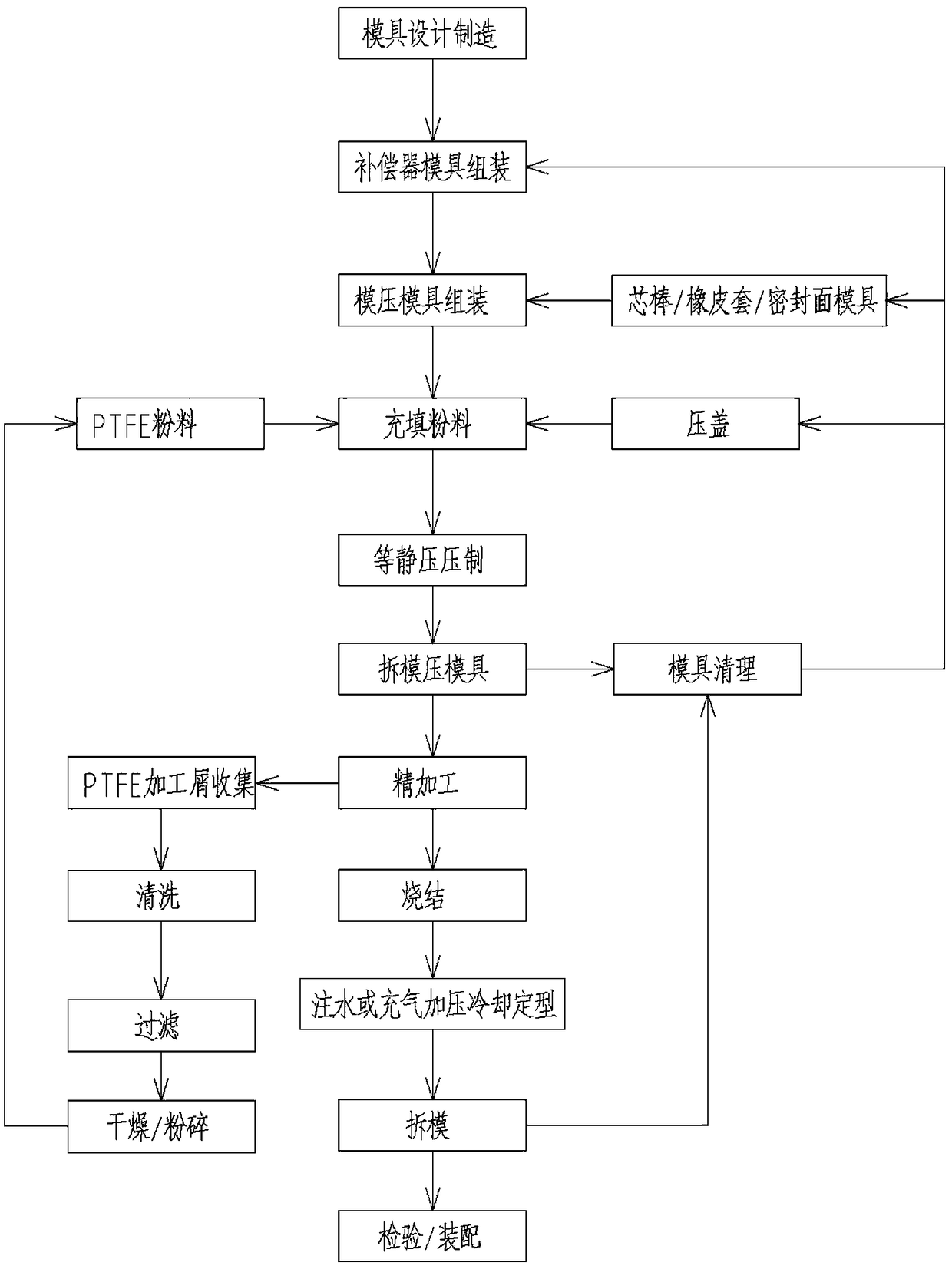

Polytetrafluoroethylene compensator and manufacturing technology thereof

A technology of polytetrafluoroethylene and manufacturing process, which is applied in the field of compensators, can solve the problems of affecting product quality, wasting resources, and uneven waveforms of compensators, so as to improve the volume resistance value, prolong the service life, and avoid the phenomenon of micropores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

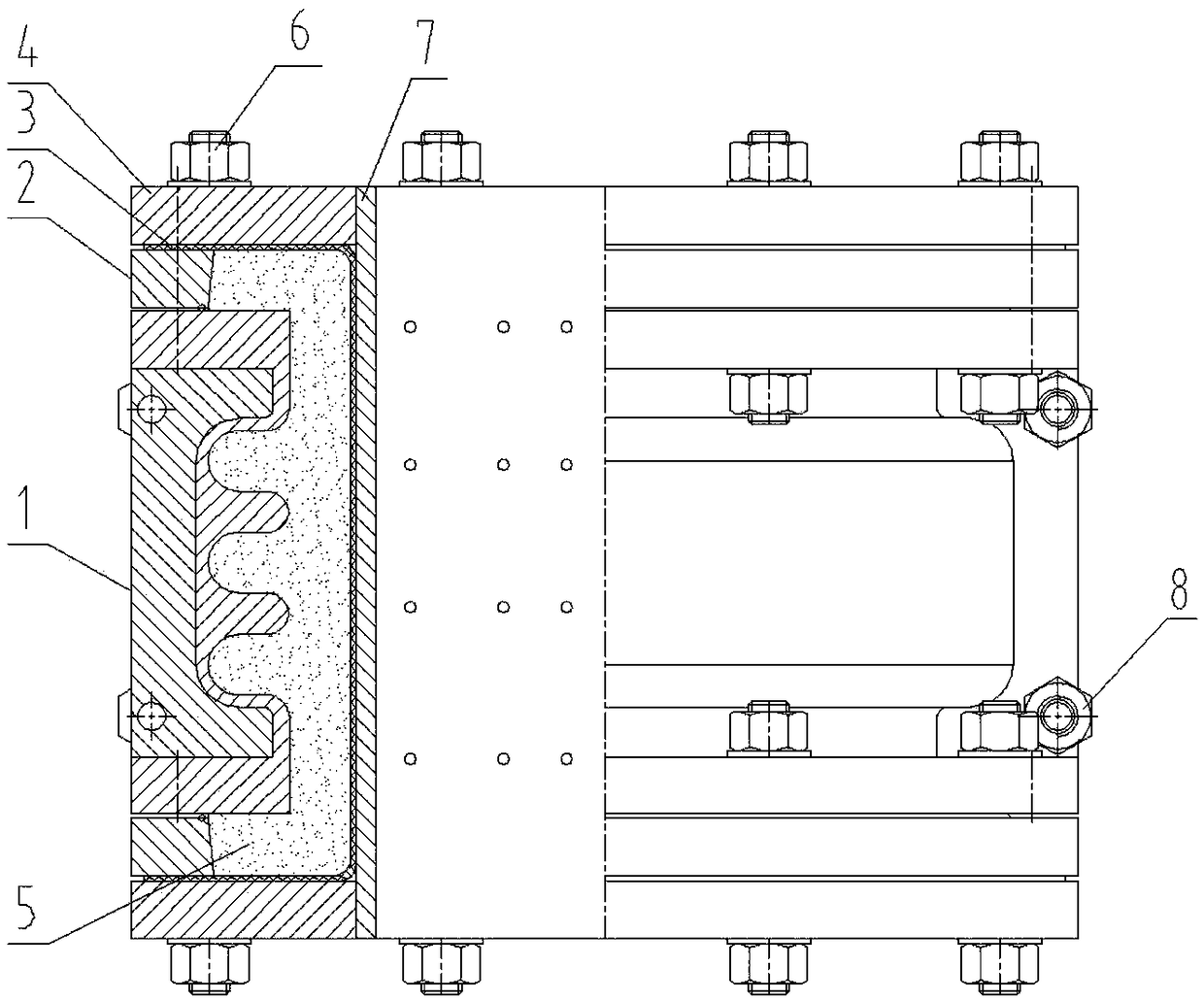

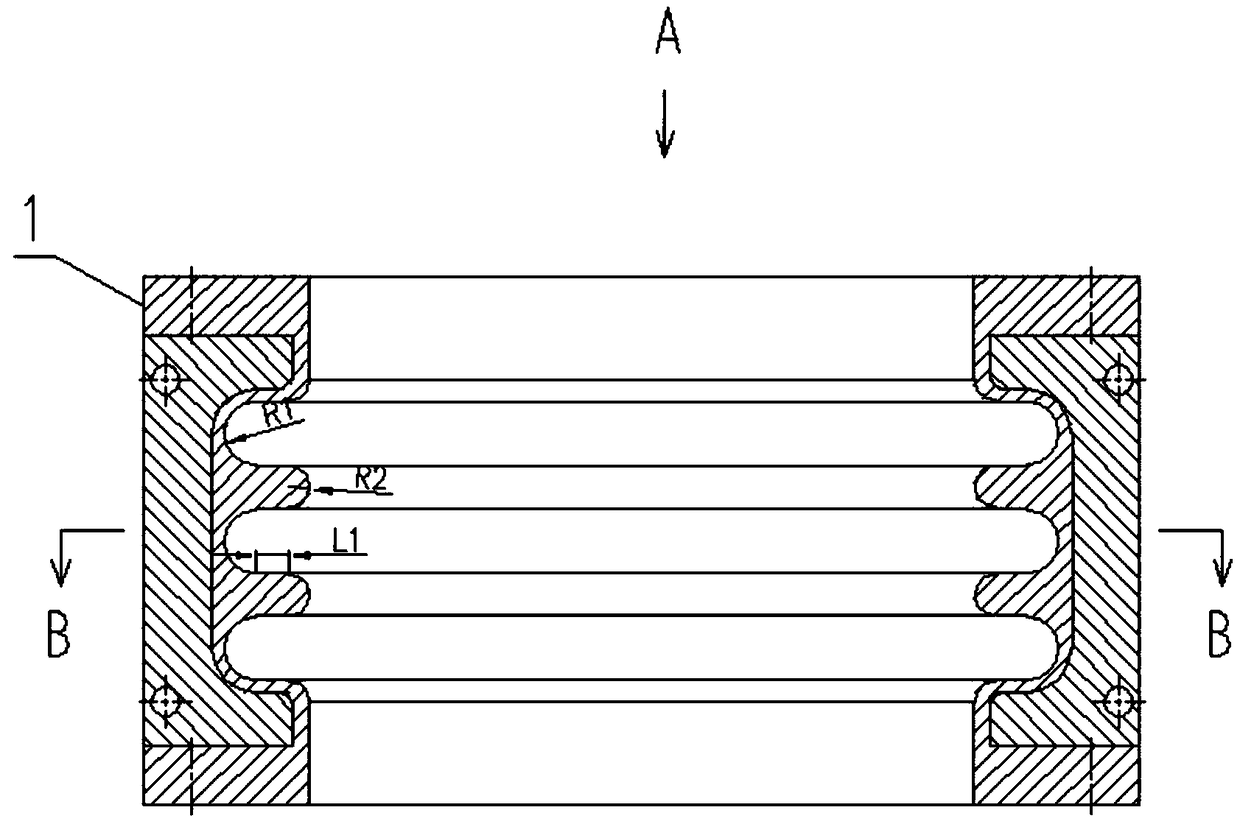

[0049] Such as Figure 2-Figure 9 As shown, the polytetrafluoroethylene compensator provided in this embodiment includes a compensator mold 1 and a tetrafluoroethylene compensator 9, each sealing surface of the compensator mold 1 is provided with a sealing surface mold 2, and one side of the compensator mold 1 There is a molded mandrel 7, a rubber sleeve 3 is provided between the compensator mold 1 and the molded mandrel 7, a sealing compression flange 4 is installed on the compensator mold 1, and a fastener is provided on the sealing compression flange 4 6. The cavity between the sealing surface mold 2, the compensator mold 1 and the rubber sleeve 3 is filled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com