Fast mounted and dismounted tooth-embedded resistance-free sliding ball support

A non-resistance, tooth-clamping technology, used in bridge parts, bridges, buildings, etc., can solve the problems of inability to remove slag and repair defects, inability to locate, and difficult to process, to reduce daily maintenance workload, and to achieve accurate and simple positioning. Convenient, overall compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

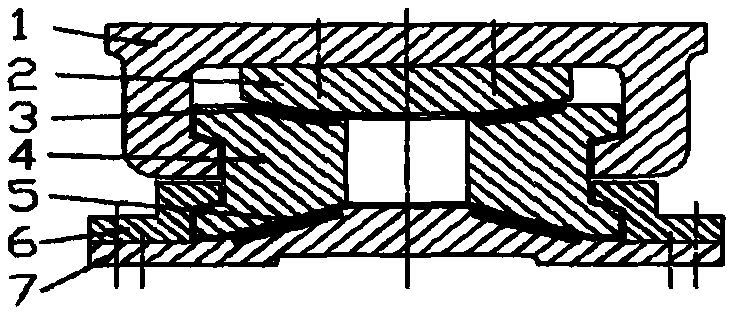

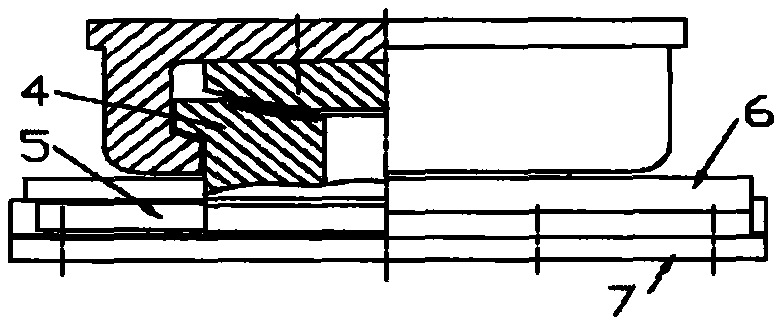

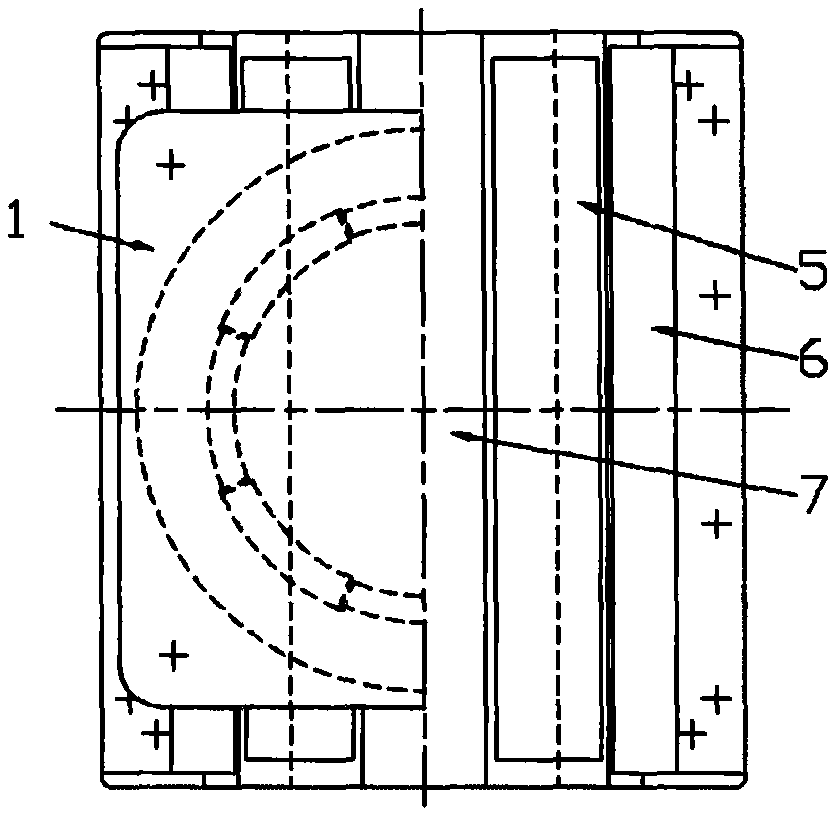

[0038] A quick-loading and dismounting tooth-clamped sliding ball bearing without resistance, comprising an upper bearing 1, a spherical crown lining plate 2, a spherical tetrafluoro sliding ring 3, a movable slider 4, a tetrafluoro sliding plate 5, a pressure plate 6, and a lower bearing 7.

[0039] The upper support 1 has four serrated inner teeth and a movable slider 4 with four serrated outer teeth to form a tensile, shear and torsion resistance device; the spherical crown-shaped lining plate 2 and the upper support 1 are integrally connected. The spherical tetrafluoro sliding ring 3 embedded on the movable slider 4 together constitutes a device without internal stress; the movable slider 4 and the tetrafluoro sliding plate 5 embedded on the convex surface of the lower support 7 together constitute a device with accurate positioning and a certain sliding direction; the pressure plate 6 Together with the lower support 7, the movable sliding block 4 is formed to move the chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com