Polyimide material and preparation method thereof

A technology of polyimide and polyamic acid is applied in the field of highly transparent polyimide material and its preparation, and achieves the effects of good solubility and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

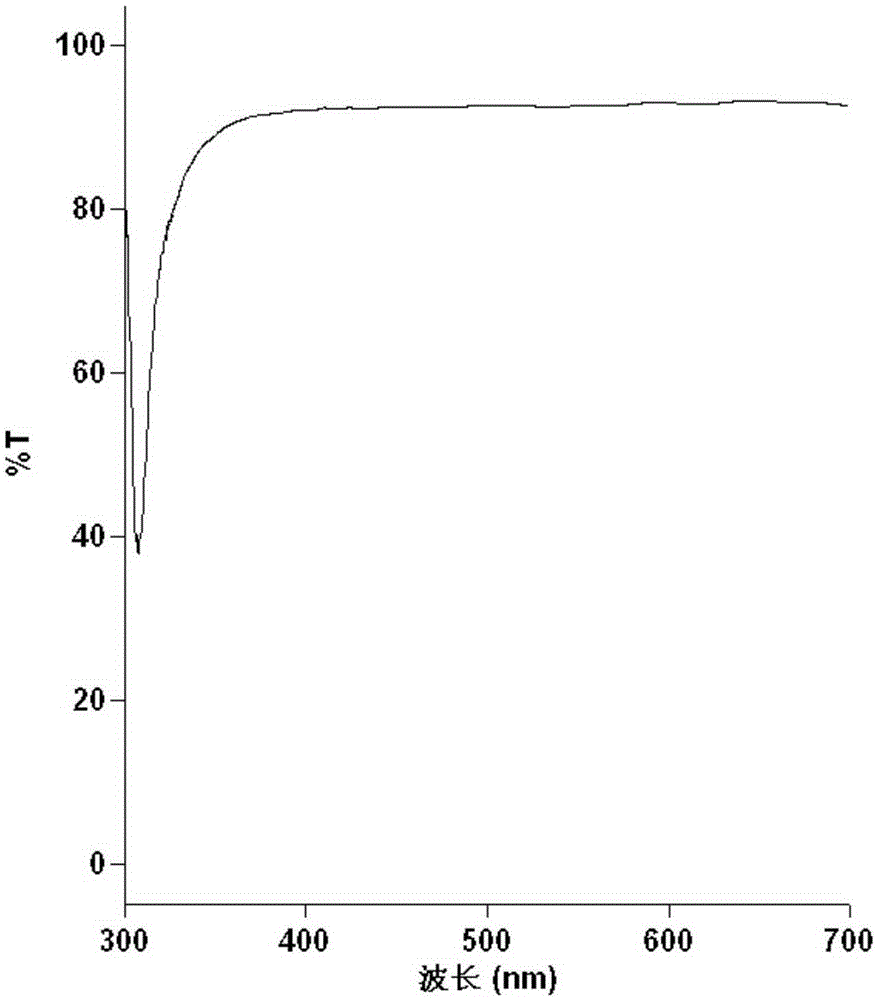

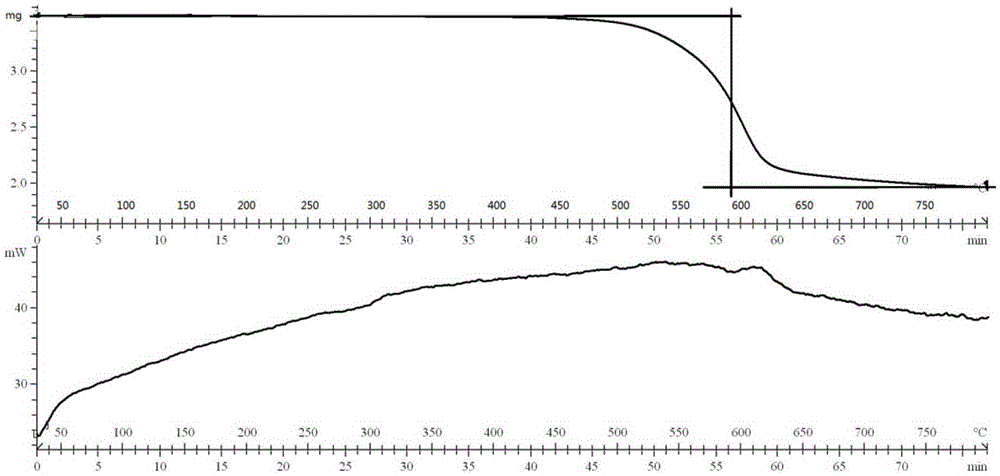

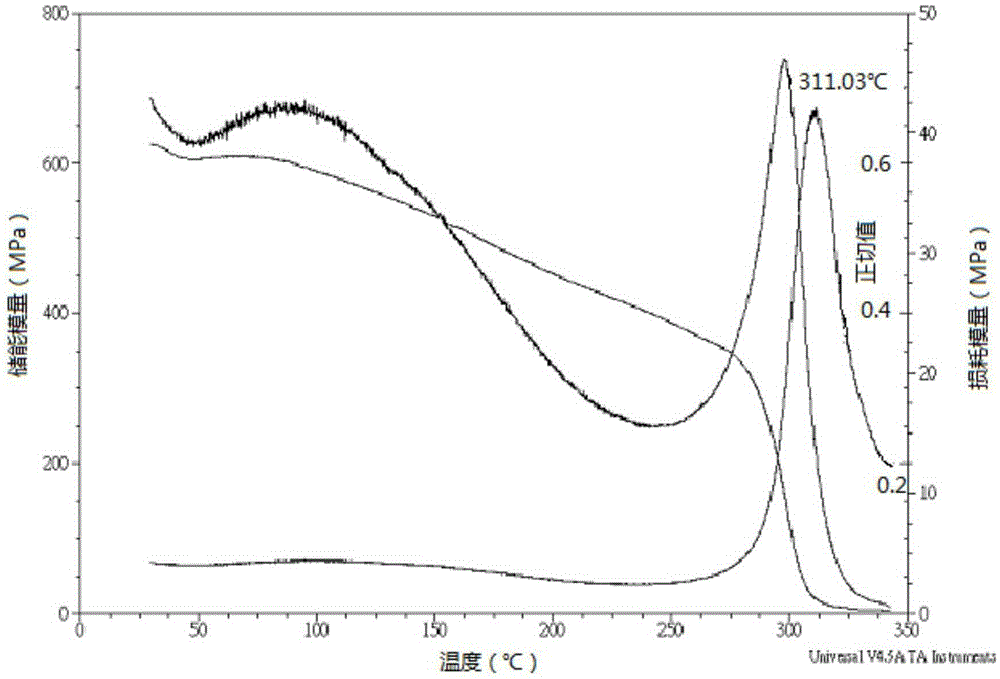

[0031] Embodiment 1 prepares highly transparent polyimide resin material

[0032] In this embodiment, the highly transparent polyimide resin material has the following structural formula:

[0033]

[0034] In the formula, n and m are positive integers greater than 15.

[0035] Under nitrogen protection, 13.45g (0.04mol) 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl ether, 1.3g (0.004mol) 2-(3,5-diamino Phenyl)-4,5,6,7-(tetrafluoroisoindoline)-1,3-dione was added to 90g of N-methylpyrrolidone, stirred at room temperature for 15min until a light yellow transparent solution was completely dissolved, and added to the system Add 7.76g (0.04mol) cyclobutanetetracarboxylic dianhydride, the system exotherms and becomes viscous, continue stirring at room temperature for 3 hours to obtain a light yellow polyamic acid solution with a solid content of 20%.

[0036] Add 80g of acetic acid to the polyamic acid solution obtained above, heat up to reflux for 10 hours for imidization, an...

Embodiment 2

[0041] Embodiment 2 prepares highly transparent polyimide resin material

[0042] In this embodiment, the highly transparent polyimide resin material has the following structural formula:

[0043]

[0044] In the formula, n and m are positive integers greater than 15.

[0045] Under nitrogen protection, 12.1g (0.036mol) 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl ether, 1.3g (0.004mol) 2-(3,5-diamino Phenyl)-4,5,6,7-(tetrafluoroisoindoline)-1,3-dione was added to 84.6g of N-methylpyrrolidone, and stirred at room temperature for 15 minutes until a light yellow transparent solution was completely dissolved. 7.76g (0.04mol) of cyclobutanetetracarboxylic dianhydride was added to the mixture, the system exothermic and became viscous, and continued to stir at room temperature for 3 hours to obtain a light yellow polyamic acid solution with a solid content of 20%.

[0046] 80 g of acetic acid was added to the polyamic acid solution obtained above, and the temperature was rais...

Embodiment 3

[0051] Embodiment 3 prepares highly transparent polyimide resin material

[0052] In this embodiment, the highly transparent polyimide resin material has the following structural formula:

[0053]

[0054] In the formula, n and m are positive integers greater than 15.

[0055] Under nitrogen protection, 12.8g (0.04mol) 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl, 1.3g (0.004mol) 2-(3,5-diaminobenzene base)-4,5,6,7-(tetrafluoroisoindoline)-1,3-dione was added to 87.4g of N-methylpyrrolidone, and stirred at room temperature for 15min until the light yellow transparent solution was completely dissolved. Add 7.76g (0.04mol) cyclobutanetetracarboxylic dianhydride, the system exotherms and becomes viscous, continue stirring at room temperature for 6 hours to obtain a light yellow polyamic acid solution with a solid content of 20%.

[0056] 80 g of acetic acid was added to the polyamic acid solution obtained above, and the temperature was raised to reflux for 10 hours for imi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com