Novel explosion-proof oxygen supercharger

A supercharger, oxygen technology, applied in the mechanical field, can solve the problems of poor sealing performance, oxygen explosion, etc., and achieve the effect of reducing the high temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

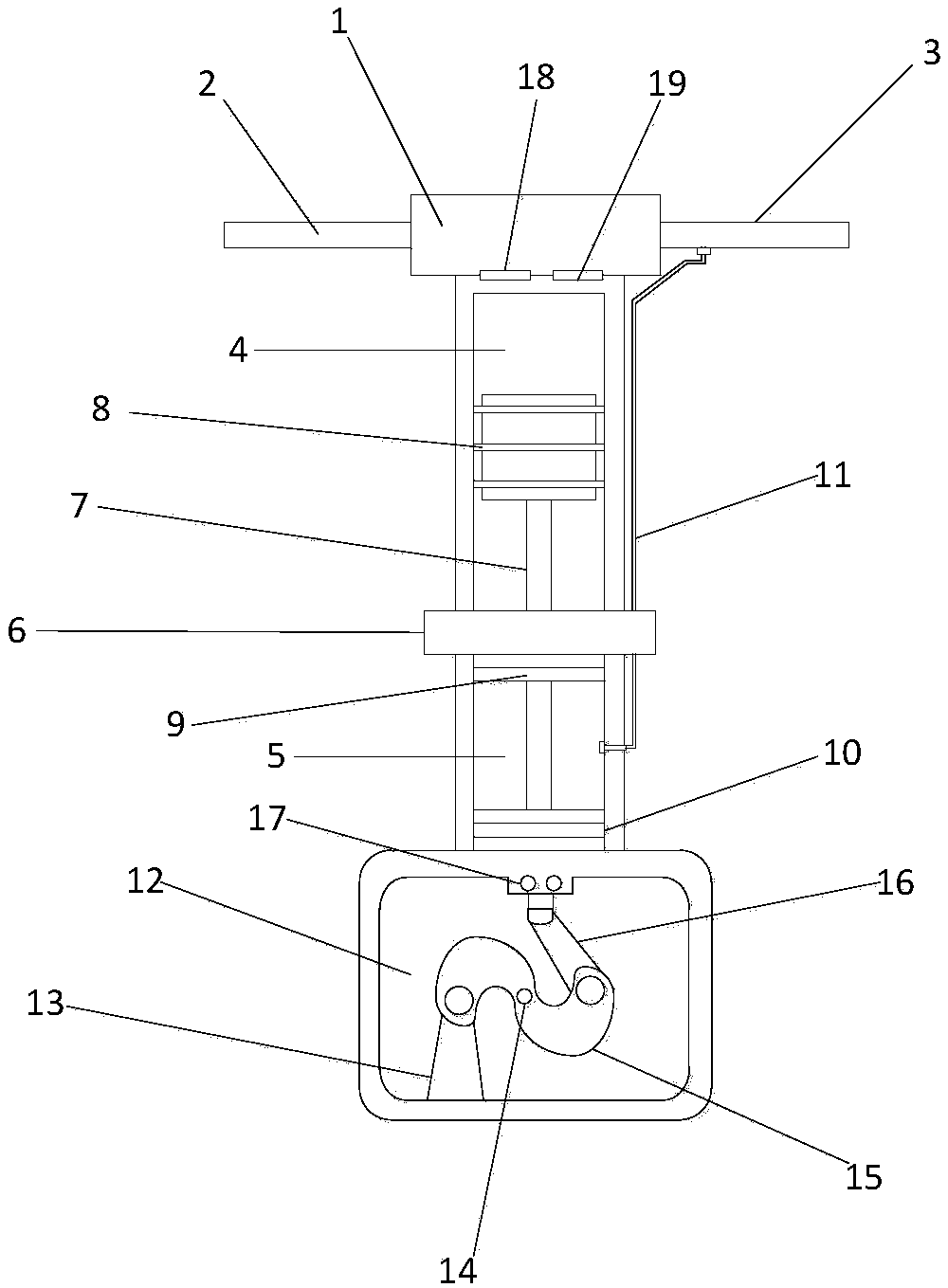

[0008] Such as figure 1 As shown, a novel explosion-proof oxygen supercharger according to the present invention adopts a technical scheme comprising an air chamber 1, an exhaust connecting pipe 2, an intake connecting pipe 3, a cylinder 4, a transition cylinder 5, and an interlayer 6 , crankshaft connecting rod 7, piston head 8, crankcase 12, base 13, shaft seal 14, crankshaft 15, linkage rod 16, oil injection hole 17, exhaust valve 18, intake valve 19; wherein cylinder 4 is a hollow cylinder The upper part of the cylinder 4 is connected to the air chamber 1; the air chamber 1 is a cuboid, and the inside is a cavity, the left side of the air chamber 1 is connected to the exhaust connecting pipe 2, and the right side is the intake connecting pipe 3; the cylinder 4 and the air chamber 1 There are exhaust valve 18 and intake valve 19 at the connection, so that the cylinder 4 communicates with the air chamber 1; the exhaust valve 18 and the intake valve 19 are one-way valves, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com