Method for preparing Yb and Tm doped sodium yttrium tetrafluorohydrazine

A technology of sodium tetrafluoroyttrium, 20min, applied in the new field of preparation of sodium tetrafluoroyttrium, can solve the problems of poor fluorescence intensity of tetrafluoroyttrium sodium, easy agglomeration of products, complicated preparation of coprecipitation method, etc., and achieve easy popularization and use, fluorescence High strength, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation steps in this example are as follows:

[0026] 1) Dissolve 30ml of N-methylpyrrolidone solution in 20ml of deionized water, stir and mix for 10min and set aside;

[0027] 2) Take 1.1mmol RCl 3 ·6H 2 O was dissolved in 5ml deionized water, in which YCl 3 ·6H 2 O is 0.2307g, YbCl 3 ·6H 2 O is 0.1263g, TmCl 3 ·6H 2 O is 0.0021g (the molar ratio of Y, Yb and Tm is 70:30:0.5, add this solution into the liquid obtained in 1), stir and mix for 30min and set aside;

[0028] 3) Weigh 554mg of NaF and dissolve it in 5ml of deionized water, then add to the mixture in 2) and stir for 30min;

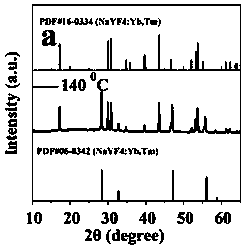

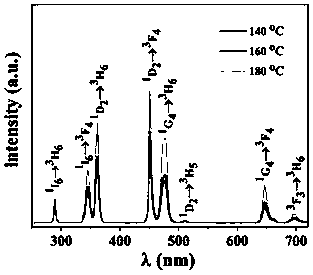

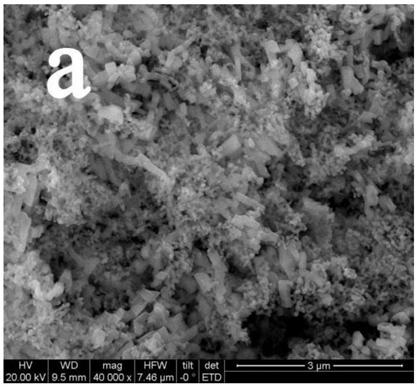

[0029] 4) Pour the mixed liquid obtained in 3) into a reaction kettle, and put it into a temperature environment of 140° C. for heat treatment for 12 hours;

[0030] 5) After the temperature of the reactor was lowered to room temperature, the obtained sample was washed by centrifugation, deionized water and absolute ethanol three times. It was further dried in an oven...

Embodiment 2

[0032] The preparation steps in this example are as follows:

[0033] 1) Dissolve 30ml of N-methylpyrrolidone solution in 20ml of deionized water, stir and mix for 10min and set aside;

[0034] 2) Take 1.1mmol RCl 3 ·6H 2 O was dissolved in 5ml deionized water, in which YCl 3 ·6H 2 O is 0.2307g, YbCl 3 ·6H 2 O is 0.1263g, TmCl 3 ·6H 2 O is 0.0021g (the molar ratio of Y, Yb and Tm is 70:30:0.5, add this solution into the liquid obtained in 1), mix and set aside;

[0035] 3) Weigh 554mg of NaF and dissolve it in 5ml of deionized water, then add to the mixture in 2) and stir for 30min;

[0036] 4) Pour the mixed liquid obtained in 3) into a reaction kettle, and put it into a temperature environment of 160° C. for heat treatment for 12 hours;

[0037] 5) After the temperature of the reaction kettle dropped to room temperature, the reaction kettle was taken out, collected by centrifugation, washed with deionized water and absolute ethanol for 3 times, and then dried in a 6...

Embodiment 3

[0039] The preparation steps in this example are as follows:

[0040] 1) Dissolve 30ml of N-methylpyrrolidone solution in 20ml of deionized water, stir and mix for 10min and set aside;

[0041] 2) Take 1.1mmol RCl 3 ·6H 2 O was dissolved in 5ml deionized water, in which YCl 3 ·6H 2 O is 0.2307g, YbCl 3 ·6H 2 O is 0.1263g, TmCl 3 ·6H 2 O is 0.0021g (the molar ratio of Y, Yb and Tm is 70:30:0.5, add this solution into the liquid obtained in 1), stir and mix for 30min and set aside;

[0042] 3) Weigh 554mg of NaF and dissolve it in 5ml of deionized water, then add to the mixture in 2) and stir for 30min;

[0043] 4) Pour the mixed liquid obtained in 3) into a reaction kettle, and put it into a temperature environment of 180° C. for heat treatment for 12 hours;

[0044] 5) After the temperature of the reaction kettle dropped to room temperature, the reaction kettle was taken out, collected by centrifugation, washed with deionized water and absolute ethanol for 3 times, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com