Flanging device for tetrafluorohydrazine pipe

A technology of PTFE tube and flanging, which is applied in the field of pipe fitting lining pipe production equipment, can solve the problems of inability to flange the PTFE tube, and achieve the effects of reducing errors, compact device structure and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

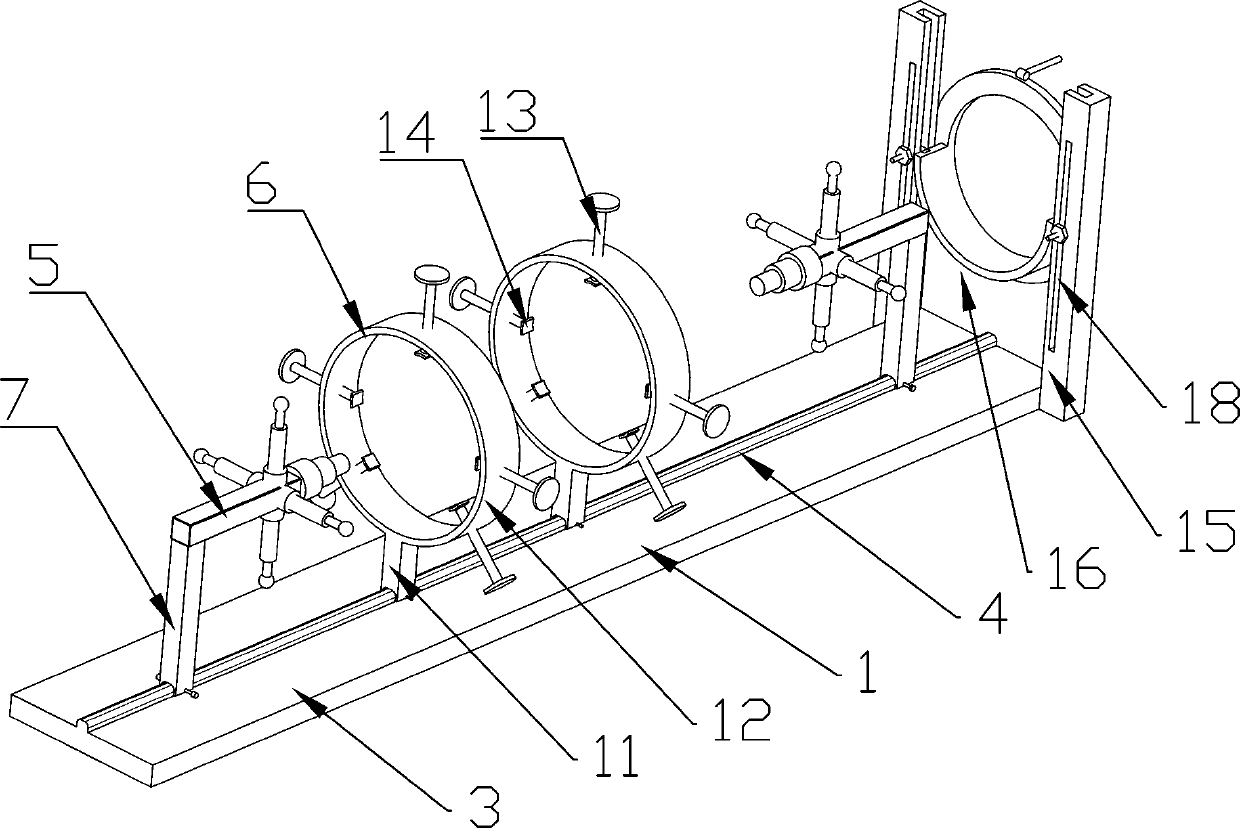

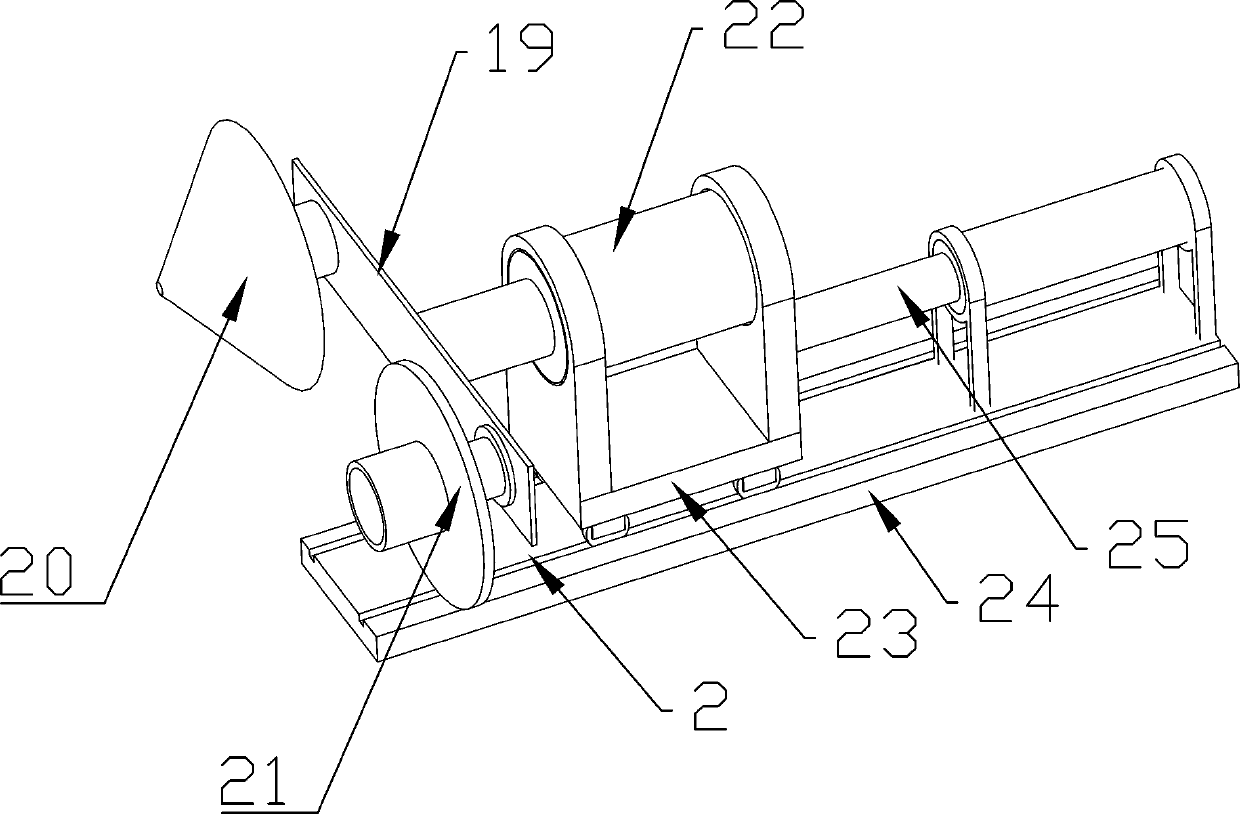

[0025] Such as Figure 1-4 As shown, a PTFE tube flanging device includes a support bracket 1 and a flanging positioning device 2 .

[0026] The support bracket 1 includes a base 3, the base 3 is fixedly connected to the ground through expansion bolts, a slide rail 4 is provided on the base 3, and a centering mechanism 5 is provided on the slide rail 4 radially symmetrically before and after, and the centering mechanism 5 There are two tightening mechanisms 6 between them, and the centering mechanism 5 and the tightening mechanism 6 are used to fix the PTFE tube. The front end of the base 3 is provided with a positioning mechanism, which is used to determine the flanging length of the PTFE tube and support it to facilitate later flanging.

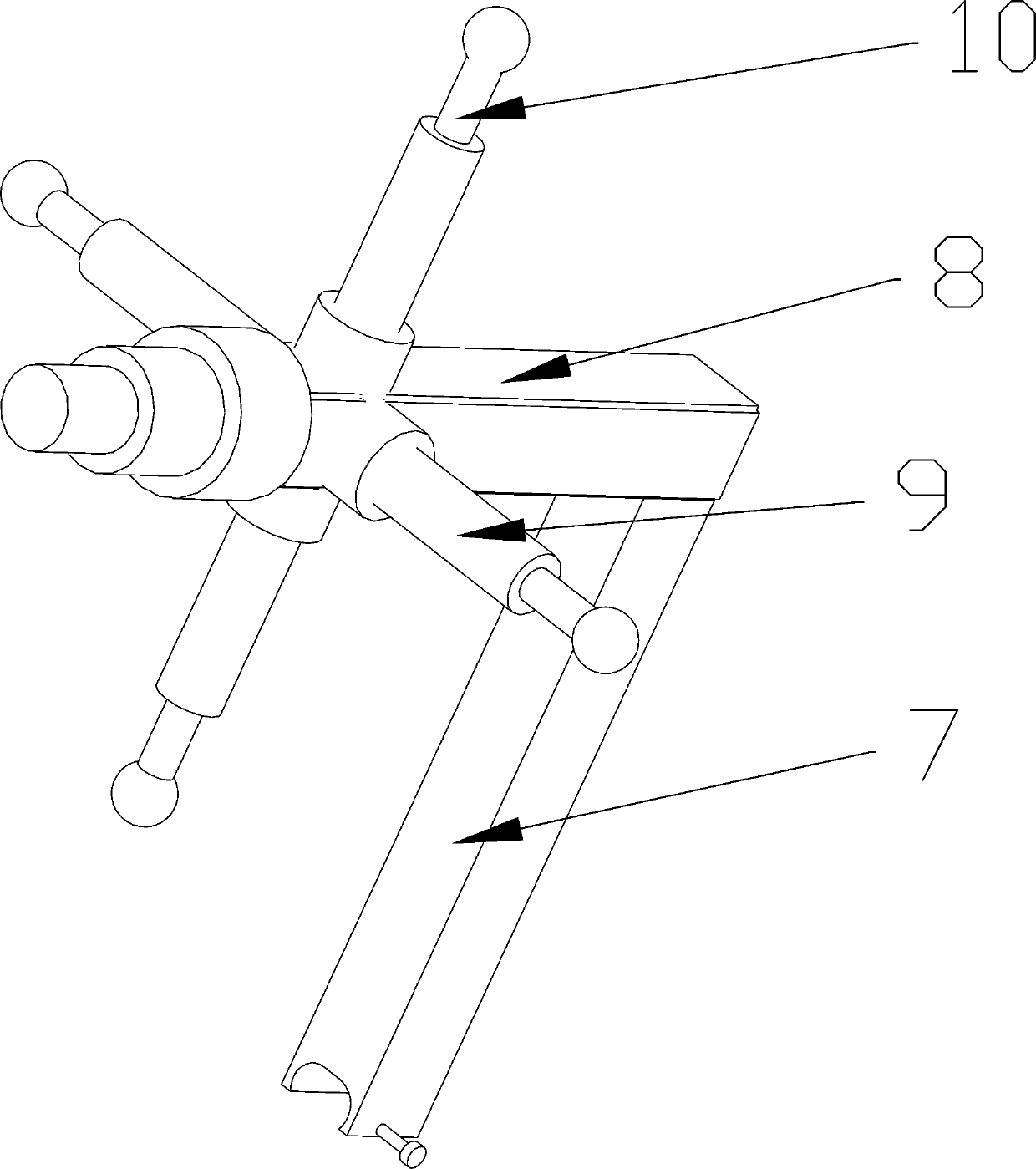

[0027] Specifically, the centering mechanism 5 includes a first leg 7, which is slidably arranged on the slide rail 4, and can pass through the bolt lock in the through hole at the bottom end of the first leg 7 after sliding to a designate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com