Fluorinated graphene-modified polytetrafluoroethylene composite material for ultrasonic motor and preparation method thereof

A technology of polytetrafluoroethylene and fluorinated graphene is applied in the fields of fluorinated graphene modified polytetrafluoroethylene composite materials for ultrasonic motors and their preparation, and wear-resistant materials for ultra-drought motors, which can solve the problem of poor creep resistance. , short service life, low wear rate and other problems, to achieve the effect of improving mechanical strength, improving creep resistance, and low surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

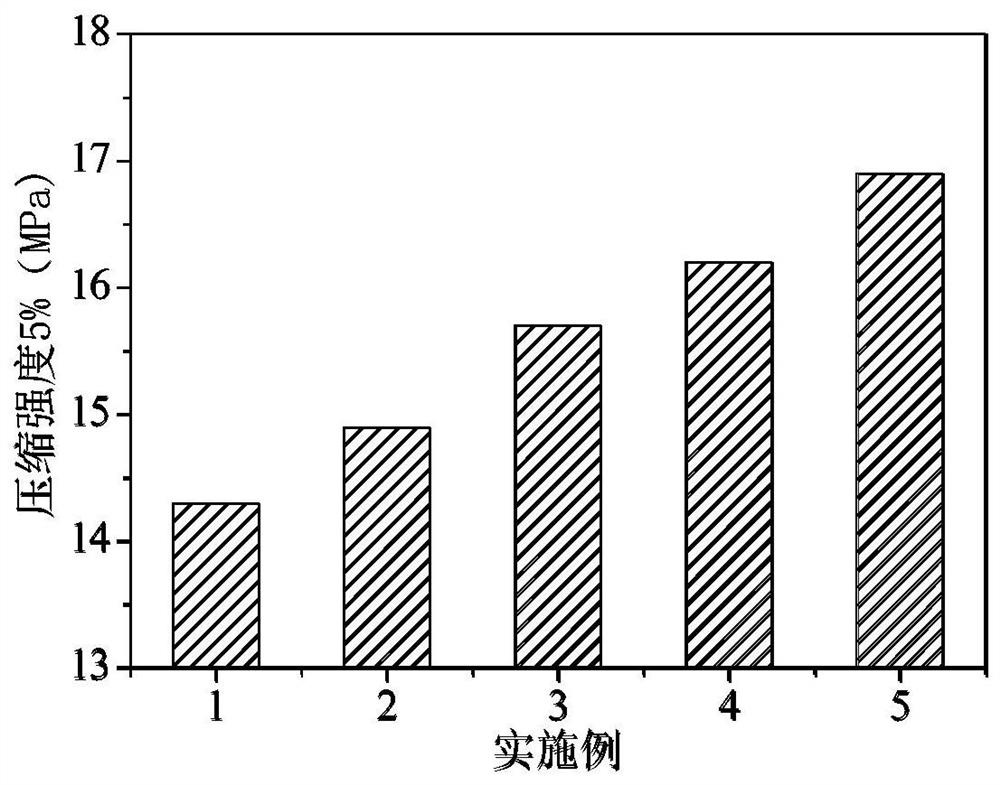

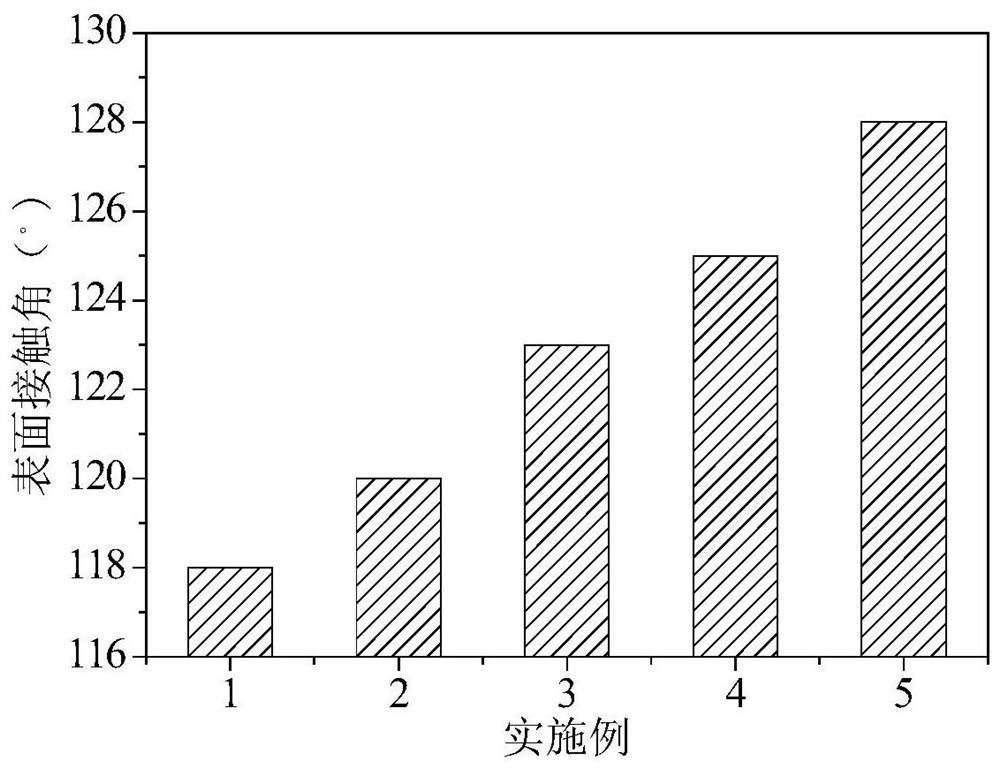

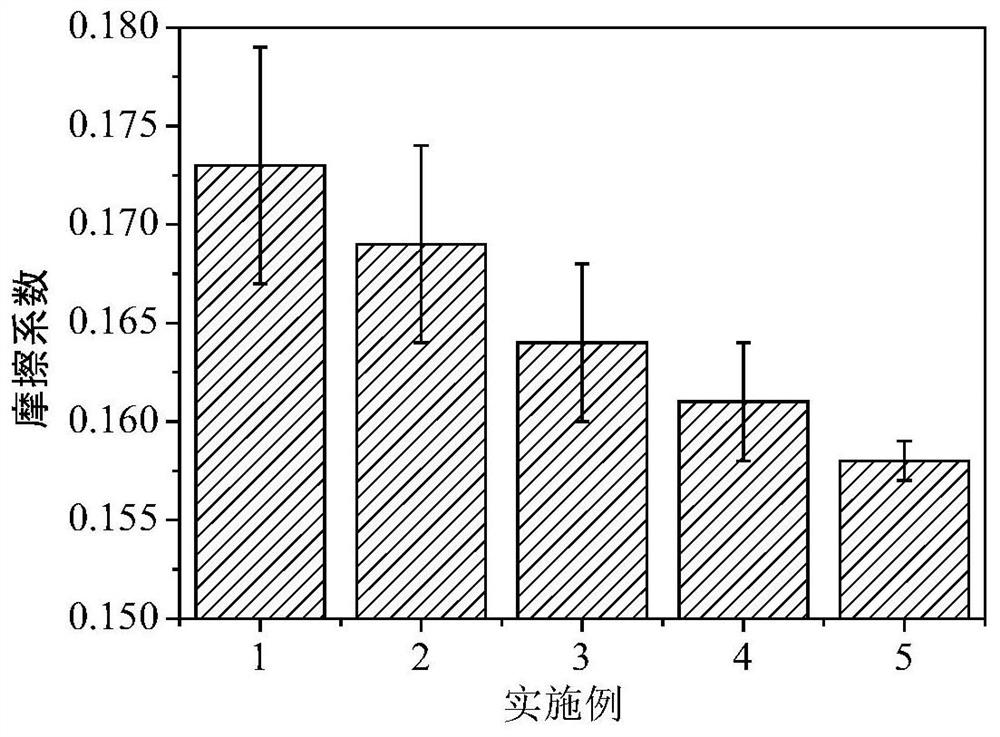

Embodiment 1

[0027] A fluorinated graphene-modified polytetrafluoroethylene composite material for an ultrasonic motor, the parts by weight of each component are as follows: 100 g of polytetrafluoroethylene, 1 g of fluorinated graphene, 1 g of multi-walled carbon nanotubes, and 1 g of aluminum silicate .

[0028] Concrete preparation steps:

[0029] 1) Add polytetrafluoroethylene, fluorinated graphene, multi-walled carbon nanotubes, and aluminum silicate powder into alcohol for ball milling for 4 hours, and then dry them in a vacuum oven overnight (at least 12 hours). Crush, and then pass through a 200-mesh sieve; the amount of alcohol should not exceed the surface of the added raw materials during ball milling (the same below);

[0030] 2) Add the mold material mixed in step 1 into the mold for cold pressing, molding at 10MPa, and hold the pressure for 10 minutes; after demoulding, sinter in a PTFE sintering furnace at a temperature of 360°C, keep warm for 2 hours, and then cool with the...

Embodiment 2

[0034] A fluorinated graphene-modified polytetrafluoroethylene composite material for an ultrasonic motor, the parts by weight of each component are as follows: polytetrafluoroethylene 100g, fluorinated graphene 2g, multi-walled carbon nanotubes 2g, aluminum silicate 2g .

[0035] Concrete preparation steps:

[0036] 1) Add polytetrafluoroethylene, fluorinated graphene, multi-walled carbon nanotubes, and aluminum silicate powder into alcohol for ball milling for 5 hours, then dry overnight (at least 12 hours) in a vacuum oven, and then use a high-speed pulverizer for grinding Pulverized, then passed through a 200-mesh sieve;

[0037] 2) Add the mold material mixed in step 1 into the mold for cold pressing, molding at 10MPa, and hold the pressure for 10 minutes; after demoulding, sinter in a PTFE sintering furnace at a temperature of 365°C, keep warm for 2 hours, and then cool with the furnace;

[0038] 3) Slice the polytetrafluoroethylene composite material made in step 2 to...

Embodiment 3

[0041] A fluorinated graphene modified polytetrafluoroethylene composite material for an ultrasonic motor, the parts by weight of each component are as follows: polytetrafluoroethylene 100g, fluorinated graphene 3g, multi-walled carbon nanotubes 3g, aluminum silicate 3g .

[0042] Concrete preparation steps:

[0043] 1) Add polytetrafluoroethylene, fluorinated graphene, multi-walled carbon nanotubes, and aluminum silicate powder into alcohol for ball milling for 6 hours, then dry overnight (at least 12 hours) in a vacuum oven, and use a high-speed pulverizer to grind Pulverized, then passed through a 200-mesh sieve;

[0044] 2) Add the mold material mixed in step 1 into the mold for cold press molding, molding at 15MPa, and hold the pressure for 15 minutes; after demolding, sinter in a PTFE sintering furnace at a temperature of 370°C, keep warm for 2 hours, and then cool with the furnace;

[0045] 3) Slice the polytetrafluoroethylene composite material made in step 2 to a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com