Tetrafluorohydrazine lining reaction kettle

A technology of lined PTFE reaction and reactor, applied in chemical/physical/physical chemical fixed reactors, detailed information of chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve equipment Unable to operate safely and normally, insufficient stirring uniformity, increased production costs, etc., to achieve the effect of improving stirring efficiency and production efficiency, improving stability, and fully responding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

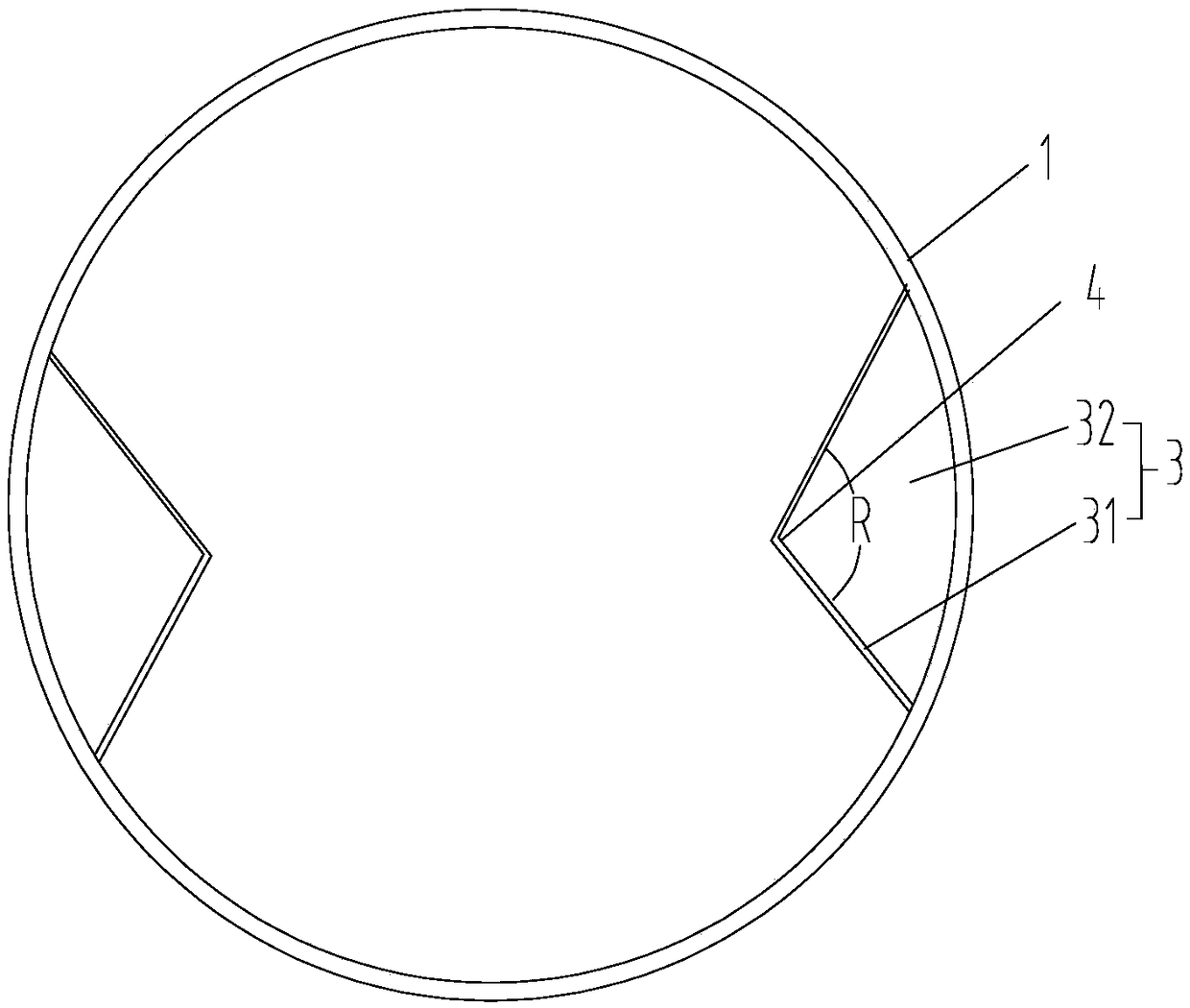

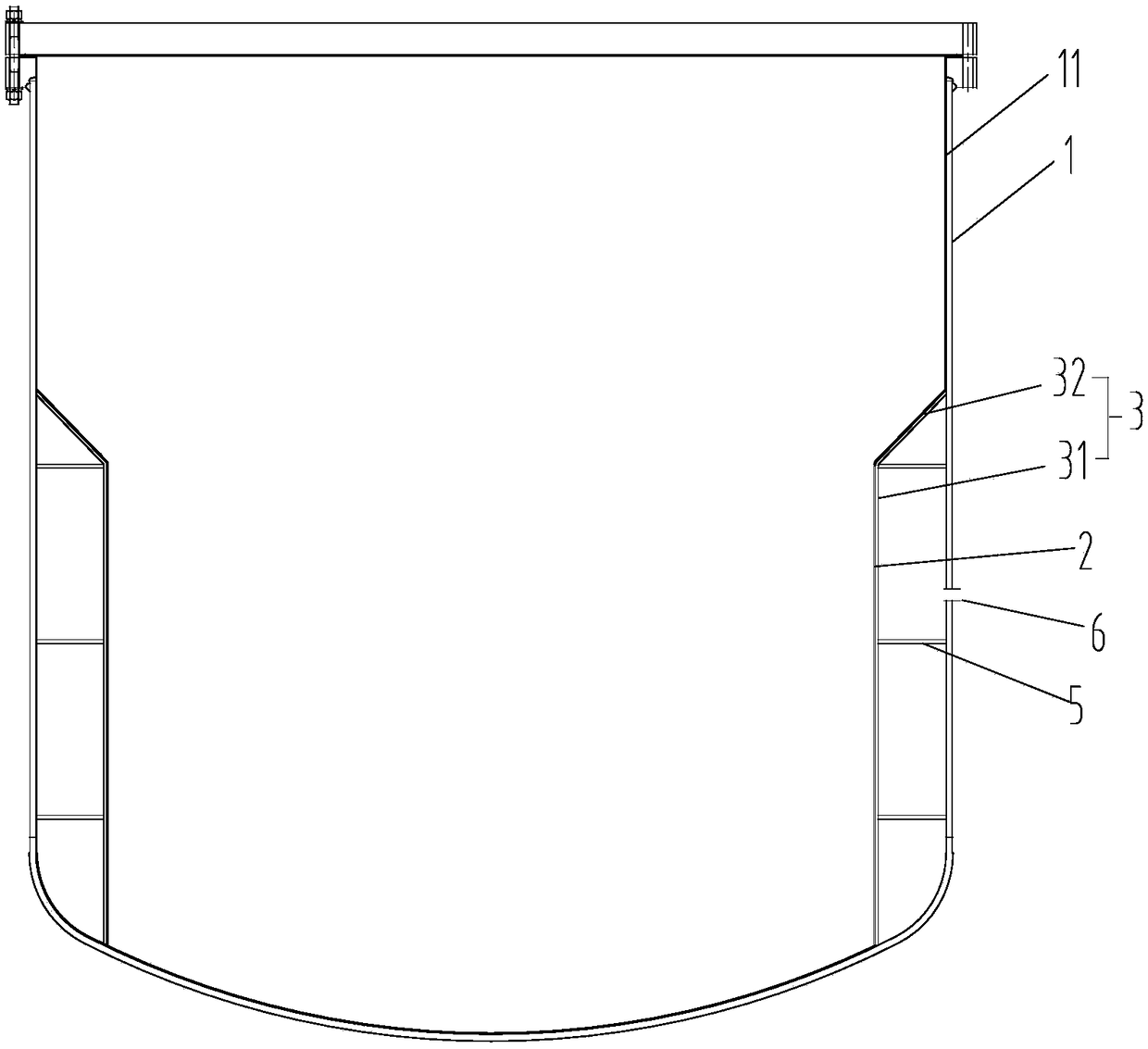

[0019] see figure 1 , 2 , the present invention provides a PTFE-lined reactor, comprising a reactor body 1, a first PTFE liner 11, a second PTFE liner 2 and a baffle assembly 3, the first PTFE liner 11 is arranged on On the inner wall of the reaction kettle body 1, the baffle assembly 3 is fixed on the inner wall of the reaction kettle body 1, and the second tetrafluoroliner 2 is arranged on the baffle assembly 3. A baffle assembly 3 is arranged in the still body 1, and a second PTFE liner 2 is arranged on the baffle assembly 3, so that the material continuously collides with the baffle assembly 3 when stirring, so that the material is more uniformly dispersed, thereby Fully react whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com