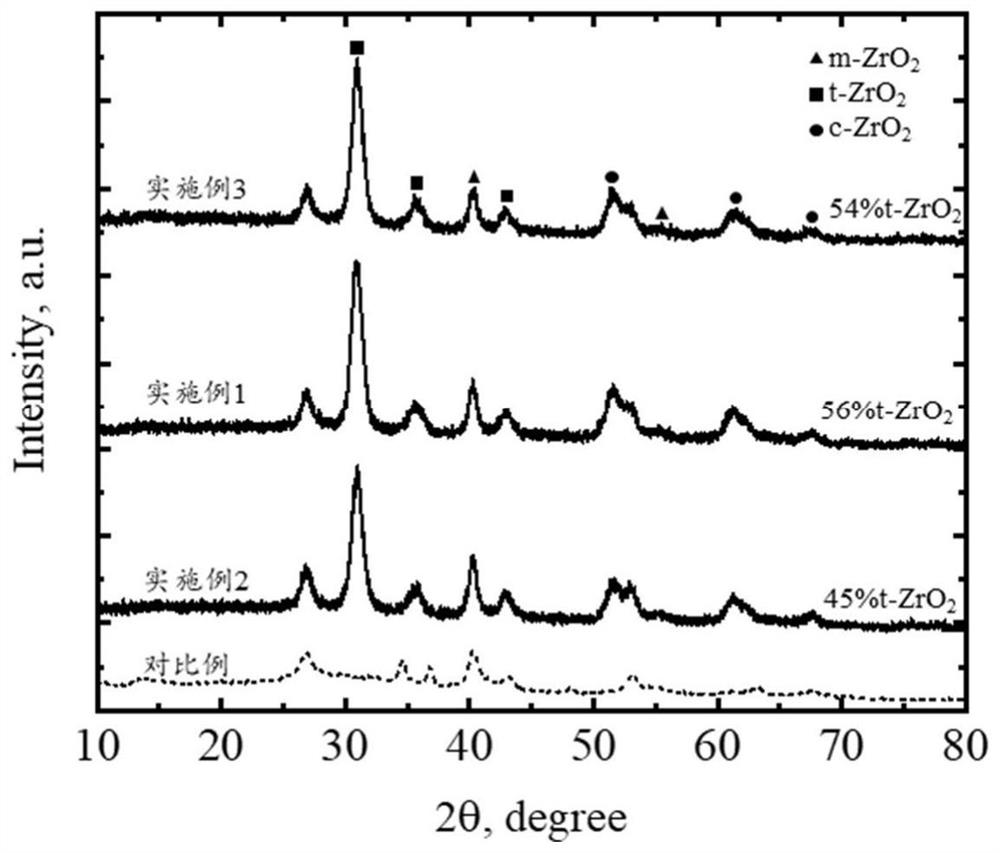

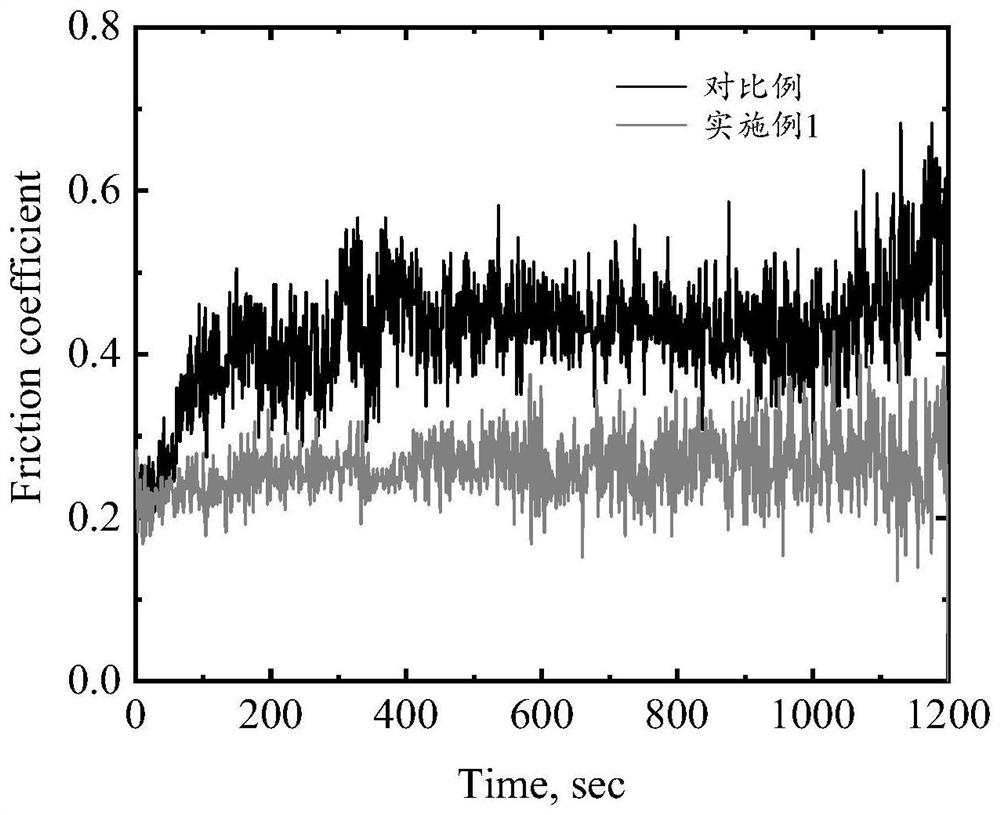

ZrO2/MgO wear-resistant film layer on magnesium alloy and preparation method thereof

A magnesium alloy, wear-resistant film technology, applied in the direction of coating, surface reaction electrolytic coating, anodizing, etc., can solve the problem of poor adhesion between the micro-arc oxidation film layer and the substrate, so as to improve easy cracking and promote surface densification. The effect of preventing microporous loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 2g of ammonium bifluoride, 4g of sodium dihydrogen phosphate, 3g of potassium fluorozirconate and 2.5g of potassium hydroxide into 1L of deionized water to obtain an electrolyte, and place the AZ91 magnesium alloy in the electrolyte for micro-arc oxidation treatment;

[0035] The process of micro-arc oxidation is:

[0036] The micro-arc oxidation voltage is cyclically pressurized from 180V to 400V, and the surface of the film layer is pressurized by 5-10V each time it is close to the arc-extinguishing state. After the arc is started, the reaction lasts for 15 minutes, and then the voltage is reduced to zero, and the power is turned off;

[0037] After the micro-arc oxidation is completed, the AZ91 magnesium alloy is rapidly cooled in the cooling liquid, and ZrO is formed in situ on the magnesium alloy after cooling. 2 / MgO wear-resistant film layer.

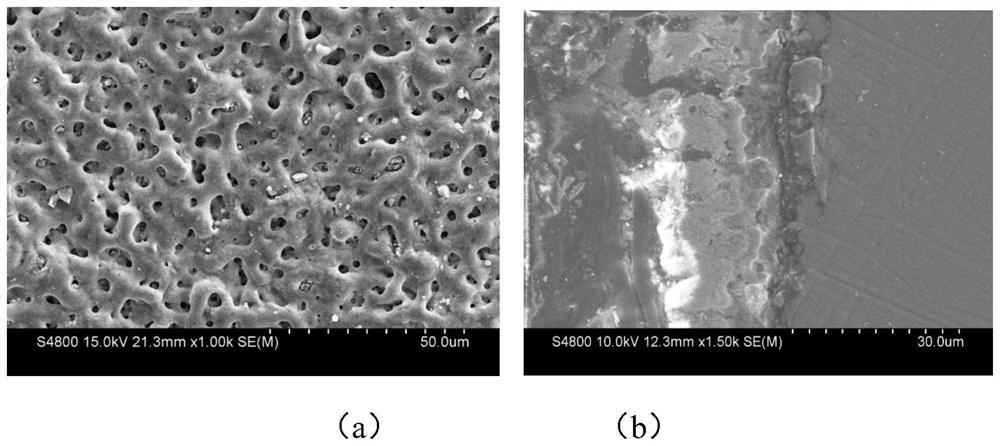

[0038] see figure 2 , figure 2 It is the SEM figure of the membrane layer of embodiment 1, and wherein, (a) is ...

Embodiment 2

[0040] Add 2g of ammonium bifluoride, 1g of potassium fluozirconate, 4g of sodium dihydrogen phosphate and 2.5g of potassium hydroxide into 1L of deionized water to obtain an electrolyte, place the magnesium alloy in the electrolyte for micro-arc oxidation treatment, and then place it in the cooling liquid Rapid cooling for in situ generation of ZrO on magnesium alloys 2 / MgO wear-resistant film layer.

[0041] The micro-arc oxidation process is as follows: the micro-arc oxidation voltage is cyclically pressurized from 180V to 450V, and the surface of the film layer is pressurized by 5-10V each time it is close to the arc-extinguishing state. The reaction lasts for 25 minutes after the arc is started, and then the voltage is reduced to zero, and the power is turned off. ;

Embodiment 3

[0043] Add 2g of ammonium bifluoride, 5g of potassium fluozirconate, 4g of sodium dihydrogen phosphate and 2.5g of potassium hydroxide into 1L of deionized water to obtain an electrolyte. The magnesium alloy is placed in the electrolyte for micro-arc oxidation treatment, followed by rapid cooling. In Situ Generation of ZrO on Magnesium Alloys 2 / MgO wear-resistant film layer.

[0044] The micro-arc oxidation process is as follows: the micro-arc oxidation voltage is 180V cyclically pressurized to 400V, each time the surface of the film layer is close to the arc-extinguishing state, pressurize 5-10V, the reaction lasts for 10 minutes after the arc is started, and then the voltage is reduced to zero, and the power is turned off.

[0045] see Figure 5 , Figure 5 It is the SEM figure of the membrane layer cross-section of embodiment 3, as can be seen from the figure, the potassium fluorozirconate of higher concentration content makes the microporous structure of the prepared zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com