Cartridge mechanical seal without bushing and bearing

A mechanical seal and bearingless technology, which is applied in the direction of mechanical equipment, non-variable pumps, machines/engines, etc., can solve the problems of low production cost, cracking of grinding surface, small size, etc., and achieve simple structure, avoid cracking, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

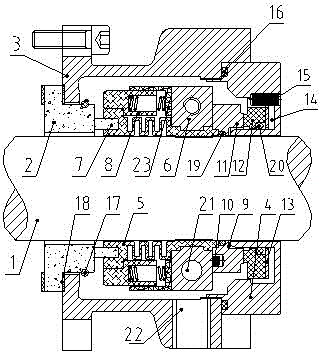

[0024] This example provides a sleeveless and bearingless double-end cartridge mechanical seal, such as figure 1 As shown, the front static ring 2, the front gland 3 and the rear gland 4 arranged on the outside of the pump shaft 1 are sequentially connected and closed with the pump shaft 1 to form a chamber, and the front gland 3 and the rear gland 4 are both spun from Lock connection, there is a flat sealing ring 16 at the connection, the pump shaft 1 is connected with the PTFE bellows 5 in the chamber, the front static ring 2 is connected with the front moving part composed of a silicon carbide wear-resistant ring embedded in the PTFE bellows 5 The surface of the ring 7 fits to form the first grinding surface, and also forms the first sealing surface of the cooling cavity. The back end of the tetrafluoro bellows 5 is fitted with a half ring 6, and the rear end of the half ring 6 is set Limit wear-resistant sheet 9, also be provided with cylindrical pin 10 between the limit w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com