Mutual-pulling type vertical turning construction method for steel towers of cable-stayed bridge

A cable-stayed bridge steel tower and construction method technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. Force deformation and other problems, to avoid high-altitude welding operations, the operation process is safe and reliable, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

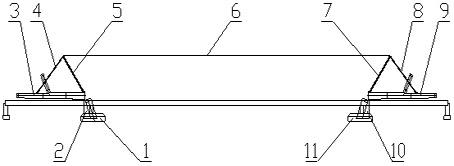

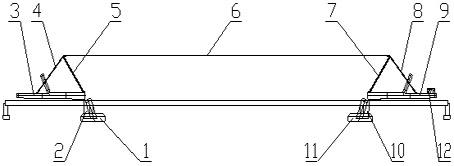

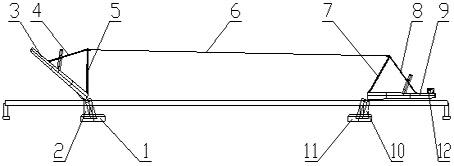

[0022] Embodiment 1: The present invention provides a construction method for a cable-stayed bridge with steel towers inter-pulling vertically. like figure 1 As shown, first, on the main pier 1 of the left bridge and the main pier 11 of the right bridge that have been built, the left steel tower pedestal 2 and the right steel tower pedestal 10 are respectively fixedly installed, and then the completed steel girders are used The bridge deck is used as a welding construction platform to complete the welding work of the left steel tower 3 and the right steel tower 9, and move the left steel tower 3 and the right steel tower 9 horizontally into place respectively. Left side tie bar 4 and left side depression bar 5 are installed on the steel tower 3 on the left side, constitute the left side tripod, right side tie rod 8 and right side depression bar 7 are installed on the right side steel tower 9, constitute the right side tripod. Penetrate the swivel oil cylinder with flexible lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com