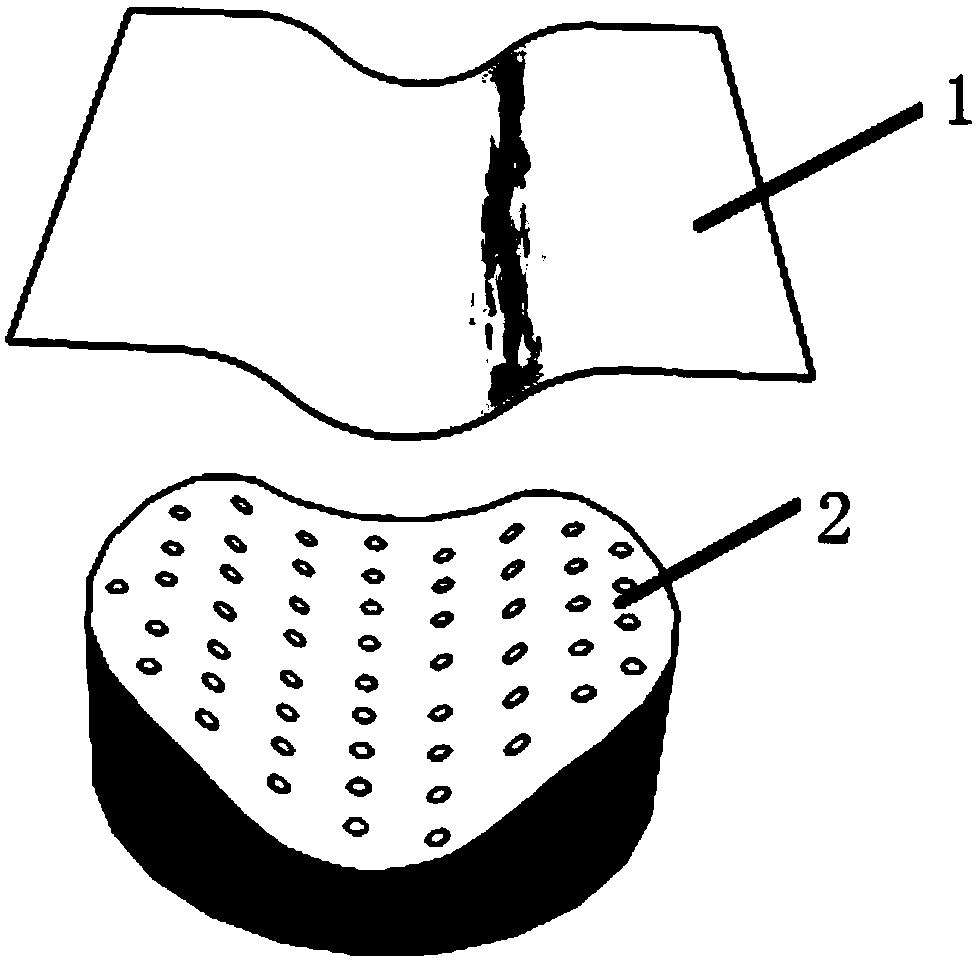

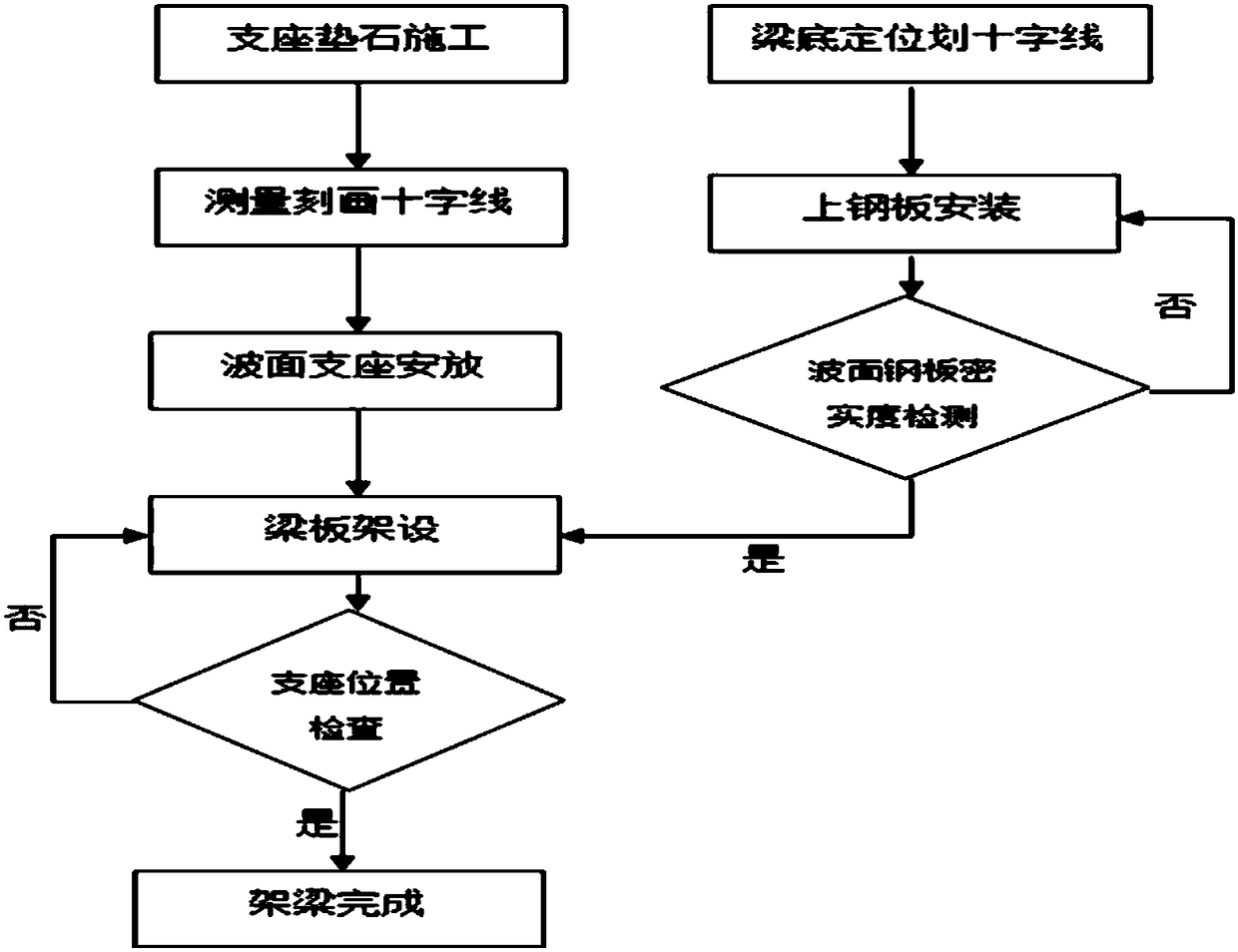

Installing method of wave surface tetrafluorohydrazine plate rubber support one-way constraint prefabricated beam plate

A technology of rubber bearings and installation methods, which is applied to bridges, bridge parts, bridge construction, etc., can solve problems such as unfavorable bridge lateral stability, sliding failure of sliding bearings, difficulty in positioning prefabricated beams, etc., to avoid longitudinal sliding failure, Improve installation efficiency and position accuracy, and increase the erection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0138] (1) Project overview

[0139] (2) Application

[0140] Among the 11 bridges in this project, the Yongning River Bridge is a new bridge, which uses pre-tensioned prestressed concrete hollow slabs, 5 spans, and a span of 20m. The original design used traditional PTFE plate rubber for 0# and 5# Bearings, considering the shortcomings of traditional bridge PTFE plate-type rubber bearings, such as large installation position deviation and prone to safety accidents, with the consent of Party A, design and supervision units, the 0# and 5# bridges of this bridge were erected In the construction of the project, the corrugated PTFE plate rubber bearing of this construction method was adopted.

example 2

[0142] (1) Project overview

[0143] (2) Application

[0144] Among the two bridges in this project, the No. 6 River bridge project has a total length of 21.04m, a single hole, and a span of 16m. The upper structure of the bridge adopts 1×16m simply supported prestressed concrete hollow slab girder, and the lower part adopts light abutment and bored pile foundation. The pile foundation is connected to the abutment cover beam. In the original design, 32 traditional PTFE rubber bearings were used in the 1# abutment. After discussion, with the consent of Party A, the design and supervision unit, the corrugated PTFE rubber bearings were used instead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com