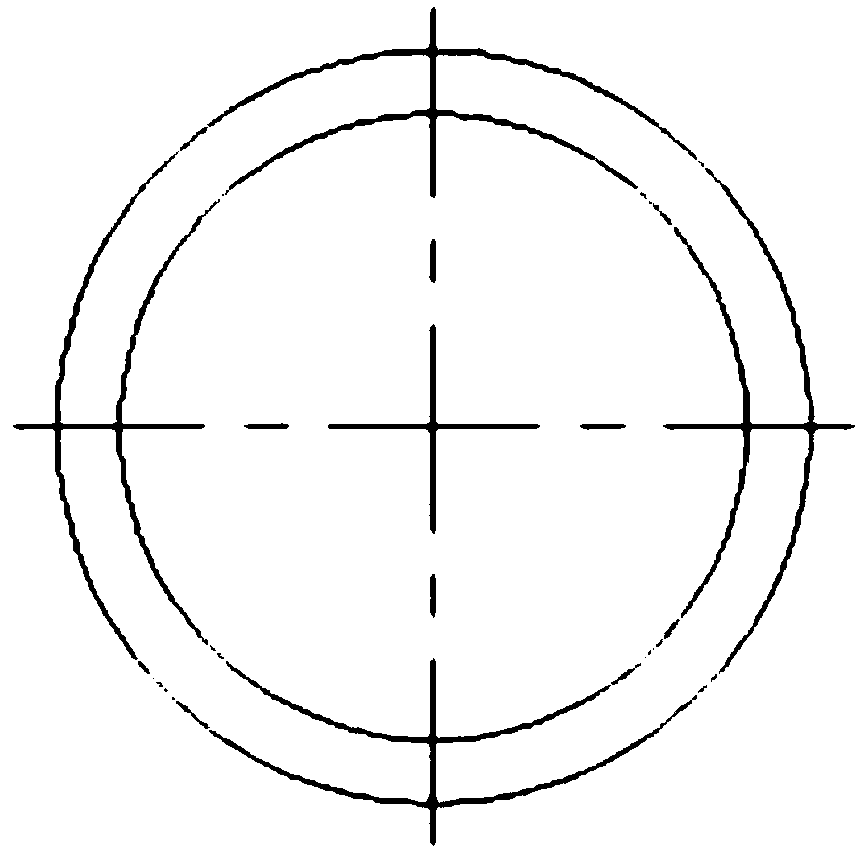

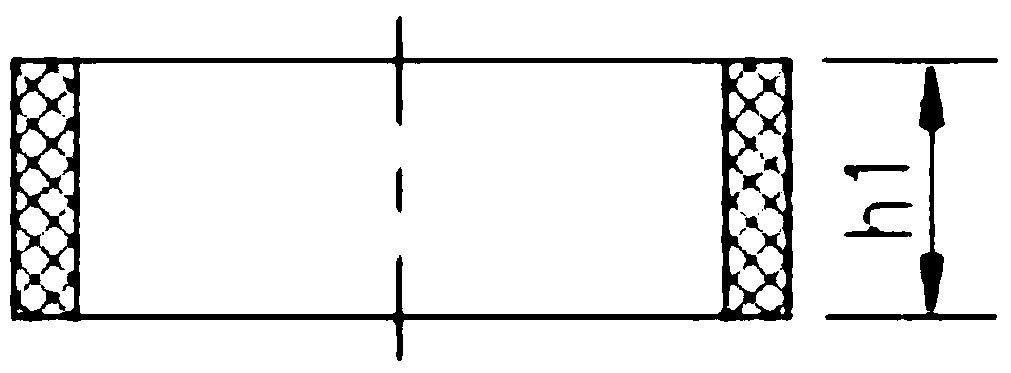

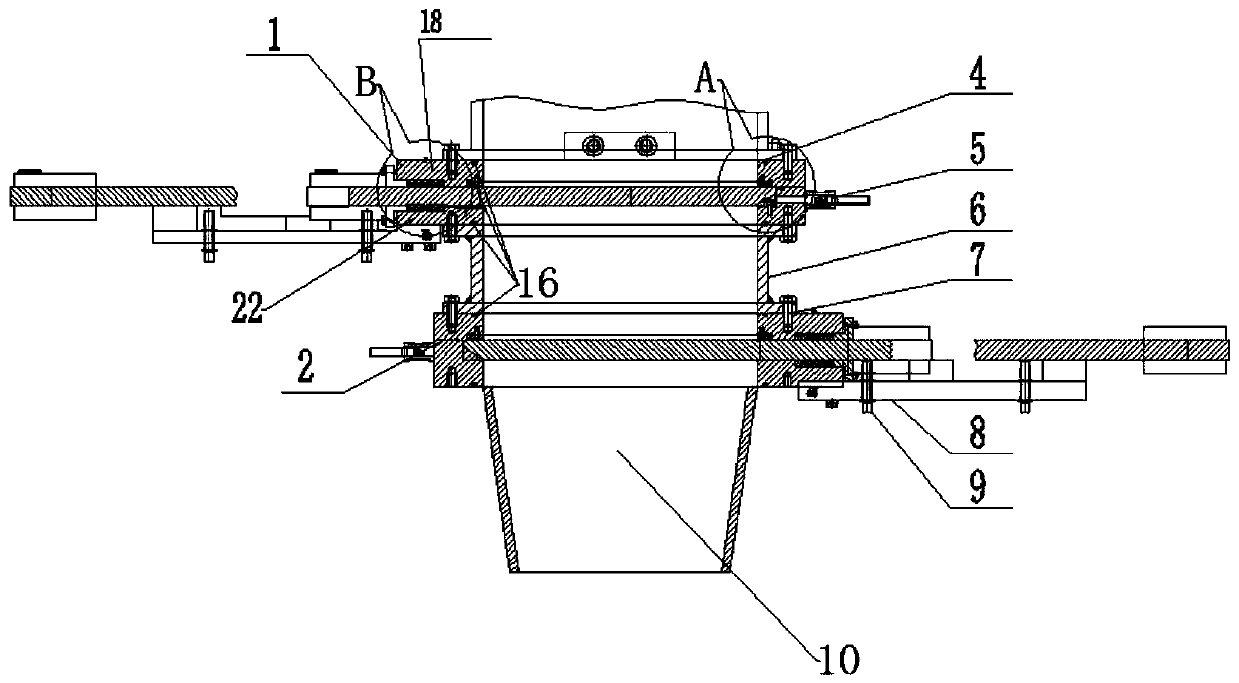

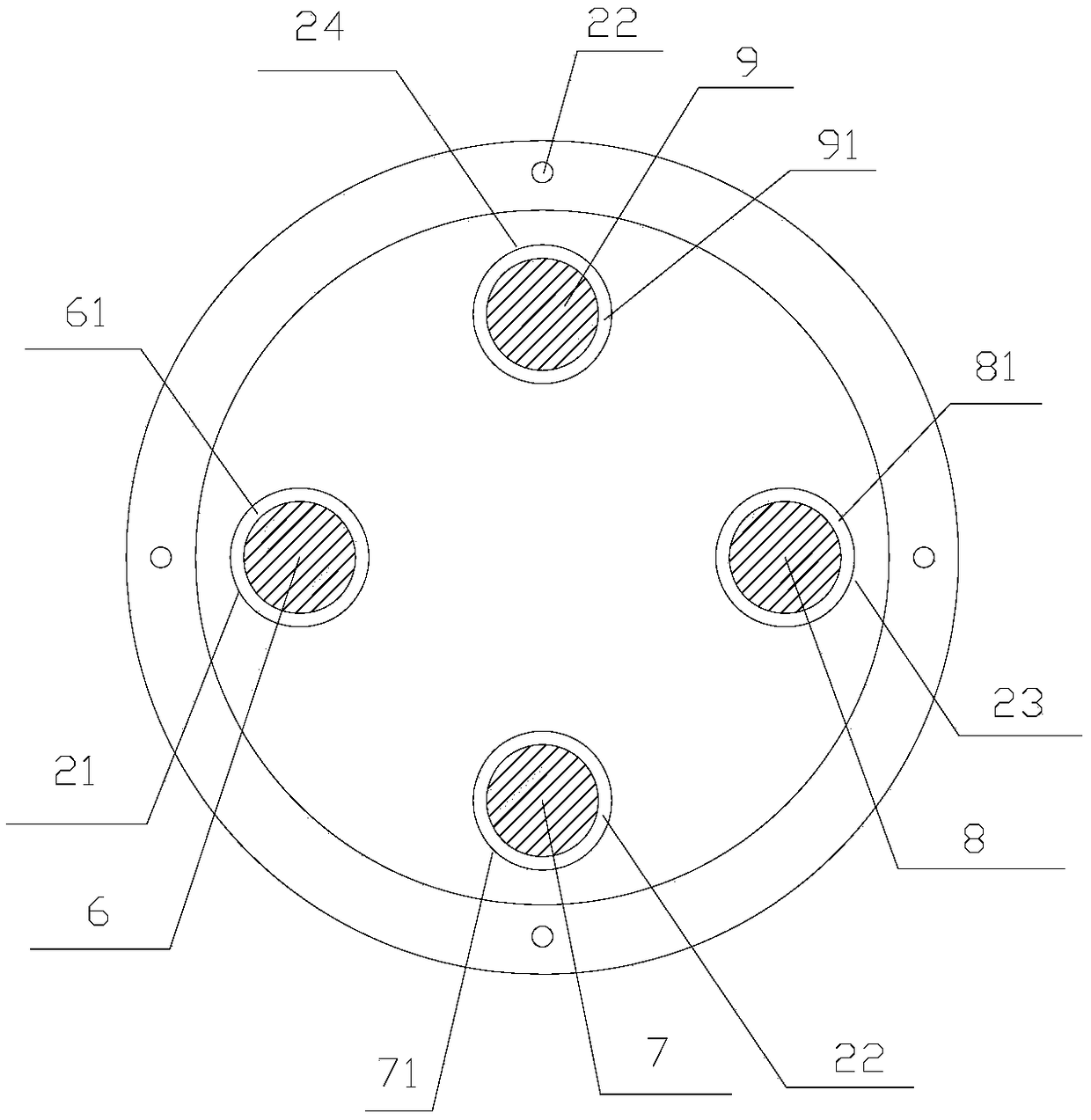

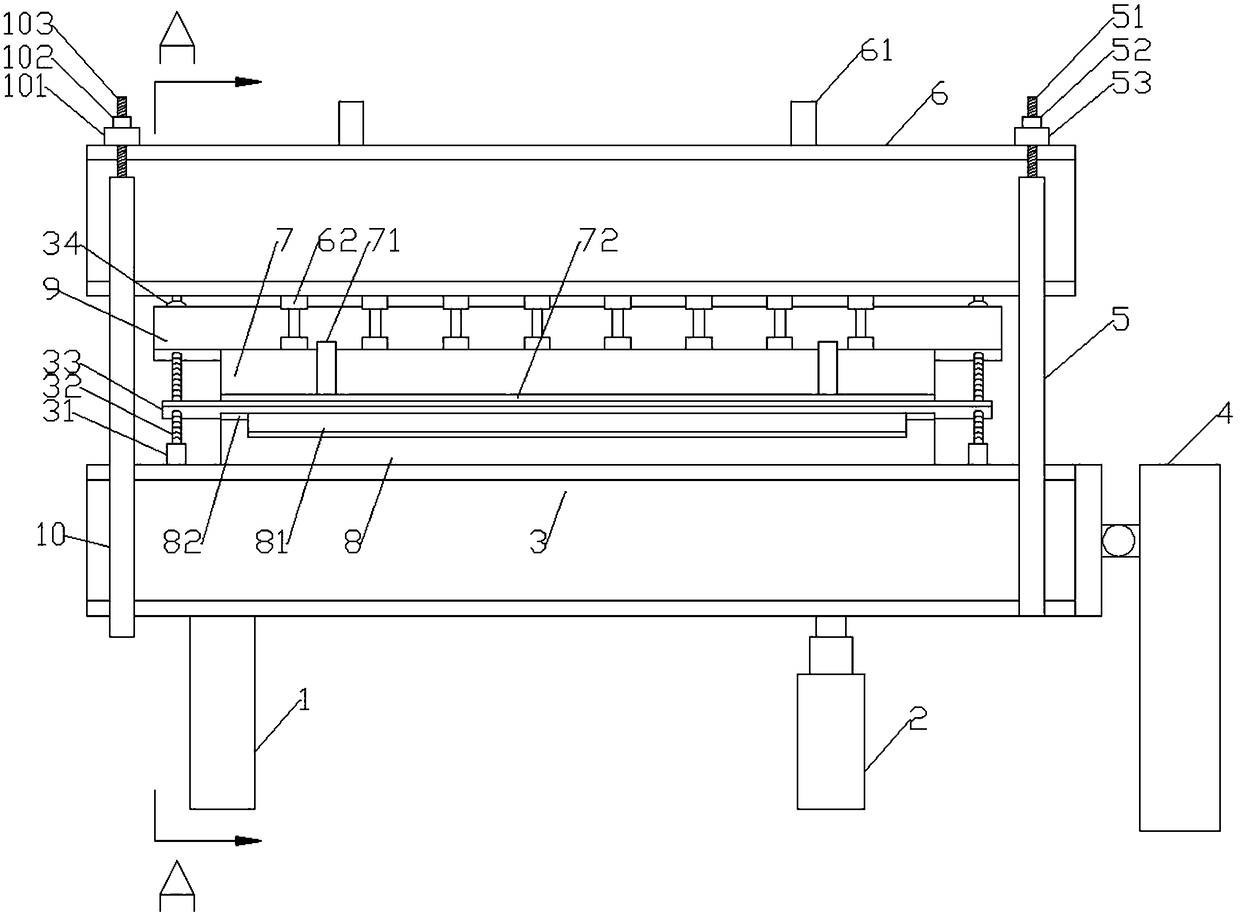

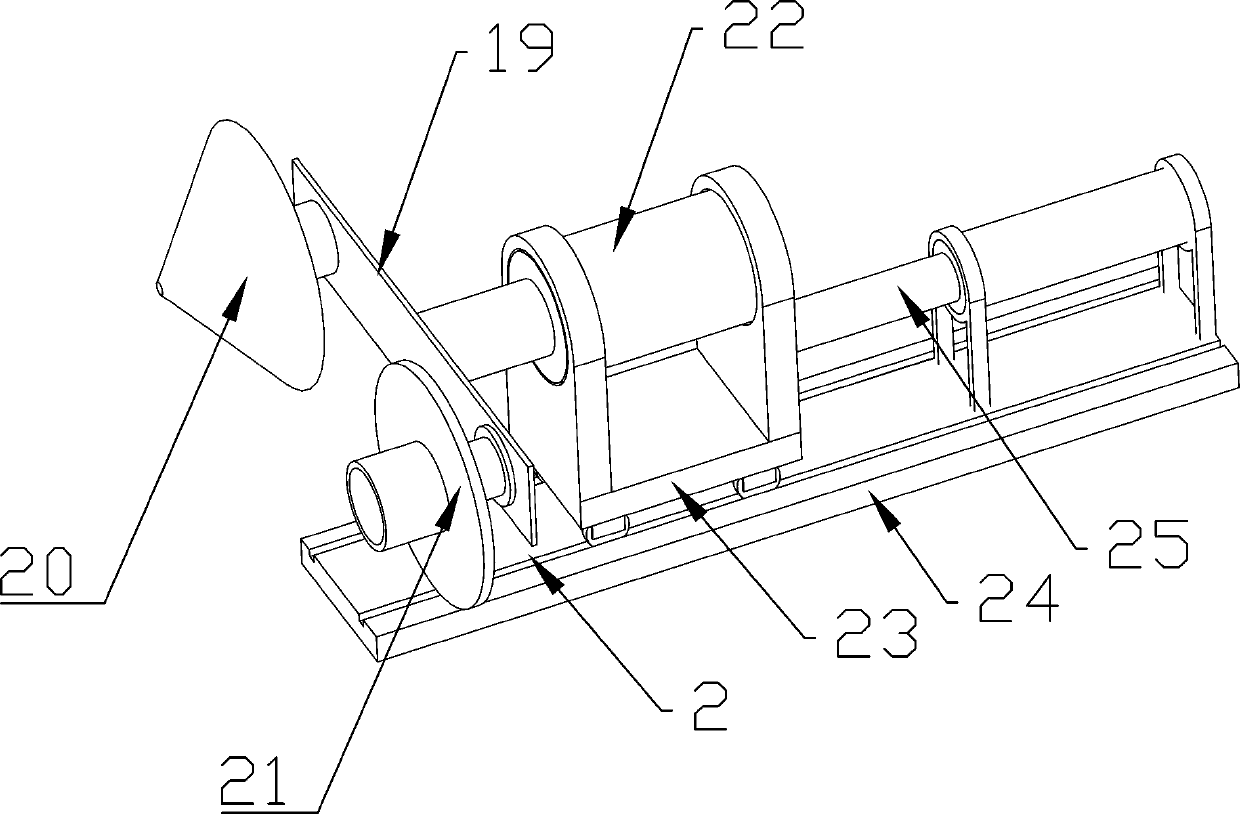

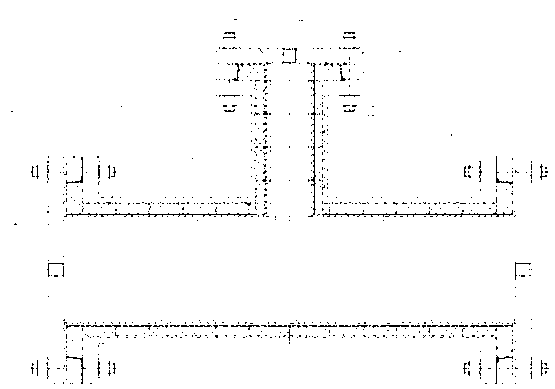

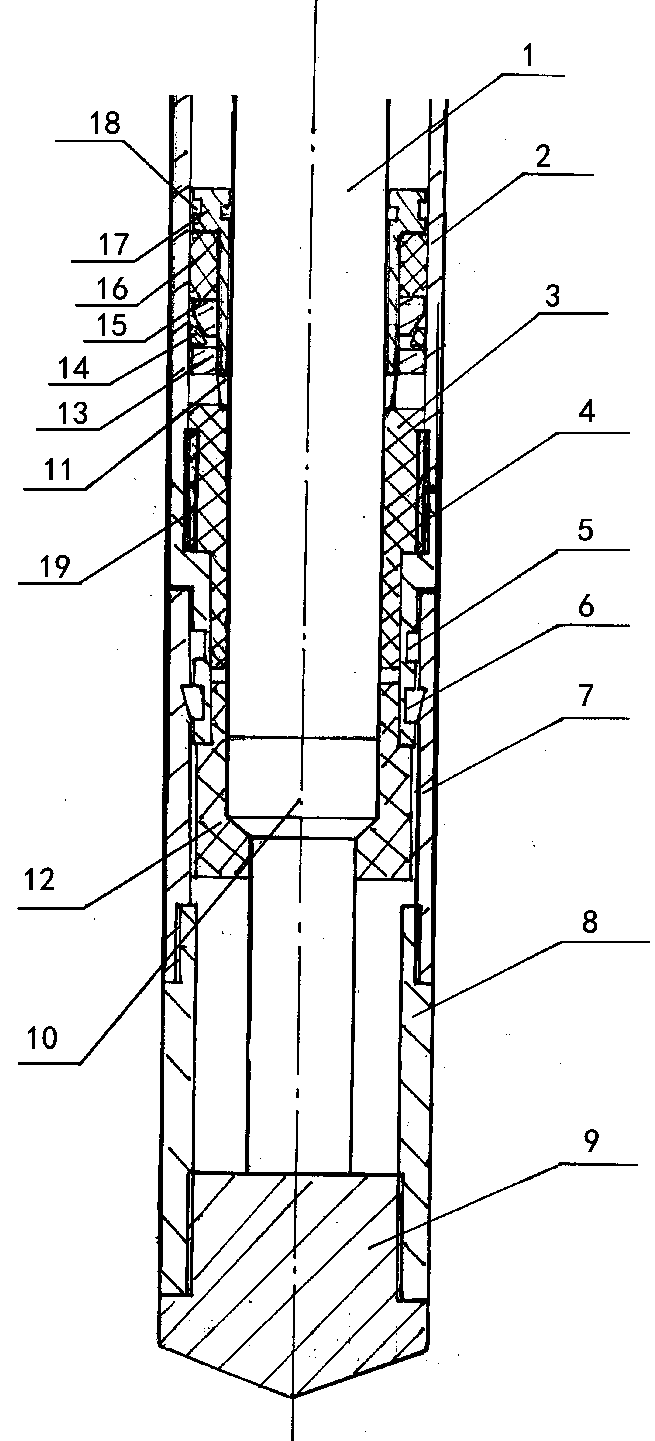

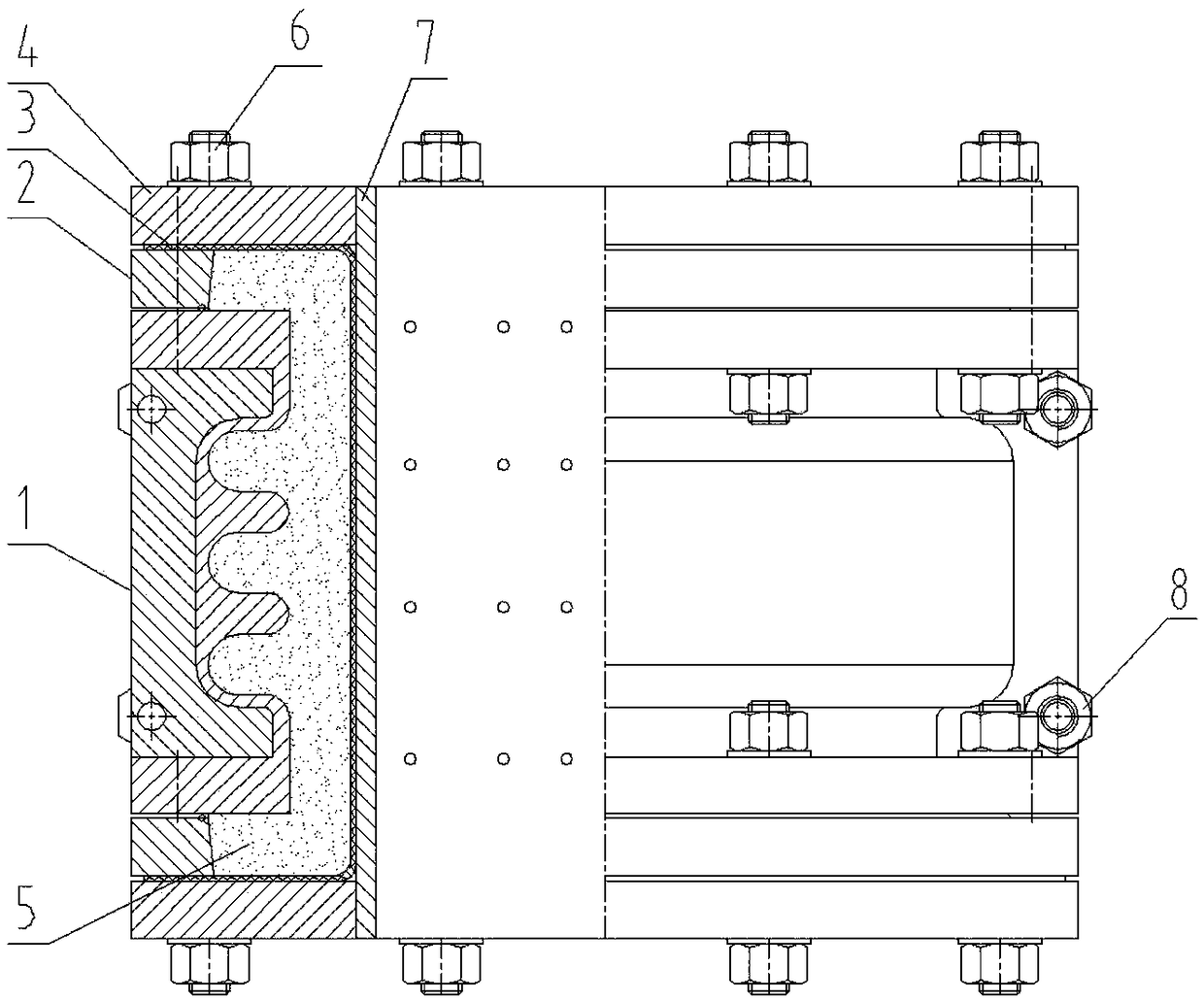

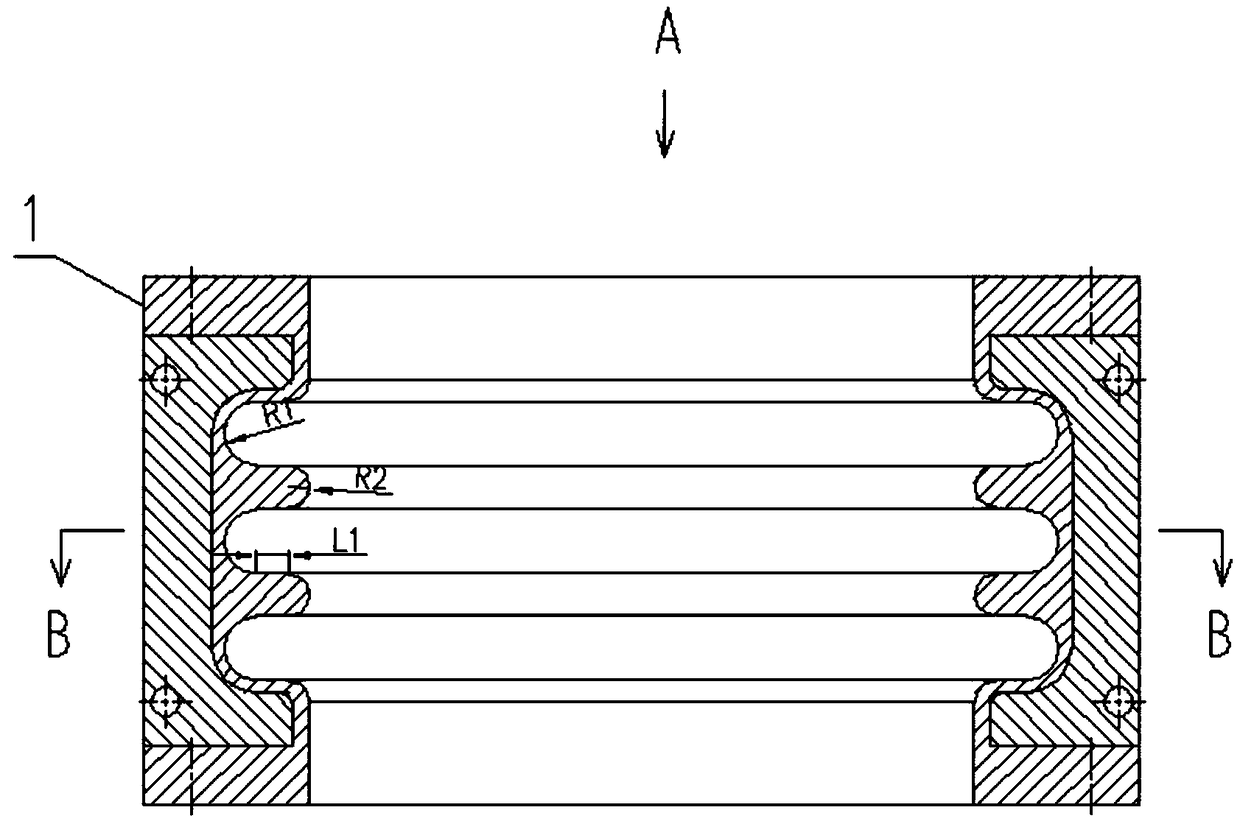

Polytetrafluoroethylene steel-liner straight pipe and die pressing technology thereof

ActiveCN108644490AFully automatedRealize semi-automationGeneral water supply conservationRigid pipesCost ControlsEngineering

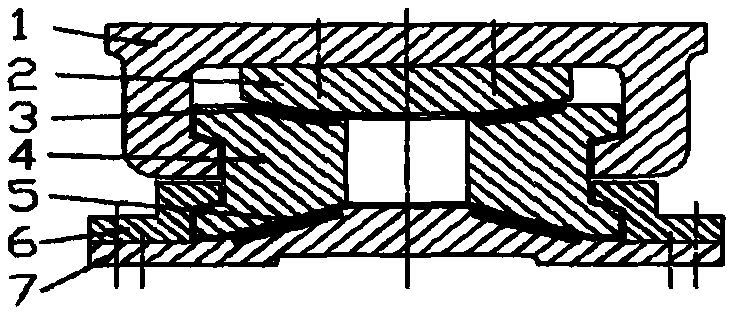

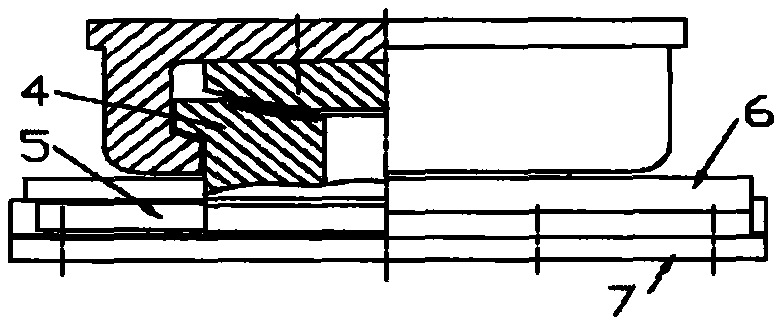

The invention discloses a polytetrafluoroethylene steel-liner straight pipe and a die pressing technology thereof, and belongs to the technical field of steel-liner straight pipes. The polytetrafluoroethylene steel-liner straight pipe comprises an upper cover plate, a lower cover plate, and a hollow circular tube shaped mandrel which is arranged between the upper cover plate and the lower cover plate, wherein the outer side of the mandrel is sleeved with a rubber sleeve, and short tetrafluorohydrazine pipes sleeve the outer side of the rubber sleeve; the outer sides of the tetrafluorohydrazineshort pipes are sleeved with die-pressing straight pipes; the tetrafluorohydrazine short pipes are provided with tetrafluorohydrazine rings between the upper cover plate and the lower cover plate; the die-pressing straight pipes are provided with sealing surface dies between the upper cover plate and the lower cover plate; and the sealing surface dies are correspondingly connected to the upper cover plate and the lower cover plate through fasteners. According to the polytetrafluoroethylene steel-liner straight pipe, automatization or semi-automatization is achieved, so that the working efficiency is greatly improved; the cost control is easily refined; the problems of agglomerating, bridging and hollowing can be avoided; the workload of fine processing is decreased; the powder loss is greatly decreased; the rubber sleeve is prevented from breaking; and the product forming rate is increased.

Owner:NANJING FUYUAN CHEM PIPELINE EQUIP

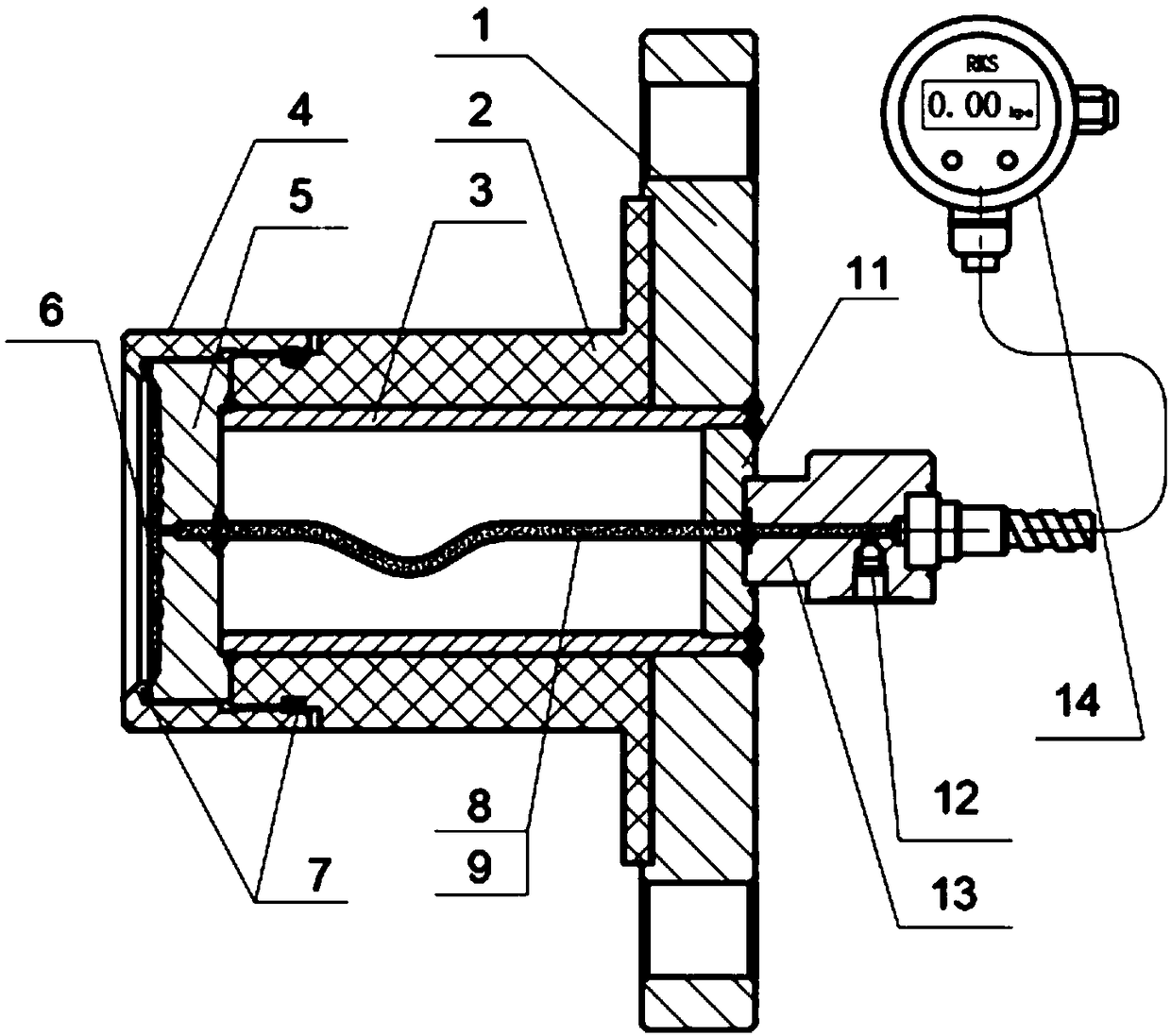

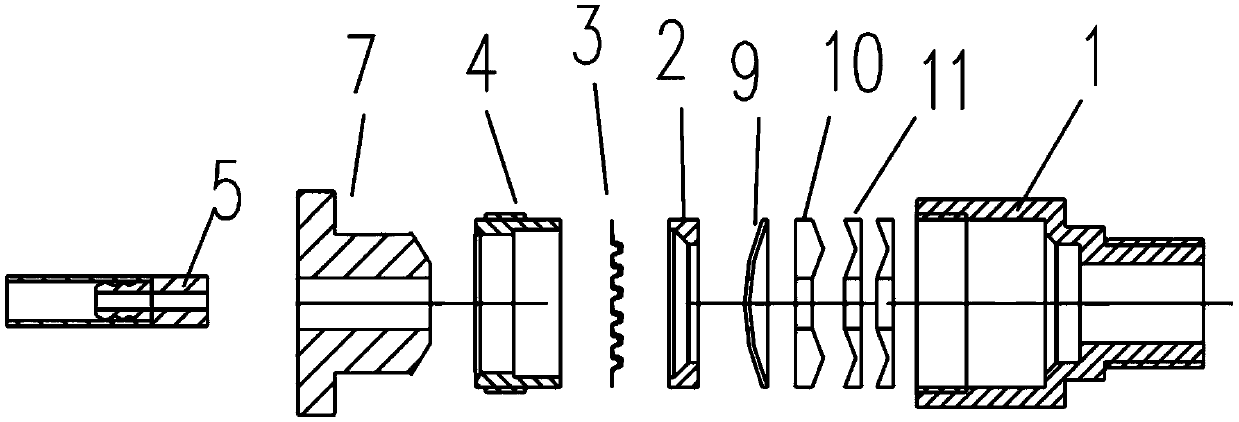

Remote transmission module and remote transmission pressure transmitter having same

PendingCN108760137ARealize pressure measurementSafe and stable jobFluid pressure measurement using elastically-deformable gaugesMarine engineeringTantalum

The present invention provides a remote transmission module used for a remote transmission pressure transmitter. The remote transmission module comprises a remote transmission part and a tantalum mebrane (6), a tetrafluorohydrazine sleeve (2) and a tetrafluorohydrazine cover (4) coating the outer surface of the remote transmission part, and a fluororubber seal ring configured to seal the tantalummebrane (6), the tetrafluorohydrazine sleeve (2) and the tetrafluorohydrazine cover (4). The present invention further provides a remote transmission pressure transmitter having the remote transmission module. Compared to an original a remote transmission pressure transmitter made of tantalum materials. The remote transmission pressure transmitter reduces the production and usage cost and ensure the long-term, stable and safe work of an instrument.

Owner:浙江洛丁森智能科技有限公司

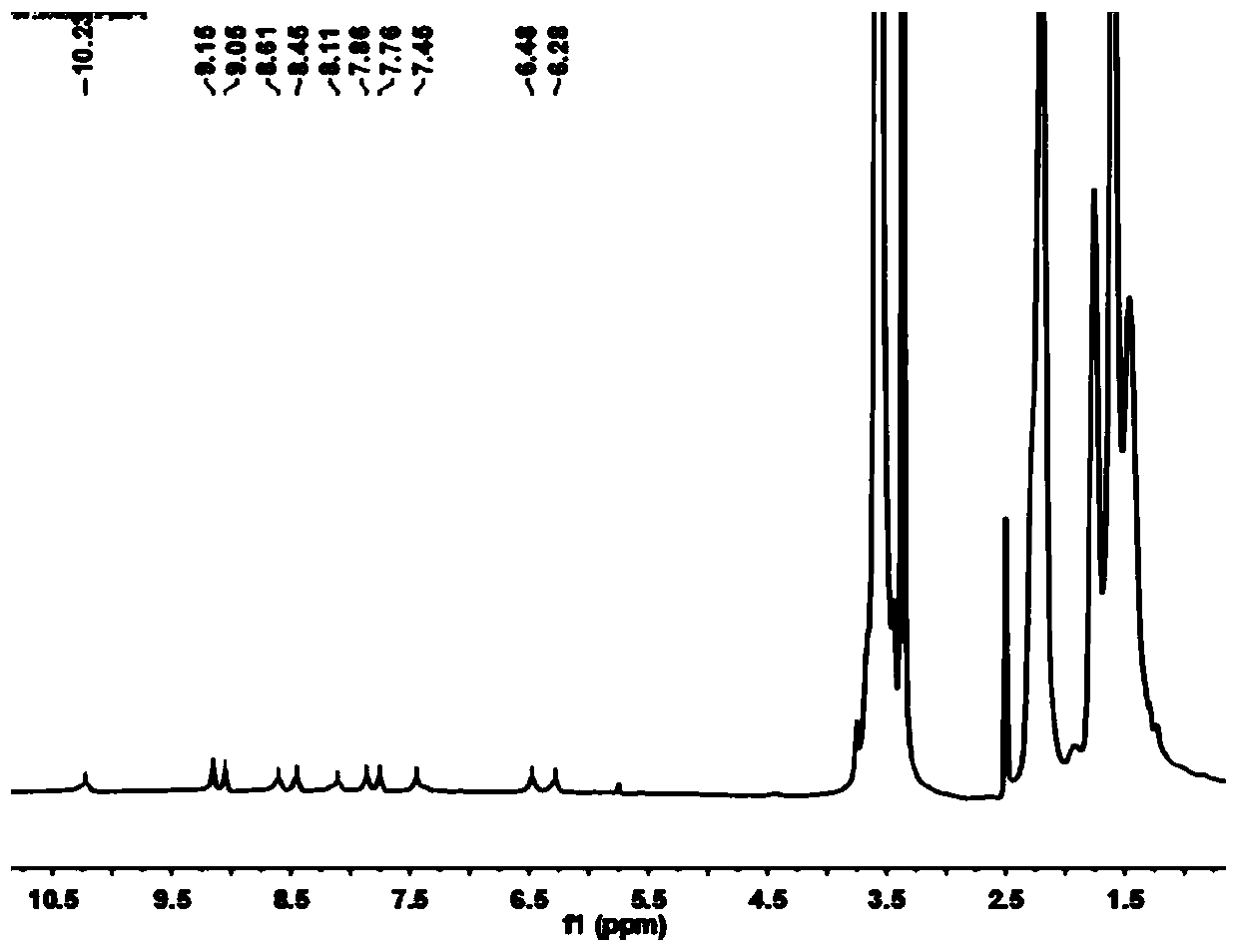

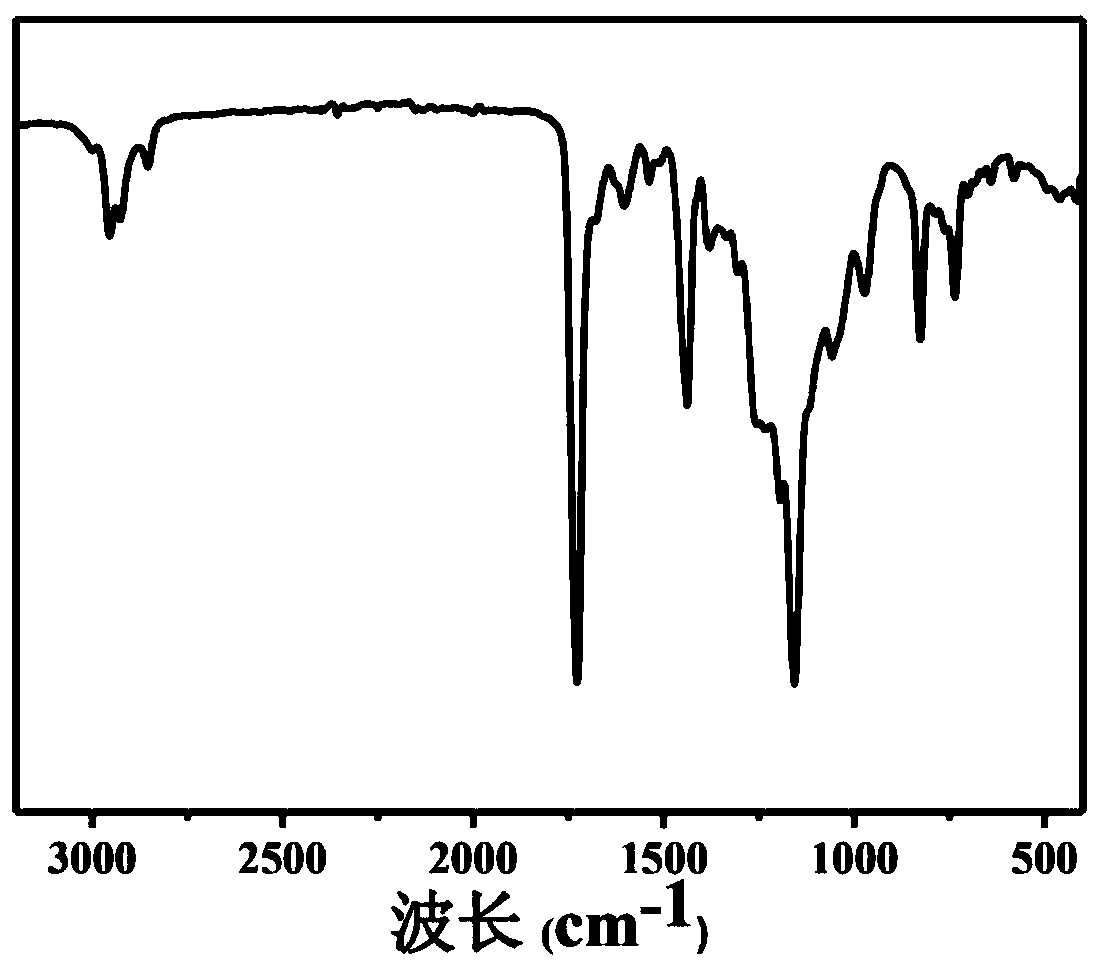

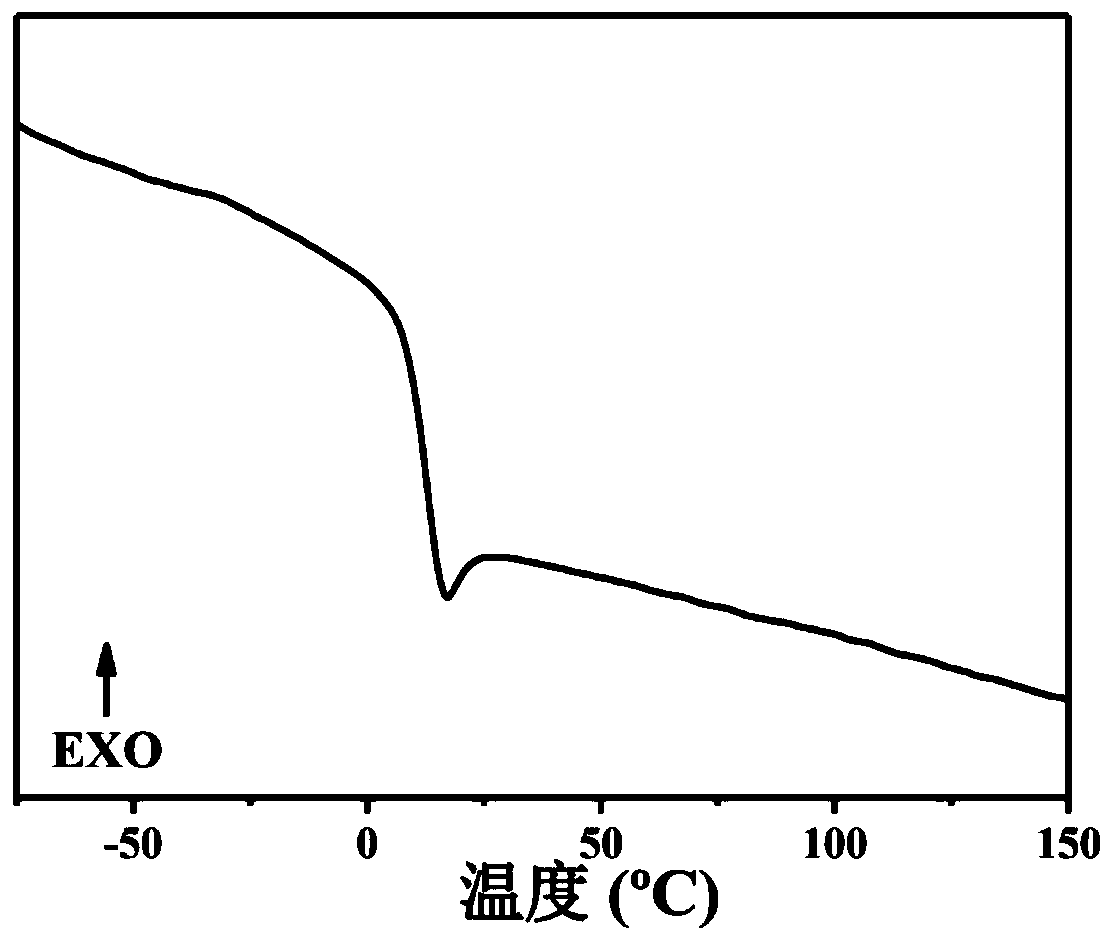

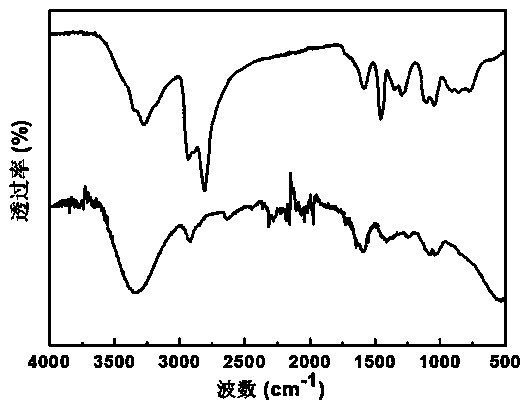

Mechanical force induced europium coordinated red light polymer film and preparation method thereof

ActiveCN109897140AHigh luminous intensityIncreased sensitivityLuminescent compositionsPolymer scienceArgon atmosphere

The invention discloses a mechanical force induced europium coordinated red light polymer film and a preparation method thereof. The preparation method comprises following steps: (1) dissolving a europium coordination compound, methyl acrylate, and azodiisobutyronitrile into N,N-dimethyl formamide, heating and stirring N,N-dimethyl formamide in an argon atmosphere, pouring N,N-dimethyl formamide into methanol to carry out precipitation to obtain methyl polyacrylate containing a linear europium coordination compound; and (2) dissolving methyl polyacrylate containing a linear europium coordination compound, methyl acrylate, diadamantane substituted 1,2-dioxocyclobutane, and azodiisobutyronitrile into tetrahydrofuran, evenly mixing, pouring the mixture into a tetrafluorohydrazine die, carrying out reactions in an argon atmosphere to obtain a polymer film, and drying to obtain the mechanical force induced europium coordinated red light polymer film. The polymer film has a crosslinking structure, the europium coordination compound is used as an energy transfer acceptor; the light emitting strength is effectively increased during the polymer film breaking process, the light emitting color is changed; as the acceptor content is increased, the light emitting strength is increased; and thus the sensitivity for flaw detection of polymer materials is improved.

Owner:TIANJIN UNIV

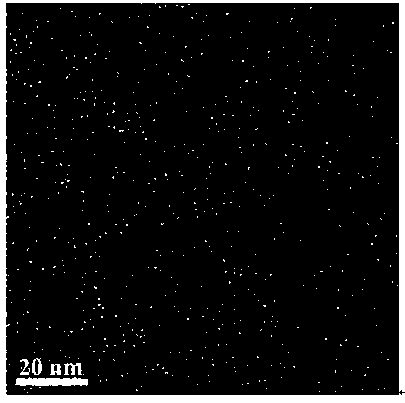

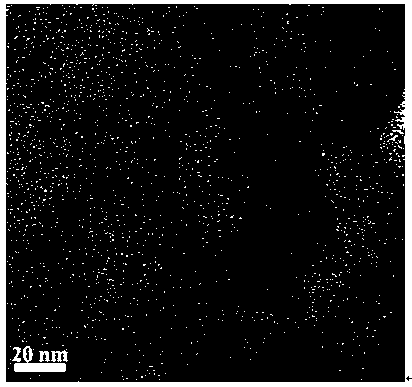

Method for detecting cancer marker by using manganese dioxide modified upconversion nanometer material

ActiveCN110082332AGood biocompatibilityLow toxicityPreparing sample for investigationFluorescence/phosphorescenceSynthesis methodsUpconversion nanoparticle

The invention discloses a method for detecting alkaline phosphatase by using manganese dioxide modified upconversion nanoparticles. An upconversion nanoparticle size of ytterbium and thulium-doped tetrafluorohydrazine sodium yttrium (NaYF4: Yb, Tm) is about 2nm and an emission spectrum is 471nm. A synthetic method of the upconversion nanoparticles of the ytterbium and thulium-doped tetrafluorohydrazine sodium yttrium (NaYF4: Yb, Tm) and the upconversion nanoparticles of manganese dioxide modification is simple. Operation for detecting the alkaline phosphatase is simple, an expensive apparatusis not needed and the operation is fast and is sensitive. During biological sample detection, an interference of autofluorescence can be avoided and toxicity is small. A linear range of the alkaline phosphatase is 0.1 U / L-100 U / L, and a detection limit is 0.41 U / L. The method has an excellent application prospect in actual biological sample analysis detection and bio-imaging.

Owner:TIANJIN NORMAL UNIVERSITY

Novel explosion-proof oxygen supercharger

InactiveCN109026603AReduce the high temperature environmentPrevent leakagePositive displacement pump componentsPositive-displacement liquid enginesExhaust valveInlet valve

The invention relates to a novel explosion-proof oxygen supercharger. According to the technical scheme, the novel explosion-proof oxygen supercharger comprises an air chamber, an exhaust connecting pipe, an air inlet connecting pipe, an air cylinder, a transition air cylinder, a partition layer, a crankshaft connecting rod, a piston head, a crankshaft box, a base, a shaft seal, a crankshaft, a linkage rod, an oil injection hole, an exhaust valve and an air inlet valve. The top and the bottom of the transition air cylinder are each provided with a tetrafluorohydrazine seal shaft sleeve, the crankshaft connecting rod penetrates the tetrafluorohydrazine graphite seal shaft sleeves, the tetrafluorohydrazine graphite seal shaft sleeves can exert the lubricating seal effect in the crankshaft connecting rod running process, and oxygen in the air cylinder can be prevented from leaking into the transition air cylinder or leakage gas in the transition air cylinder is prevented from entering thecrankshaft box. According to the test, the oxygen leakage rate of the device can be controlled to the level below 0.5%, and the accident potentials of oxygen leakage and explosion prevention can be thoroughly avoided.

Owner:威海威高海盛医用设备有限公司

Dual-mode system soil-removal gate

InactiveCN111075461ASolve the gushing problemExtended service lifeTunnelsStructural engineeringActuator

The invention discloses a dual-mode system soil-removal gate which comprises an upper valve body, a lower valve body, a first gate and a second gate. The first gate is arranged at the lower end of a capacity sleeve pipe; hydraulic actuators are arranged on two sides of the first gate; the second soil-removal gate is arranged at the upper end of the capacity sleeve pipe; flushing devices are arranged on two sides of the first gate and the second gate; a groove is formed in the connected part of the lower valve body and a flashboard; a copper wedge block is arranged in the groove and is fixed into the groove through a screw; an eleven-degree oblique angle matched with the copper wedge block is arranged at the tail end of the flashboard; a T-shaped groove is formed in the connecting part of the upper valve body and the flashboard; a rectangular copper bar is arranged in the groove and is abutted against a rectangular tetrafluorohydrazine sealing block; and the rectangular tetrafluorohydrazine sealing block is connected with the upper valve body through an adjusting bolt. According to the mode system soil-removal gate for a shield tunneling machine, the first soil-removal gate, the second soil-removal gate and the capacity sleeve pipe are combined for removing soil and discharging muddy water, so that the problem that the muddy water is spouted is effectively solved, a high-efficient water stopping performance is realized, muck is not easy to accumulate, the service life is long, and the soil removal amount can be adjusted at any time so as to realize a soil plug effect.

Owner:ANHUI TONGDU FLOW TECH

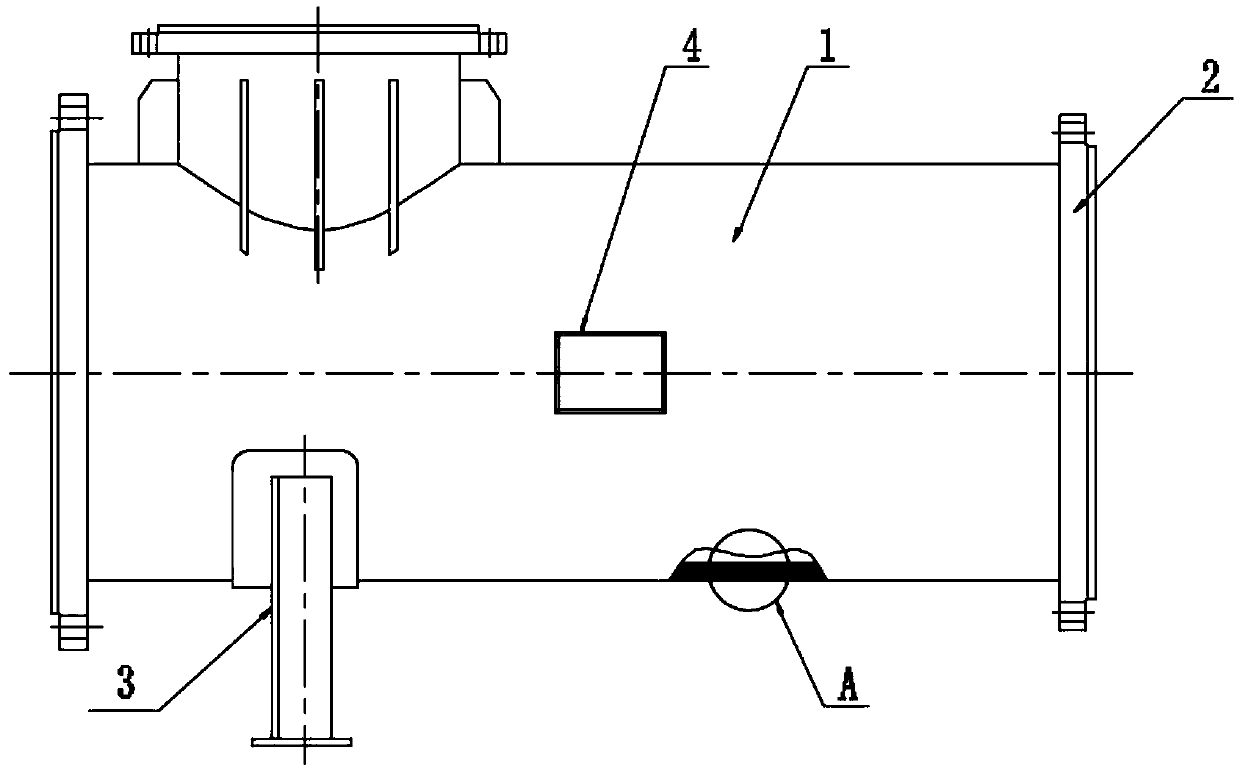

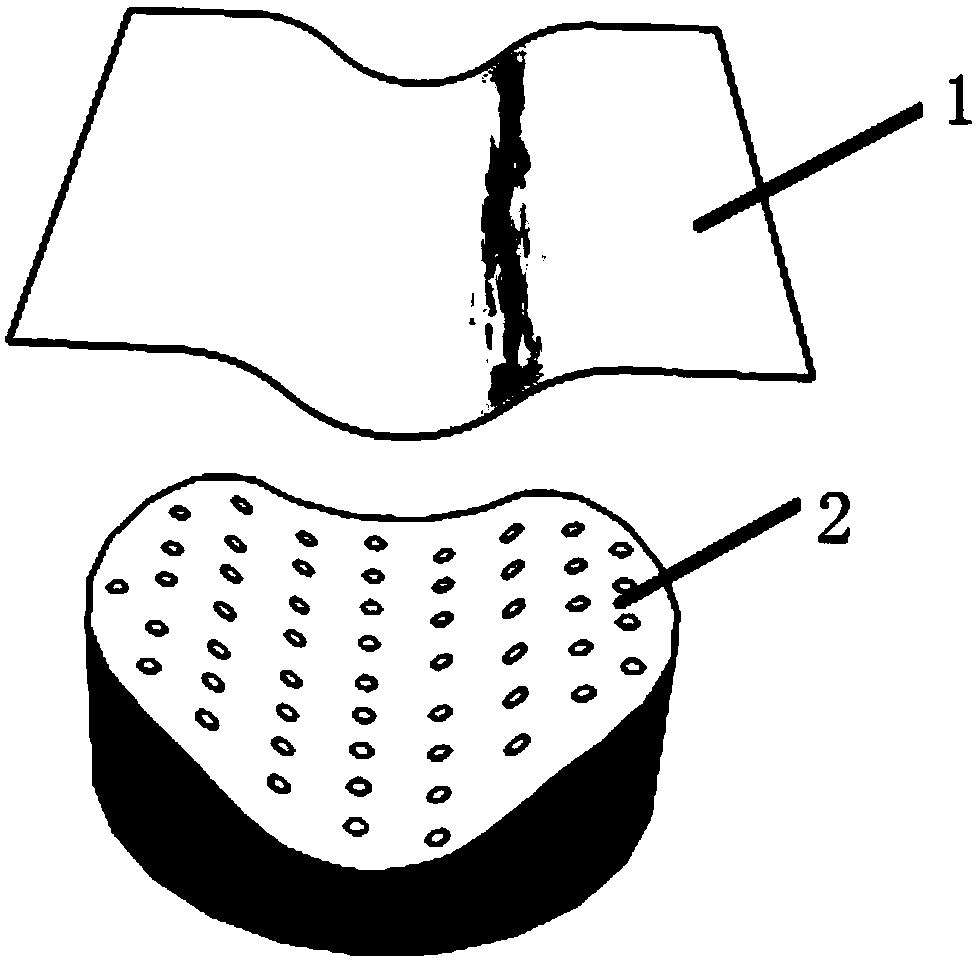

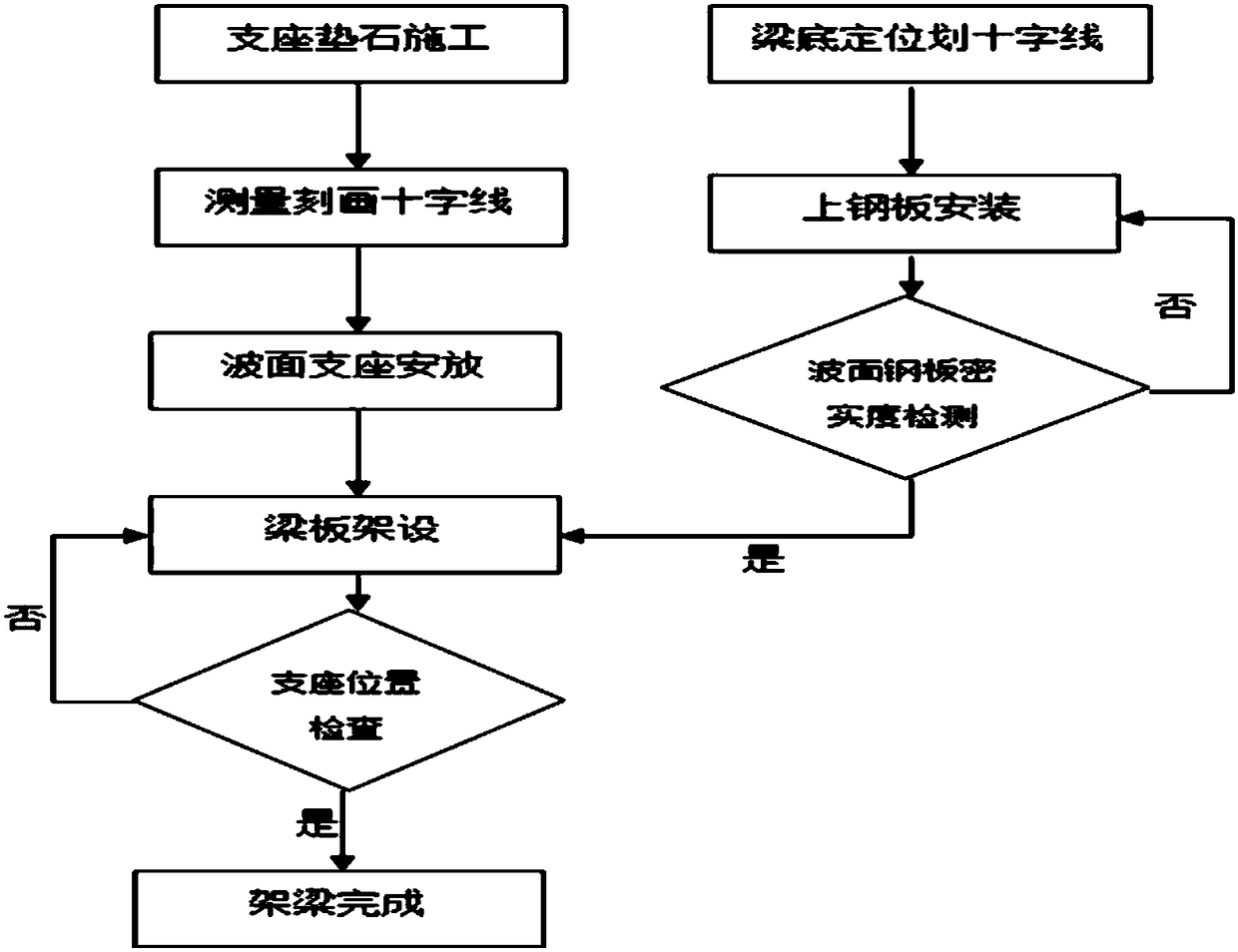

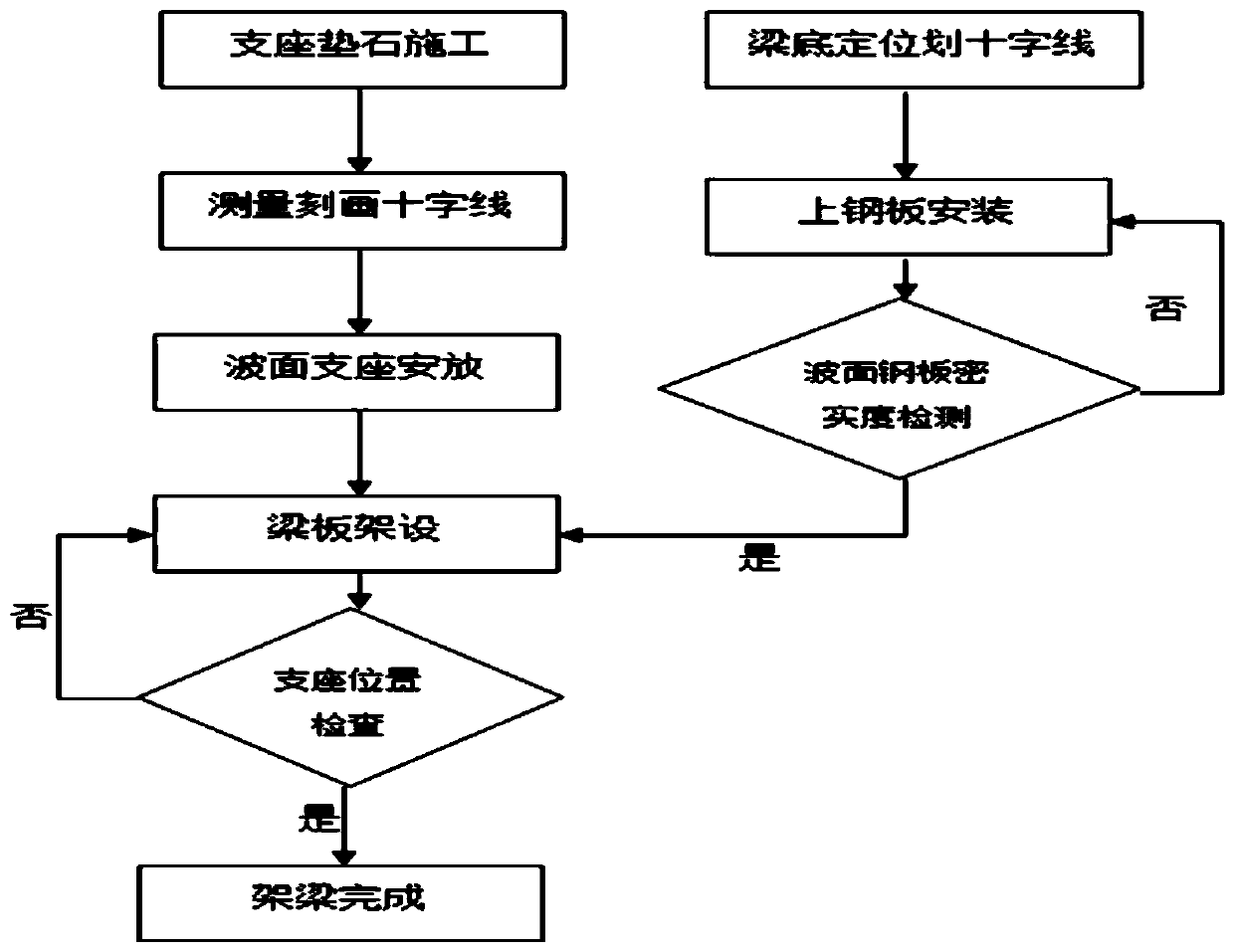

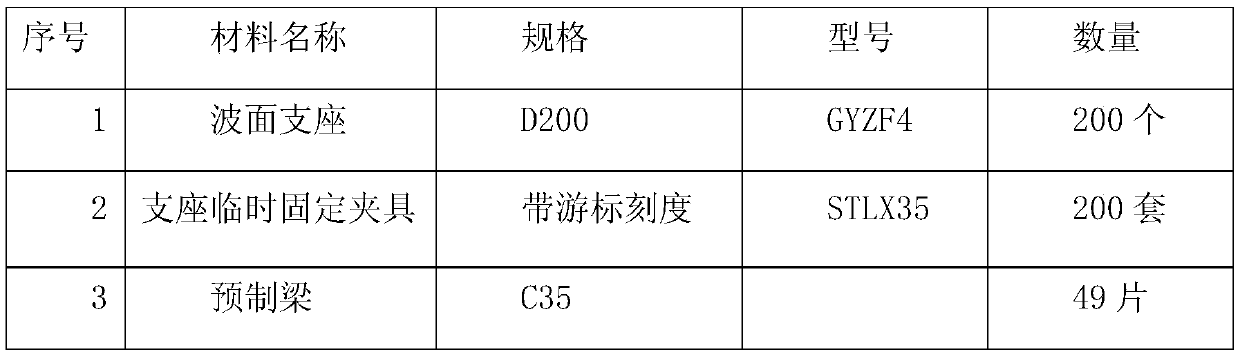

Installing method of wave surface tetrafluorohydrazine plate rubber support one-way constraint prefabricated beam plate

ActiveCN108103941AAvoid easy controlAvoid the disadvantages of being prone to slipping accidentsBridge structural detailsBridge erection/assemblyEngineeringSilicone grease

The invention discloses an installing method of a wave surface tetrafluorohydrazine plate rubber support one-way constraint prefabricated beam plate. Certain constraint force is exerted on a prefabricated beam in the installing process, and the disadvantages that due to omnibearing movement of the prefabricated beam, the installing position is uneasy to control and a slip accident easily occurs are avoided; the use of tetrafluorohydrazine plate rubber support silicone grease oil is guaranteed, longitudinal slide failure of the support is avoided, and the service life of the support is prolonged; in the later using process of a bridge, elastic constraint force is exerted on the prefabricated beam, part of impact force of a vehicle and seismic force can be buffered, and anti-impact and seismic performance of the bridge is improved. By means of the installing method of the wave surface tetrafluorohydrazine plate rubber support one-way constraint prefabricated beam plate, the installing efficiency and position accuracy of the prefabricated beam are improved, the service life of the support and the beam plate is prolonged, materials are saved, environmental pollution is reduced, the time in the installing process is greatly shortened, repeated use of a machine is reduced, and the installing method is significant in safety of the installing, constructing and operating stage of the prefabricated beam.

Owner:雨发建设集团有限公司

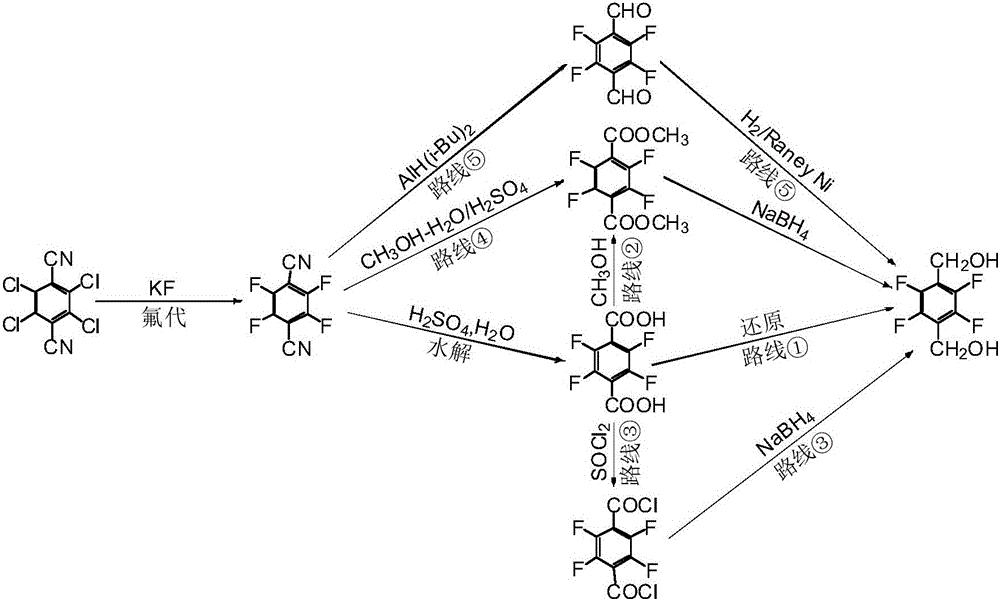

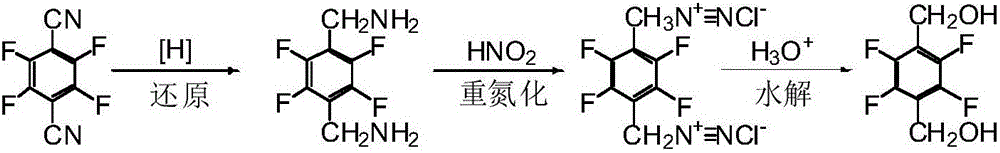

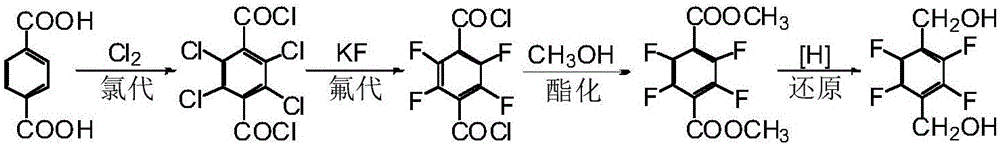

Preparation method of 2,3,5,6-tetrafluorohydrazine-1,4-benzene dimethanol

ActiveCN106565421ARaw materials are cheap and easy to getShort synthetic routePreparation by halogen eliminationHalogenated hydrocarbon preparationChemical synthesisDistillation

The invention discloses a preparation method of 2,3,5,6-tetrafluorohydrazine-1,4-benzene dimethanol, and belongs to the technical field of fine chemical synthesis. The preparation method is characterized by comprising the following reaction steps that (1) chlorine is led into paraxylene under catalyzing of a catalyst and irradiation of visible light to achieve chlorination, then nitrogen is led in to expel residual hydrogen chloride gas, and 1,4-dual(trichloromethyl)-2,3,5,6-tetrachlorobenzene is obtained; (2) the 1,4-dual(trichloromethyl)-2,3,5,6-tetrachlorobenzene and potassium fluoride are subject to fluorization and alcoholysis in an alcohol solvent, the solvent is recycled through reduced pressure distillation, washing is carried out the neutral state is obtained, drying is carried out, and 1,4-dual(silane oxygen methyl chloride)-2,3,5,6-tetrachlorobenzene is obtained; and (3) hydrogen is led into the 1,4-dual(silane oxygen methyl chloride)-2,3,5,6-tetrachlorobenzene in a solvent containing a metal catalyst and an acid-binding agent to be subject to catalytic hydrogenation reduction, an upper-layer organic phase is subject to cooling, suction filtration and drying to obtain the2,3,5,6-tetrafluorohydrazine-1,4-benzene dimethanol. The preparation method has the beneficial effects that the raw materials are low in price and easy to obtain, the synthetic route is short, operation is easy and convenient, and the product cost is low.

Owner:岳阳中科华昂精细化工科技有限公司 +1

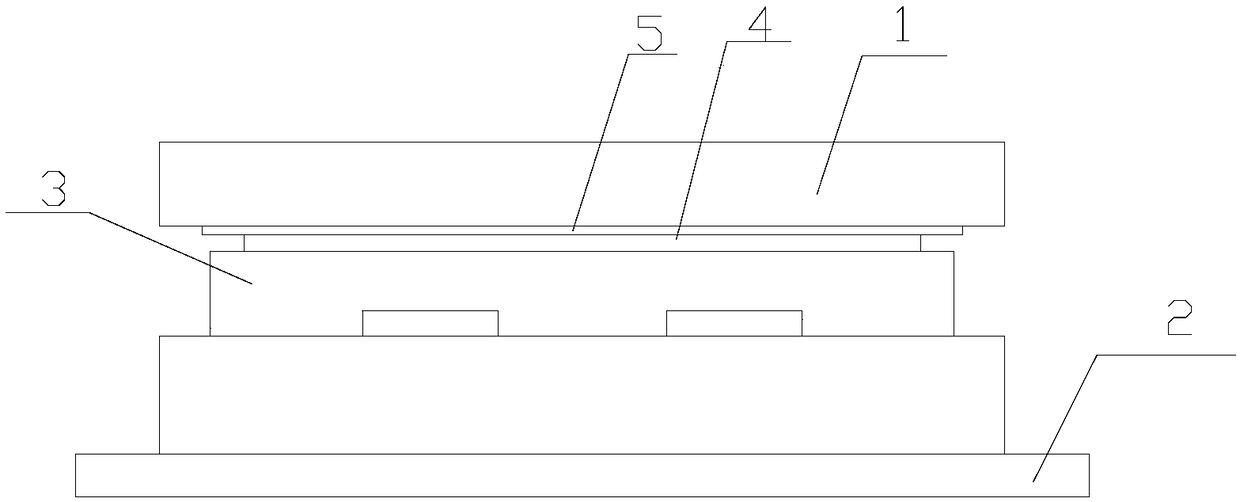

Multiple-point bearing pot type rubber support

InactiveCN108842604AReasonable structureImprove bearing capacityBridge structural detailsSlide plateMultiple point

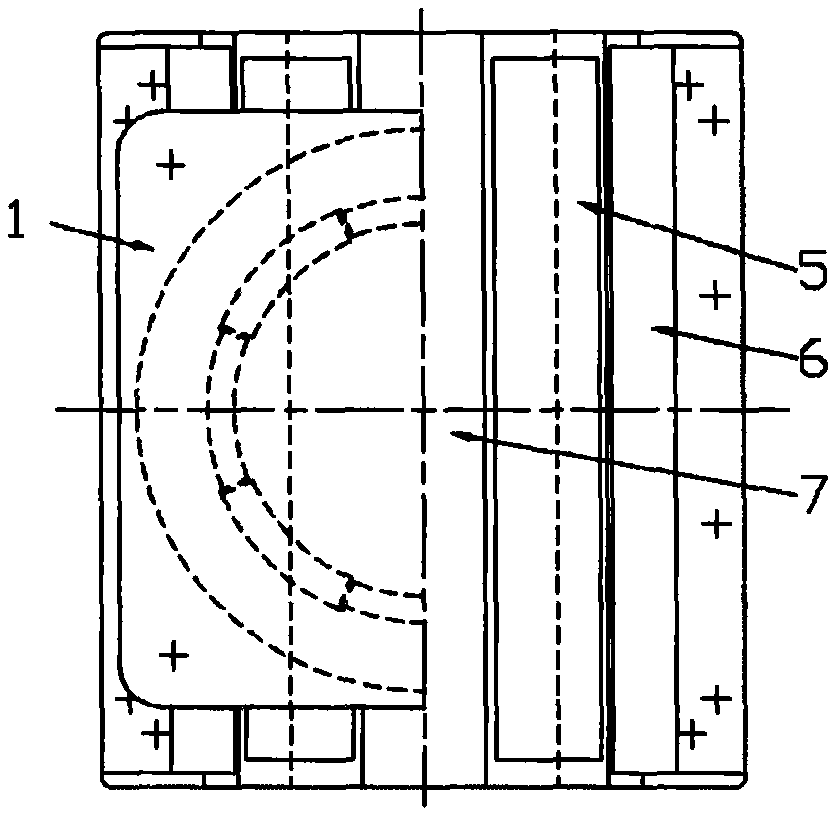

The invention discloses a multiple-point bearing pot type rubber support. The multiple-point bearing pot type rubber support comprises an upper support plate, a lower support base plate, a middle supporting plate, a tetrafluorohydrazine sliding plate, a stainless steel plate, a first rubber mat, a second rubber mat, a third rubber mat and a fourth rubber mat, wherein the middle supporting plate isarranged on the lower support base plate, the first rubber mat, the second rubber mat, the third rubber mat and the fourth rubber mat are arranged between the lower support plate and the middle supporting plate, the tetrafluorohydrazine sliding plate is arranged on the middle supporting plate, and the upper support plate is arranged on the tetrafluorohydrazine sliding plate; the stainless steel plate is arranged between the tetrafluorohydrazine sliding plate and the upper support plate, and the tetrafluorohydrazine sliding plate is slidably connected with the stainless steel plate which is embedded into the upper support plate. According to the multiple-point bearing pot type rubber support, four pot type cavities are formed in the lower support base plate, the rubber mats are arranged inthe four pot type cavities respectively, the middle supporting plate is provided with four supporting feet, the four supporting feet are matched with the rubber mats in the four pot type cavities, and the supporting force borne by the support is uniformly dispersed to the four rubber mats, so that the bearing capacity is higher, and the anti-seismic effect is better.

Owner:XINCHANG HESHENGXIN BUSINESS CO LTD

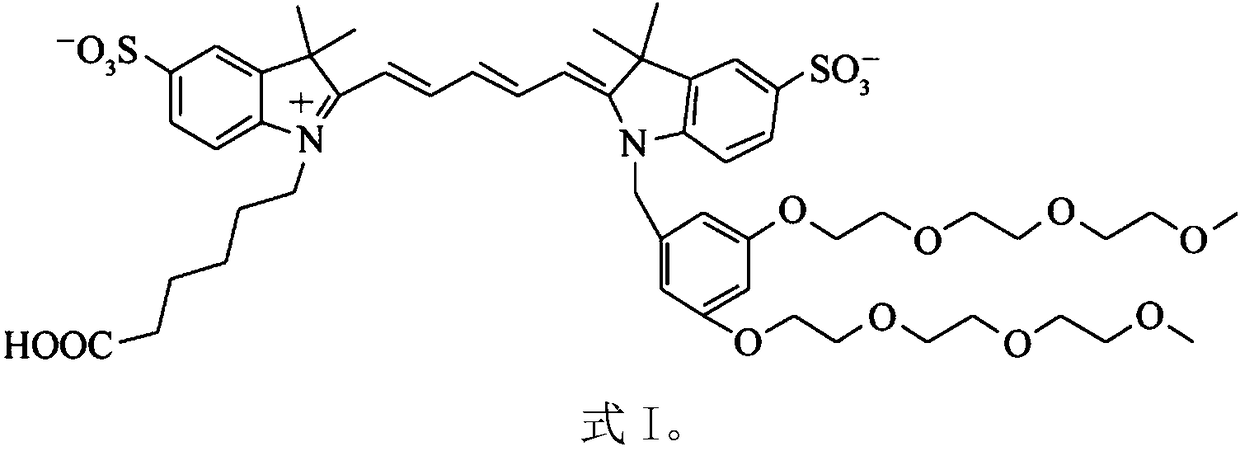

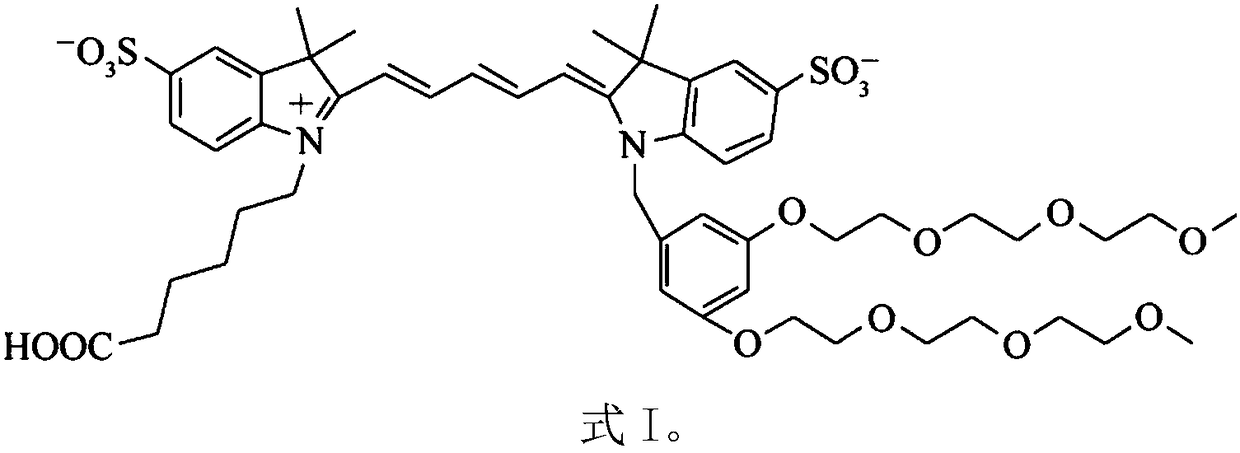

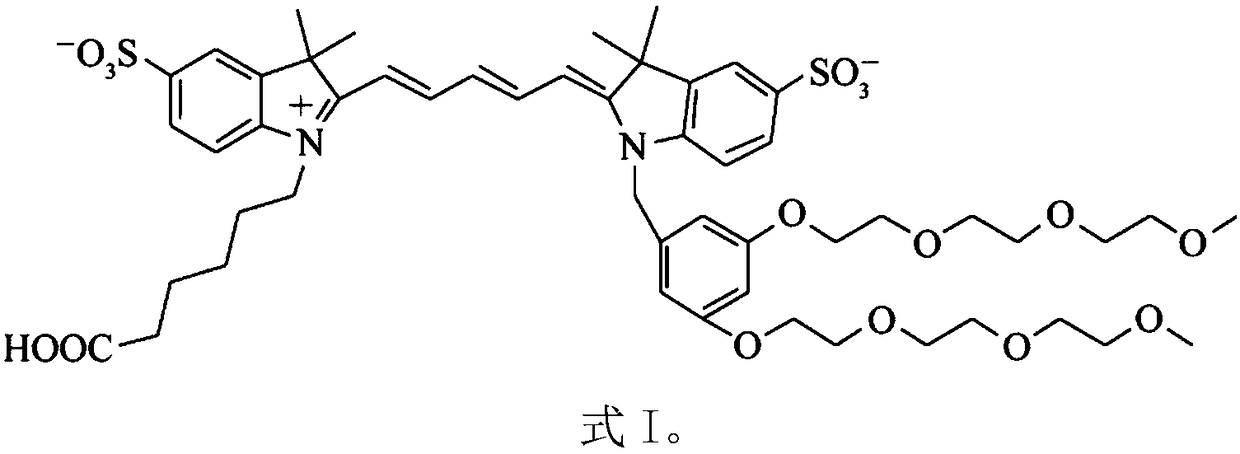

Urine microalbumin detection reagent strip and preparation method thereof

ActiveCN108226147AEasy to distinguish visuallyMachine readableMaterial analysis by observing effect on chemical indicatorReagent stripSodium azide

The invention provides a urine microalbumin detection reagent strip and a preparation method thereof, and belongs to the technical field of medical examination. The reagent strip comprises a supporting plate and a filter paper sheet, wherein the filter paper sheet is attached onto the supporting plate; the filter paper sheet is immerged in dyeing liquid; the dyeing liquid is prepared from a reagent I and a reagent II; the reagent I is prepared from cyanine dyes, trolamine buffer solution, Triton X-100, sodium benzoate and PEG-4000; the reagent II is prepared from disodium hydrogen phosphate-monosodium orthophosphate buffer solution, O-(N-succinimido)-N N N'N'-tetramethyl tetrafluorohydrazine carbamide borate, sodium azide and dimethyl acetamide. The cyanine dyes of the prepared urine microalbumin detection reagent strip can fast react with microalbumin in urine; when the concentration of the microalbumin is in a range of 0 to 200mg / L, the test paper is at the obvious color gradation from being achromatic color to dark blue; the visual distinguishing and machine reading are easy; the determination result is accurate; the stability is high.

Owner:李宏奎

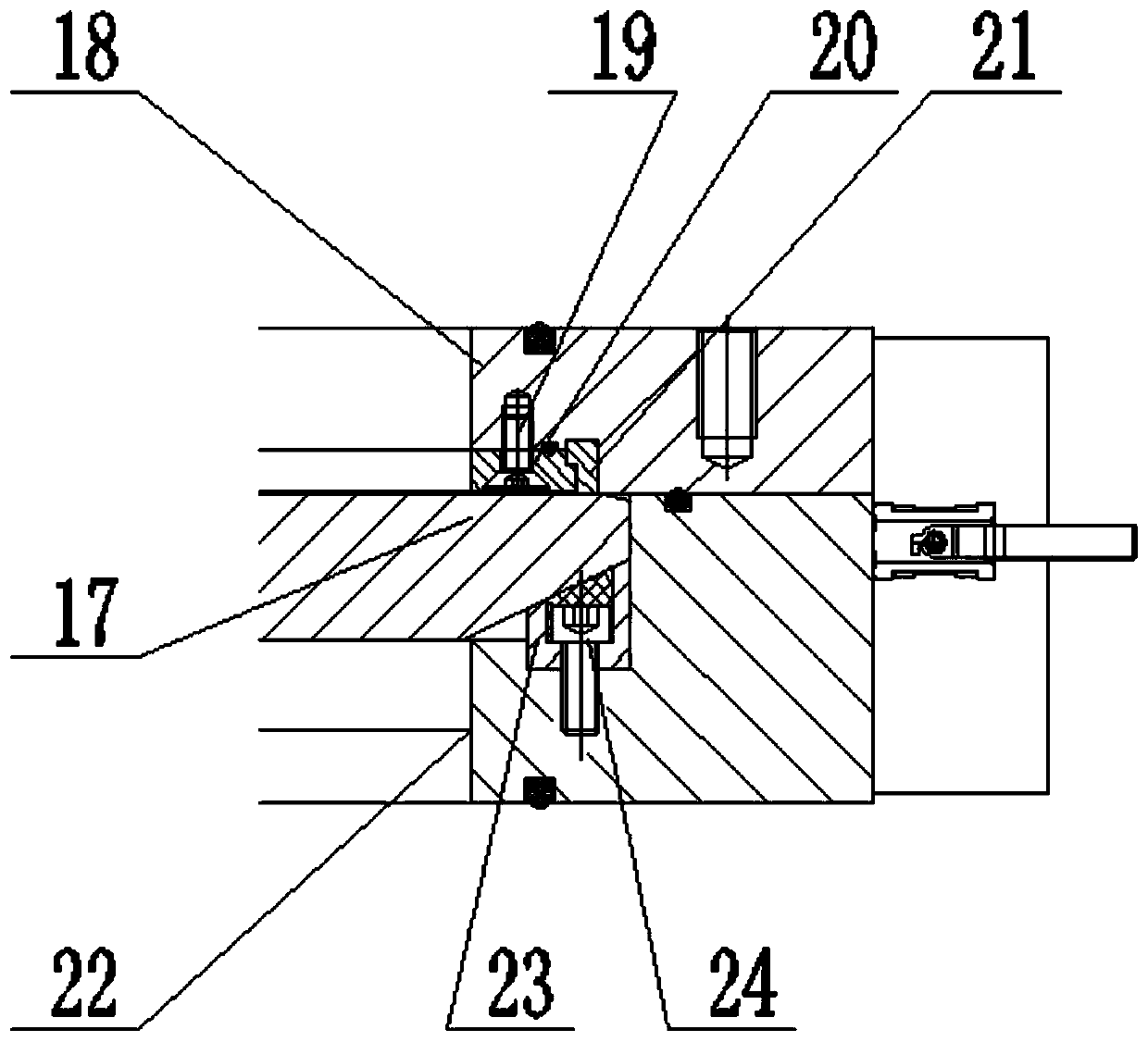

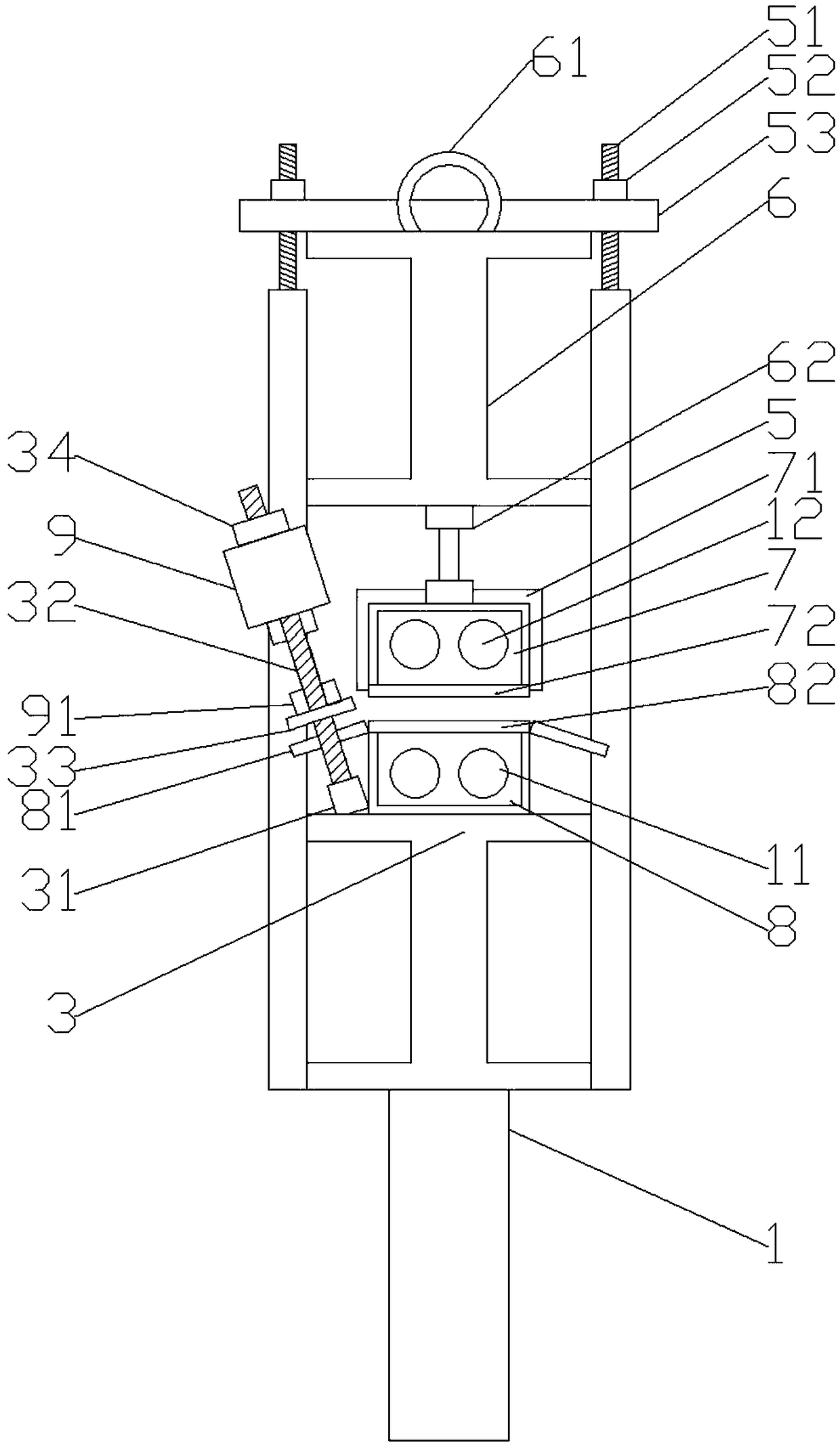

Electric heating knife rest for butting tetrafluorohydrazine cylinder

The invention discloses an electric heating knife rest for butting a tetrafluorohydrazine cylinder. The electric heating knife rest comprises a side fixing frame; a lower bracket is hinged to the sidefixing frame; one side, close to the side fixing frame, of the lower end of the lower bracket is provided with a jacking device, and the other side is provided with supporting legs; the upper end face of the lower bracket is provided with a lower heating box; the two sides of the upper end of the lower heating box are each provided with an inclined side supporting plate; the upper end face of thelower bracket is provided with a fixing seat; the fixing seat is provided with a screw rod I; the screw rod I is sequentially sleeved with a nut I, a side bracket and a pressing bar from top to bottom; the lower end of the side bracket is provided with a plurality of pressing blocks II; a heating tube I is arranged inside the lower heating box; a lower heating plate is arranged at the upper end of the lower heating box; an upper bracket is arranged above the lower bracket; the lower end of the upper bracket is provided with a plurality of pressing blocks I; an upper heating box is arranged atthe lower ends of the pressing blocks I; a heating tube II is arranged inside the upper heating box; and the lower end of the upper heating box is provided with an upper heating plate. The contact area of a joint of the tetrafluorohydrazine cylinder butted by using the electric heating knife rest disclosed by the invention is large, the firmness is higher, a pressed surface is uniform in thickness and high in quality, and the molded tetrafluorohydrazine cylinder is higher in durability.

Owner:安徽高旭新材料科技有限公司

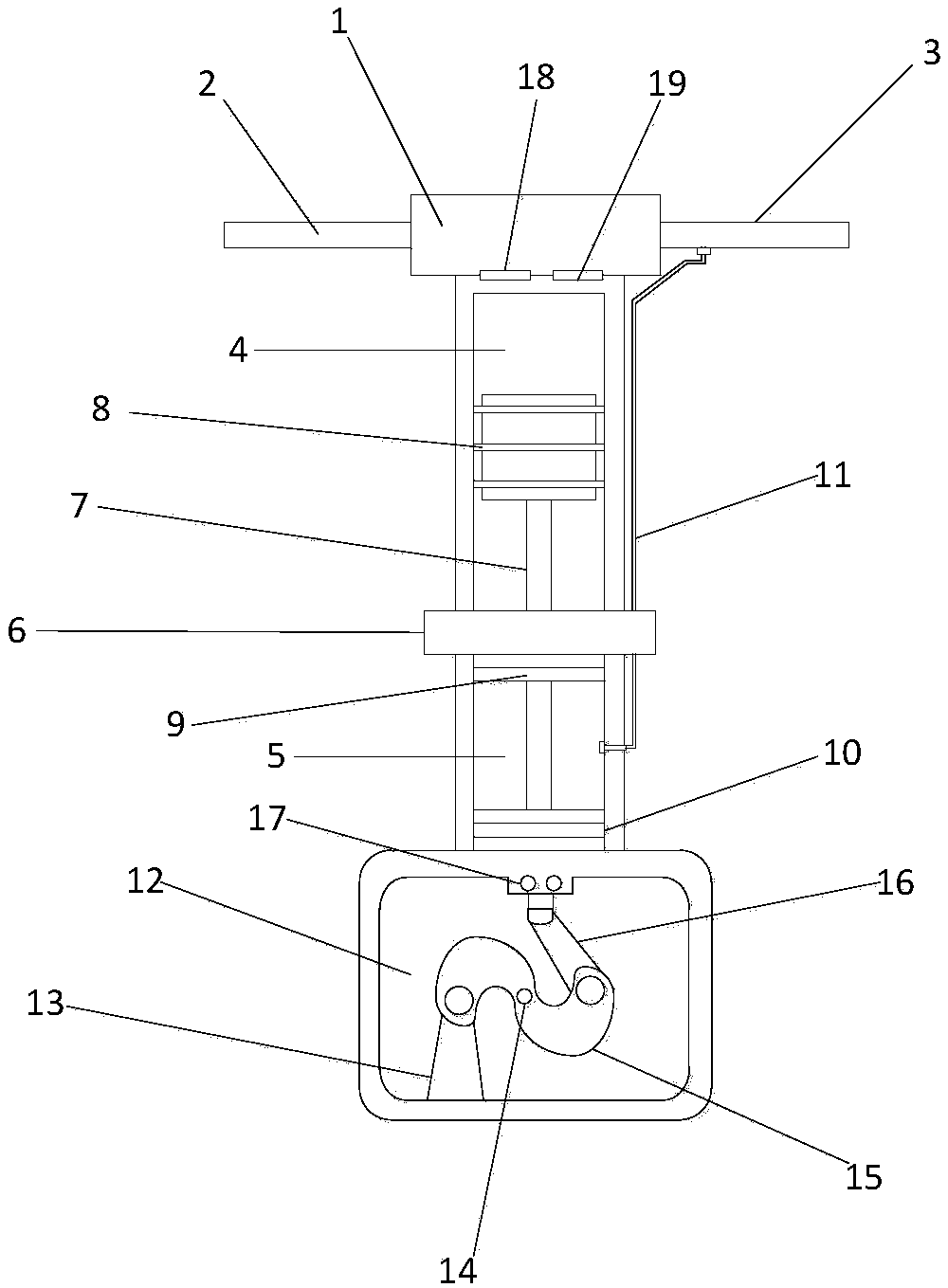

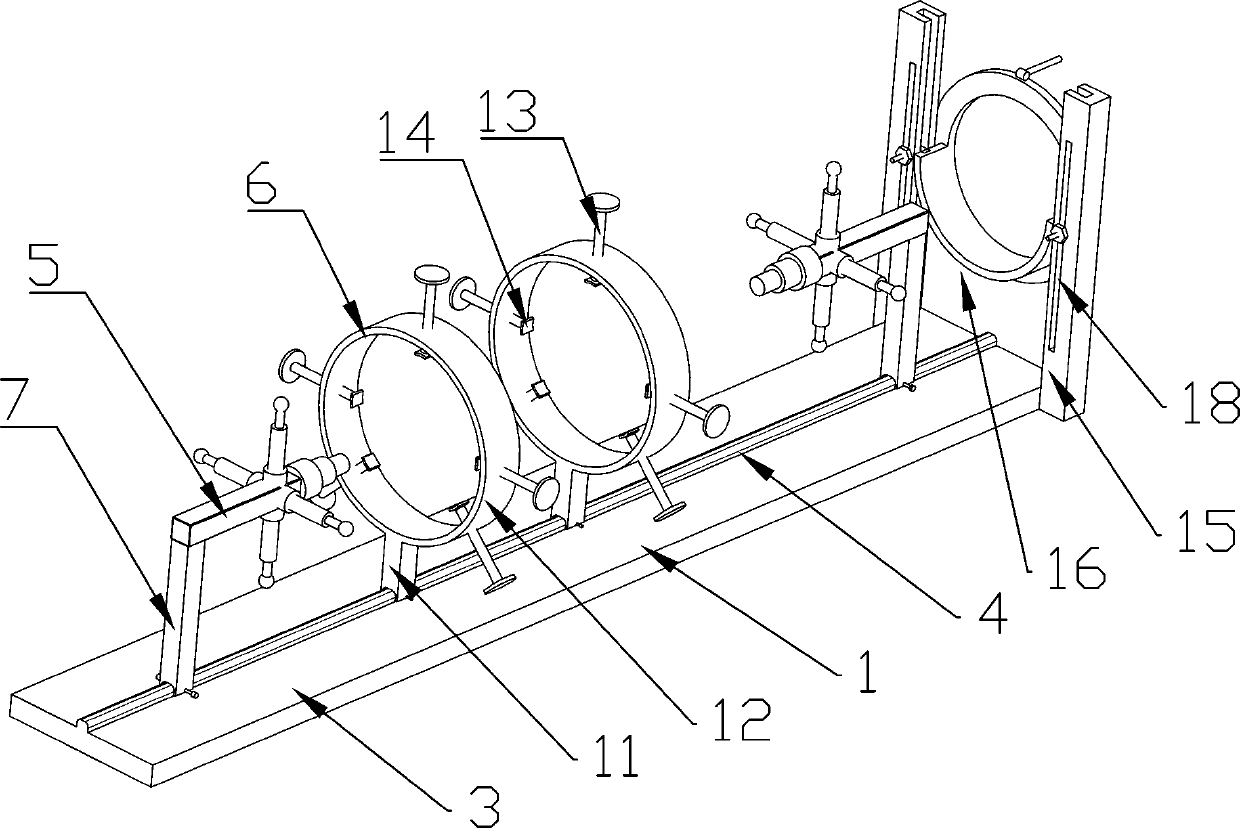

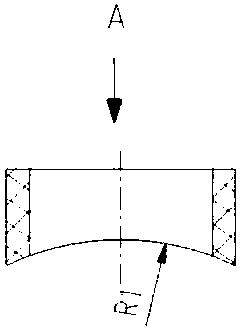

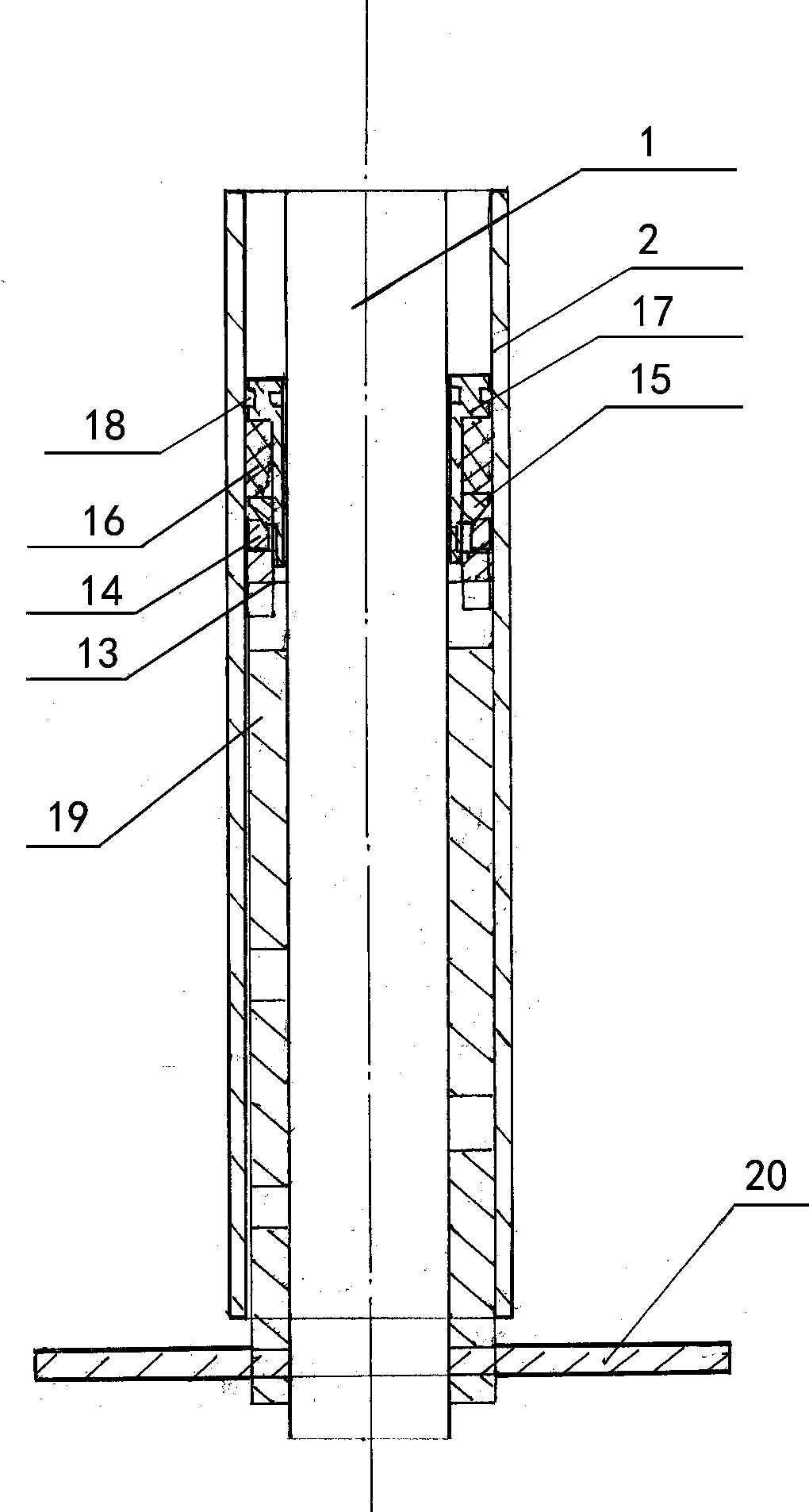

Flanging device for tetrafluorohydrazine pipe

The invention relates to a flanging device for a tetrafluorohydrazine pipe. The flanging device comprises a supporting bracket and a flanging positioning device. The supporting bracket comprises a base, the base is provided with a slide rail, centering mechanisms are symmetrically and radially arranged on the front and rear portions of the slide rail, one or more jacking mechanisms are arranged between the two centering mechanisms, and the front end of the slide rail is provided with a positioning mechanism. The flanging positioning device comprises a mounting base, the left and right sides ofthe front end of the mounting base are provided with a conical heating flanging mechanism and a stock mold respectively, the rear end of the mounting base is connected with a motor, and the motor isslidingly arranged on a slide base through a support and pushed by an air cylinder to move frontwards and backwards. The flanging device for the tetrafluorohydrazine pipe can improve the work efficiency.

Owner:湖北世纪伟业防腐科技有限公司

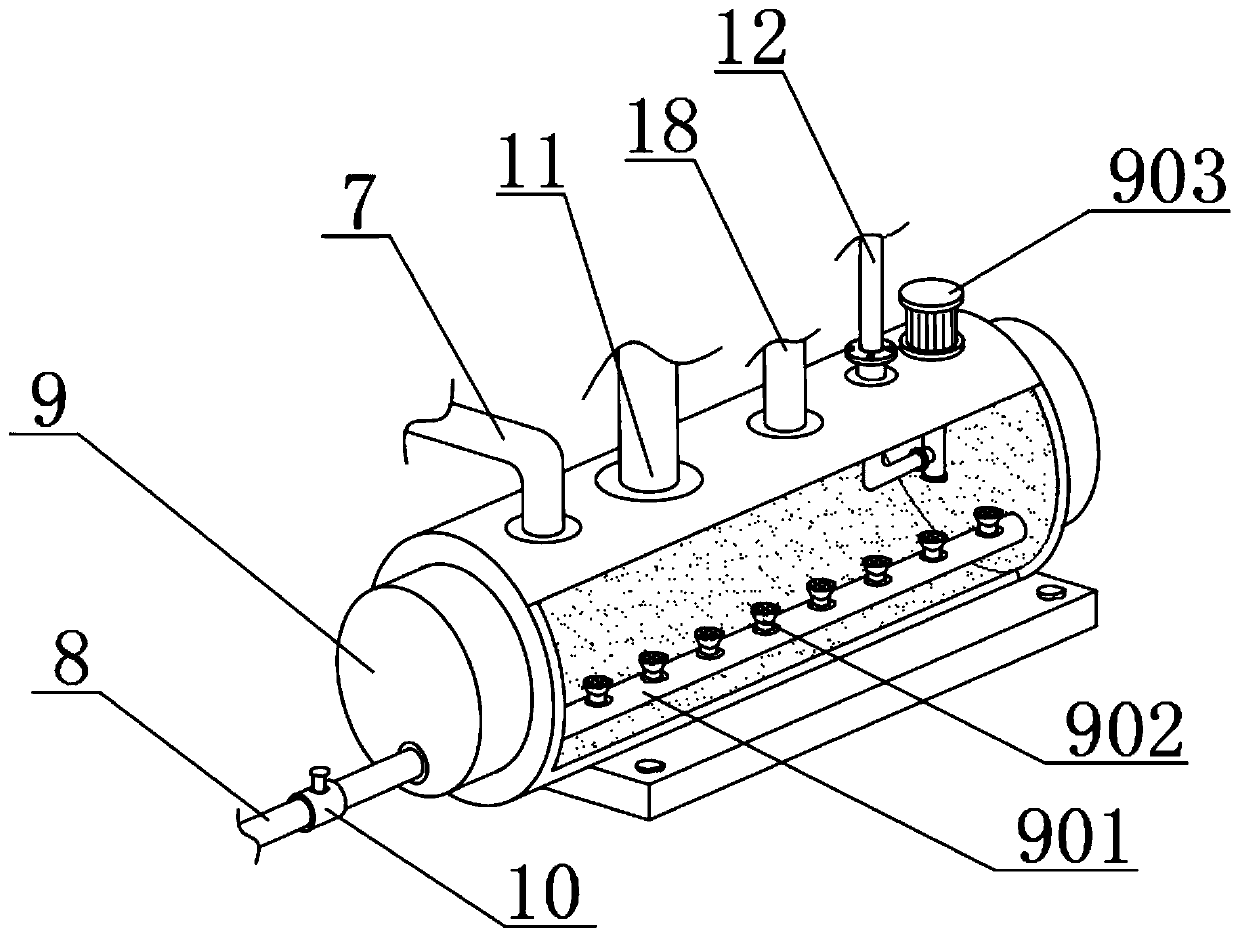

Steel lining polytetrafluoroethylene tee joint and mold pressing process thereof

ActiveCN108644512AFully automatedRealize semi-automationBranching pipesTubular articlesCost ControlsMachining

The invention discloses a steel lining polytetrafluoroethylene tee joint and a mold pressing process thereof, and belongs to the technical field of steel lining tee joints. The steel lining polytetrafluoroethylene tee joint comprises a tee joint steel part, a main pipe and a branch pipe, wherein the main pipe and the branch pipe are arranged in the tee joint steel part and are communicated. The main pipe comprises a hollow round-pipe-shaped main pipe core rod and two main pipe glands. A tee joint rubber sleeve is arranged on the outer side of the main pipe core rod. A main pipe tetrafluorohydrazine short pipe is arranged on the outer side of the tee joint rubber sleeve in a sleeving manner. The branch pipe comprises a hollow round-pipe-shaped branch pipe core rod and two branch pipe glands. The outer side of the branch pipe core rod is sleeved with a tee joint rubber sleeve, and a branch pipe tetrafluorohydrazine short pipe is arranged on the outer side of the tee joint rubber sleeve in a sleeving manner. A semi-circular gap main pipe tetrafluorohydrazine short pipe and a branch pipe arc opening short pipe connected with the semi-circular gap main pipe tetrafluorohydrazine short pipe are arranged at the joint of the main pipe tetrafluorohydrazine short pipe and the branch pipe tetrafluorohydrazine short pipe. According to the steel lining polytetrafluoroethylene tee joint, automation or semi-automation can be achieved, the work efficiency is greatly improved, cost control can be refined easily, powder bridging and empty drum scrapping are avoided, the finish machining amount is reduced, powder consumption is reduced, and the product forming ratio is increased.

Owner:NANJING FUYUAN CHEM PIPELINE EQUIP

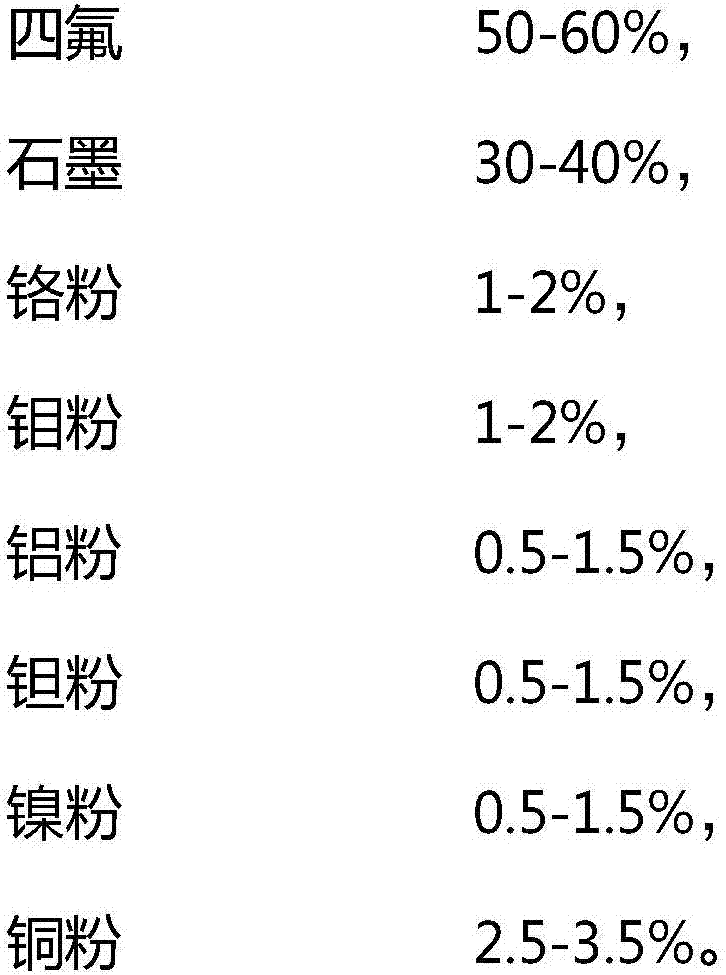

Chlorine-resistant modified graphite sealing material for valves

InactiveCN106893238AImprove chlorine resistanceImprove sealingOther chemical processesGraphiteCopper

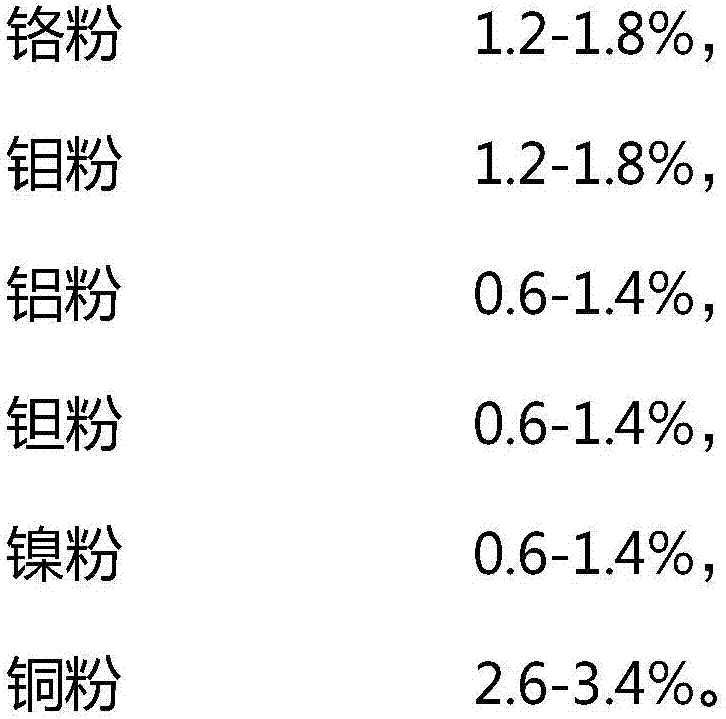

The invention discloses a chlorine-resistant modified graphite sealing material for valves. The chlorine-resistant modified graphite sealing material for the valves comprises, by weight, 50-60% of tetrafluorohydrazine, 30-40% of graphite, 1-2% of chromium powder, 1-2% of molybdenum powder, 0.5-1.5% of aluminum powder, 0.5-1.5% of tantalum powder, 0.5-1.5% of nickel powder and 2.5-3.5% of copper powder. The chlorine-resistant modified graphite sealing material for the valves has the advantages that made of the graphite and the tetrafluorohydrazine, the valves are effectively improved in chlorine resistance, excellent in sealing performance, higher in strength, long in service life and have less maintenance cost.

Owner:淄博华文工贸有限公司

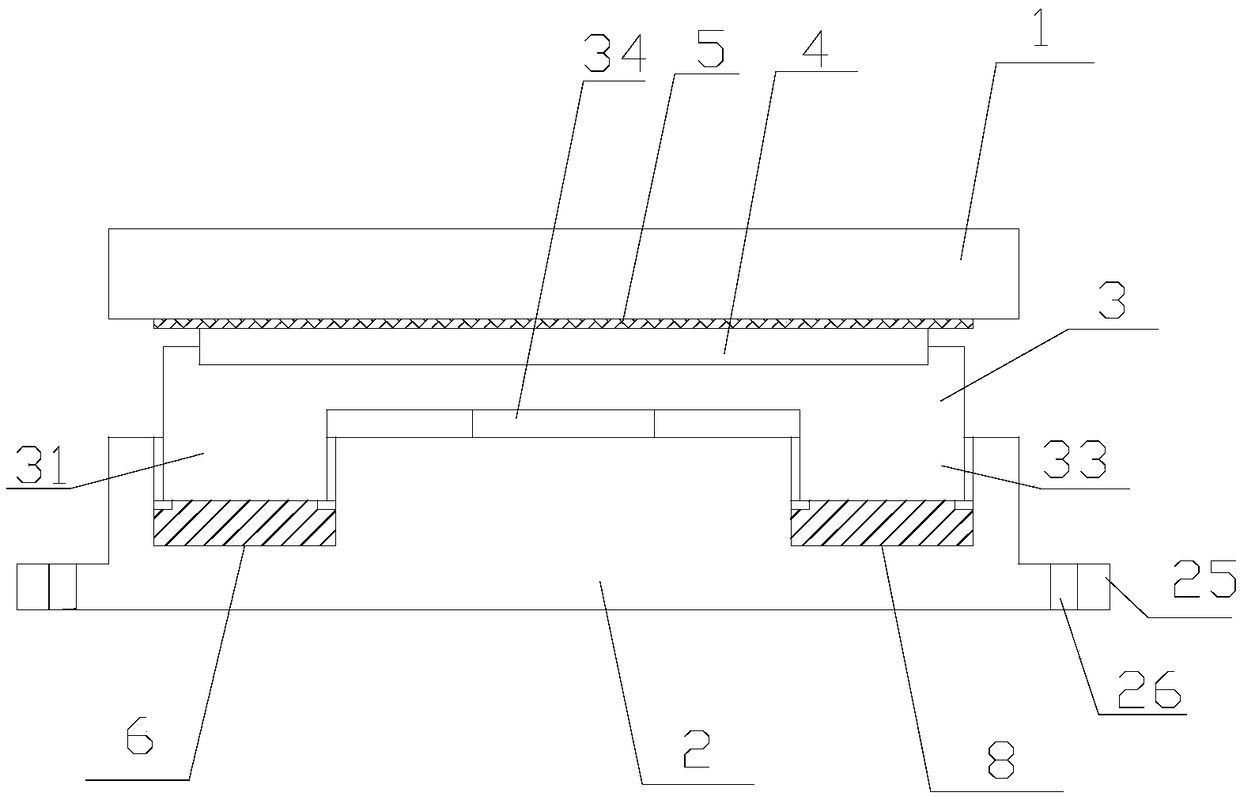

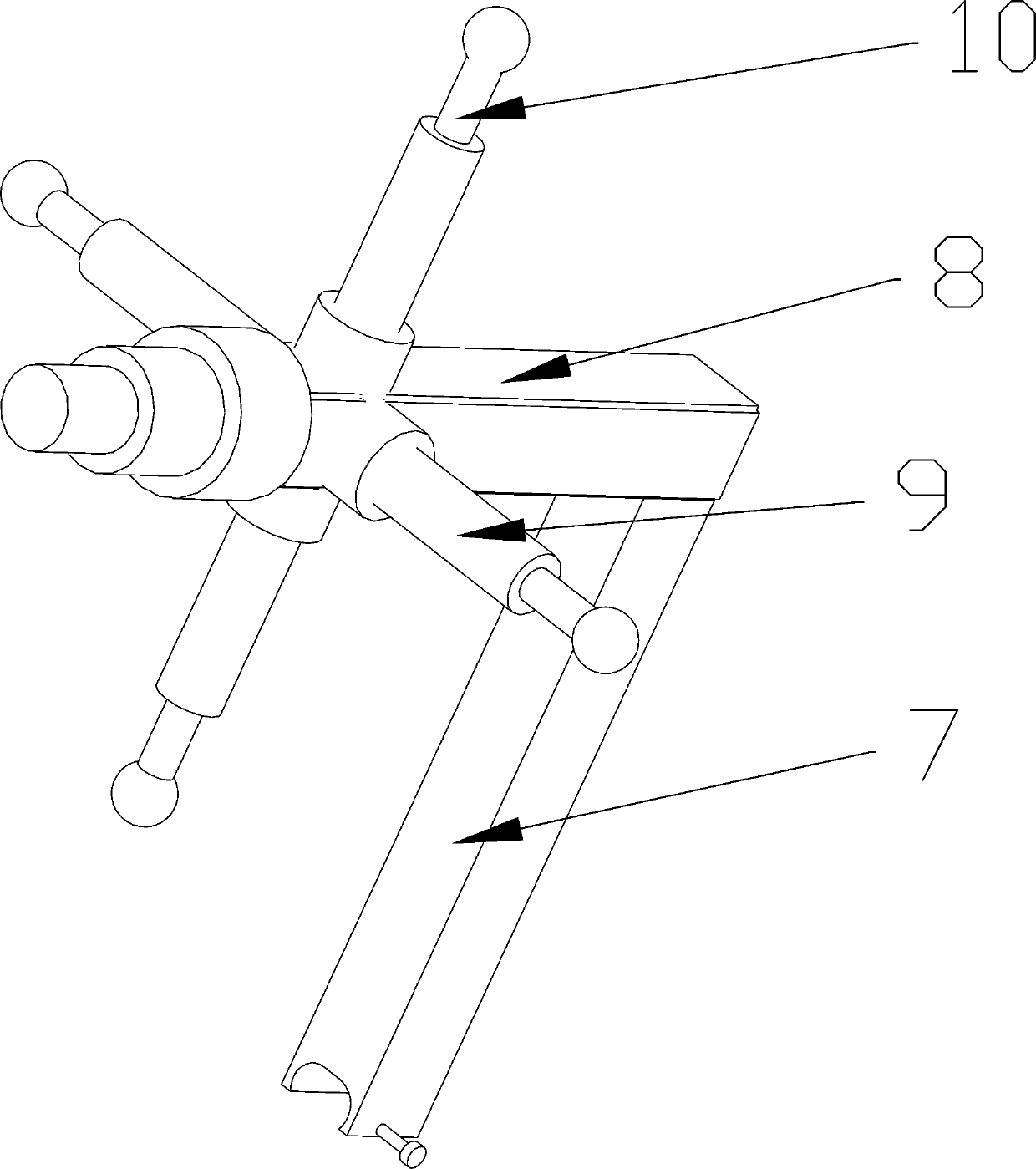

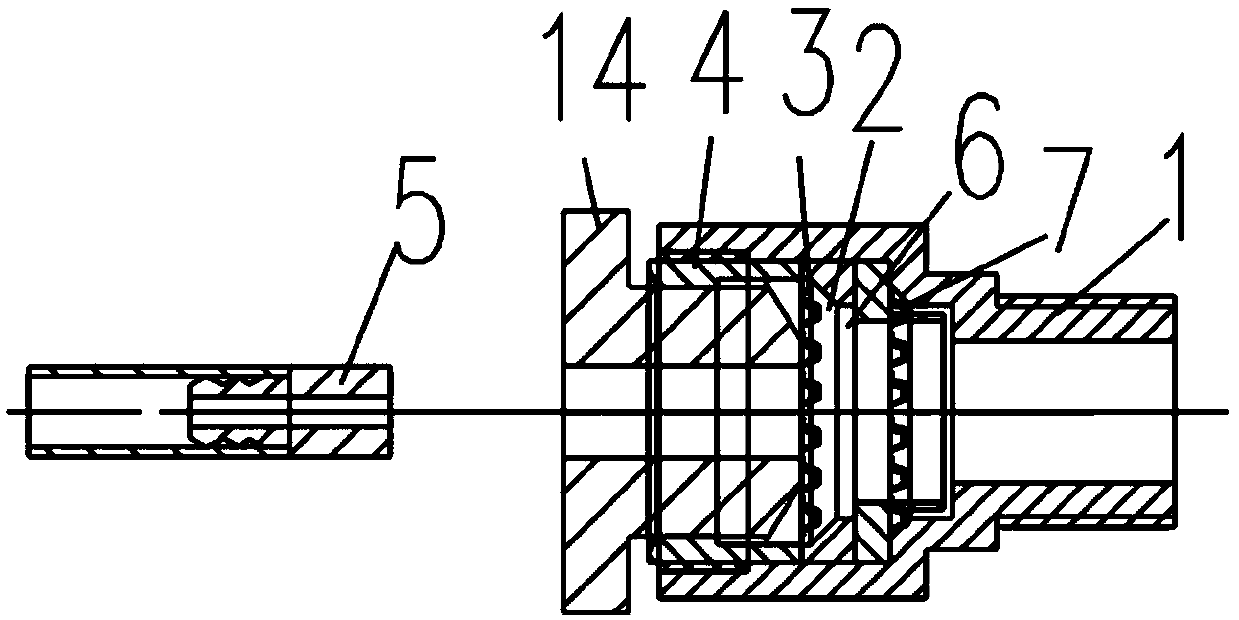

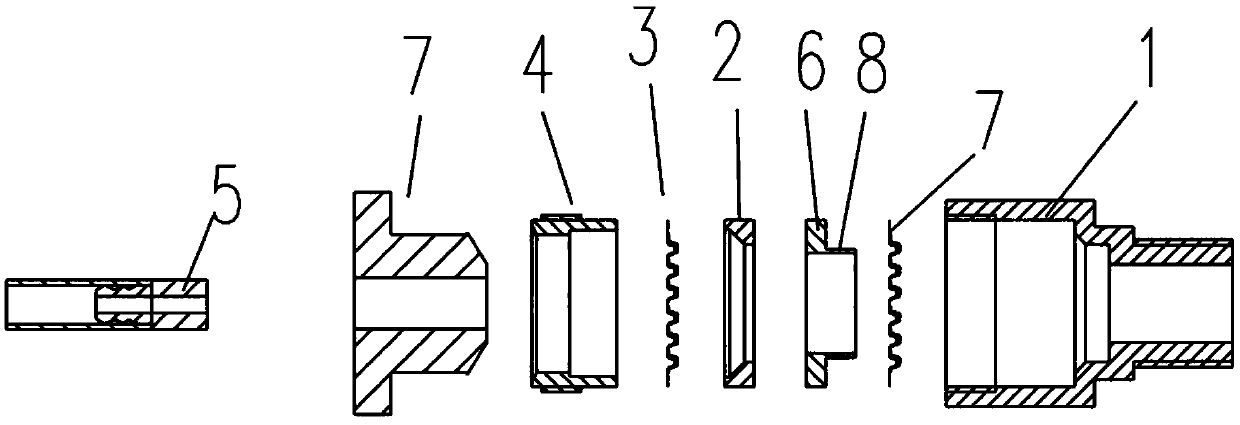

Fast mounted and dismounted tooth-embedded resistance-free sliding ball support

InactiveCN109750596ANo stress concentrationLarge momentBridge structural detailsSlide plateEngineering

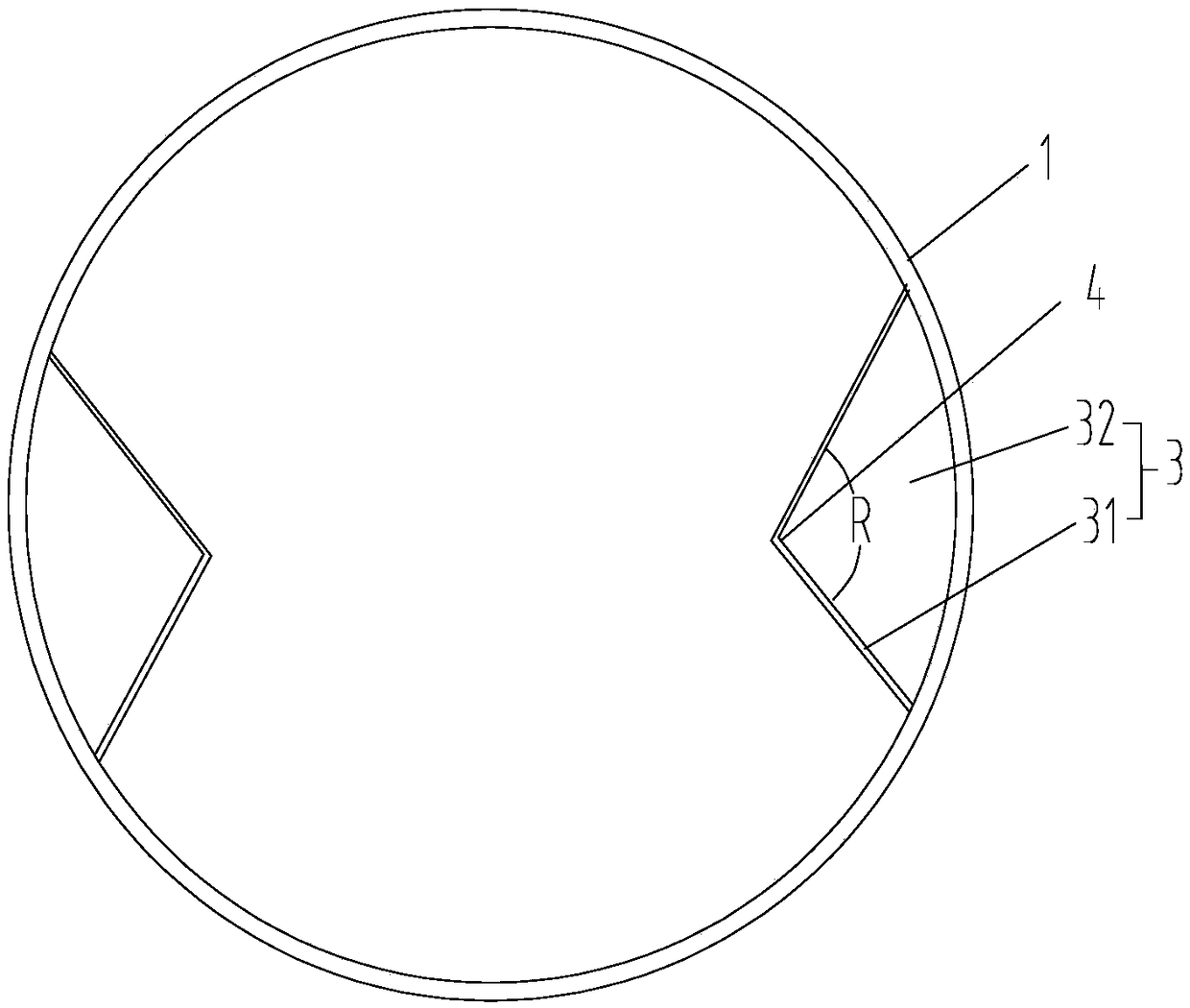

The invention discloses a concrete monorail rail beam movable support, and particularly relates to a fast mounted and dismounted tooth-embedded resistance-free sliding ball support. The fast mounted and dismounted tooth-embedded resistance-free sliding ball support comprises an upper support (1), a spherical crown liner plate (2), a spherical tetrafluorohydrazine sliding ring (3), a movable sliding block (4), a tetrafluorohydrazine sliding plate (5), a pressing plate (6) and a lower support (7); the upper support (1) is provided with four sawtooth-shaped inner teeth to constitute an anti-pull,anti-shear and anti-twisting device with the movable sliding block (4) with four sawtooth-shaped outer teeth; the spherical crown liner plate (2) of the upper support (1) and the spherical tetrafluorohydrazine sliding ring (3) embedded in the movable sliding block (4) constitute an inner-stress-free device; and the pressing plate 6 and the lower support 7 constitute a sliding groove of the movable sliding block 4. According to the support, the problems that the rail beam movable support bears composite stress such as pulling, shearing, pressing and twisting are effectively solved, and the stress acting on an anchor box and a bridge pier is eliminated; the movable support is compact in structure, is quickly mounted and dismounted, and directionally moves without resistance and deviations;and the support is also suitable for being applied to other bridges.

Owner:青岛德固特轨道装备有限公司

A mechanical force-induced europium-coordinated red photopolymer film and its preparation method

ActiveCN109897140BHigh luminous intensityIncreased sensitivityLuminescent compositionsArgon atmospherePolymer thin films

The invention discloses a mechanical force induced europium coordinated red light polymer film and a preparation method thereof. The preparation method comprises following steps: (1) dissolving a europium coordination compound, methyl acrylate, and azodiisobutyronitrile into N,N-dimethyl formamide, heating and stirring N,N-dimethyl formamide in an argon atmosphere, pouring N,N-dimethyl formamide into methanol to carry out precipitation to obtain methyl polyacrylate containing a linear europium coordination compound; and (2) dissolving methyl polyacrylate containing a linear europium coordination compound, methyl acrylate, diadamantane substituted 1,2-dioxocyclobutane, and azodiisobutyronitrile into tetrahydrofuran, evenly mixing, pouring the mixture into a tetrafluorohydrazine die, carrying out reactions in an argon atmosphere to obtain a polymer film, and drying to obtain the mechanical force induced europium coordinated red light polymer film. The polymer film has a crosslinking structure, the europium coordination compound is used as an energy transfer acceptor; the light emitting strength is effectively increased during the polymer film breaking process, the light emitting color is changed; as the acceptor content is increased, the light emitting strength is increased; and thus the sensitivity for flaw detection of polymer materials is improved.

Owner:TIANJIN UNIV

Transfer pump filter with bag-shaped filter screen

InactiveCN109806640AReduce maintenance costsIncrease production capacityGravity filtersFlangeTetrafluorohydrazine

The invention relates to a transfer pump filter with a bag-shaped filter screen. The bag-shaped filter screen is mounted on the filter, wherein the filter is connected by a plurality of flanges; the bag-shaped filter screen is fixed on the filter with a tetrafluorohydrazine belt, an external device is connected with an internal device by a flange, flange screws are removed during maintenance, andthe bag-shaped filter screen is cleaned, thus being convenient and simple. The technology has the beneficial effects of reducing maintenance cost and improving productivity.

Owner:潜江宜生新材料有限公司

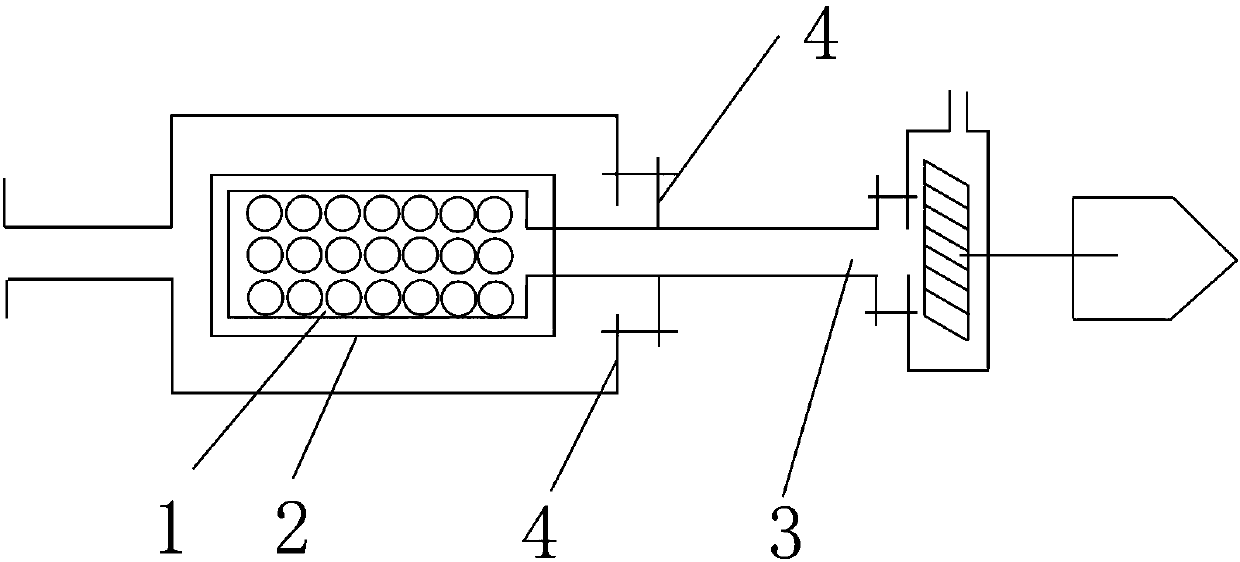

Catalyst for preparing 1,3,3,3-tetrafluoropropene from 1,1,1,3,3-pentafluoropropane

ActiveCN106902849BLow costReduce inactivationPreparation by hydrogen halide split-offPhysical/chemical process catalysts1,3,3,3-TetrafluoropropenePentafluoropropane

The invention discloses a catalyst for preparing 1,3,3,3-tetrafluoropropene from 1,1,1,3,3-pentafluoropropane, the composition of which is M x O y / AlF 3 , where the carrier AlF 3 It has an alpha phase structure and a specific surface area greater than 150m 2 ·g ‑1 , active carrier with pore size distribution concentrated in 15nm~40nm, M x O y For MgO, Fe 2 O 3 ,Co. 2 O 3 Or one of CuO, M x O y and AlF 3 The molar ratio is 1:5~50. The preparation method of the catalyst is: using active α-phase AlF with large specific surface area and mesoporous structure 3 As a carrier, the soluble salt of any element such as Mg, Fe, Co or Cu is loaded with equal amounts of impregnation method, and then dried and roasted at high temperature to form a catalyst. The catalyst in the present invention has excellent performance, does not need to use expensive precious metal compounds in the preparation process, has low cost and high activity. When reacting at 280°C, the conversion rate of 1,1,1,3,3-pentafluoropropane can reach 70%. Above, the catalyst has a long life, can operate stably for 360 hours, and does not need to introduce diluent gas during the reaction process, so it has industrial application value.

Owner:XIAN MODERN CHEM RES INST

Continuous oil pipe logging auxiliary treatment device and method

The invention relates to a continuous oil pipe logging auxiliary treatment device and method. A setting device is connected to the lower end of a lining pipe, a setting wrench is aligned with the setting device for rotation, the lining pipe moves downwards, a lock spring drives a cone body to move upwards, a seal rubber cylinder is extruded to expand to achieve seal, the lower end of a seal tetrafluorohydrazine protection pad connected with a continuous oil pipe is connected with a transition joint, the lower portion of the transition joint is provided with a seal rubber ring and an opening supporting ring, a seal protection sleeve is movably connected with the transition joint through the opening supporting ring, the tail end of a test cable carries out connection on a test tube throughconnection with a test wiring head, and the lower end of the test tube is provided with a guiding shoe. The device has the beneficial effects that due to split design, manufacturing is easy and reliable, no welding exists, heating of an electronic element is avoided, meanwhile, fixing of the electronic element is added, use of the electronic element is firmer and more reliable, and compared with an original direct abut-welding process, the breakage phenomenon due to a fragile and rigid welding opening can be overcome.

Owner:DONGYING VOCATIONAL COLLEGE

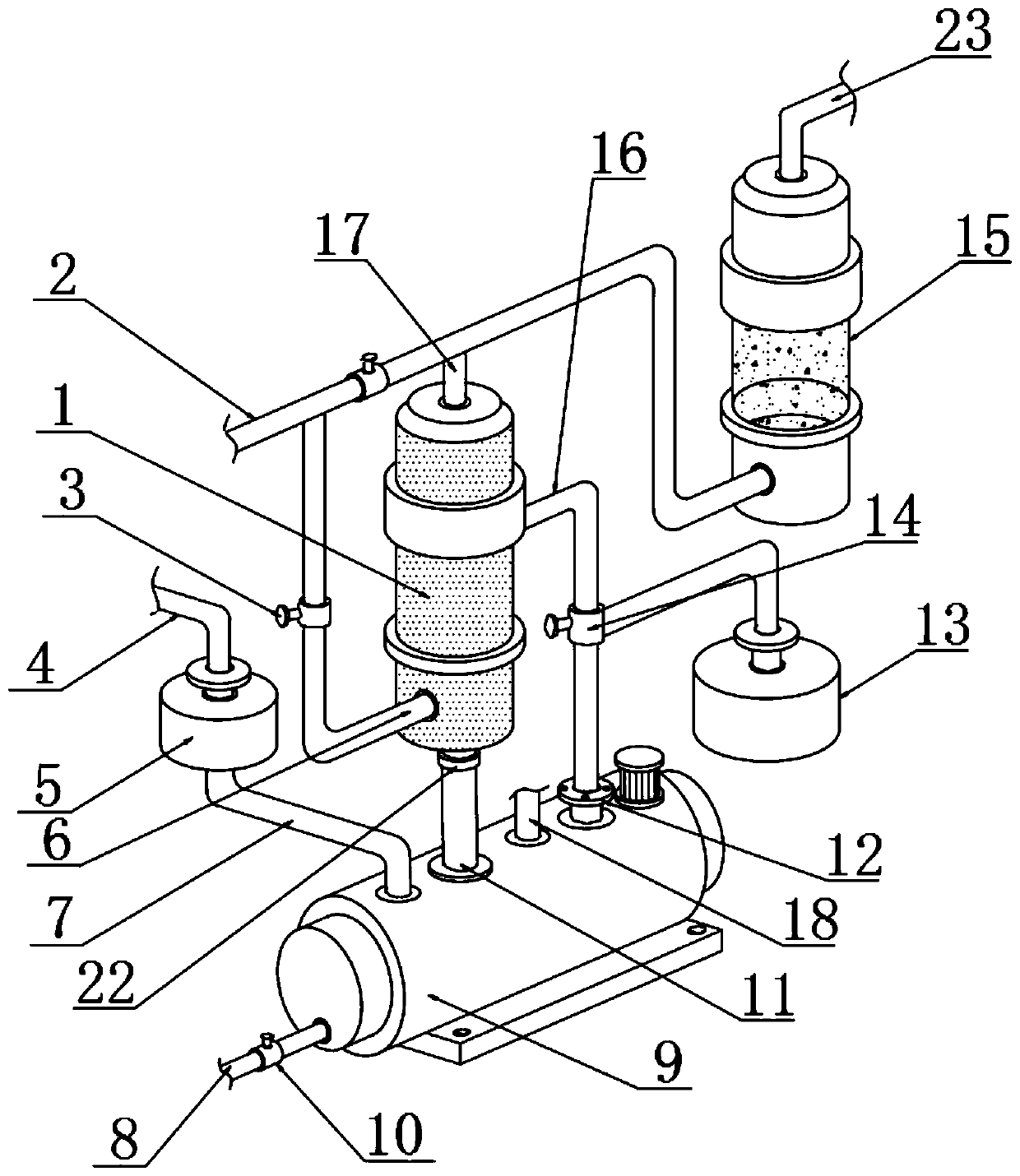

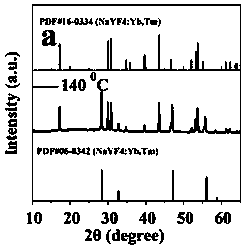

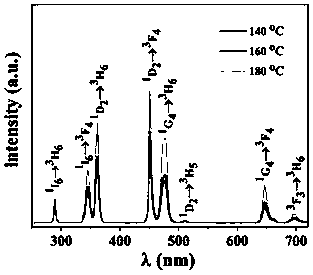

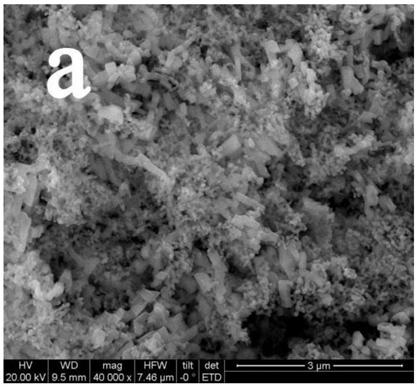

Method for preparing Yb and Tm doped sodium yttrium tetrafluorohydrazine

InactiveCN109679655AEasy to operateHigh purityChemical industryLuminescent compositionsCalcium Chloride HexahydrateYtterbium chloride

The invention relates to a method for preparing Yb and Tm doped sodium yttrium tetrafluorohydrazine and belongs to the technical field of fluorescent nano material preparation. A hydrothermal method is adopted for preparation. The method is basically characterized by comprising the following steps: taking deionized water and N-methyl pyrrolidone as solvents, and ytterbium chloride hexahydrate, thulium chloride hexahydrate and yttrium chloride hexahydrate as raw materials, mixing and stirring, adding sodium fluoride, putting the mixed liquid into a reaction kettle, carrying out thermal treatment for 12 hours at 140-180 DEG C, naturally cooling to the room temperature, centrifuging, collecting a sample, and washing with deionized water and absolute ethyl alcohol three times to obtain a hexagonal and cubic mixed phase or pure hexagonal phase-phase sodium yttrium tetrafluorohydrazine upconversion fluorescence material. Under excitation of laser of 980nm, the material has a very good fluorescence property, and has a main emission peak at 362nm, 451nm and 475nm. The method is simple to operate and good in energy conservation, greenness and environment protection, and the prepared productis high in fluorescence strength, wide in application range and easy to popularize and produce.

Owner:ANHUI UNIV OF SCI & TECH

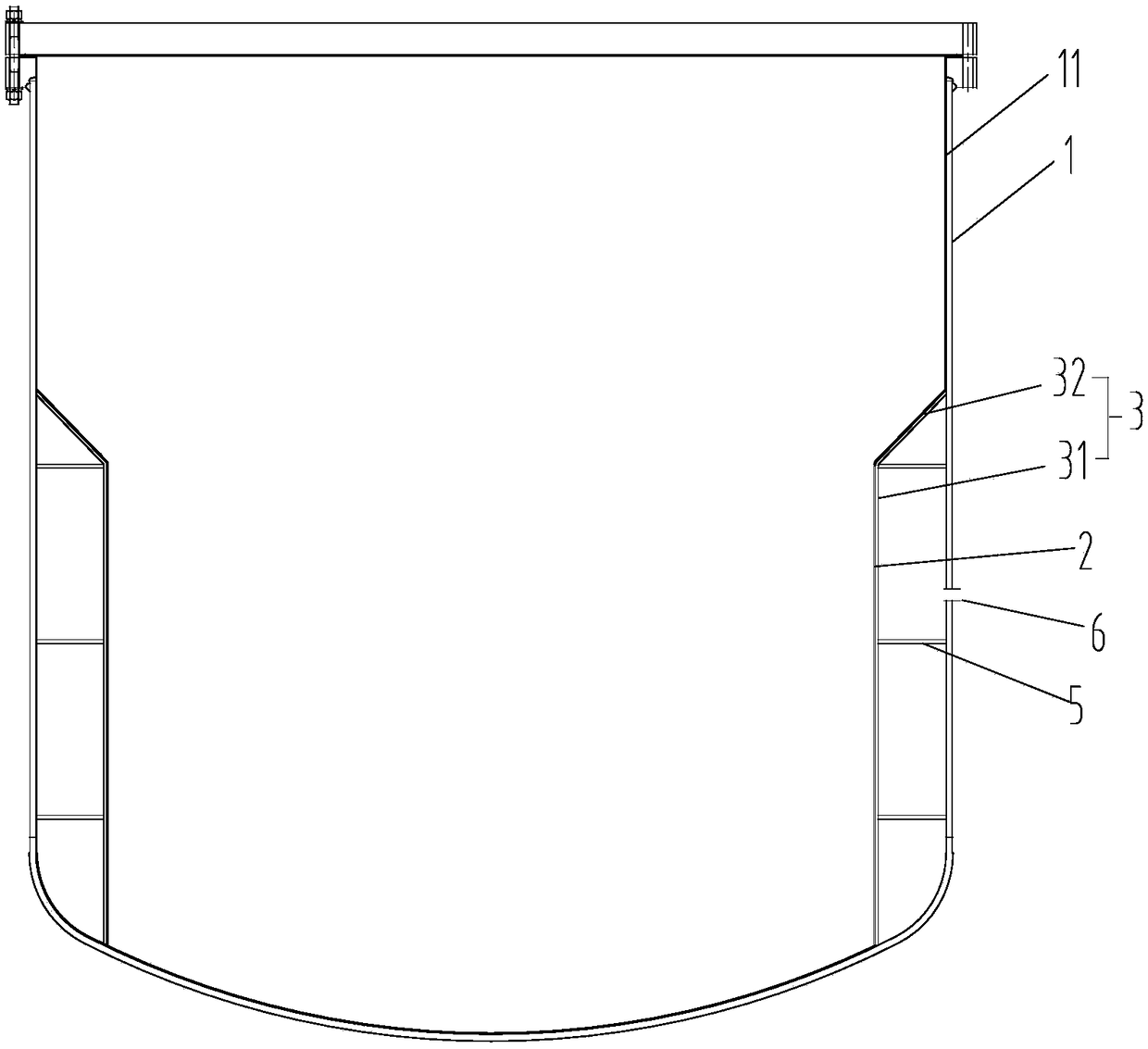

Tetrafluorohydrazine lining reaction kettle

PendingCN109261103AIncreased turbulenceImprove stabilityChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsControl engineeringTetrafluorohydrazine

The present application discloses a tetrafluorohydrazine lining reaction kettle comprising a reaction kettle body, a first tetrafluorohydrazine lining, a second tetrafluorohydrazine lining and a flowblocking assembly. The first tetrafluorohydrazine lining is disposed on the inner wall of the reaction kettle body, the flow blocking assembly is fixed on the inner wall of the reaction kettle body, and the second tetrafluorohydrazine lining is arranged on the flow blocking assembly. By arranging the flow blocking assembly in the reaction kettle body and arranging the second tetrafluorohydrazine lining on the flow blocking assembly, during the stirring, materials continuously collide with the flow blocking assembly, the materials are dispersed evenly, and thus full reaction is performed; the materials in the reaction kettle body are prevented from forming a vortex, a turbulent flow in the reaction kettle body is added, thereby improving overall stability of the reaction kettle body, also improving stirring efficiency and production efficiency, and also reducing the abrasion of the first tetrafluorohydrazine lining in the reaction kettle body after the materials form the vortex.

Owner:四达氟塑股份有限公司

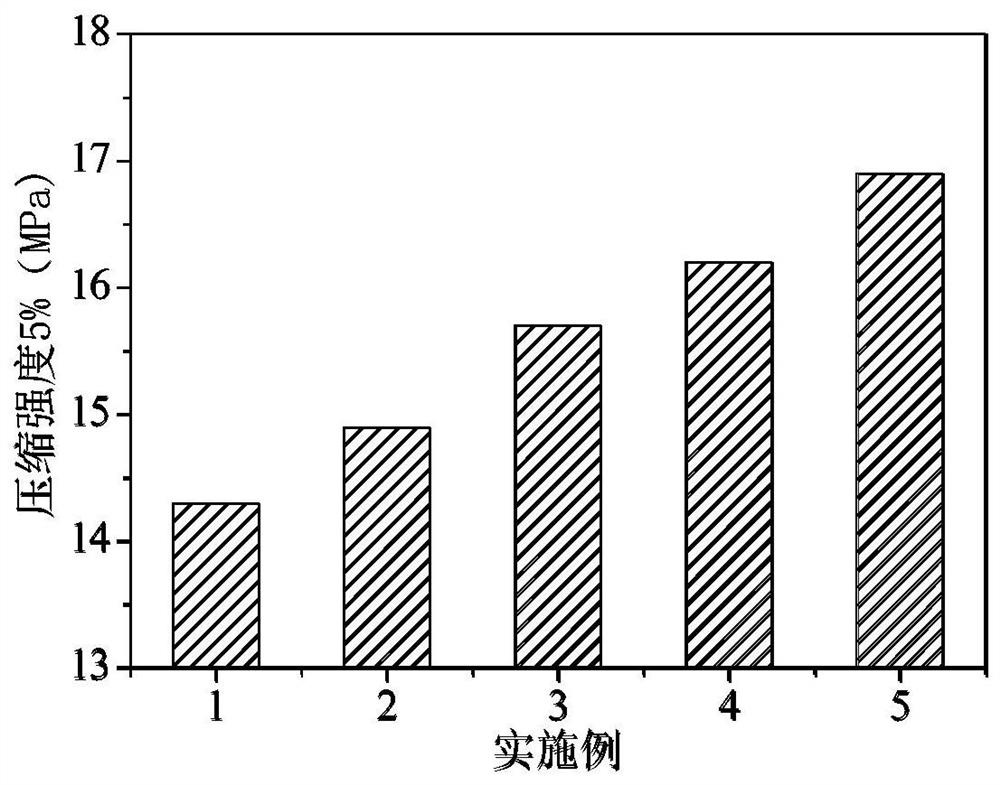

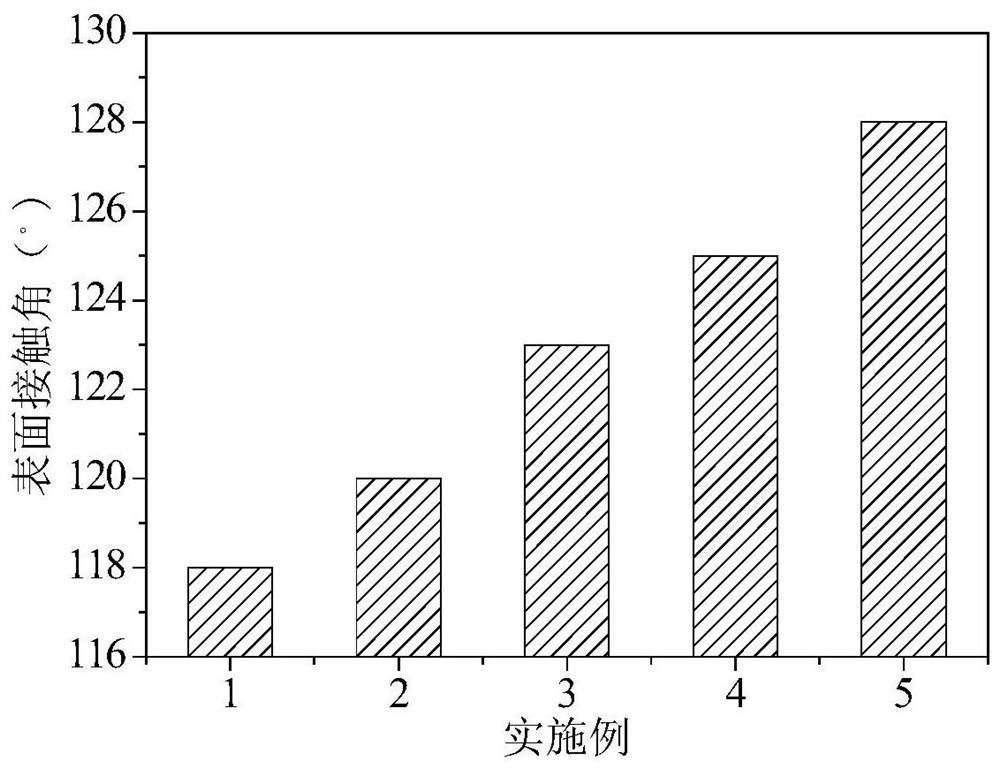

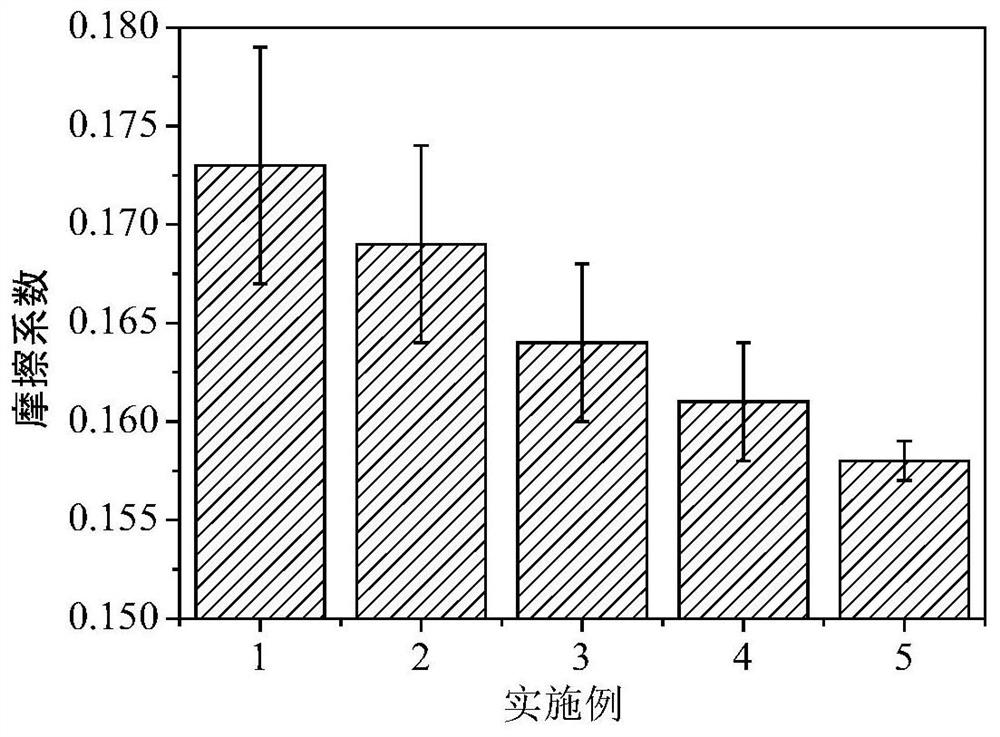

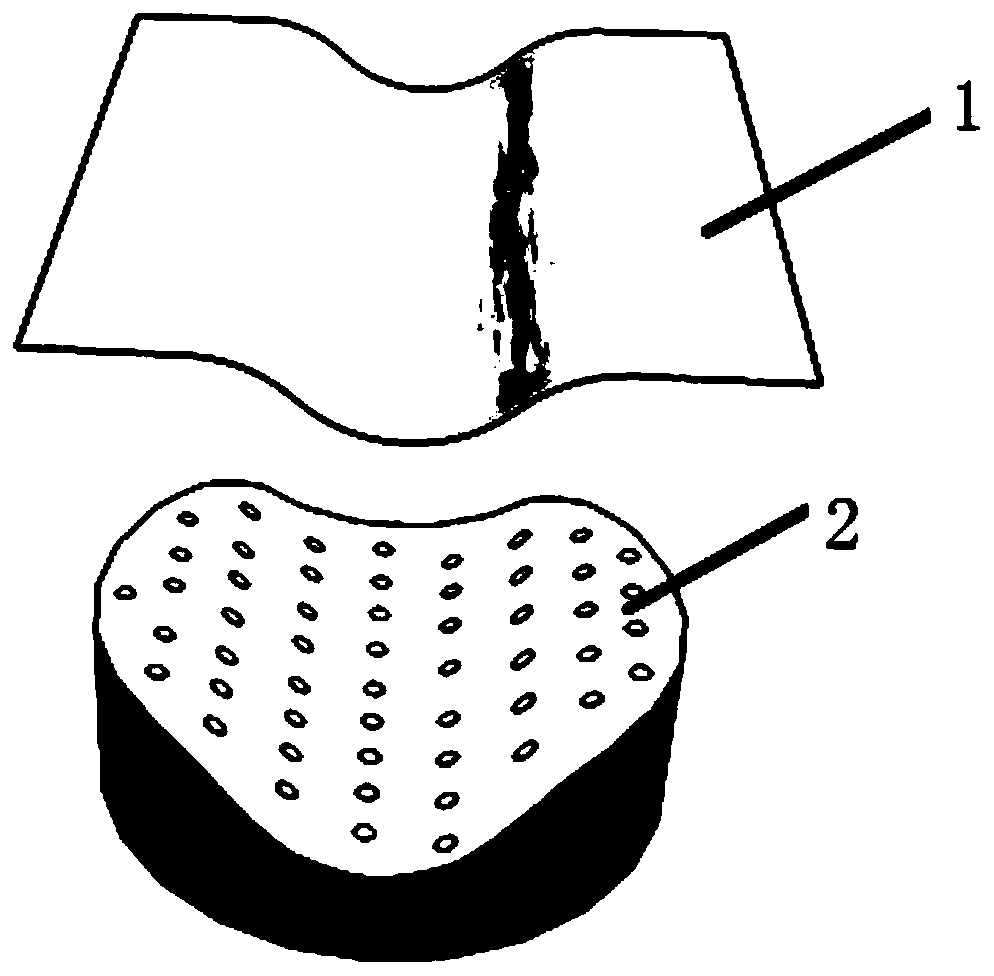

Fluorinated graphene-modified polytetrafluoroethylene composite material for ultrasonic motor and preparation method thereof

ActiveCN109762281BLower surface free energyGuaranteed startup reliabilityAluminum silicateUltrasonic motor

The invention provides a fluorinated graphene modified polytetrafluoroethylene composite material for an ultrasonic motor, and a preparation method of the fluorinated graphene modified polytetrafluoroethylene composite material. The fluorinated graphene modified polytetrafluoroethylene composite material is characterized by being prepared from the following raw materials in parts by weight: 100 parts of polytetrafluoroethylene, 1-5 parts of fluorinated graphene, 1-5 parts of multiwalled carbon nanotubes, and 1-5 parts of aluminium silicate. The preparation method of the fluorinated graphene modified polytetrafluoroethylene composite material comprises the steps that composite powder is subjected to ball milling, evenly mixed, and then added into a die for cold press molding, the die pressure is 10-20 MPa, the pressure is maintained for 10-20 minutes, then die releasing is conducted, sintering is conducted in a tetrafluorohydrazine sintering furnace, and the temperature is 360-380 DEG C. The fluorinated graphene modified polytetrafluoroethylene composite material has the low surface energy, high mechanical strength, stable friction coefficient and ultra-low abrasion rate, starting failure and adhesive abrasion caused by the fact that the friction interface of the ultrasonic motor is stored with pressure for a long time can be lowered, the storing stability of the ultrasonic motor is greatly improved, and the service life of the ultrasonic motor is greatly prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A method for installing prefabricated beams and slabs with one-way restraint of corrugated PTFE rubber bearings

ActiveCN108103941BAvoid vertical sliding failureEasy to useBridge structural detailsBridge erection/assemblyEngineeringSilicone grease

The invention discloses an installing method of a wave surface tetrafluorohydrazine plate rubber support one-way constraint prefabricated beam plate. Certain constraint force is exerted on a prefabricated beam in the installing process, and the disadvantages that due to omnibearing movement of the prefabricated beam, the installing position is uneasy to control and a slip accident easily occurs are avoided; the use of tetrafluorohydrazine plate rubber support silicone grease oil is guaranteed, longitudinal slide failure of the support is avoided, and the service life of the support is prolonged; in the later using process of a bridge, elastic constraint force is exerted on the prefabricated beam, part of impact force of a vehicle and seismic force can be buffered, and anti-impact and seismic performance of the bridge is improved. By means of the installing method of the wave surface tetrafluorohydrazine plate rubber support one-way constraint prefabricated beam plate, the installing efficiency and position accuracy of the prefabricated beam are improved, the service life of the support and the beam plate is prolonged, materials are saved, environmental pollution is reduced, the time in the installing process is greatly shortened, repeated use of a machine is reduced, and the installing method is significant in safety of the installing, constructing and operating stage of the prefabricated beam.

Owner:雨发建设集团有限公司

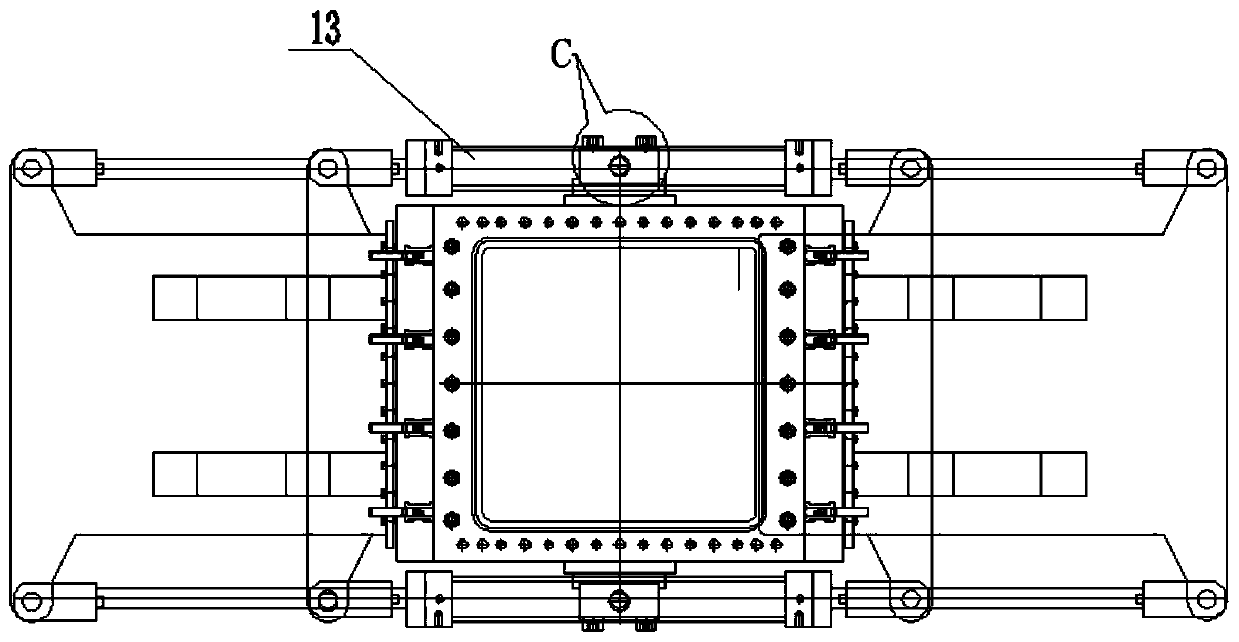

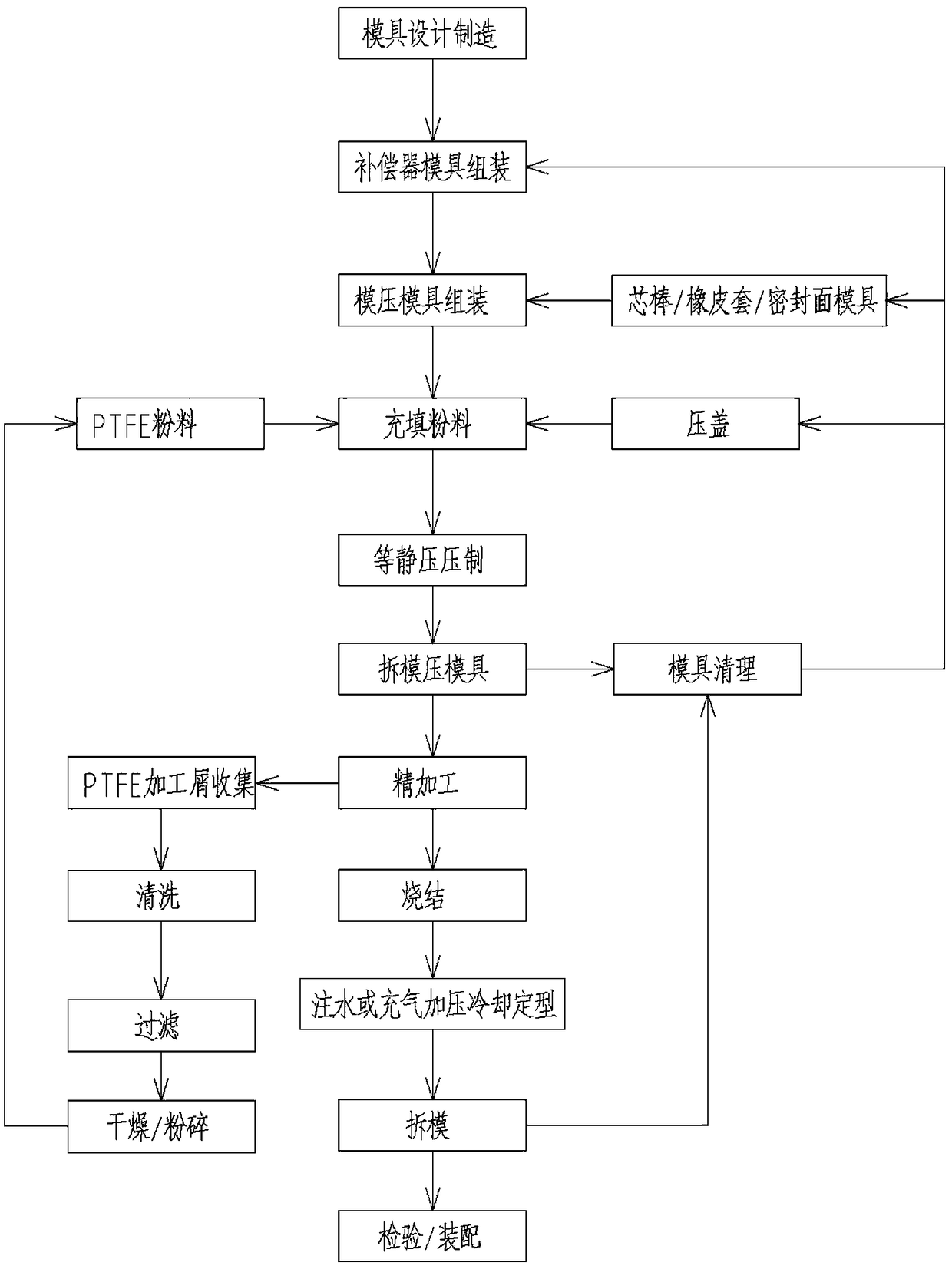

Polytetrafluoroethylene compensator and manufacturing technology thereof

PendingCN108644523ANo local tensile deformationAvoid MicroporosityPipeline expansion-compensationTetrafluoroethyleneManufacturing technology

The invention discloses a polytetrafluoroethylene compensator and a manufacturing technology thereof, and belongs to the technical field of compensators. The polytetrafluoroethylene compensator comprises a compensator die and a tetrafluorohydrazine compensator, wherein a sealing surface die is arranged on each sealing surface of the compensator die; a die pressing mandrel is arranged at one side of the compensator die; a rubber sleeve is arranged between the compensator die and the die pressing mandrel; a sealing compressing flange is mounted on the compensator die; a fastener is arranged on the sealing compressing flange; empty cavities among the sealing surface die, the compensator die and the rubber sleeve are filled with PTFE (polytetrafluoroethylene) powder; and the compensator die isof a single-wave or multi-wave form and is manufactured through a stainless steel material. The polytetrafluoroethylene compensator is simple in structure, and convenient to use, and can be insertedand formed in one time; the size is uniform; in addition, wave form is fixed, so that the thermal deformation is avoided; standardization is easily realized; local stretching deformation is avoided; micropores are avoided. Therefore, the service life is greatly prolonged; and meanwhile, waste materials are not produced in the whole circulating process, so that the energy saving and consumption reducing effects can be achieved.

Owner:NANJING FUYUAN CHEM PIPELINE EQUIP

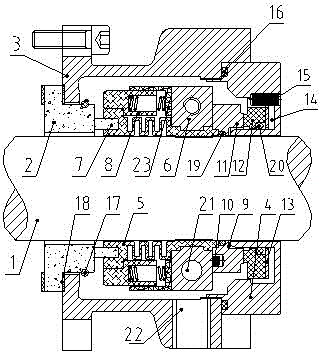

Cartridge mechanical seal without bushing and bearing

PendingCN106678073ASave raw materialsAccelerated corrosionPump componentsPumpsCooling effectEngineering

The invention discloses a double-end-face cartridge mechanical seal without a bushing and a bearing. A front static ring, a front gland and a rear gland are arranged on the outer side of a pump body and sequentially connected, the front static ring, the front gland, the rear gland and the pump body are closed to form a cavity, and a pump shaft is connected with a tetrafluorohydrazine corrugated pipe in the cavity; and the surface of the front static ring and the surface of a front movable ring formed by embedding silicon carbide into the tetrafluorohydrazine corrugated pipe are matched to form a first grinding face, a half sub half ring is clamped to the rear end of the tetrafluorohydrazine corrugated pipe, a limiting wearproof piece is arranged at the rear end of the half sub half ring, a cylindrical pin is arranged between the limiting wearproof piece and the half sub half ring and is in transmission fit with a cold movable ring at the rear end, and the cold movable ring, a cold static ring, a push ring and a second elastic compensation element are sequentially connected with the rear end of the limiting wearproof piece. The surface of the cold movable ring and the surface of the cold static ring are matched to form a second grinding face. The cartridge mechanical seal has the beneficial effects of being capable of saving energy, environmentally-friendly, good in cooling effect, efficient in seal, light and handy in size, wide in application range and low in manufacturing cost and solves the problems that mechanical seal fails due to dry grinding caused by unsmooth supply, blockage, local vacuum and the like of a medium in the equipment operation process.

Owner:ZHANGJIAGANG XINQUAN SEALS CO LTD

Corrosion-resisting quick coupling

InactiveCN108679336AQuick installationQuick disassemblySleeve/socket jointsJoints with sealing surfacesCouplingLantern

The invention discloses a corrosion-resisting quick coupling. The quick coupling comprises a fixing socket and a male plug matched with the fixing socket. A sealing component, a holder, a first elastic lantern ring and a pressing sleeve are arranged in the fixing socket from inside to outside in sequence. The pressing sleeve is fixedly connected with the fixing socket. A top cover is arranged in the pressing sleeve, and a through hole allowing the male plug to penetrate through is formed in the top cover axially. A plurality of first openings are uniformly distributed in the inner wall of thefirst elastic lantern ring in the circumferential direction, a plurality of second openings are uniformly distributed in the outer wall of the first elastic lantern ring in the circumferential direction, and the first openings and the second openings are formed in a staggered mode. The corrosion-resisting quick coupling is simple in structure and easy to implement; the coupling is quick and convenient to mount and dismount; and the first elastic lantern ring and a second elastic lantern ring are made of the stainless steel material, a pressing component and pressing sheets are made of the tetrafluorohydrazine material, the corrosion resistance of the coupling is improved, the service life of the coupling is prolonged, in addition, the production cost is low, and the quick coupling is easier to apply and popularize.

Owner:杭州福路涂装设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com