A mechanical force-induced europium-coordinated red photopolymer film and its preparation method

A technology of polymer films and europium complexes, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of phase separation, low luminous efficiency, mismatched emission spectrum and ultraviolet absorption spectrum, etc. The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a europium-coordinated red photopolymer film induced by mechanical force, comprising the following steps:

[0043] (1) The complex Eu(TTA) of 30mg europium 3 (Aphen), 1mL of methyl acrylate, 6mg of azobisisobutyronitrile dissolved in 6mL of N,N-dimethylformamide, deoxygenated by freezing, heated and stirred at 60°C for 60h under the protection of argon, poured into methanol Settling to obtain linear polymethylacrylate (linear-Eu-1) containing europium complex;

[0044] (2) Dissolve 0.3 g of linear-Eu-1 obtained in step (1), 2 mL of methyl acrylate, 10 mg of bis-adamantane-substituted 1,2-dioxetane, and 10 mg of azobisisobutyronitrile in 1 mL of tetrahydrofuran, Stir well and pour into rectangular PTFE molds. Under the condition of argon protection, react at 55°C for 12h to obtain a uniform transparent polymer film, and vacuum dry at 60°C for 12h to obtain a mechanically induced europium-coordinated red photopolymer film (Eu-PMA-1).

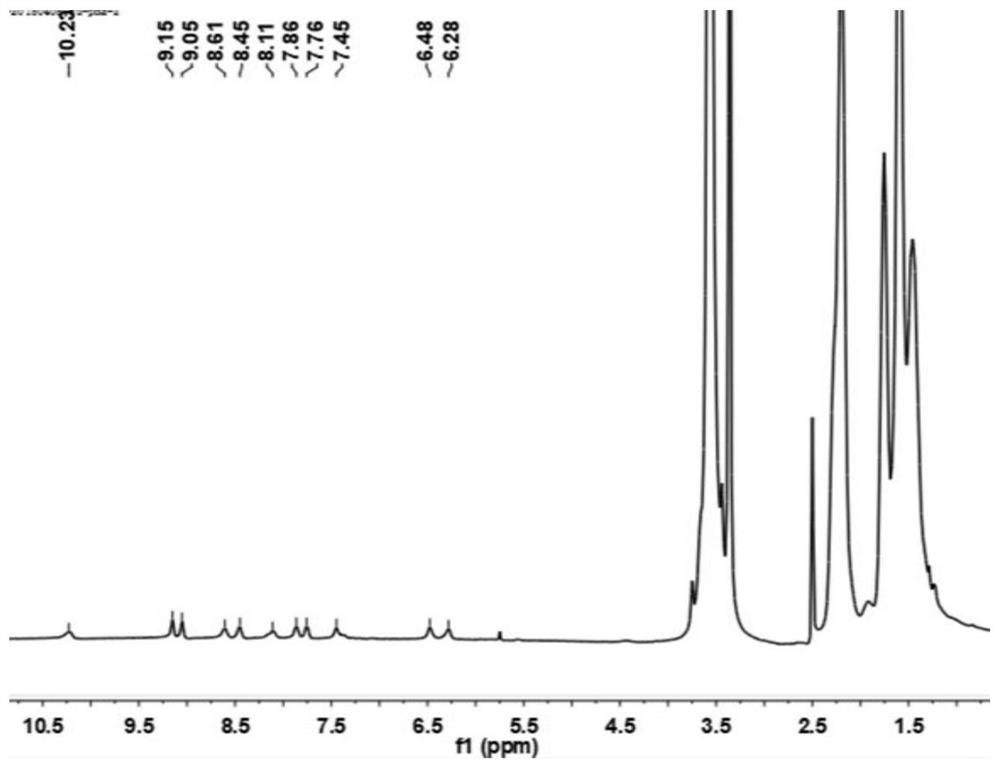

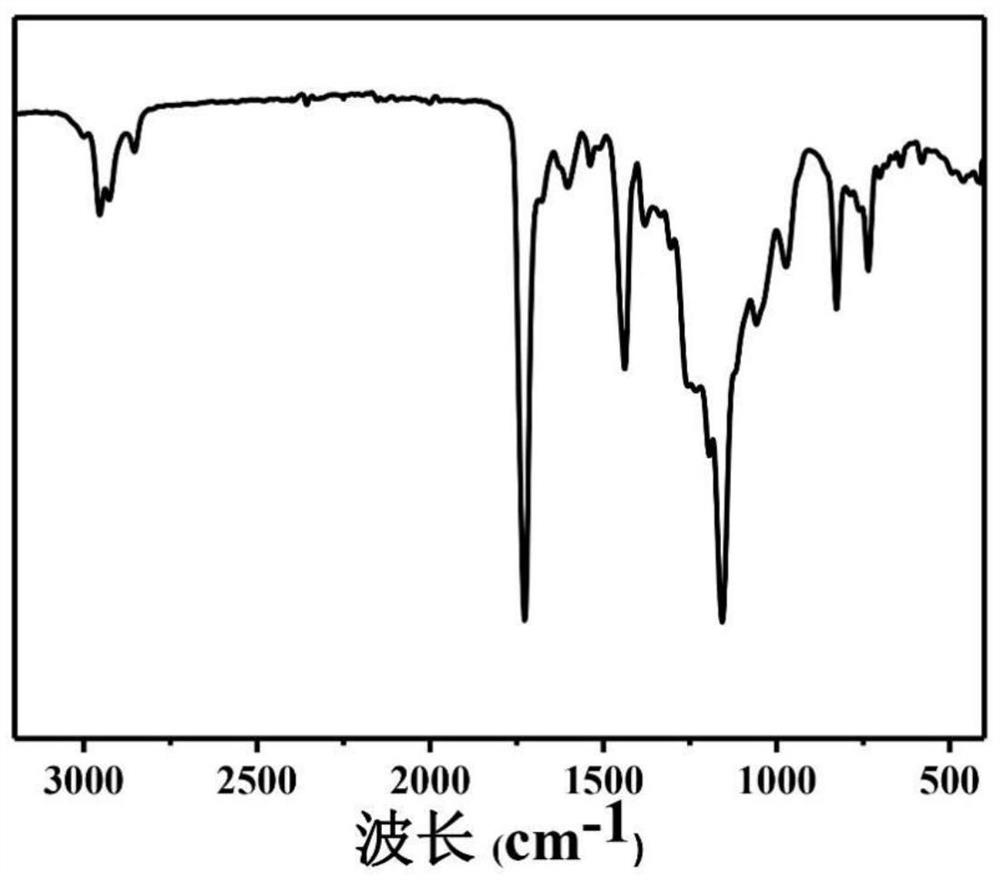

[0045] fi...

Embodiment 2

[0051] A method for preparing a europium-coordinated red photopolymer film induced by mechanical force, comprising the following steps:

[0052] (1) The complex Eu(TTA) of 50mg europium 3 (Aphen), 1mL of methyl acrylate, 6mg of azobisisobutyronitrile dissolved in 6mL of N,N-dimethylformamide, deoxygenated by freezing, heated and stirred at 55°C for 60h under the protection of argon, poured into methanol Settling to obtain linear polymethylacrylate (linear-Eu-2) containing europium complex;

[0053] (2) Dissolve 0.3 g of linear-Eu-2 obtained in step (1), 2 mL of methyl acrylate, 10 mg of bis-adamantane-substituted 1,2-dioxetane, and 8 mg of azobisisobutyronitrile in 1 mL of tetrahydrofuran, Stir well and pour into rectangular PTFE molds. Under the condition of argon protection, react at 55°C for 15h to obtain a uniform transparent polymer film, and dry it in vacuum at 55°C for 24h to obtain a mechanically induced europium-coordinated red photopolymer film (Eu-PMA-2) .

[00...

Embodiment 3

[0057] A method for preparing a europium-coordinated red photopolymer film induced by mechanical force, comprising the following steps:

[0058] (1) The complex Eu(TTA) of 100mg europium 3 (Aphen), 1mL of methyl acrylate, 6mg of azobisisobutyronitrile dissolved in 6mL of N,N-dimethylformamide, deoxygenated by freezing, heated and stirred at 65°C for 50h under nitrogen protection, poured into methanol to settle , to obtain linear polymethylacrylate (linear-Eu-3) containing europium complex;

[0059] (2) 0.3 g of linear-Eu-3 obtained in step (1), 2 mL of methyl acrylate, 10 mg of bis-amantane-substituted 1,2-dioxetane, and 15 mg of azobisisobutyronitrile were dissolved in 1 mL of tetrahydrofuran, Stir well and pour into rectangular PTFE molds. Under the condition of nitrogen protection, react at 65°C for 12h to obtain a transparent polymer film with uniform texture, and dry it in vacuum at 65°C for 12h to obtain a mechanically induced europium-coordinated red photopolymer film...

PUM

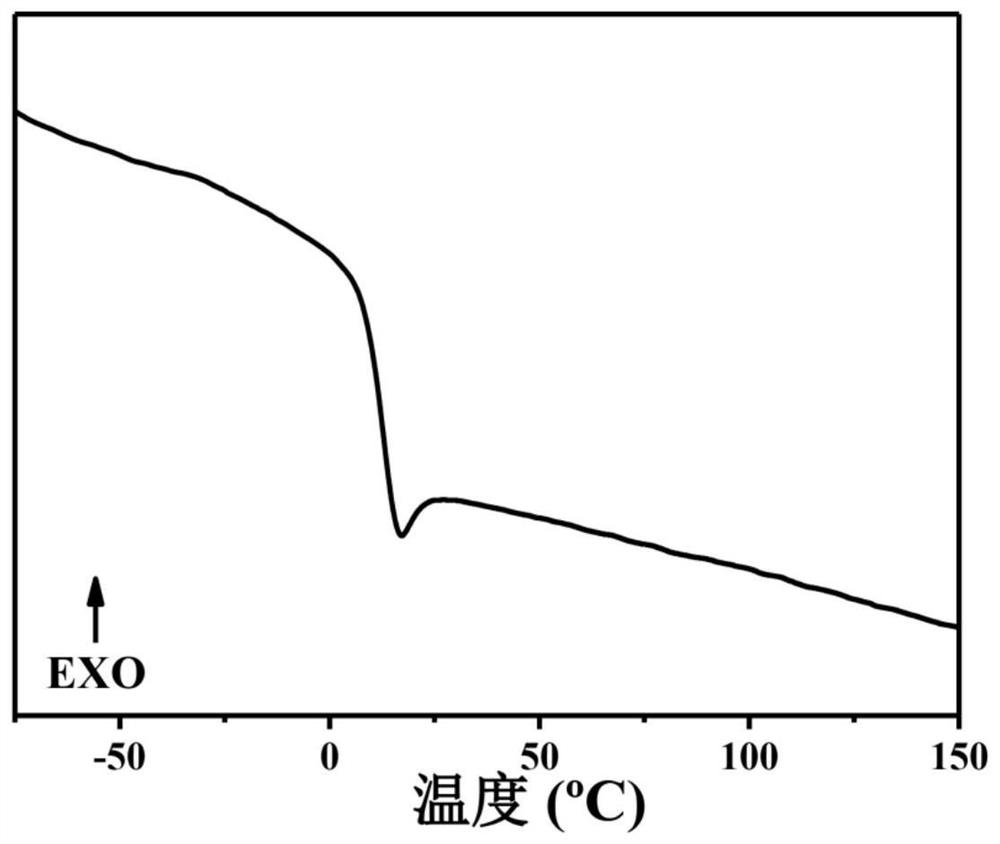

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com