Ceiling reverse supporting system structure with suspenders

A technology of reverse support and system structure, applied to ceilings, building components, building structures, etc., can solve the problems of unclear setting of ceiling reverse support, unreasonable design and construction, and difficult to guarantee welding quality, so as to avoid Horizontal and vertical deformation and cracking, avoiding high-altitude welding operations, and improving the effect of assembly adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

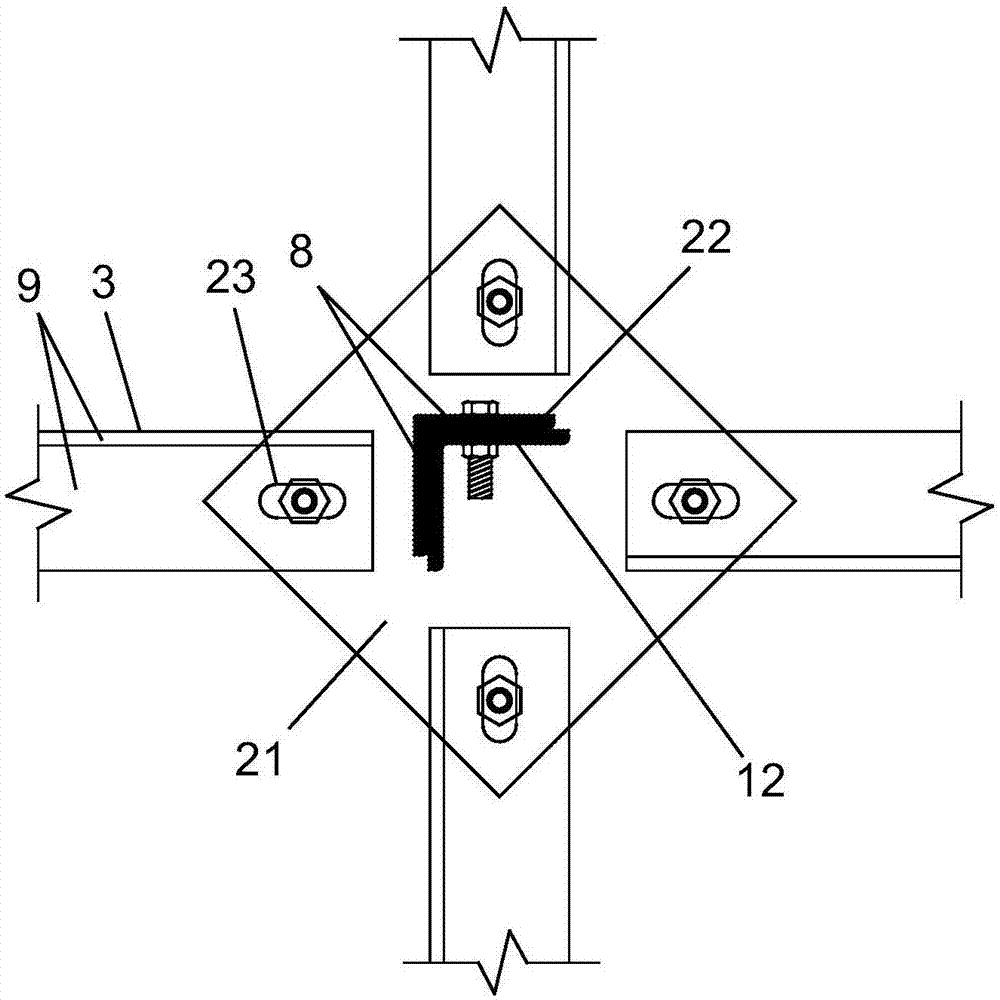

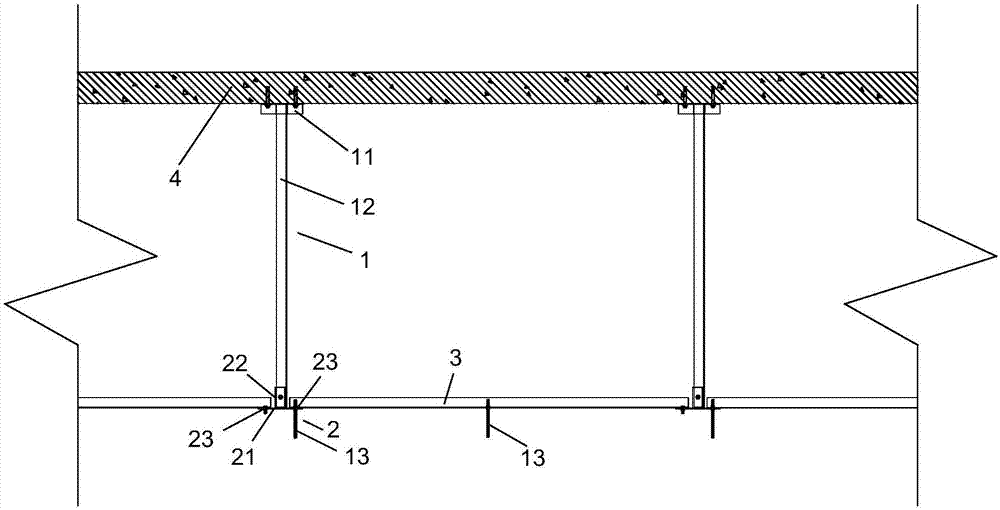

[0022] Such as figure 1 As shown, the suspended ceiling reverse support system structure with suspenders includes a plurality of reverse support frames 1 arranged in a matrix. Connecting frames 2 are installed at the bottom of the reverse support frames 1, and horizontal supports are installed between adjacent connecting frames 2. pole 3.

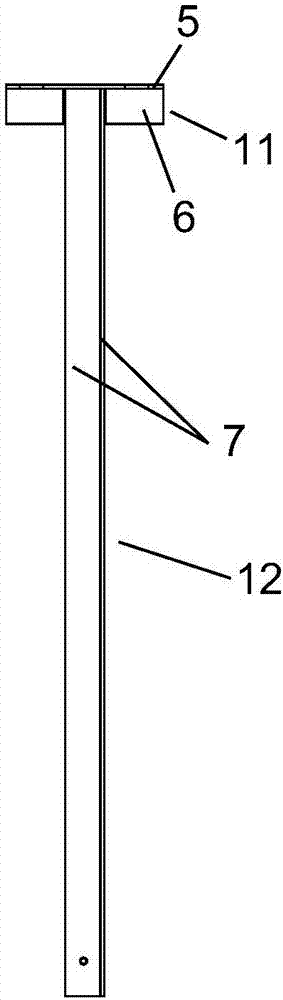

[0023] The anti-support frame 1 includes connecting angle brackets 11 and anti-support rods 12 .

[0024] The connecting angle code 11 is fixedly installed on the concrete fixture 4, and the top of the anti-support rod 12 is fixedly connected with the connecting angle code 11.

[0025] The connecting frame 2 includes a bottom plate 21, and a mounting rod 22 is arranged vertically in the center of the bottom plate 21.

[0026] The mounting rod 22 is connected to the bottom end of the counter support rod 12 .

[0027] The connection holes 23 provided at the four corners of the bottom plate 21 are connected with the ends of the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com