Multiple-point bearing pot type rubber support

A technology of rubber bearings and heavy pots, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of weak earthquake resistance, inability to disperse force evenly, and limited bearing capacity, so as to achieve reasonable structure, strong bearing capacity, Good anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

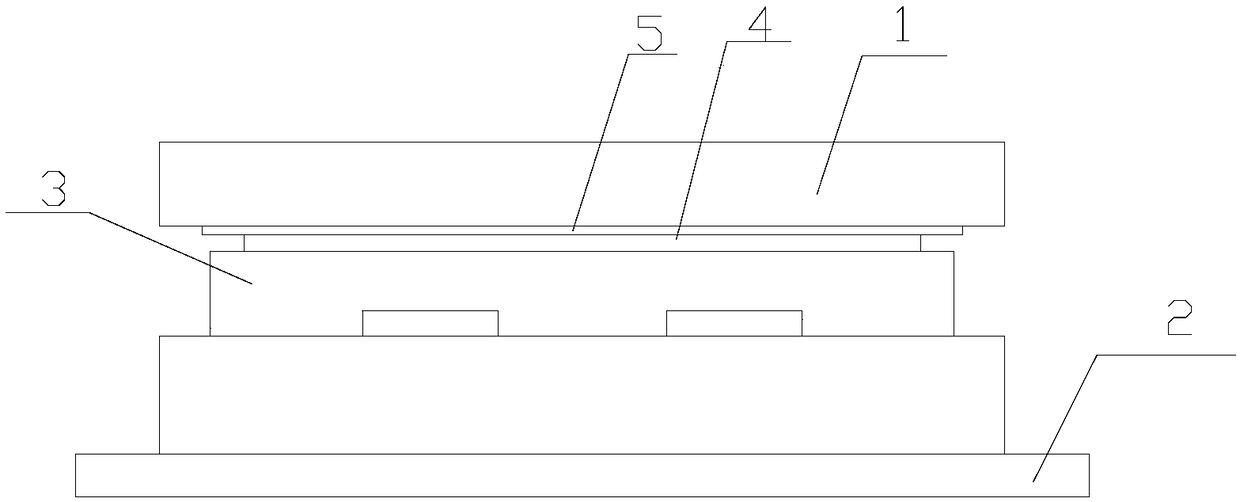

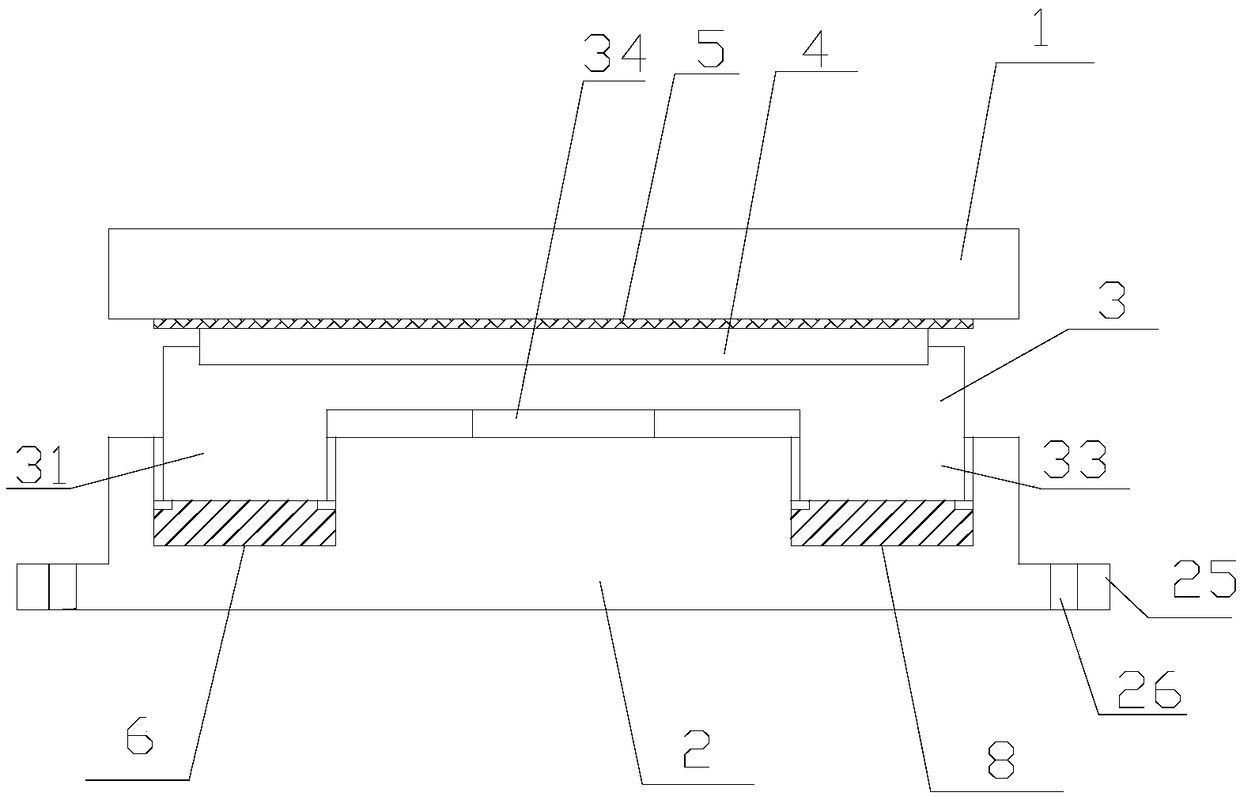

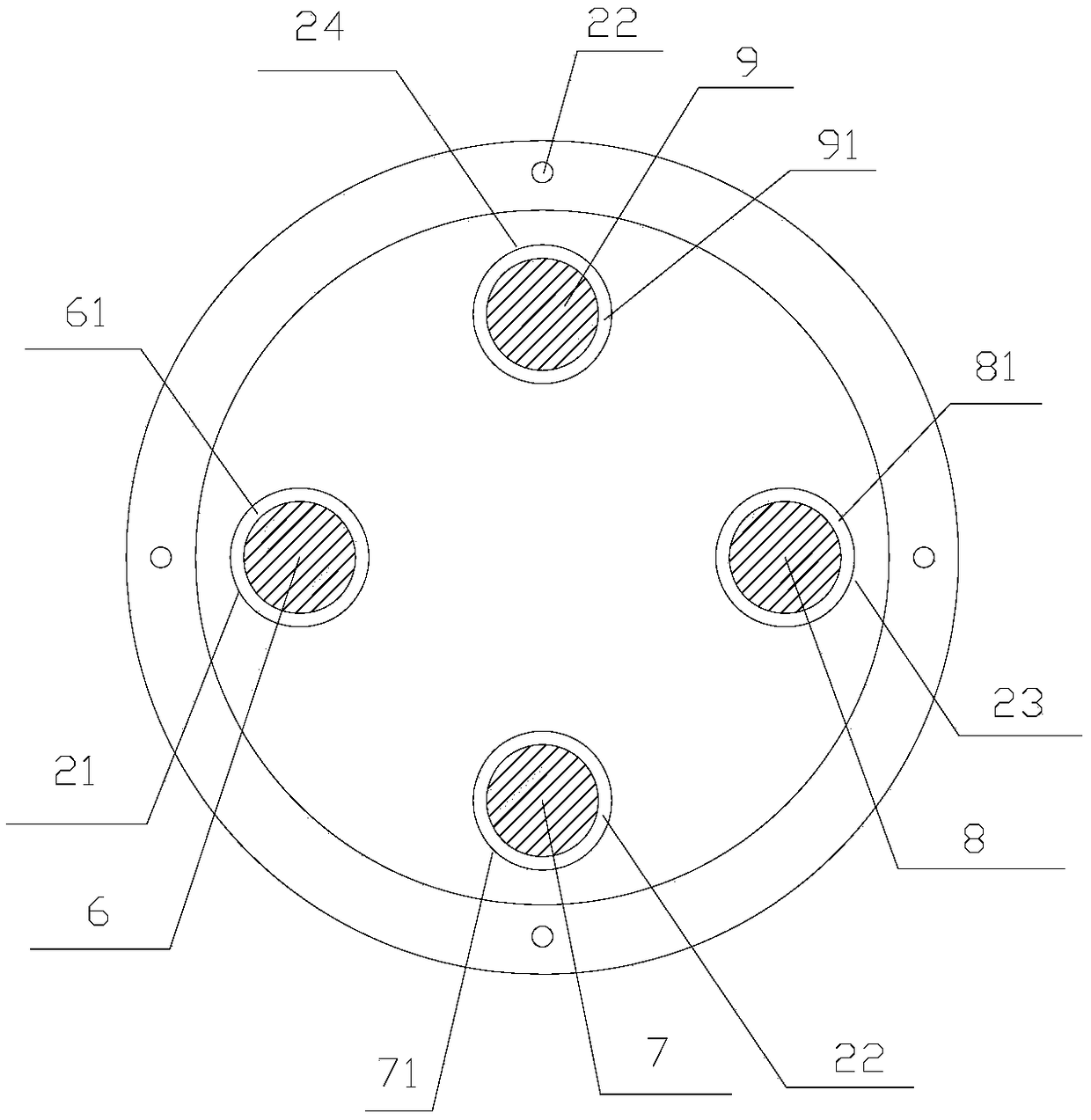

[0016] refer to figure 1 , figure 2 , image 3 with Figure 4 , a multi-point load-bearing pot rubber bearing of the present invention, comprising an upper bearing plate 1, a lower supporting base plate 2, an intermediate supporting plate 3, a PTFE sliding plate 4, a stainless steel plate 5, a first rubber pad 6, and a second rubber pad 7. The third rubber pad 8, the fourth rubber pad 9, the lower support base plate 2 is provided with the middle support plate 3, the first rubber pad 6, the second support plate 3 are provided between the lower support base plate 2 and the intermediate support plate 3 Two rubber pads 7, the third rubber pad 8, the fourth rubber pad 9, the middle support plate 3 is provided with a PTFE slide plate 4, the PTFE slide plate 4 is provided with an upper bearing plate 1, and the PTFE slide plate 4 is provided with an upper support plate 1. A stainless steel plate 5 is provided between the slide plate 4 and the upper support plate 1, the PTFE slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com