A semi-submersible lifting and dismantling platform crane installation method

An installation method and semi-submersible technology, applied in the field of ships, can solve the problems of semi-submersible platform structure and system complexity, inconvenient installation and disassembly, and long design cycle, so as to avoid high-altitude welding operations, reduce the overall construction period, and improve installation quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

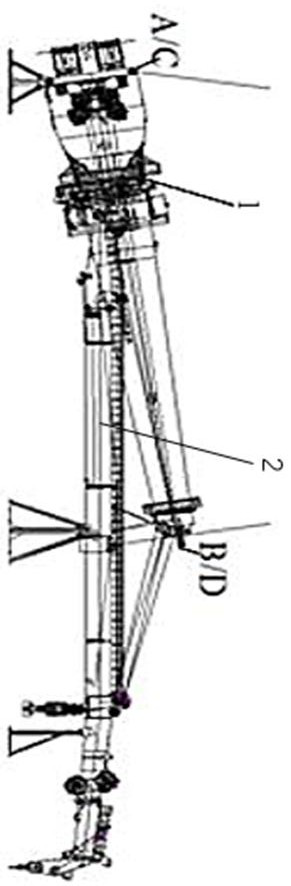

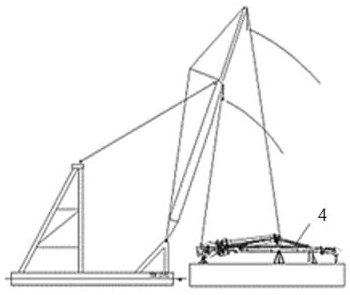

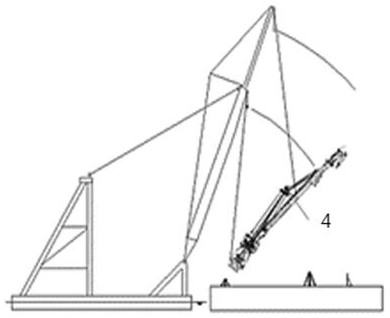

[0023] A semi-submersible lifting and dismantling platform crane installation method, the lifting steps of the crane 4 are as follows: install the general column 1 and the boom 2 through bearings on the wharf to form a complete crane 4, and then install the crane 4 Transport to the mooring position of the floating crane, first remove the fixing of the crane 4 and the transport ship, and prepare and connect the rigging as required. Connect the rigging to the lifting point of the crane according to the position of the rigging arrangement, and tighten it naturally. Hoist evenly until the crane is 0.05 meters away from the base. Then stop for 5 minutes and continue to lift after observing that there is no abnormality. The resultant force of the lifting hook force should be directly above the center of gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com