Superposition beam structure for prefabricated bridge surface plate and steel beam close combination

A bridge deck and composite beam technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of intermittent and discontinuous shear force transmission, stress concentration, and poor connection strength, so as to improve the longitudinal distribution length of load and improve Stress state, increase the effect of spanning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

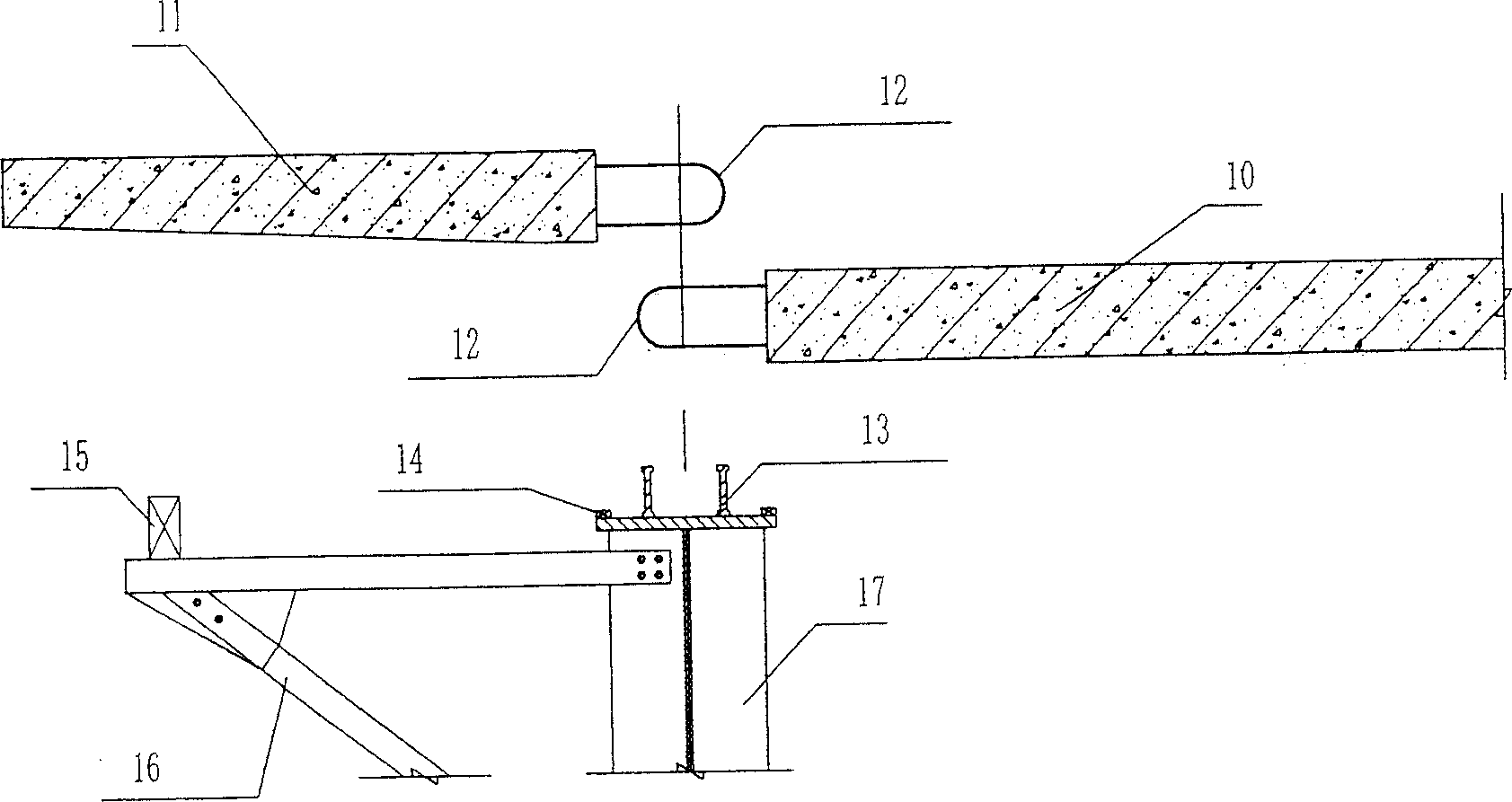

[0051] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

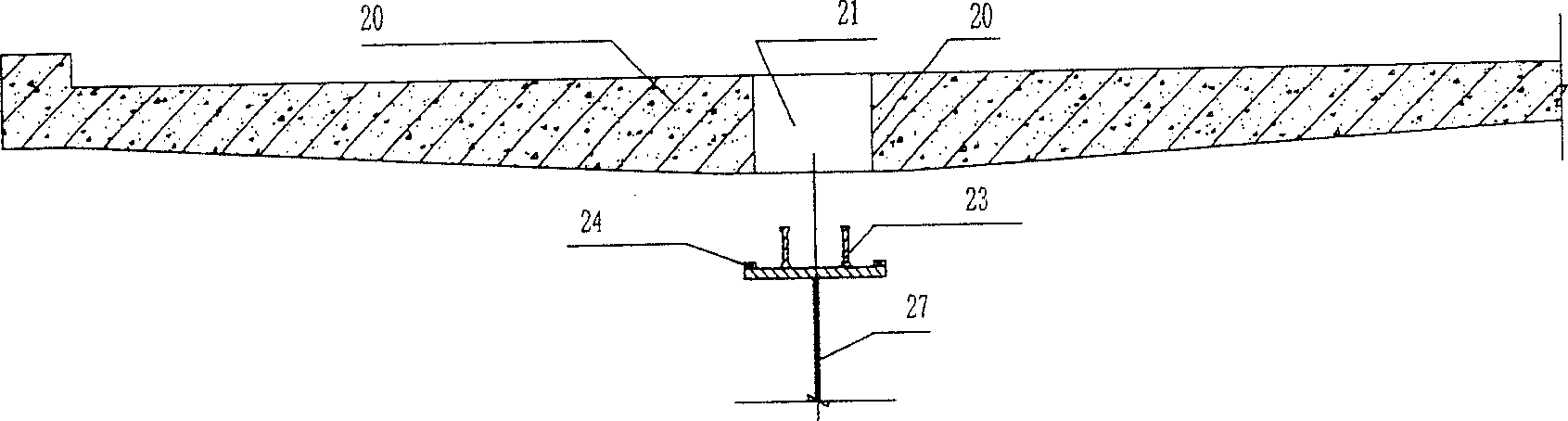

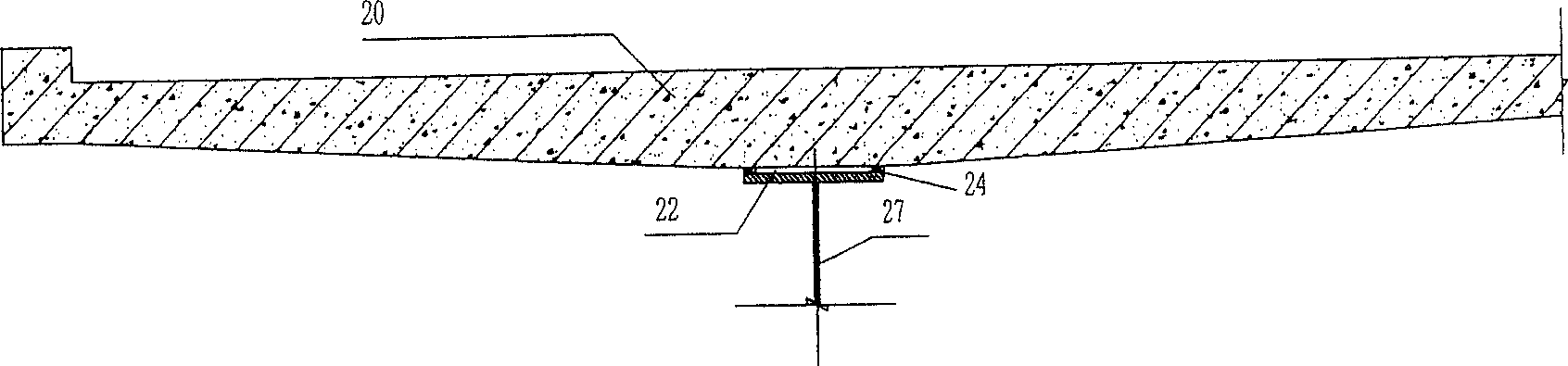

[0052] In this specification, let the edge of the plate perpendicular to the direction of the bridge body be the end, let the edge of the plate parallel to the direction of the bridge body be the wing, and assume that pouring a prefabricated concrete bridge deck on the steel girder is the first phase of on-site pouring. Adjacent bridge decks that have been poured on steel girders are connected together for the second phase of in-situ pouring. see Figure 5 , as shown in 6, the composite beam structure in which the prefabricated bridge deck and the steel beam are closely combined in the present invention includes:

[0053] Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com