Transfer pump filter with bag-shaped filter screen

A filter and bag-shaped technology, which is applied in the field of bag-shaped screen filter of transfer pump, can solve the problems of affecting production capacity, blocking impeller of centrifugal pump, and inability to filter fine particles, etc., and achieves the effect of reducing maintenance cost and improving production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

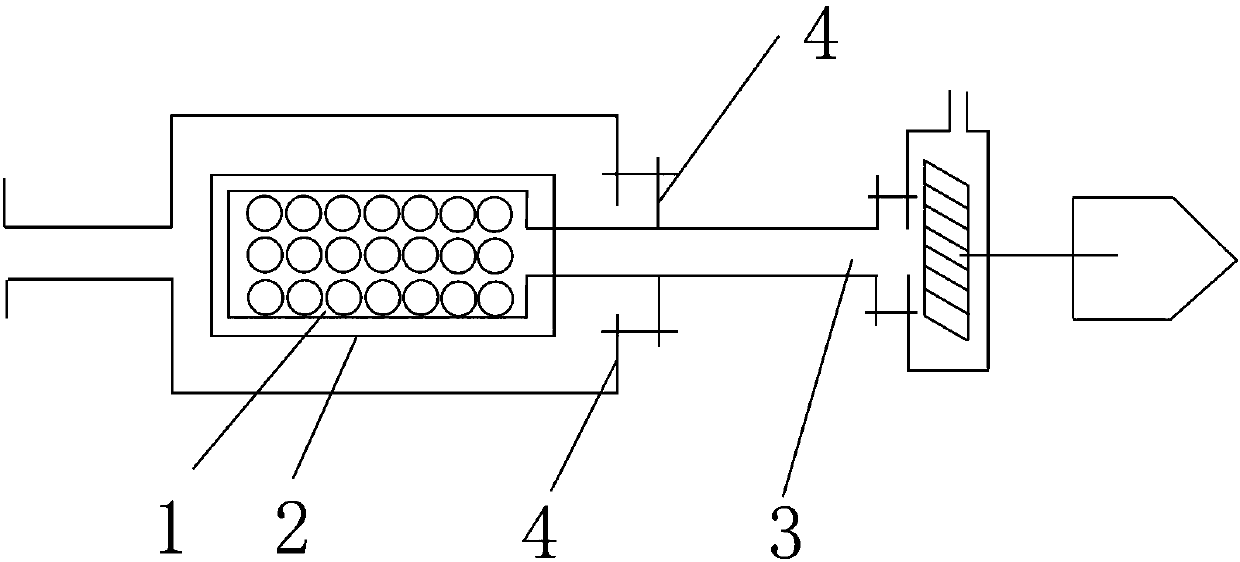

[0009] according to figure 1 The bag-shaped filter screen filter of the material transfer pump shown is provided with a bag-shaped filter screen 2, the bag-shaped filter screen 2 is installed on the filter 1, and several flanges 4 are used to connect the filter device 3.

[0010] Operation procedure: fix the bag filter 2 on the filter 1 with PTFE tape, connect the external device with the internal device with flange 4, remove the screws of flange 4 during maintenance, and clean the bag filter, which is convenient and simple .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com