Patents

Literature

56results about How to "Avoid looseness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Night puck

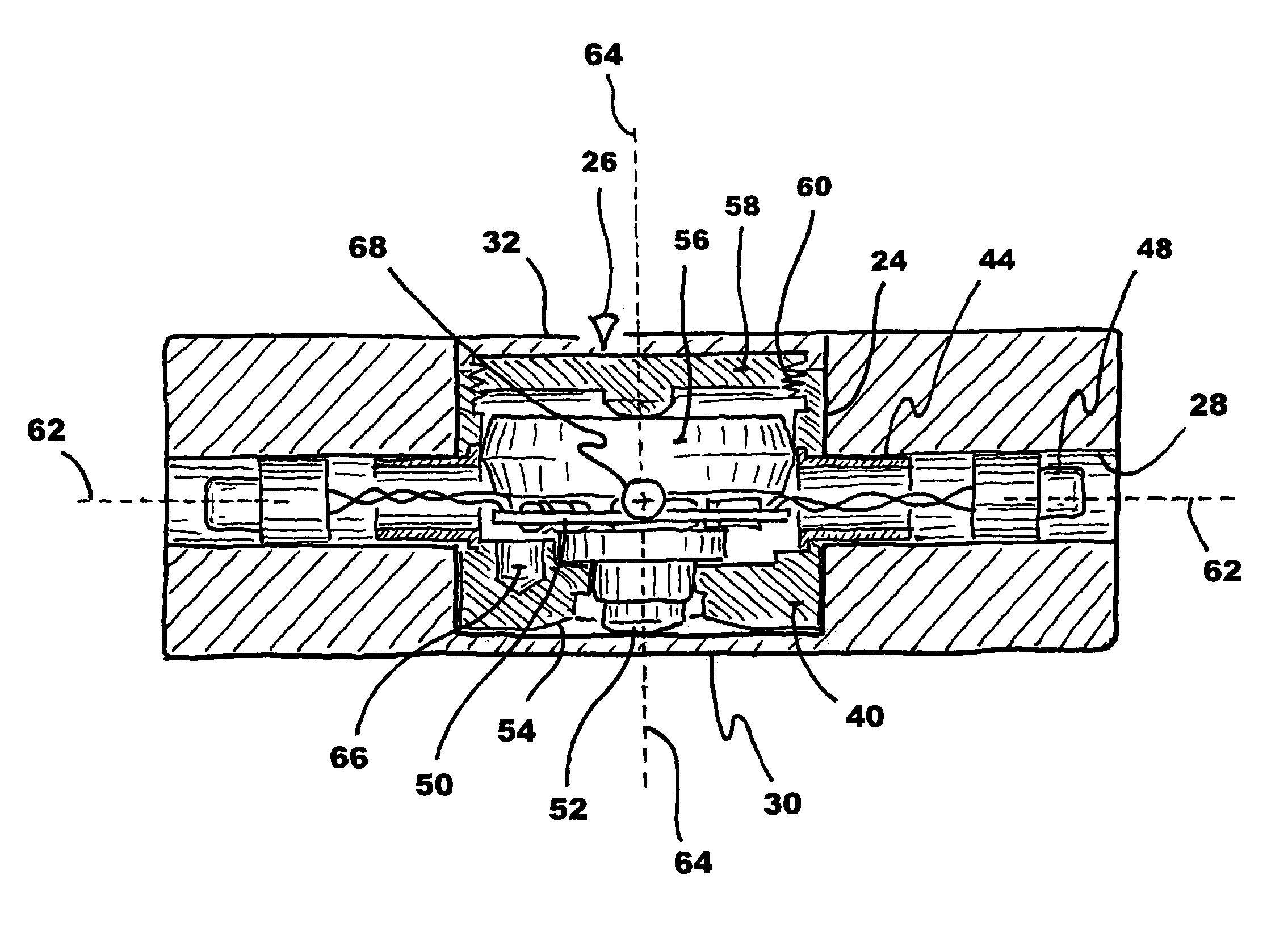

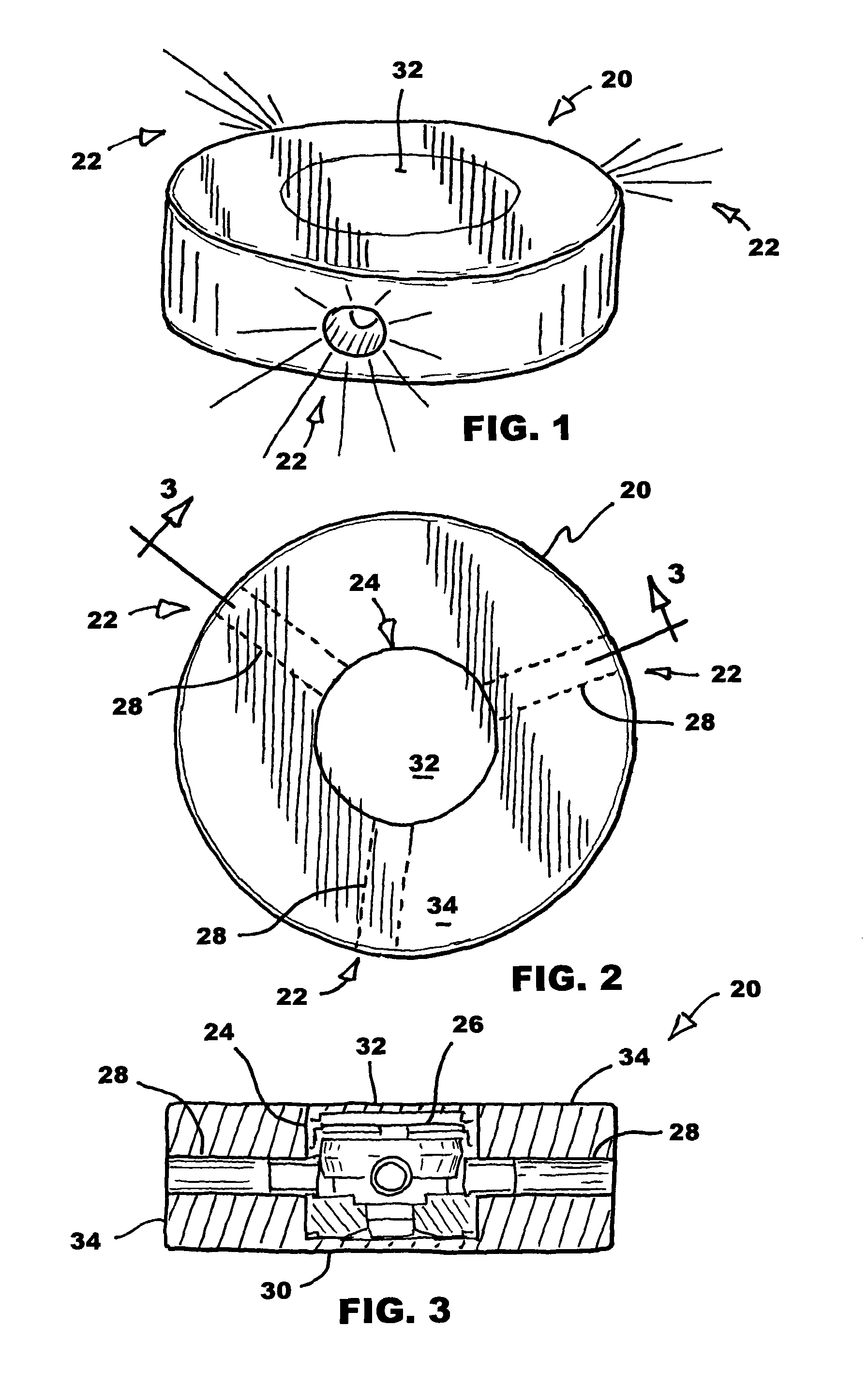

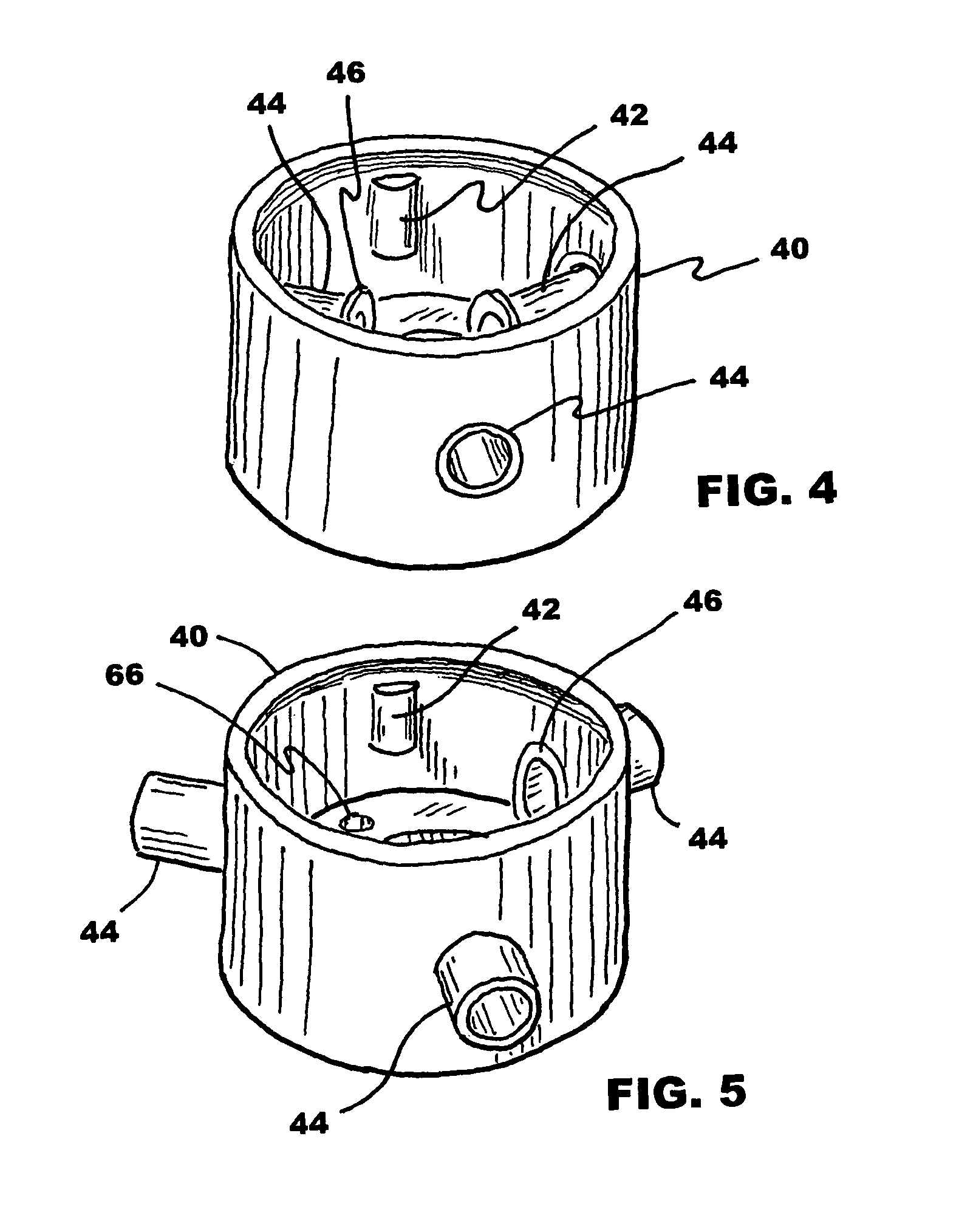

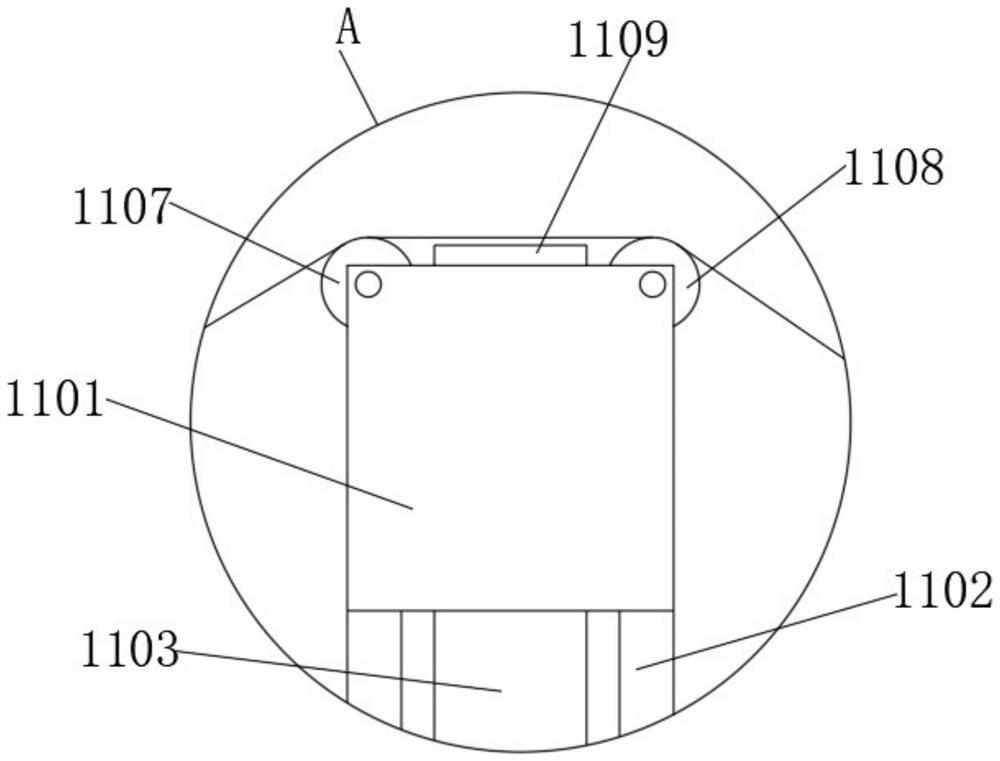

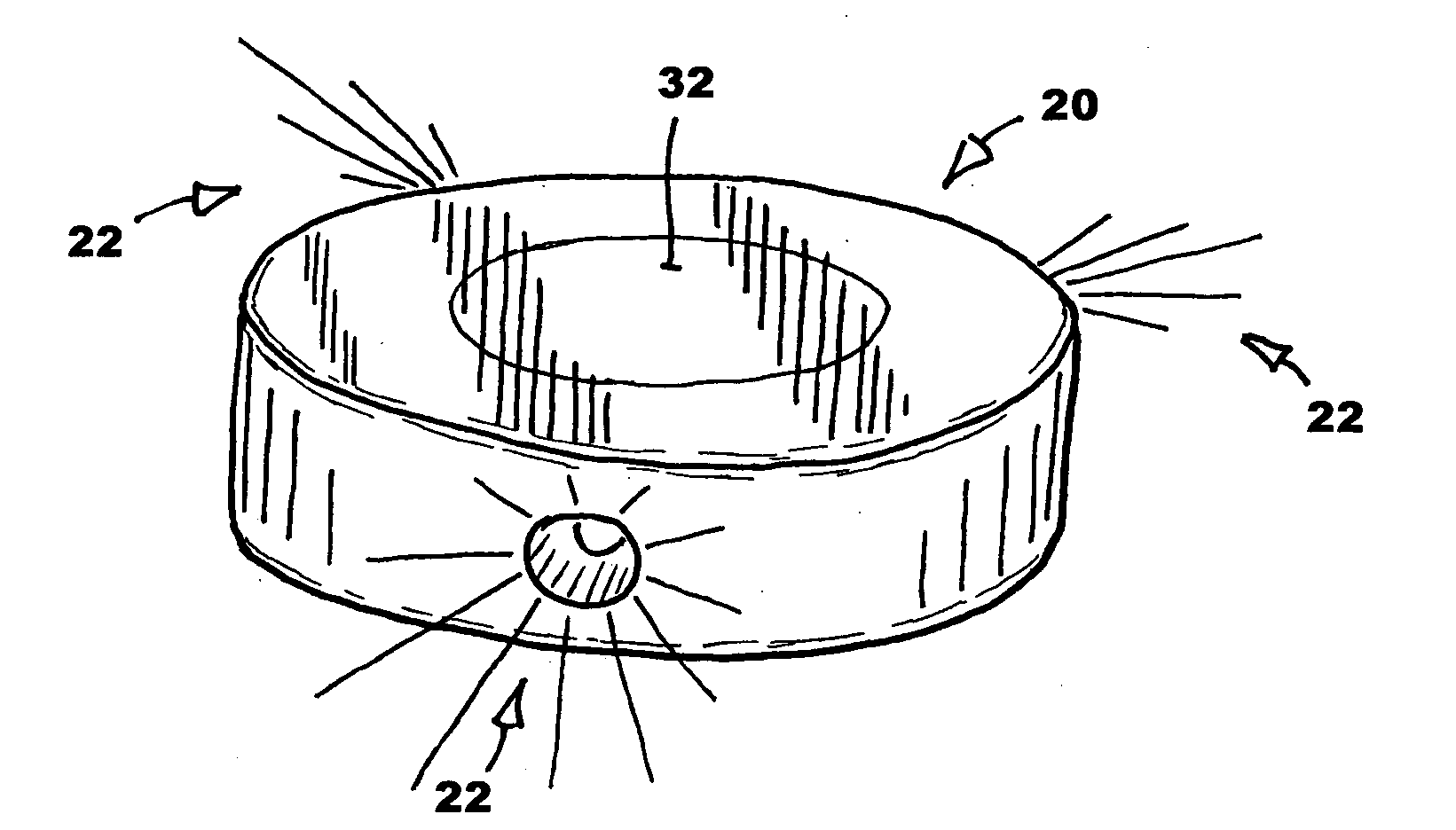

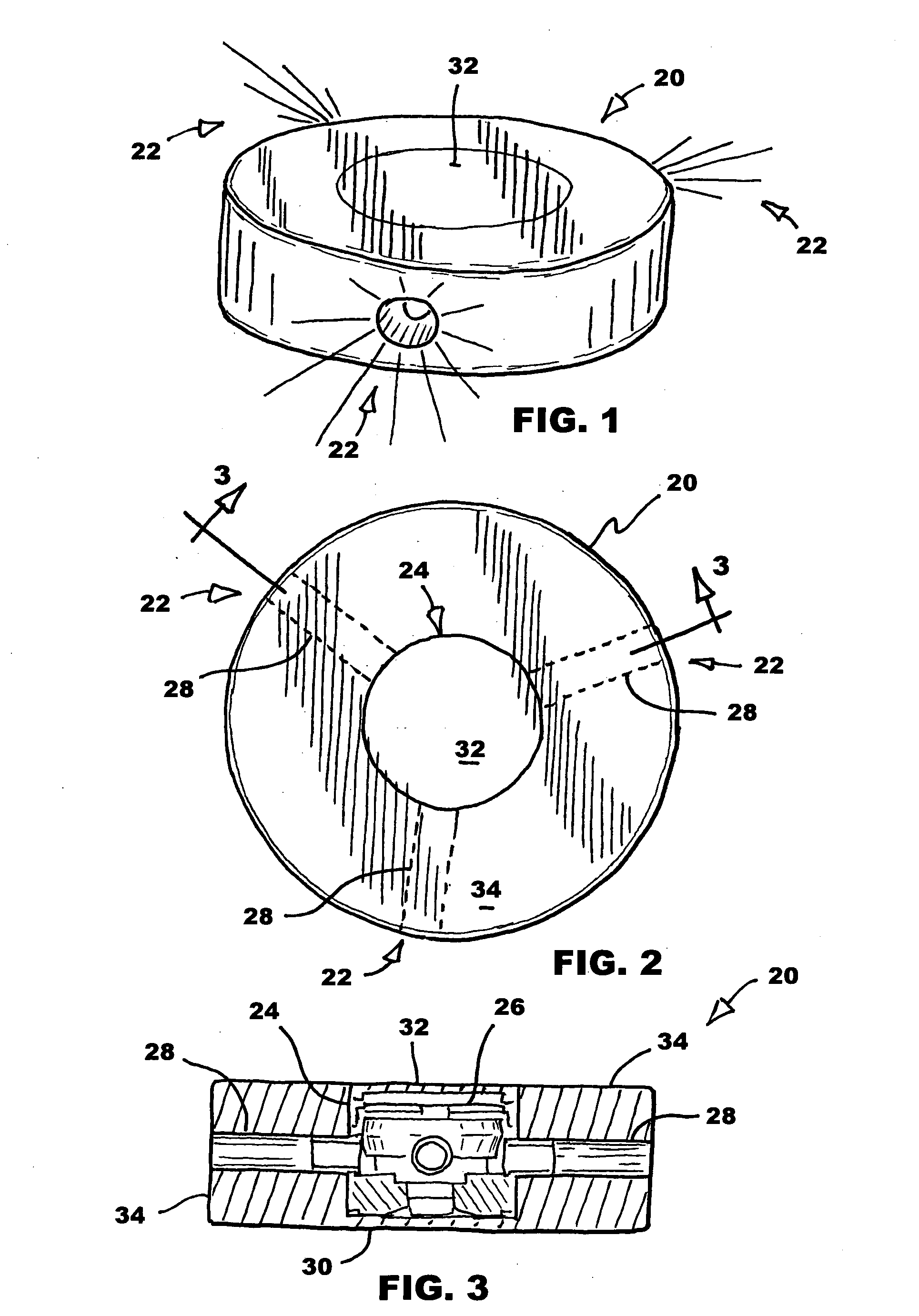

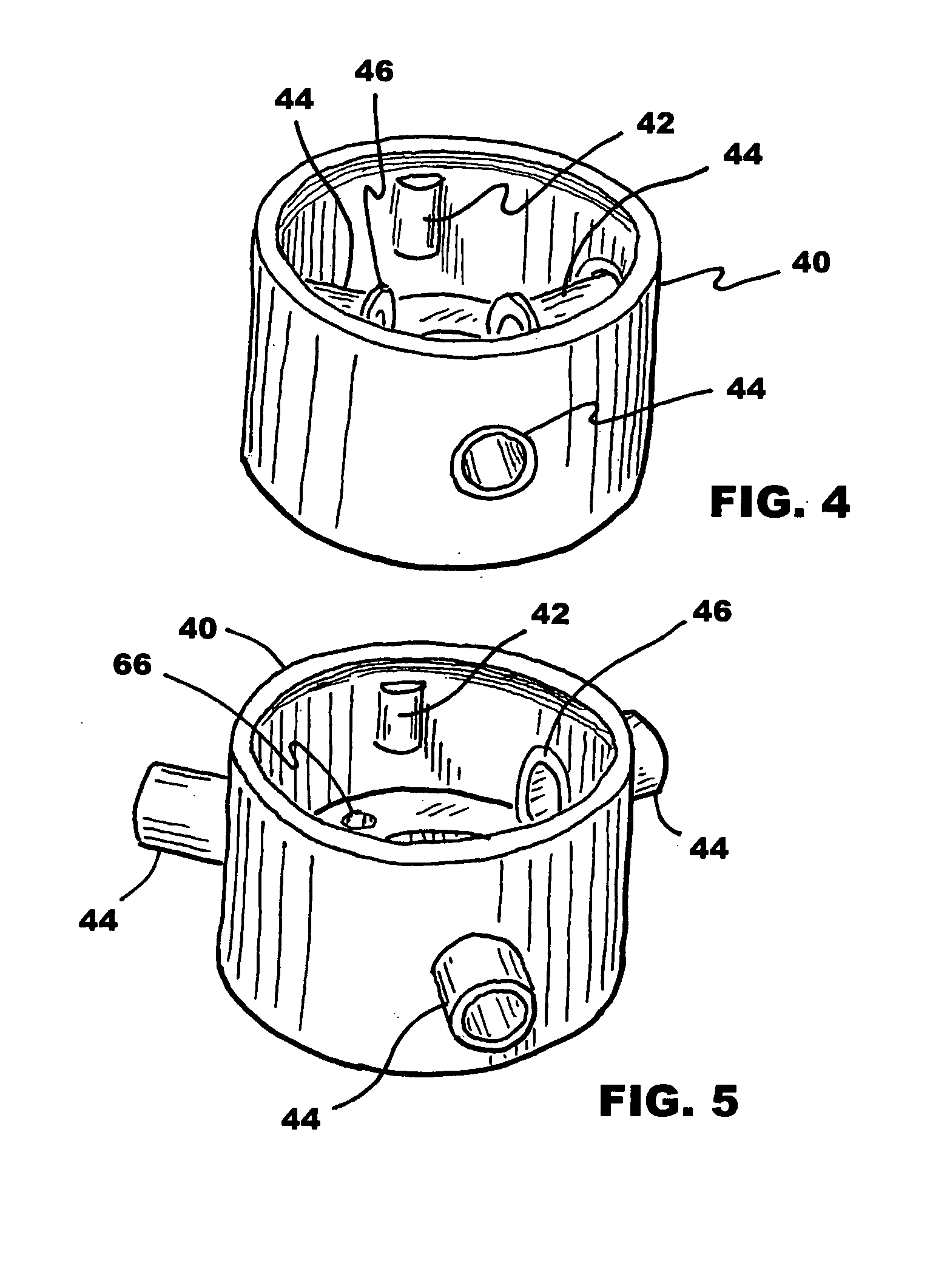

ActiveUS9463360B1Predictable behaviorAvoid playingBall sportsRacket sportsCircular discThin membrane

The night puck has a median plane contiguous with a circumference thereof. The centroid of the puck is located at an intersection of the axis of rotation of the puck with the median plane. A cylindrical cavity extends therein along the natural axis of rotation. This cylindrical cavity has a thin membrane-like bottom wall. A series of holes extend radially along the median plane from the cylindrical cavity to the circumference of the puck. An electronic module is mounted in the cylindrical cavity. This electronic module comprises a battery and has a center of gravity that is located on the centroid of the puck. A push-button switch is held against the membrane-like bottom wall for operation of the switch by a depression of the membrane-like bottom wall. A series of diodes are mounted in the radial holes and are connected to the electronic module, for illuminating rays of lights around the puck.

Owner:NIGHT PUCK TECH INC

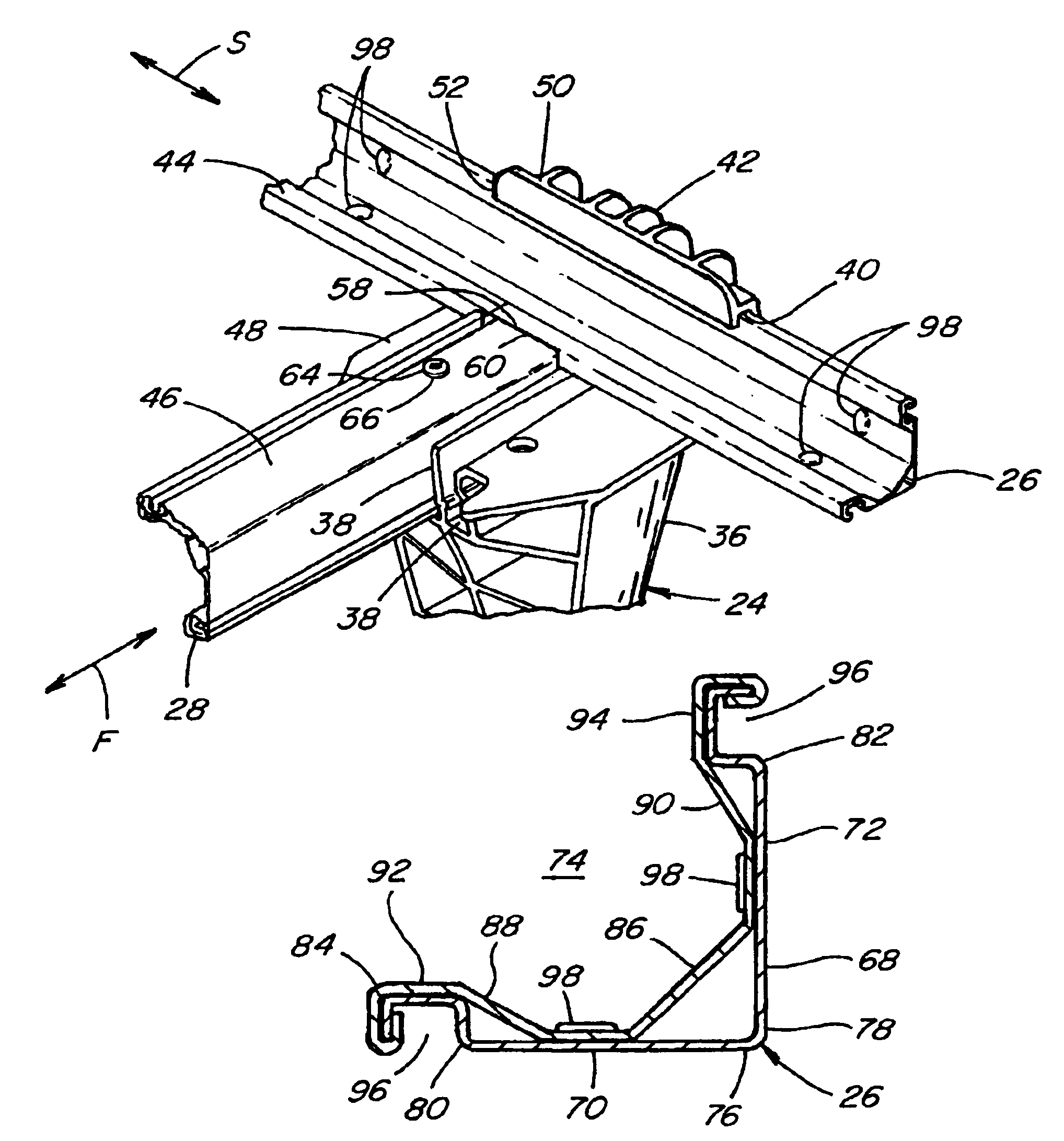

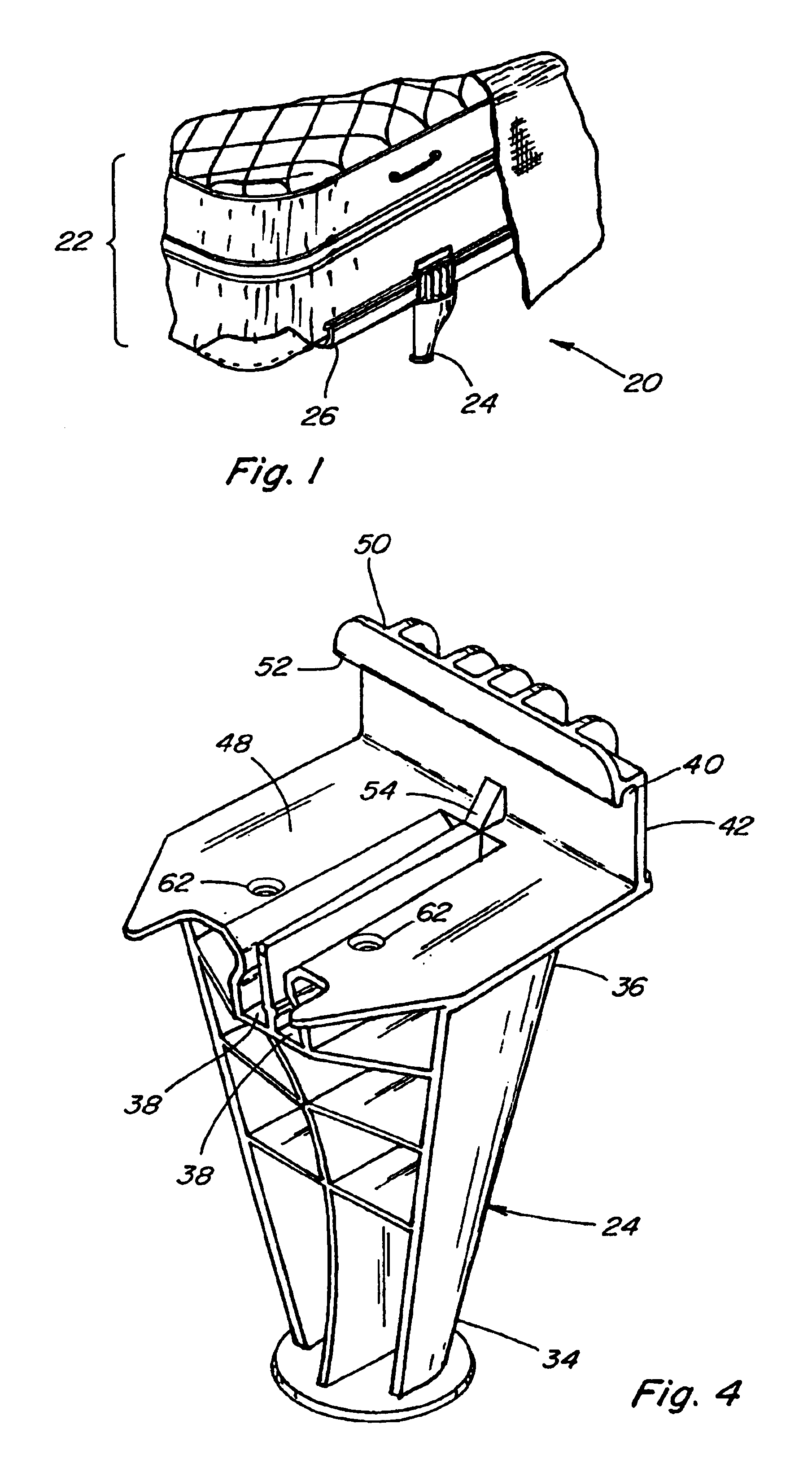

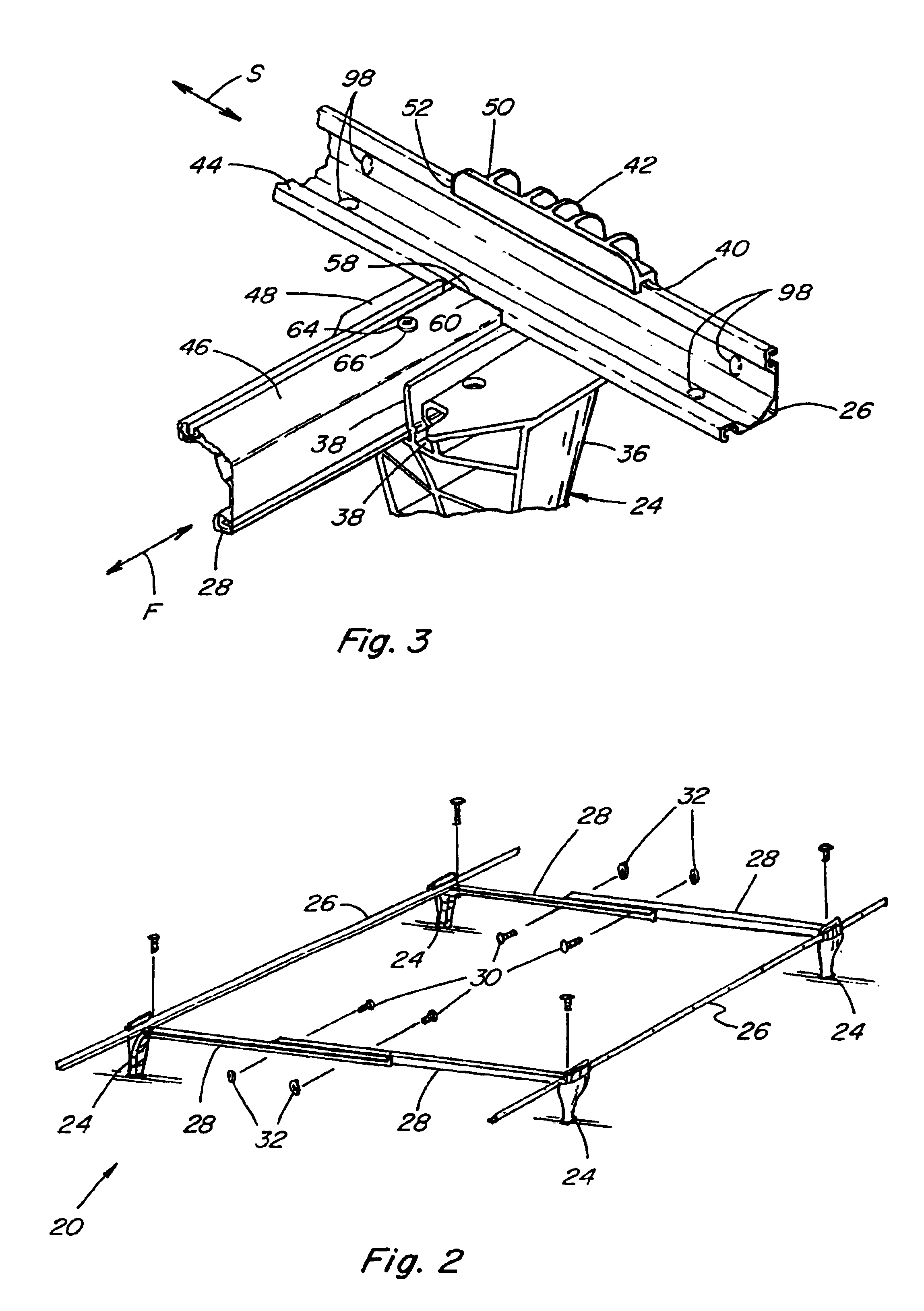

Bed frame

InactiveUS6941596B2Avoid loosenessPrevent saggingSpring mattressesSofasClassical mechanicsStructural engineering

A bed frame assembly for supporting a bed in a substantially flat manner above a floor including interlocking elongate rails and feet for forming a rectangular, flat platform, each of the feet including an upper portion defining a receptacle oriented in a first direction for receiving a longitudinal end a portion of a first of the rails, and a second receptacle oriented in a second direction at about a 90 degree angle to the first direction for receiving a portion of a second of the rails, such that when received in the receptacles, respectively, the first and second rails being in abutting interlocking relation and extend in the first and second directions defining the platform, and elements cooperatively engageable with each of the feet, respectively, for holding the rails in the abutting relation.

Owner:SCHUMAN ETHAN JOEL +1

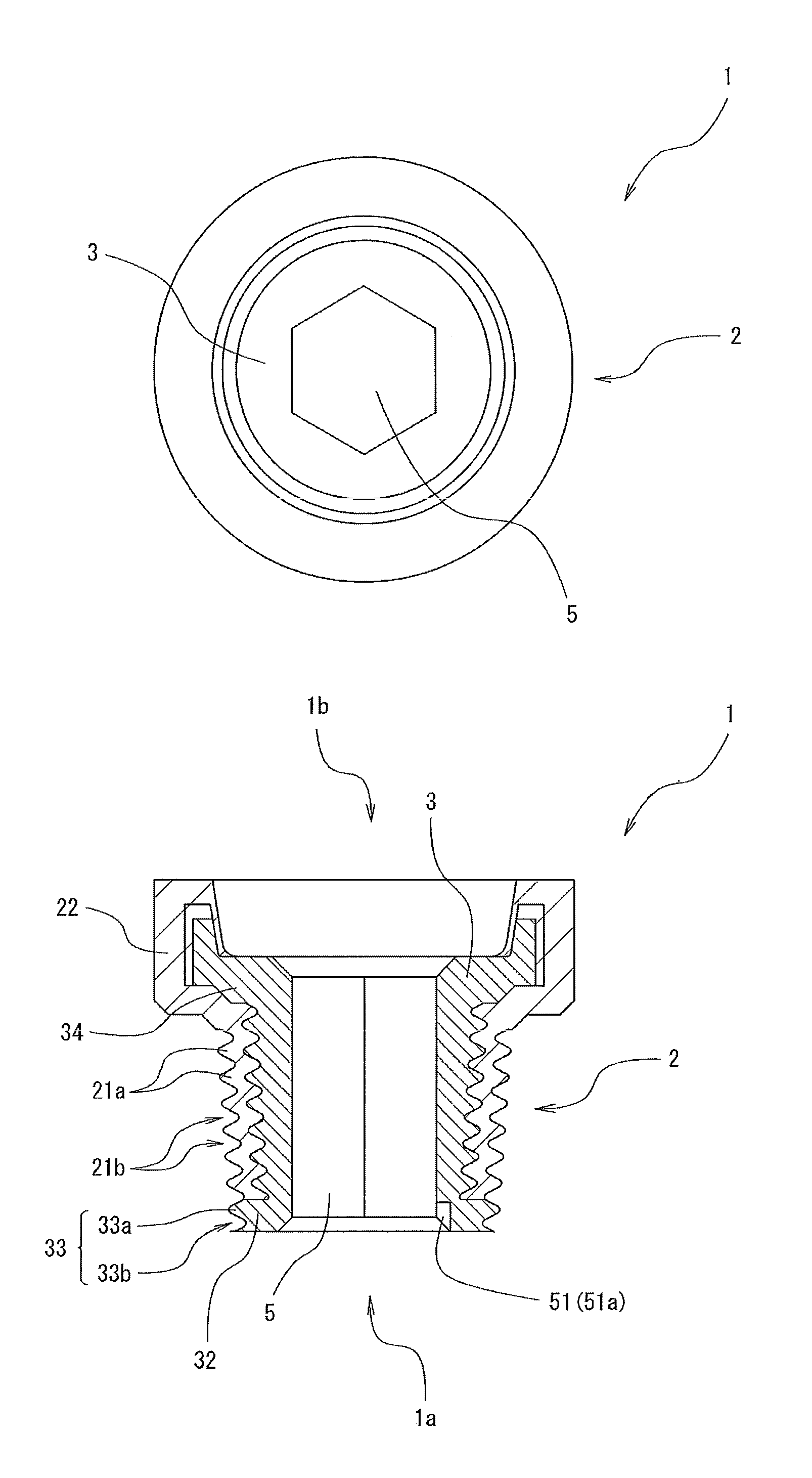

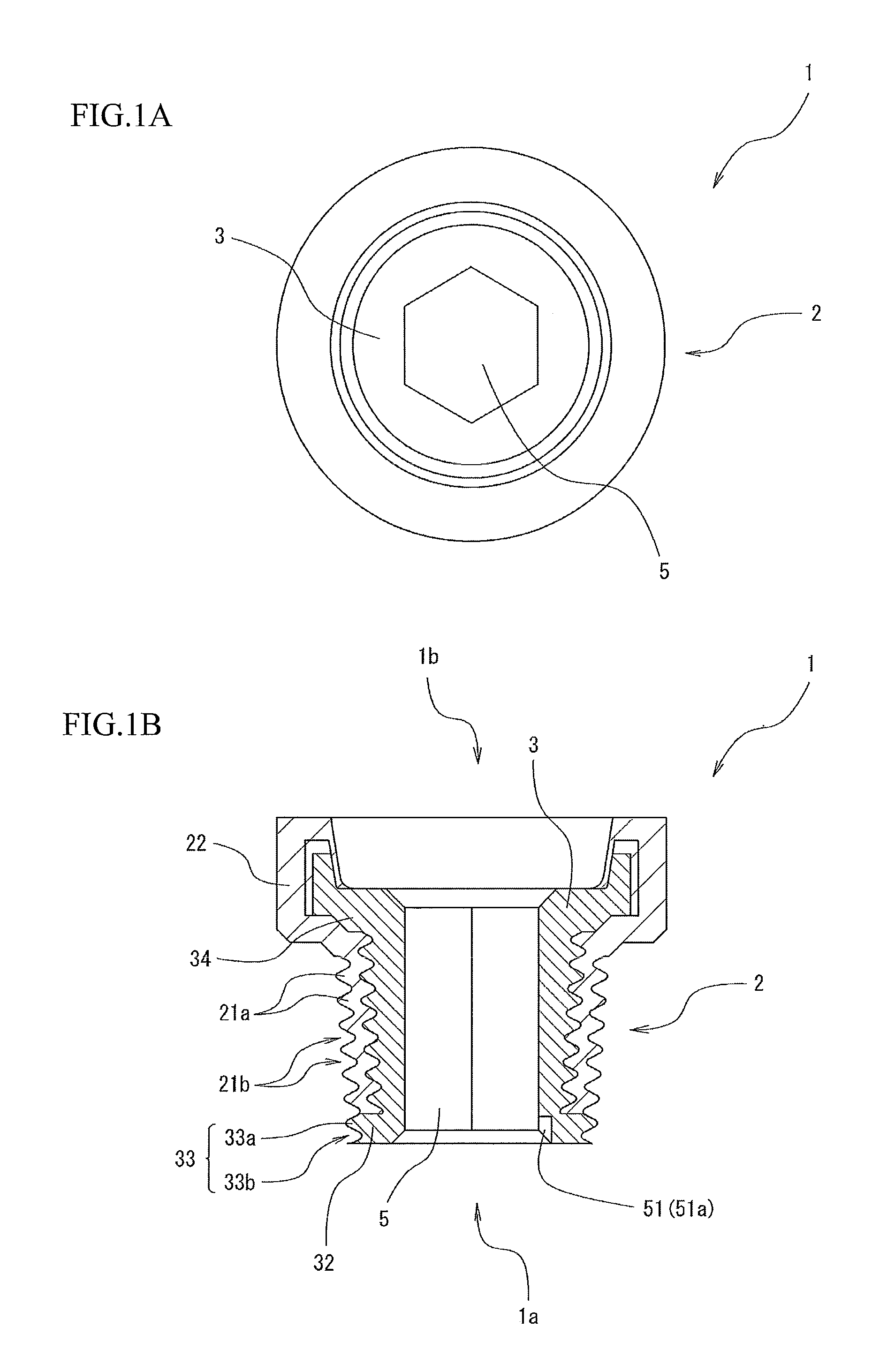

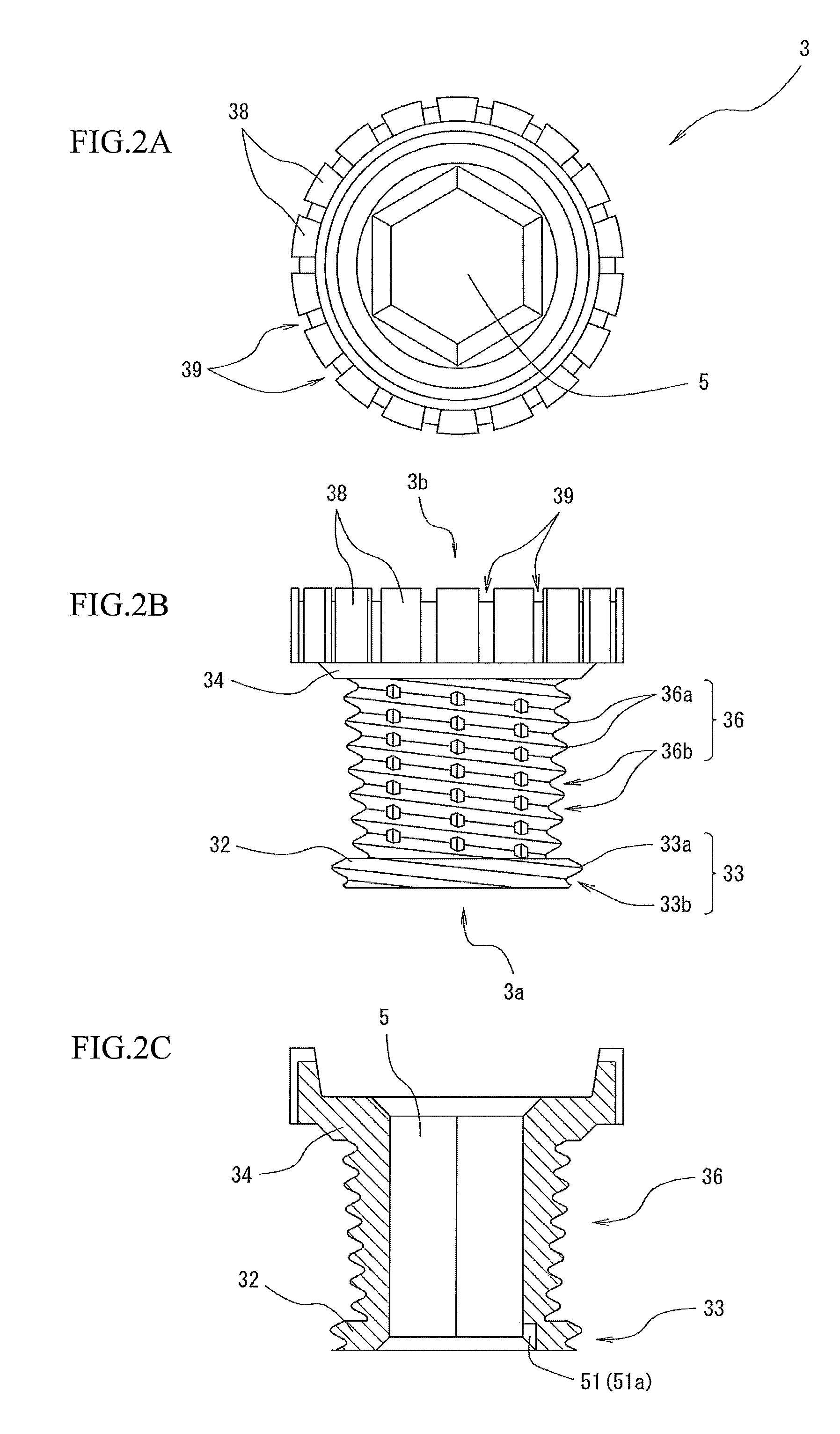

Thread, fastening system, pipe fitting and method for manufacturing thread

To provide a thread in which looseness can be prevented over a long period of time, and a high sealing properties can be maintained, a manufacturing method of the thread, a fastening system using the thread, and a pipe fitting using the thread. A thread according to the present invention is provided, wherein, a screw thread member of which screw threads are formed on an outer periphery thereof and which is made up of a softer material than that of an insert core is formed in a close contact with an outer periphery of the insert core, large-diameter parts that sandwich the screw thread member therebetween in an axis line direction are formed, in a fore end part and a rear end part of the insert core or an intermediate part nearer to the fore end part 3a from the rear end part, and screw threads that are continuous to screw threads of the screw thread member are formed on an outer periphery of a large-diameter part of the fore end part.

Owner:YUGEN KAISHA HAMA INT

Preparation method of aluminum-titanium-boron wire grain refiner

The invention relates to a preparation method of an aluminum-titanium-boron wire grain refiner. The preparation method is implemented by continuous cast rolling after smelting and specifically comprises the following steps: (1) melting: adding a pure aluminum ingot into a crucible furnace, melting into liquid aluminum, and heating; (2) alloying: sequentially adding potassium chloride, potassium fluotitanate and potassium fluotitanate into the liquid aluminum in the liquid aluminum heating process in the step (1), and heating while stirring until the reaction is complete, thereby obtaining liquid alloy aluminum; (3) stirring, degassing and deslagging: transferring the liquid alloy aluminum prepared in the step (2) into an industrial-frequency core-free holding furnace, and stirring and degassing; and (4) continuous cast rolling: transferring the deslagged liquid aluminum into a mold, carrying out rubber filtration, crystallizing the wheel die cavity, carrying out continuous rolling by a continuous rolling machine, and taking up to obtain the aluminum-titanium-boron wire. The preparation method avoids the phenomenon of blistering or loosening since the liquid aluminum is oxidized or absorbs gas, and enhances the elongation percentage of the aluminum-titanium-boron wire.

Owner:NANTONG ANGSHEN METAL MATERIALS

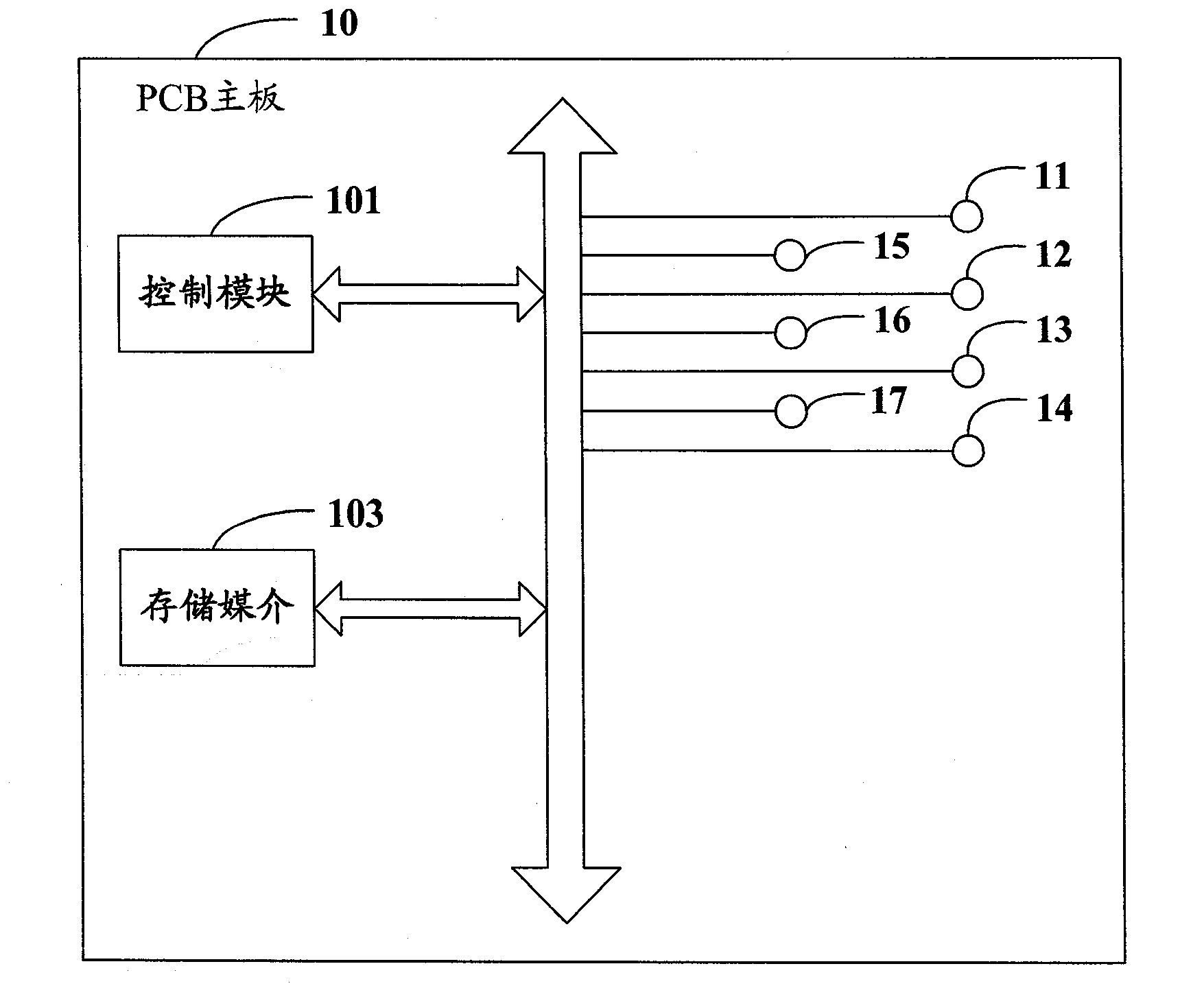

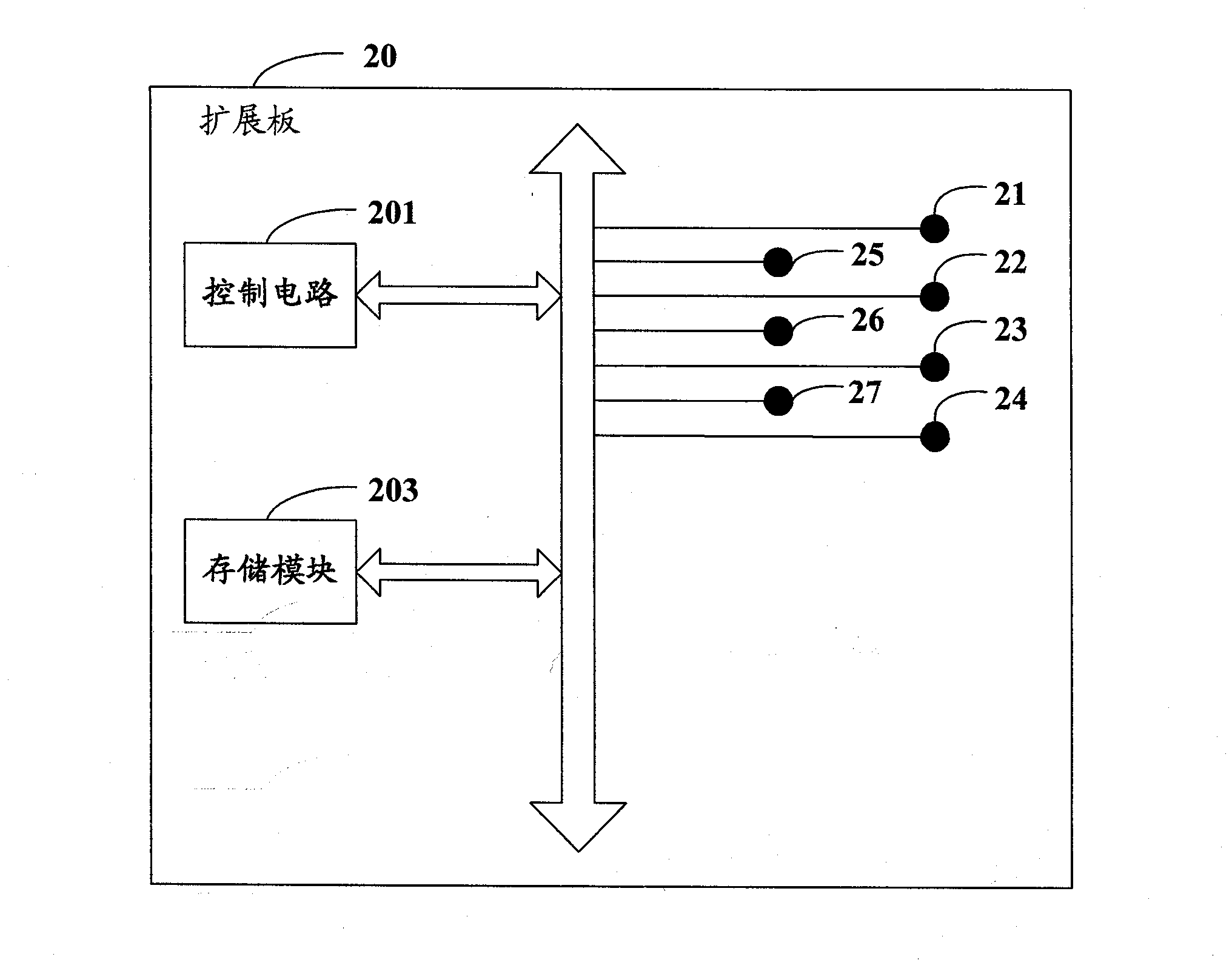

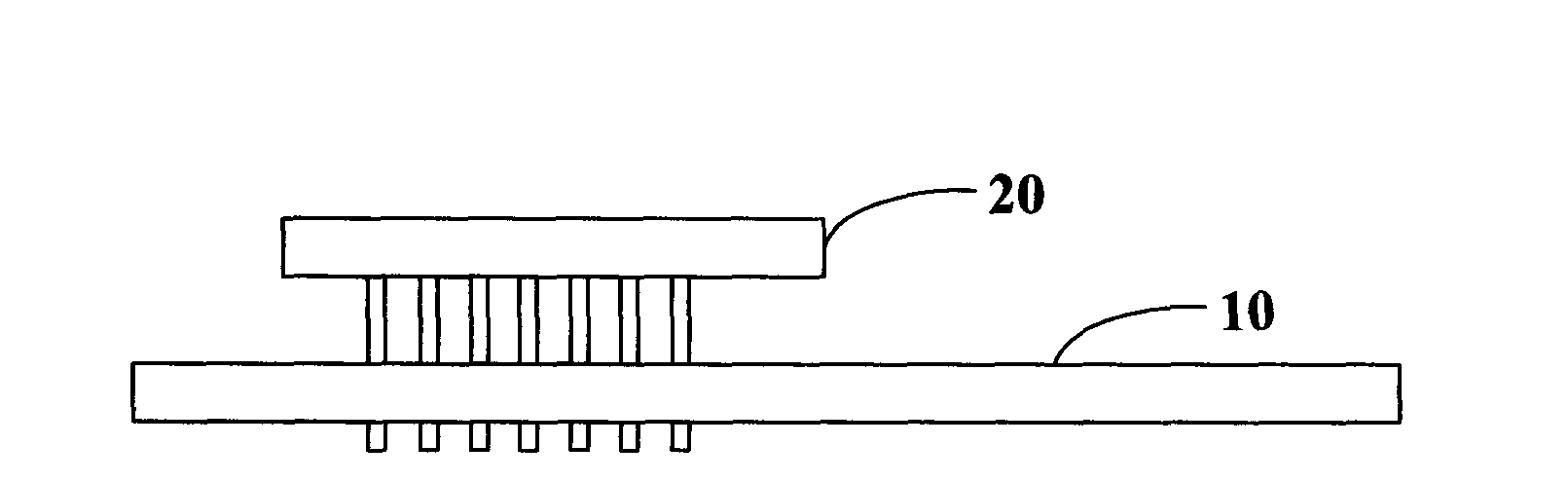

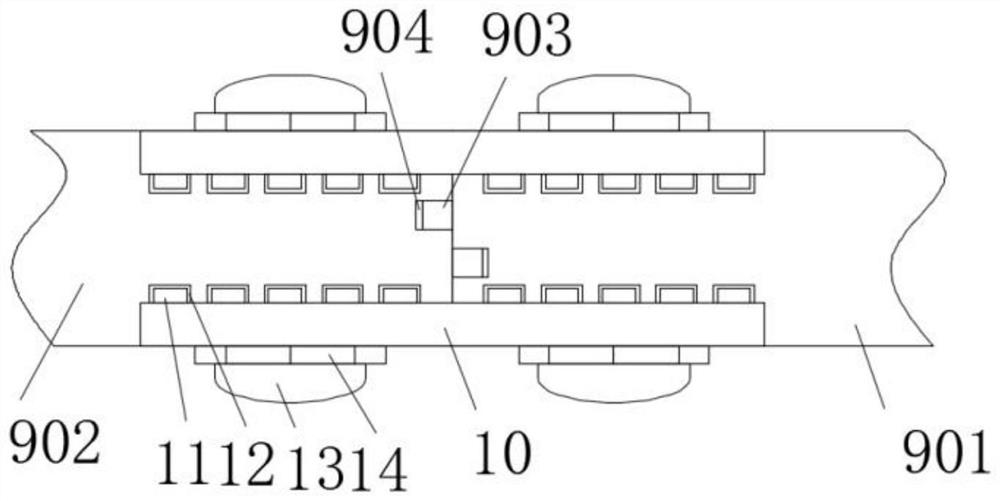

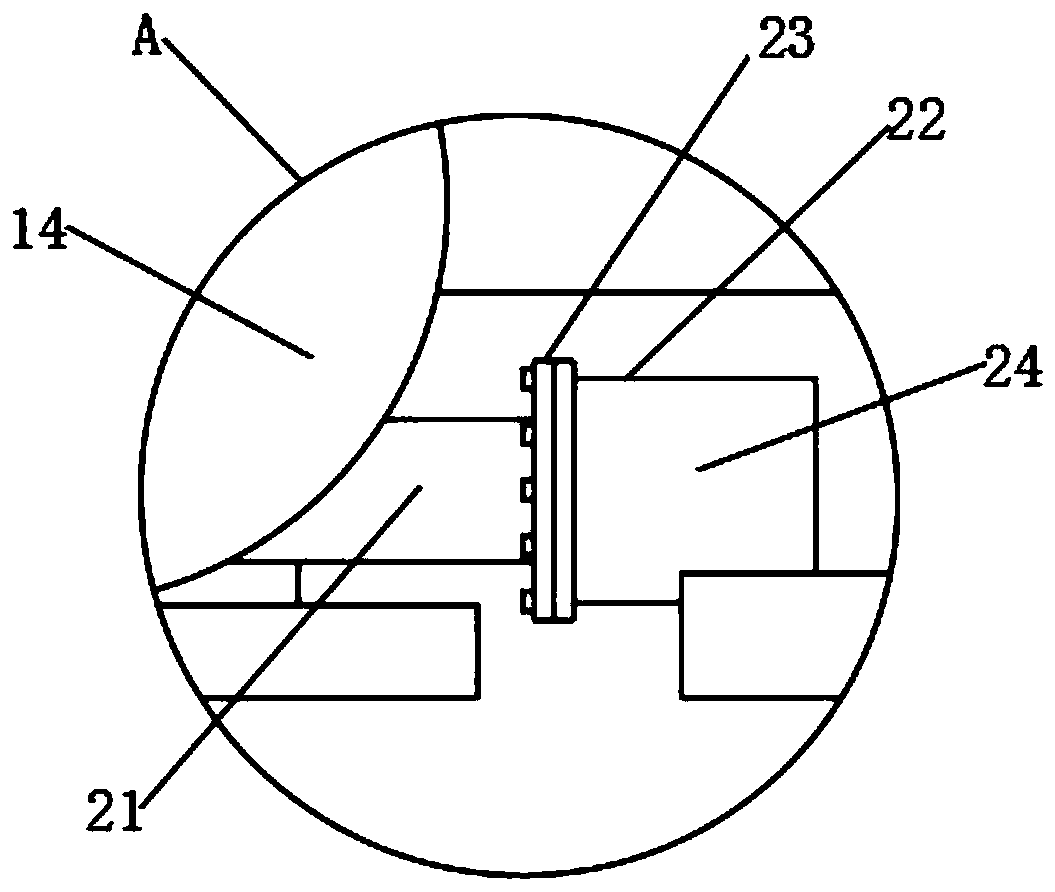

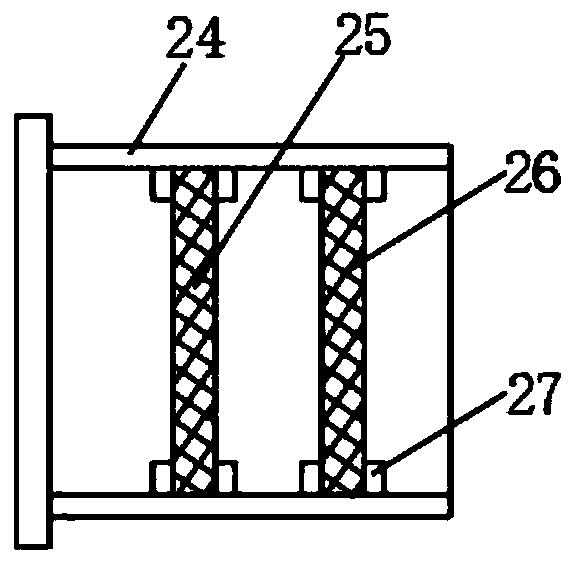

Extension PCB

InactiveCN103857170AAvoid loosenessImprove experiencePrinted circuit detailsElectrical connectionEngineering

The invention is applicable to the storage field, and provides an extension PCB. The extension PCB comprises a PCB main board and an expansion board; the PCB main board is provided with a plurality of pin holes; the expansion board is provided with a plurality of pins; and the plurality of pins arranged on the expansion board are correspondingly inserted into the plurality of pin holes arranged on the PCB main board so as to form an electrical connection. The extension PCB provided by the invention can avoid the looseness problem which is usually caused by the adopted USB interface, and can realize a novel and steady expansion PCB, so as to improve the user experience.

Owner:FUTUREPATH TECH

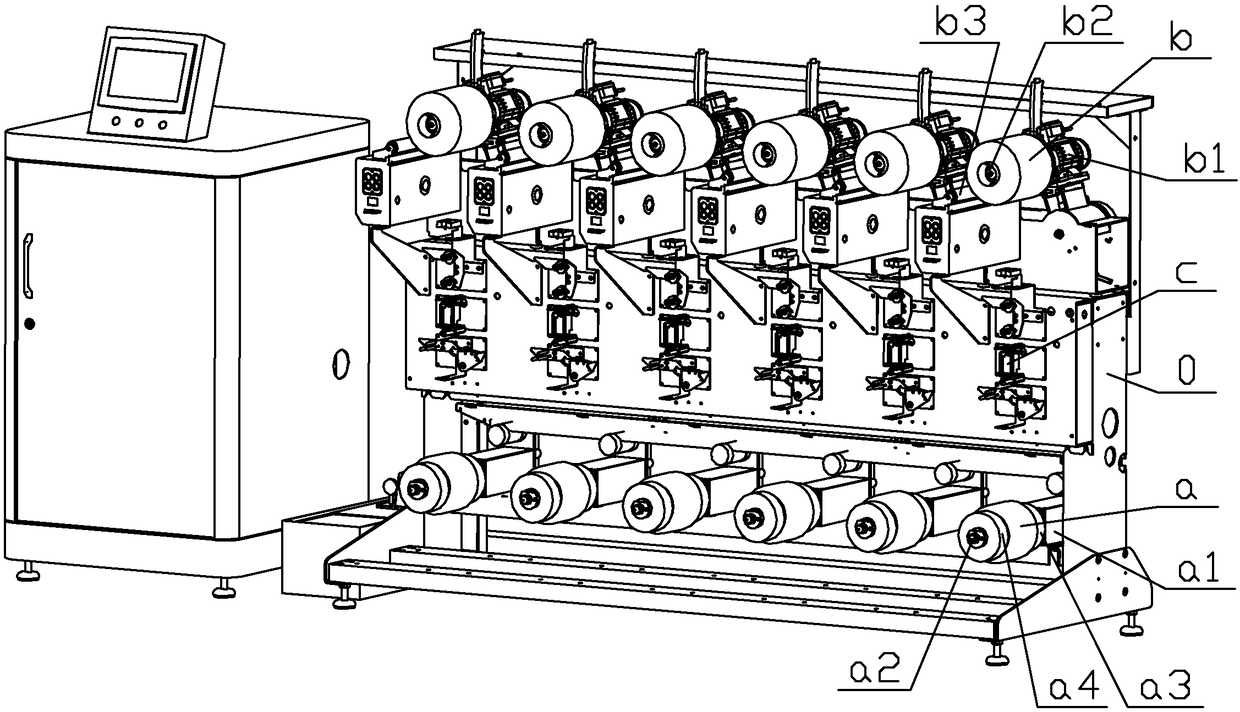

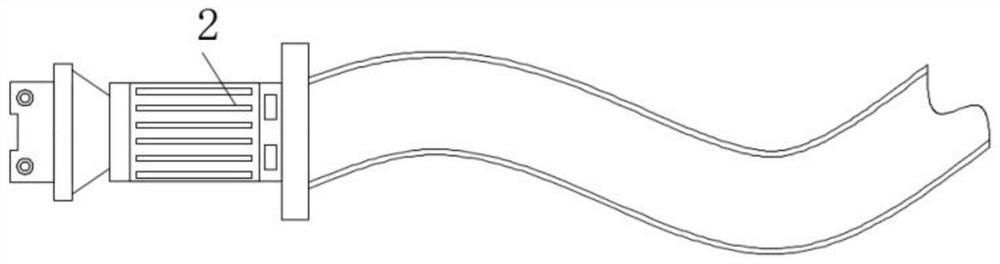

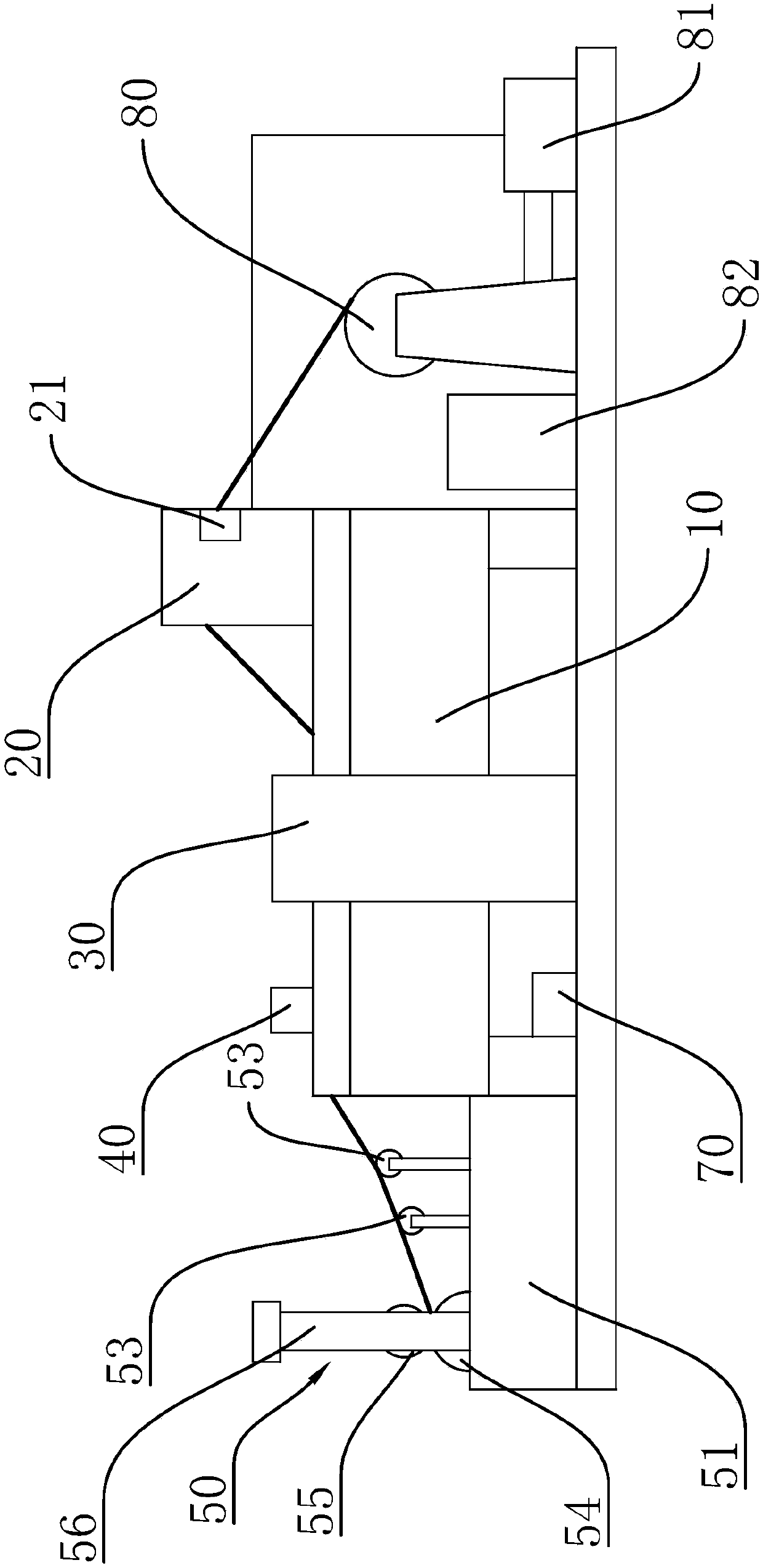

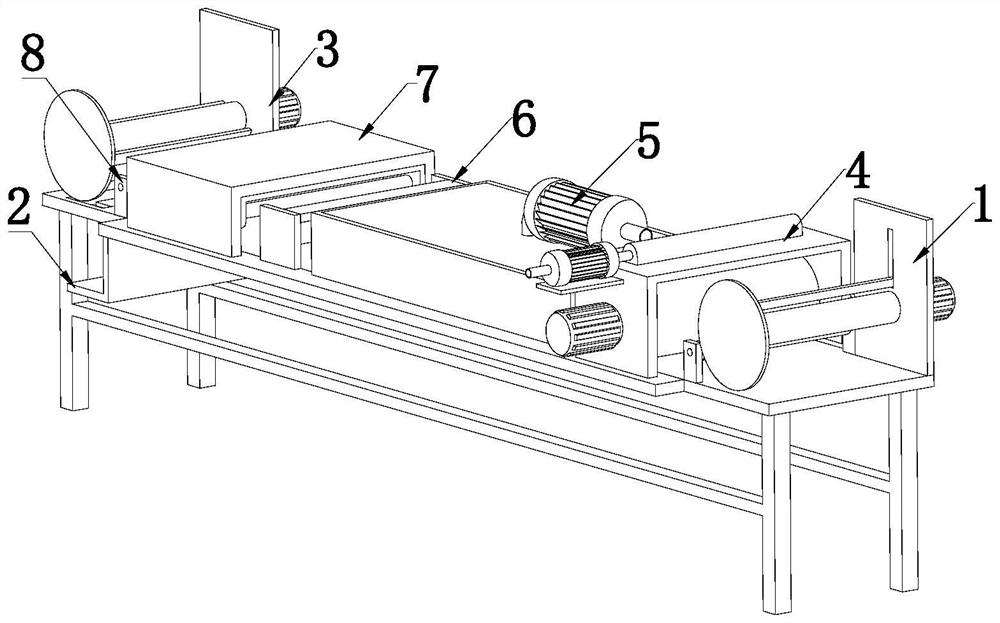

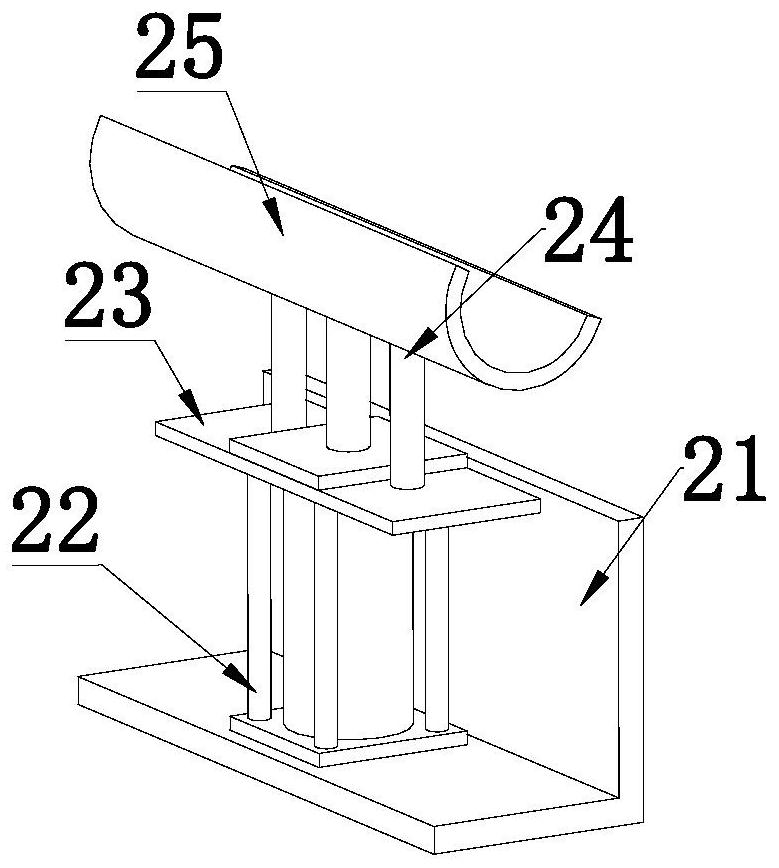

Viscose filament whole machine mechanism

PendingCN108892001AAvoid knotsImproved positioning and stabilityFilament handlingViscose fiberFilament yarn

The invention discloses a viscose filament whole machine mechanism. The surface of an abutting wheel on an active winding mechanism of the viscose filament whole machine mechanism has a slight inclination angle; by means of the inclination angle, the shape of a main reel and the elasticity of yarn after winding, the yarn can be well kept clamped and wound by the abutting wheel and the main reel, the phenomenon of winding loosening of some positions caused by insufficient matching of an original columnar abutting wheel is avoided, and the net conditions of the well wound yarn are reduced. A unwinding mechanism can deform well through a columnar elastic lining plate, and is distracted after reeled yarn is sleeved, an inner pressing disc and an outer pressing disc are sleeved in a front-rearmode to form a stable structure, the inner pressing disc and the outer pressing disc sleeve a rotating shaft and can drive the rotation to achieve yarn unwinding; if the yarn becomes loosened in the unwinding process, the elastic lining plate can be further distracted by means of elasticity, so that the yarn keeps a good tensioned state, the knotting and winding caused by yarn loosening are avoided, a yarn reeling mode such as the positioning and stabilization of viscose filaments is improved, and quick unwinding is achieved.

Owner:XINCHANG WANSHIFA TEXTILE MACHINERY

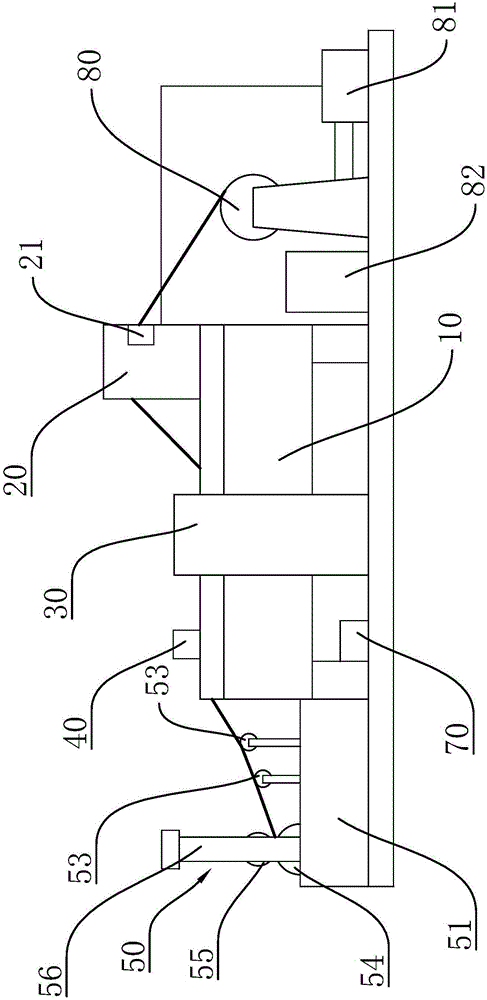

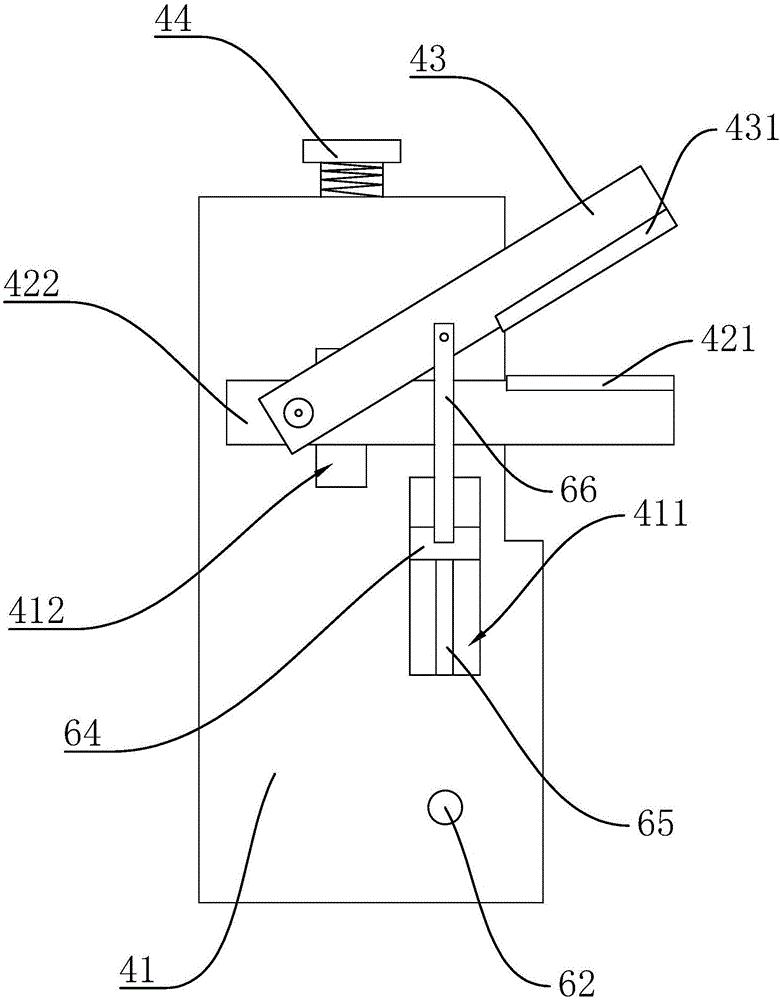

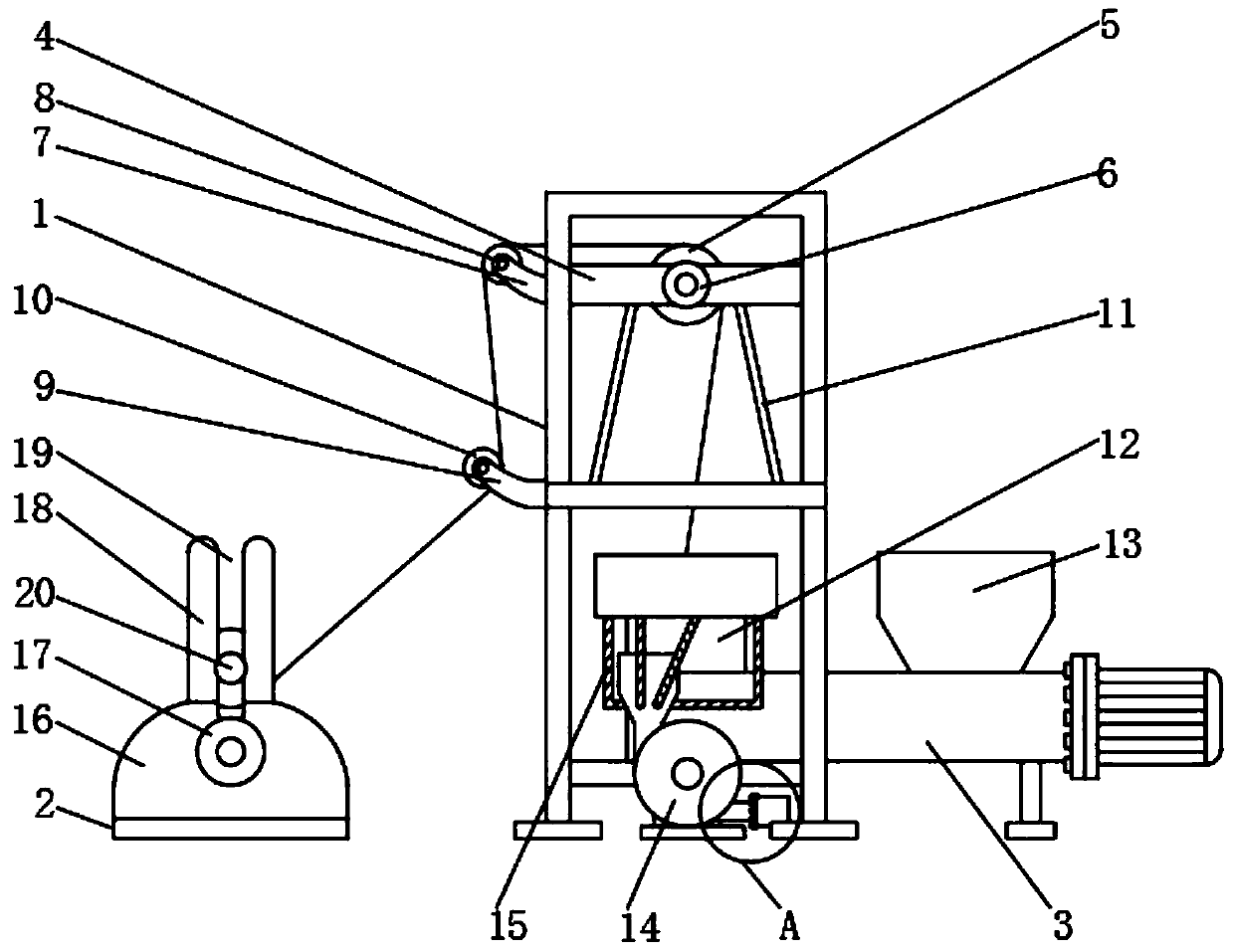

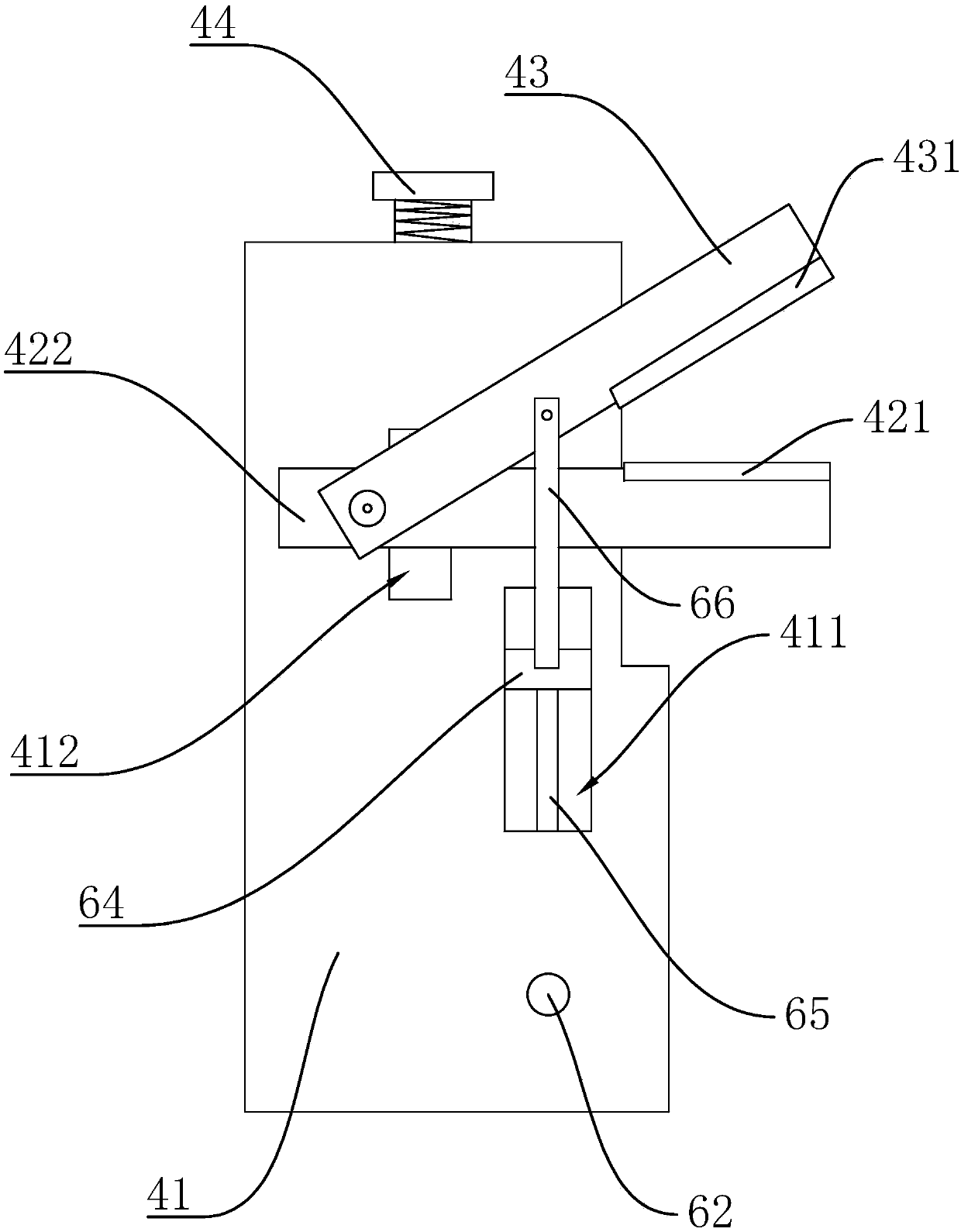

Rapier loom

ActiveCN106048864AImprove surface qualityAccurate and fast resetLoomsAuxillary apparatusPush and pullMotor drive

The invention provides a rapier loom which comprises a workbench, a warp let-off mechanism, a weft let-off mechanism, a slitter edge cutting mechanism and a rolling mechanism. The slitter edge cutting mechanism comprises a cutter rest, a fixed cutter body and a movable cutter body, the fixed cutter body is provided with a first blade, the movable cutter body is provided with a second blade, the fixed cutter body is fixed to the cutter rest in a height-adjustable mode, the movable cutter body is hinged to the fixed cutter body, and the first blade and the second blade abut against each other to form a cutting opening; the slitter edge cutting mechanism further comprises a motor driving the movable cutter body to rotate, a transmission shaft and a rotating disc, and the transmission shaft is controlled by the motor and fixedly connected to the center of the rotating disc; the cutter rest is provided with a longitudinal sliding groove, a sliding block is arranged in the sliding groove, a first connecting rod used for driving the sliding block to rise and fall is arranged between the sliding block and the rotating disc, a second connecting rod used for pushing and pulling the movable cutter body is arranged between the sliding block and the movable cutter body, one side of the sliding block is fixedly connected with the second connecting rod, and the second connecting rod is hinged to the movable cutter body; the other side of the sliding block is hinged to the first connecting rod, and the first connecting rod is hinged to the eccentric position of the rotating disc.

Owner:LANGXI YUANHUA TEXTILE

Cable structure with middle reinforcing rib

ActiveCN111883302AImprove physical tensile propertiesImprove deformation abilityFlexible cablesFlexible conductorsElectrical conductorStructural engineering

The invention belongs to the technical field of cables, particularly relates to a cable structure with a middle reinforcing rib, and aims to solve the problem of cable waste in the using process of aused cable due to the fact that the toughness and ductility of an existing cable are poor and the cable is easy to break in the cable pulling process. According to the scheme, the cable comprises a cable body, one end of the cable body is fixedly connected with conductors, the cable body comprises a center line, a plurality of conductors are fixedly attached to the outer side of the center line, insulating layers are arranged on the outer sides of the conductors, the space between the conductors is filled with filler, and the outer side of the filler is fixedly wrapped with a shielding layer;compared with a traditional cable, the cable greatly improves the physical tensile property, and the cable is not prone to breakage in the pulling process; meanwhile, bending adjustment can be conducted on the cable, and the deformation performance of the cable is improved.

Owner:ANHUI HUANYU CABLE GROUP

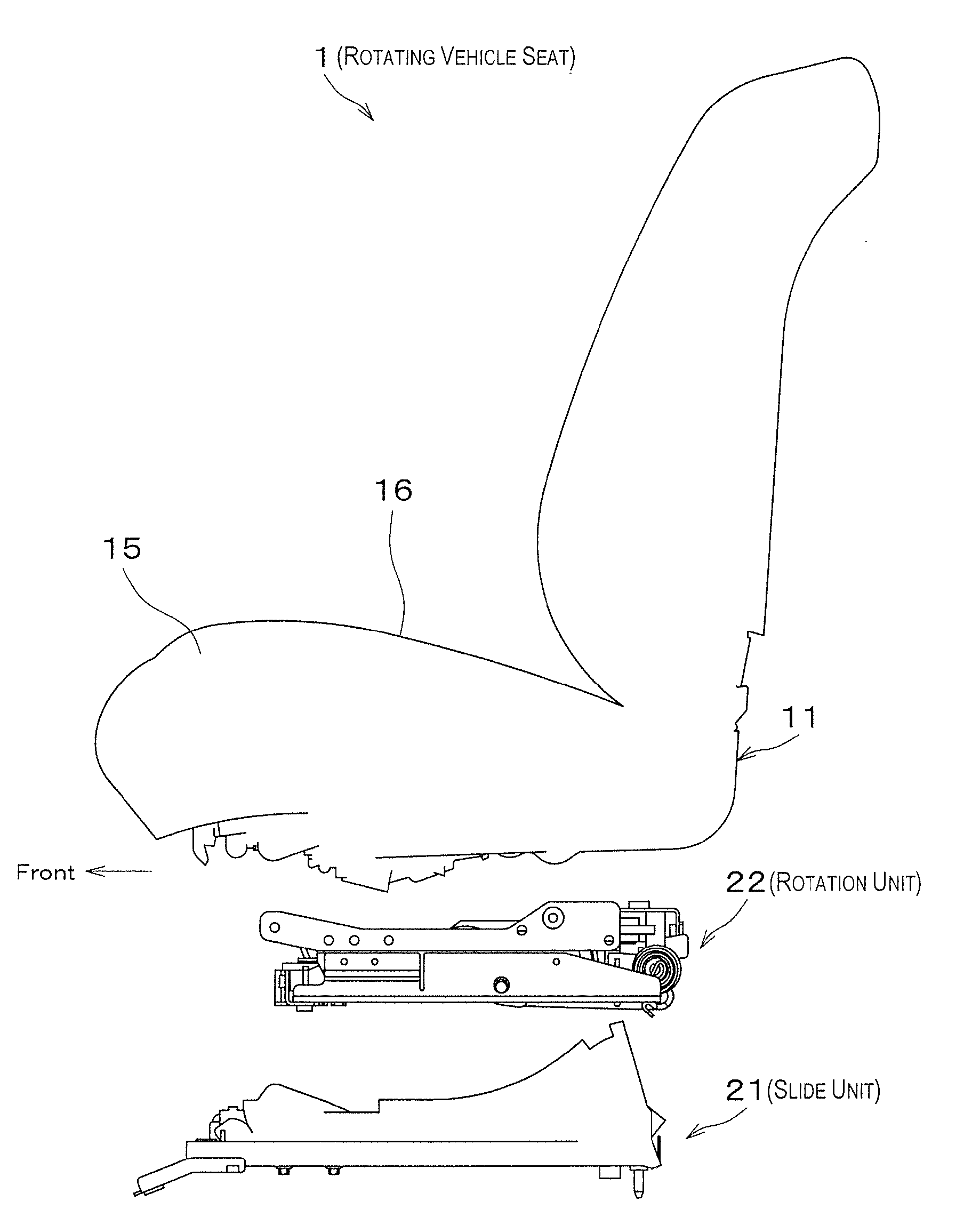

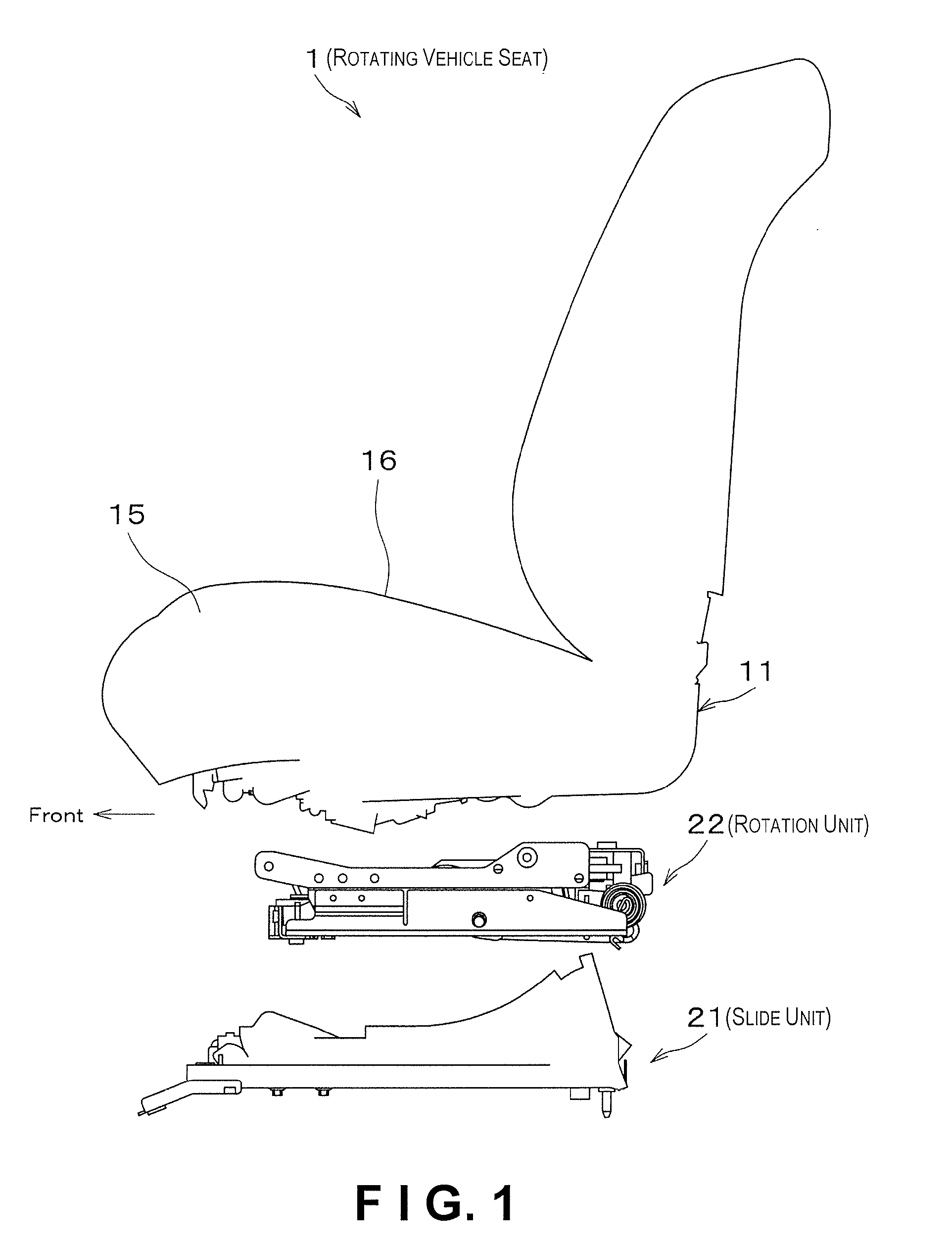

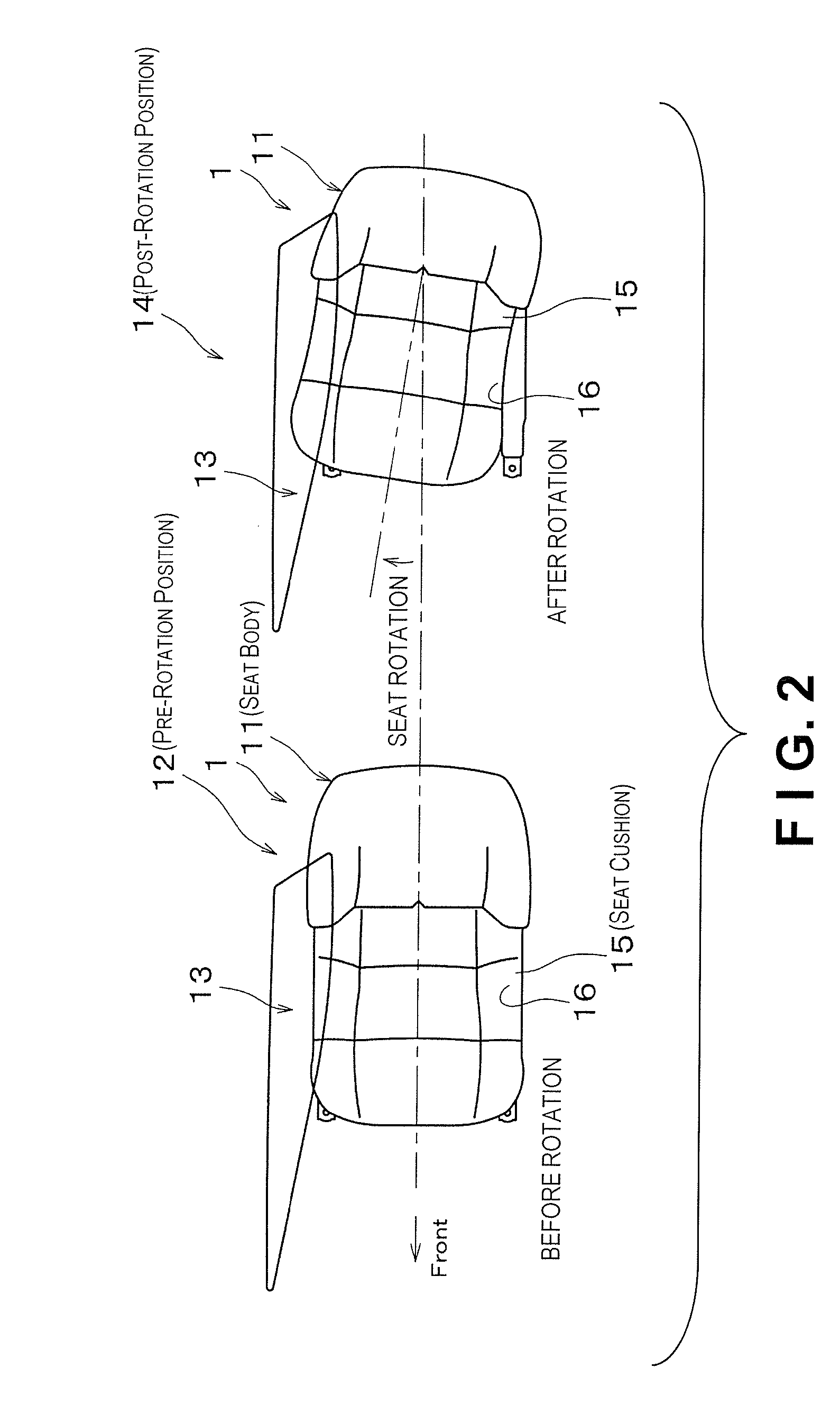

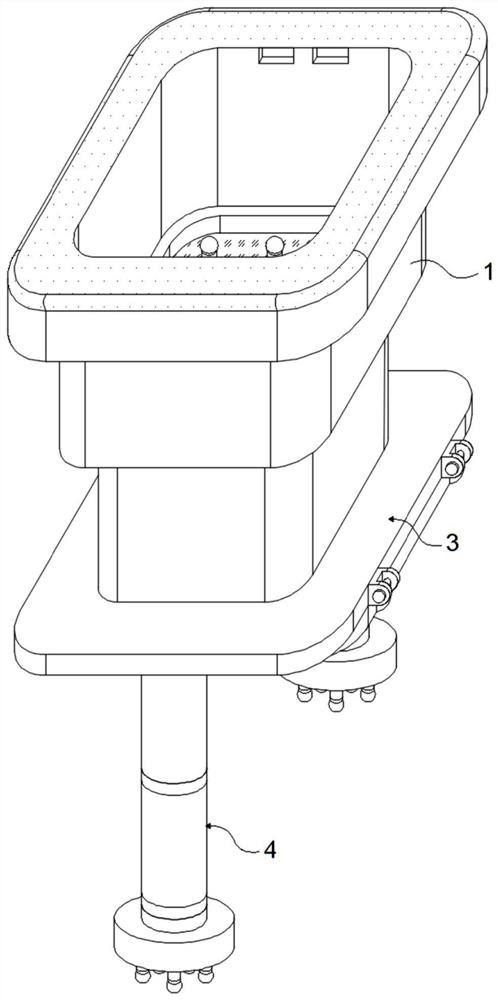

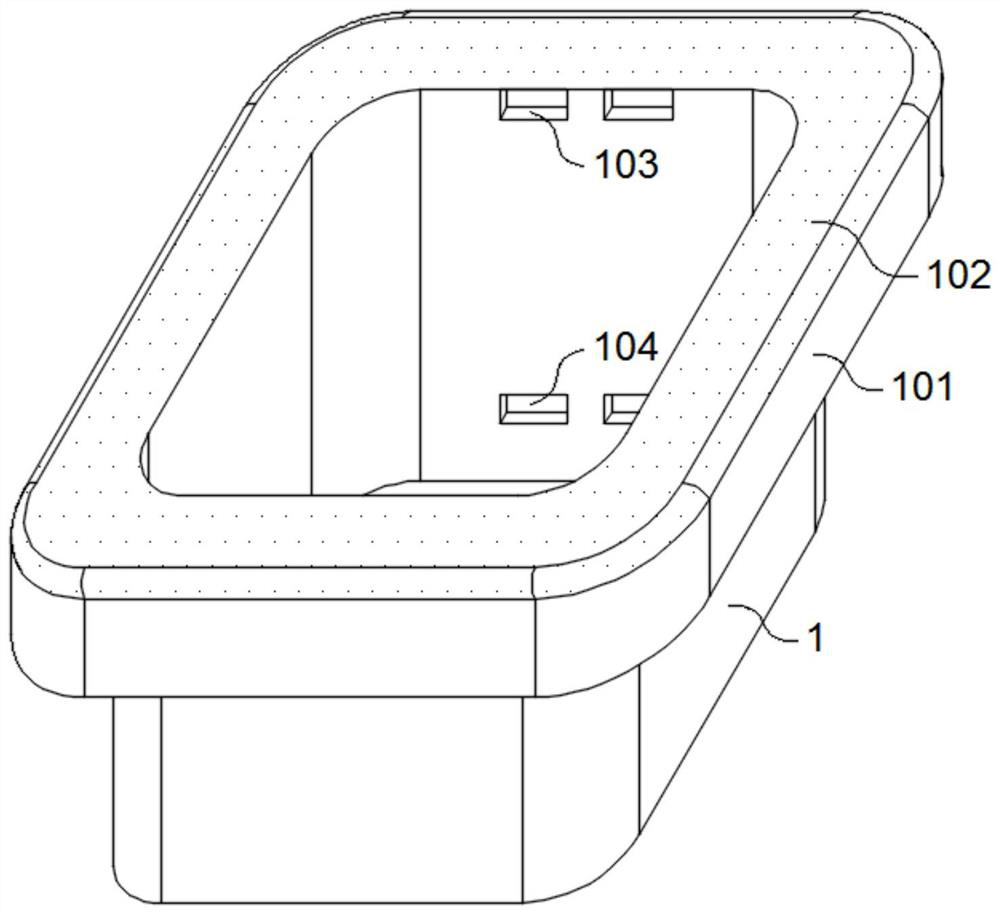

Rotating vehicle seat

InactiveUS20090218865A1Rapid loweringAvoid loosenessOperating chairsDental chairsEngineeringMechanical engineering

Owner:AUTECH JAPAN INC

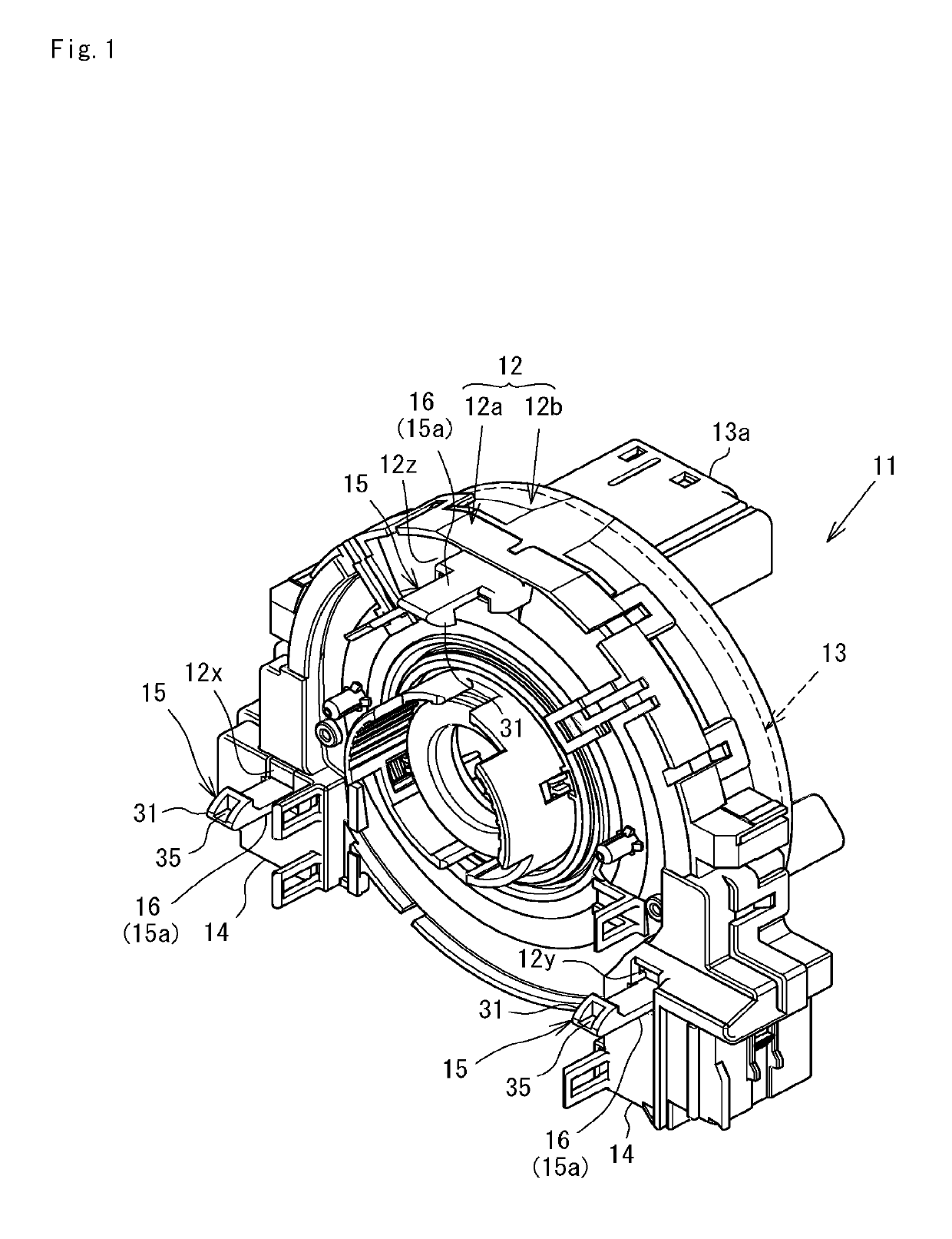

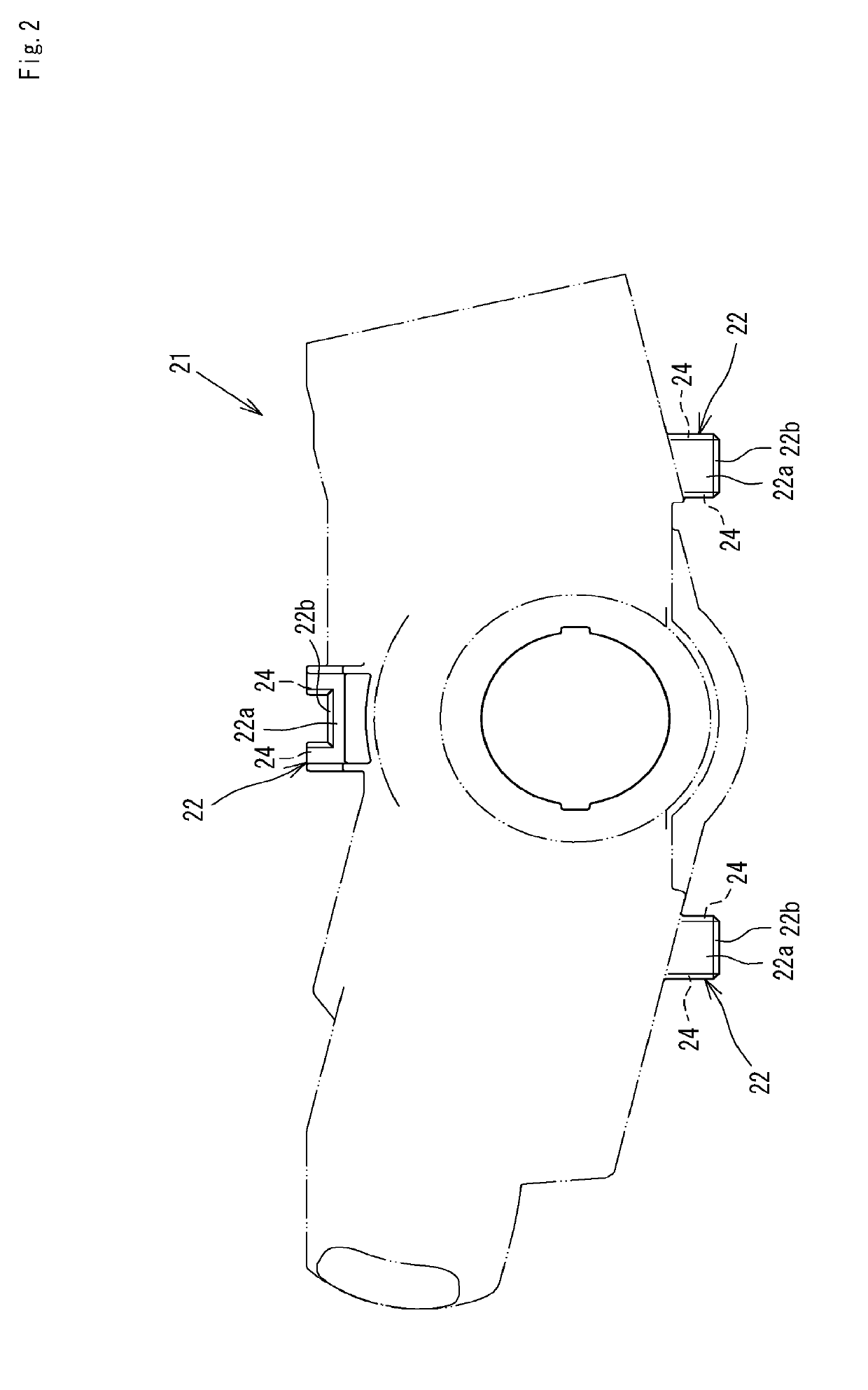

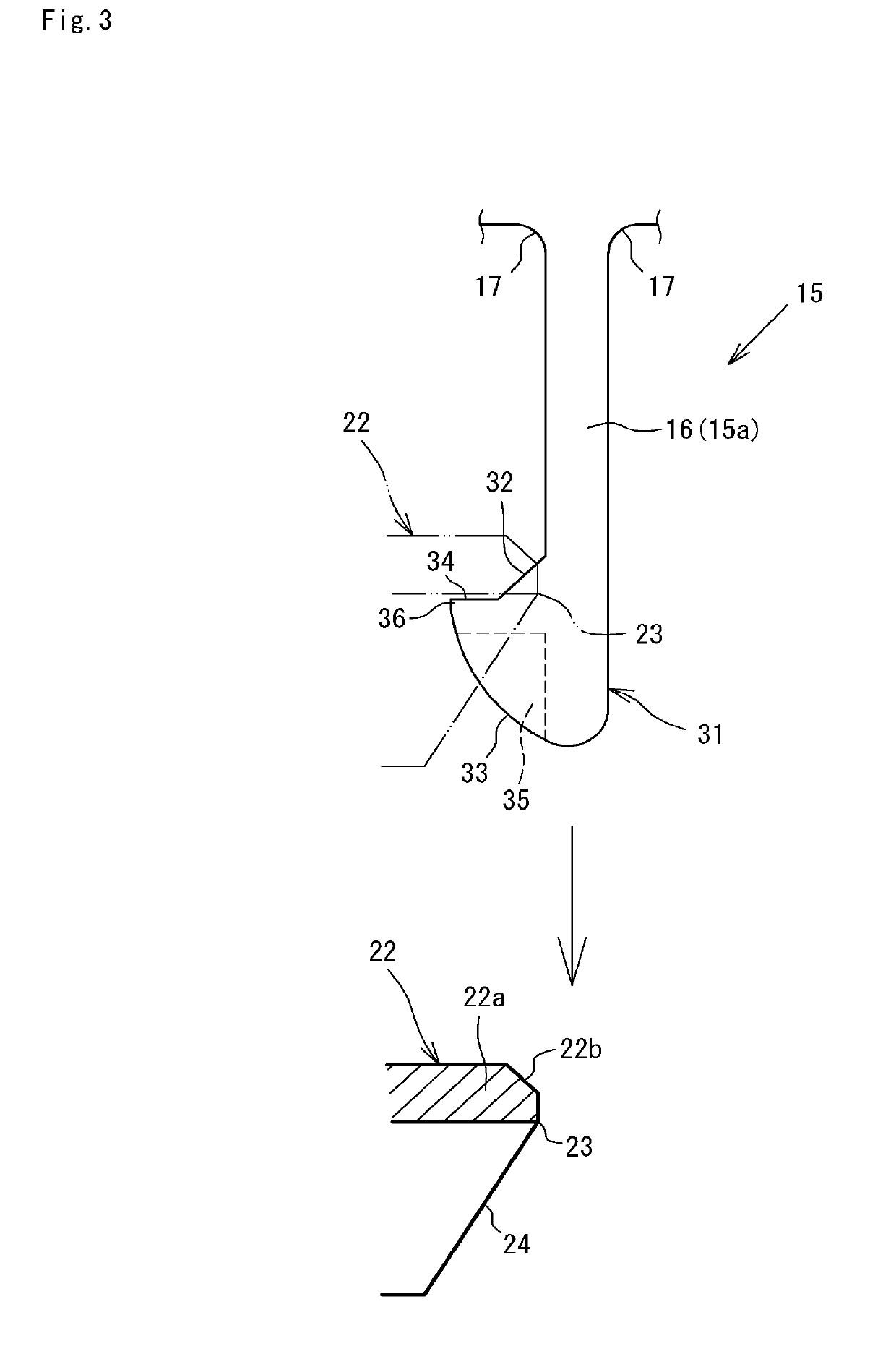

Rotary connector and fixing structure of rotary connector

ActiveUS20190221979A1Avoid loosenessPrevent unexpected liftingCoupling device connectionsVehicle connectorsSteering wheelEngineering

Looseness of a rotary connector and lifting of the rotary connector which occurs depending on a harness wiring state are prevented, to reduce inconvenience such as generation of an abnormal sound due to the rotary connector contacting a steering wheel.In a fixing structure of a rotary connector, which includes a projecting piece 15 to fix the rotary connector to a combination switch and a locked portion 22a to be locked by the projecting piece 15 and in which a laterally protruding locking claw 31 is formed in a tip portion of the projecting piece 15, the locking claw 31 of the projecting piece 15 is integrally provided with a flexible urging portion 15a that displaces and urges the locking claw 31 in a locking direction. A contact surface 32 is formed on the locking claw 31, the contact surface 32 obliquely coming into contact with a locking side corner 23 of the locked portion 22a from the opposing side

Owner:FURUKAWA ELECTRIC CO LTD +3

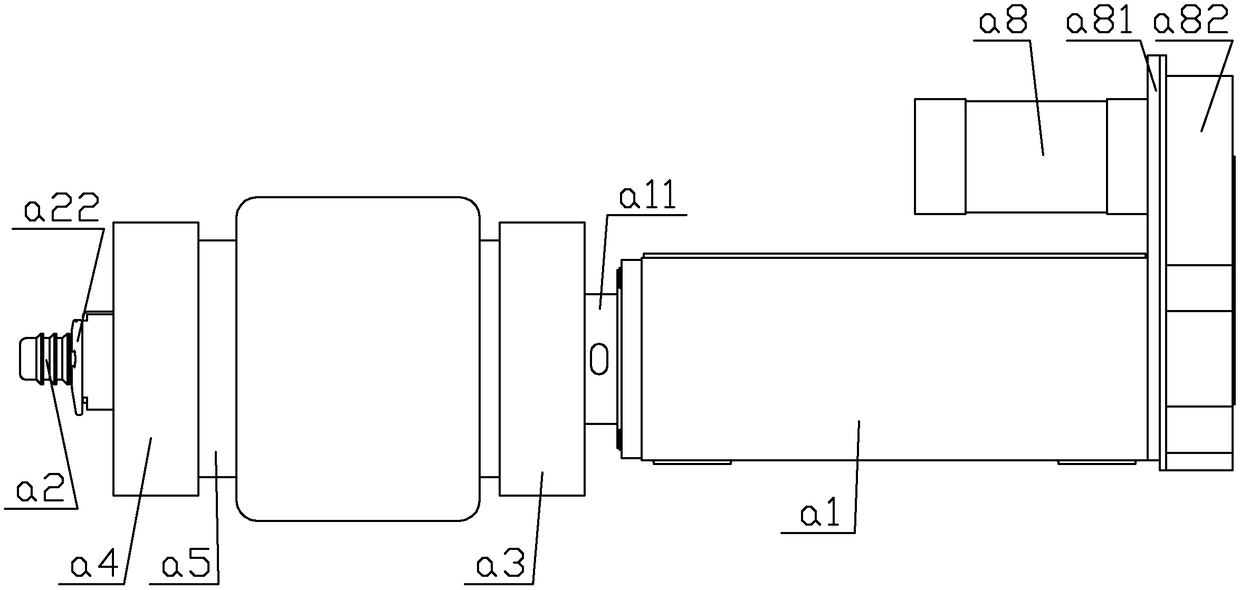

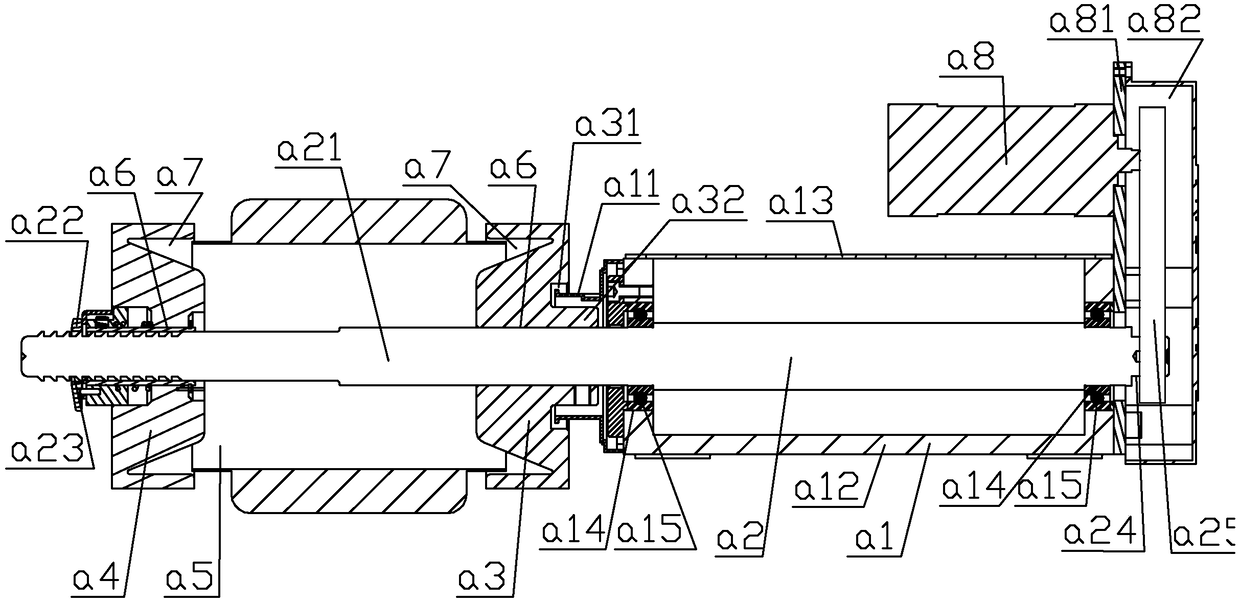

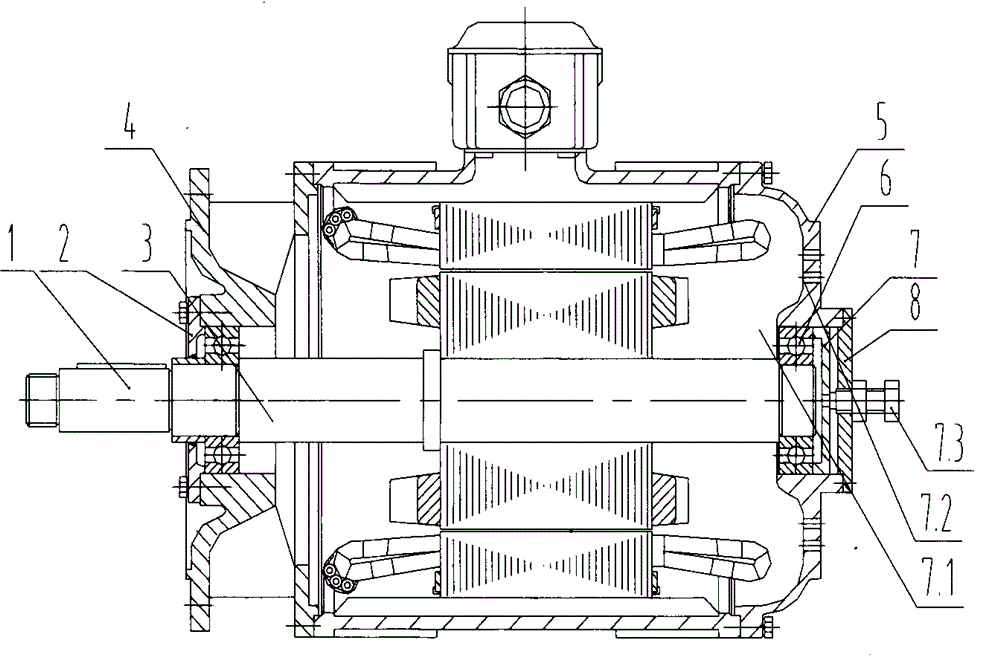

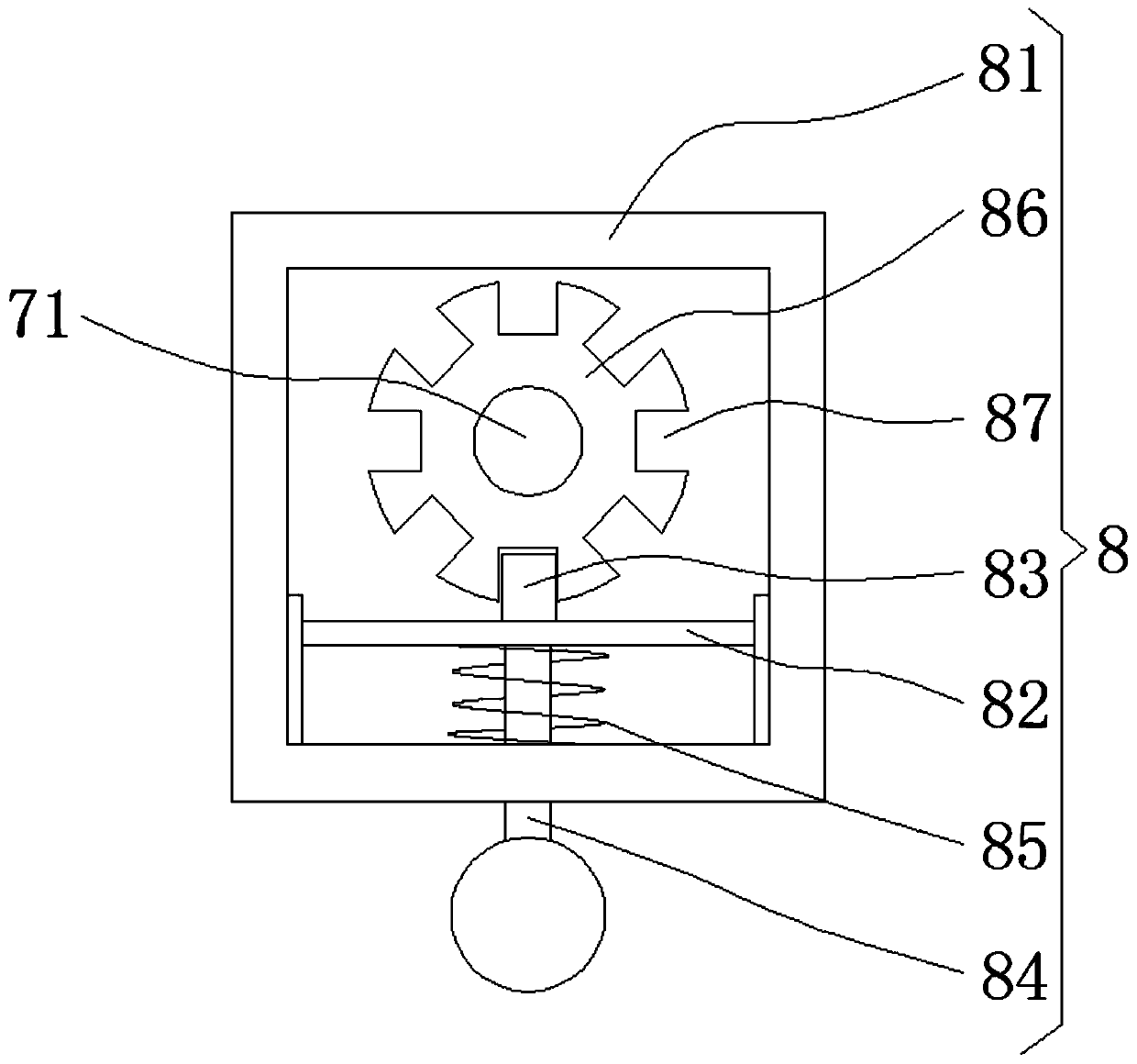

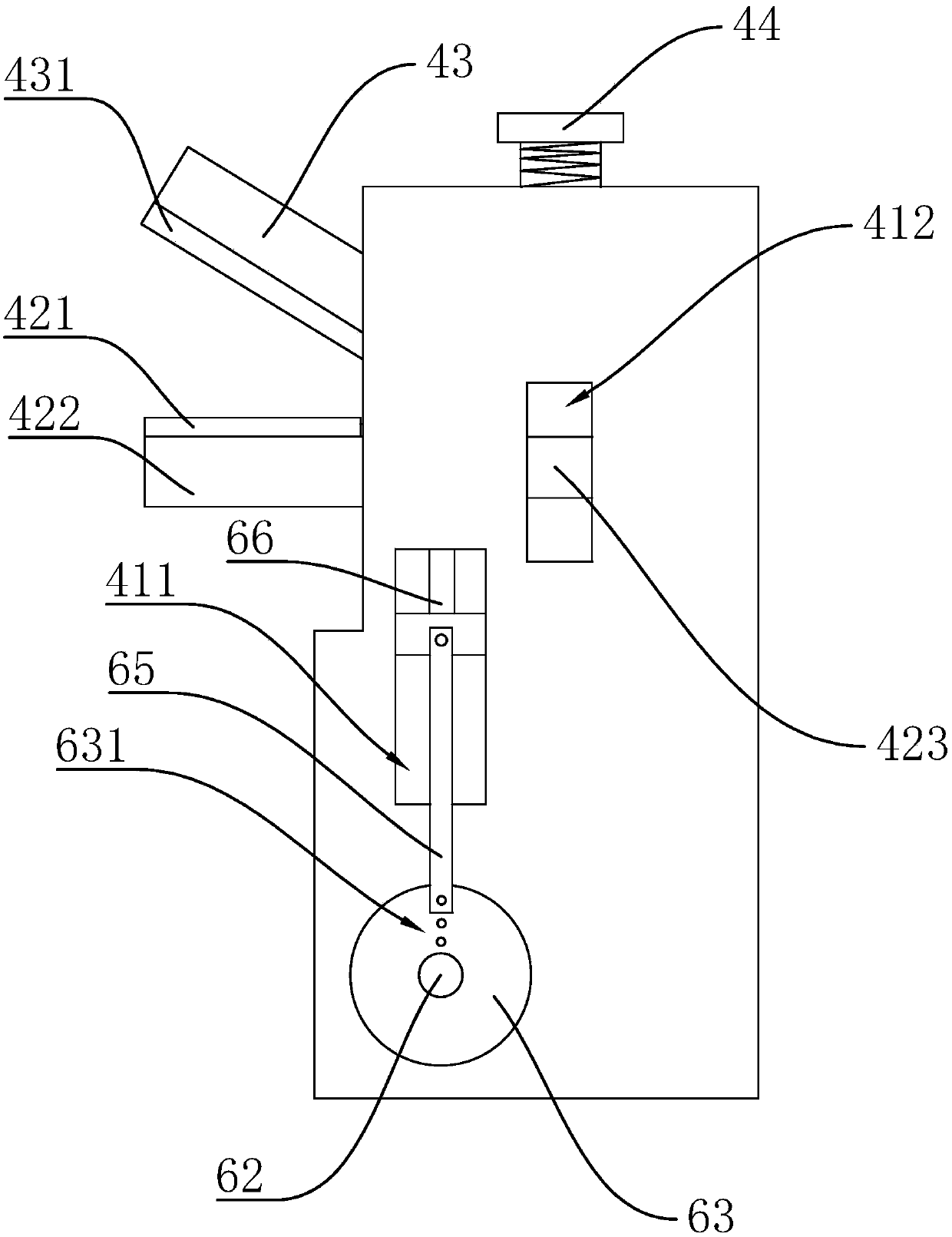

Convenient adjustment structure for motor bearing gap

InactiveCN104659948AEasy to operateAvoid loosenessSupports/enclosures/casingsInterference fitEngineering

The invention discloses a convenient adjustment structure for a motor bearing gap. The convenient adjustment structure comprises a motor shaft, a front end bearing, a rear end bearing, a front end cover, a rear end cover, a front end bearing gland and a rear end bearing gland, wherein the outer circles of the front end bearing and the rear end bearing are respectively embedded into inner holes in the front end cover and the rear end cover; the inner circles of the front end bearing and the rear end bearing interference fit with the two ends of the shaft shoulder of the motor shaft in a sleeving manner; the right end surface of the front end bearing gland is in contact with the left end surface of the outer circle of the front end bearing; a gap is reserved between the right end surface of the rear end bearing and the left end surface of the rear end bearing gland; a gap adjustment device is arranged between the right end surface of the rear end bearing and the left end surface of the rear end bearing gland; the further improvement is that the gap adjustment device comprises a pressing plate and an adjustment screw; the adjustment screw is in threaded connection with the pressing plate; the end part of the adjustment screw penetrates through the pressing plate and is pressed against the pressing plate. According to the convenient adjustment structure, the axial gap of a motor bearing can be adjusted conveniently and quickly at any time; the operation is very simple.

Owner:JIANGSU YUANDONG ELECTRIC MOTOR MFG

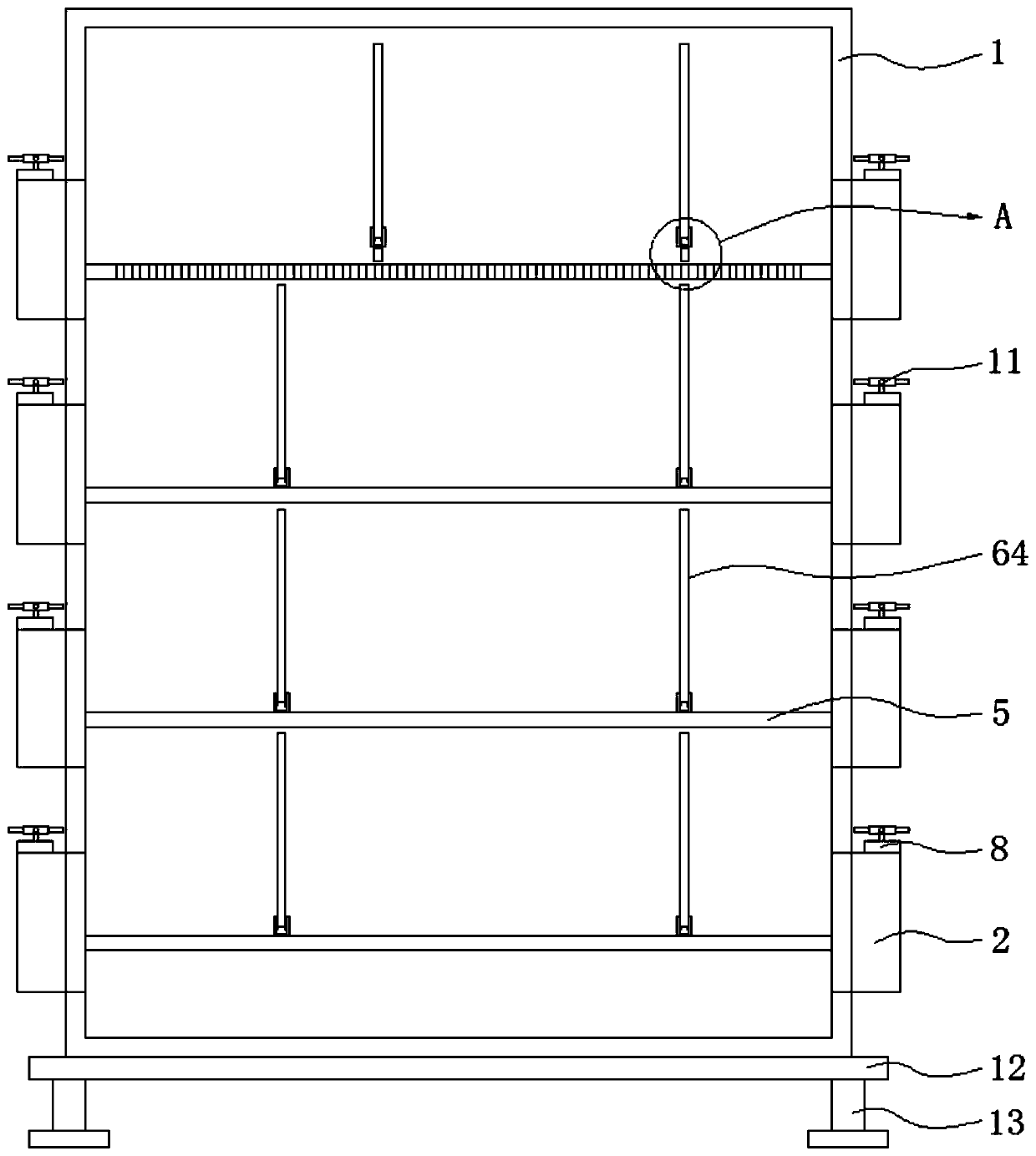

Logistics placing rack capable of adjusting storage space conveniently

PendingCN111348295AEasy to adjust storage spaceGuaranteed stabilityRigid containersExternal fittingsInterior spaceLogistics management

Owner:安徽华源物流有限责任公司

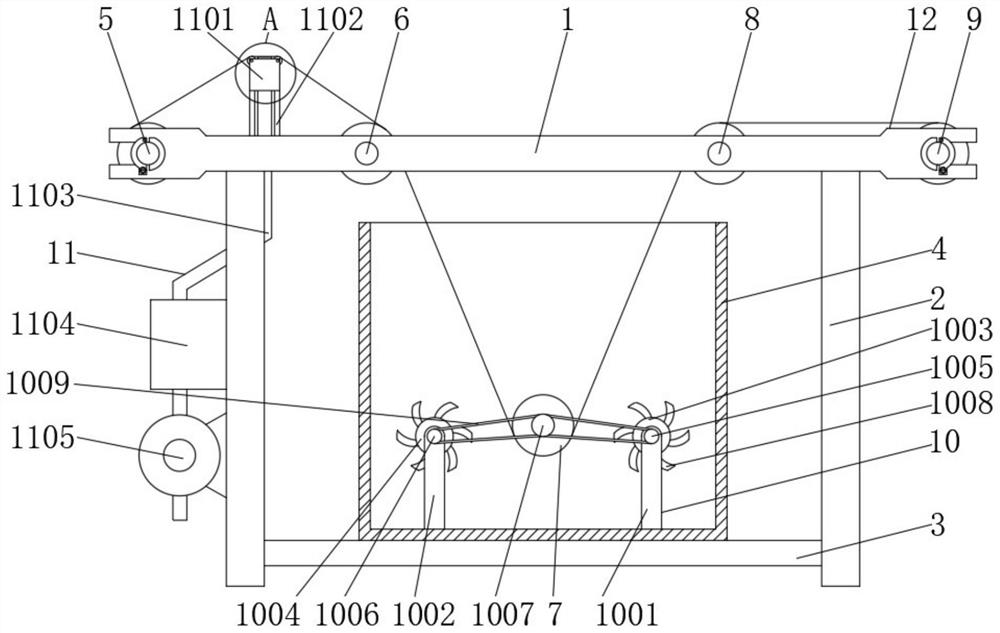

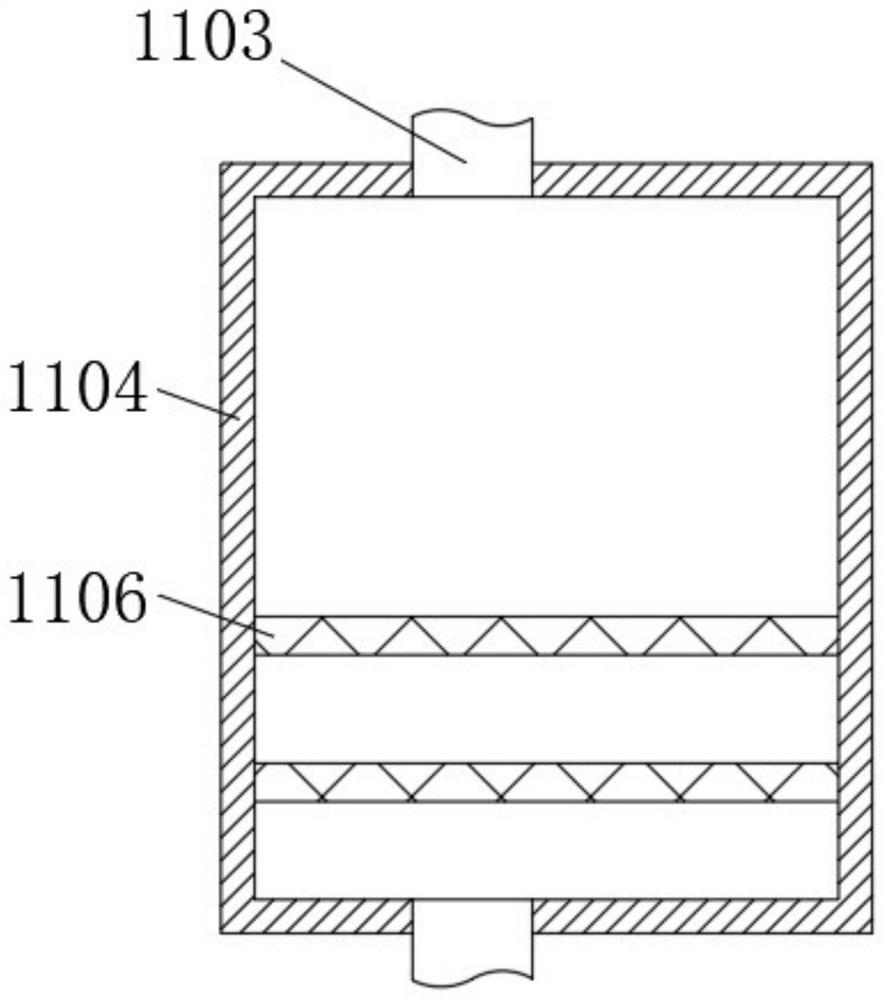

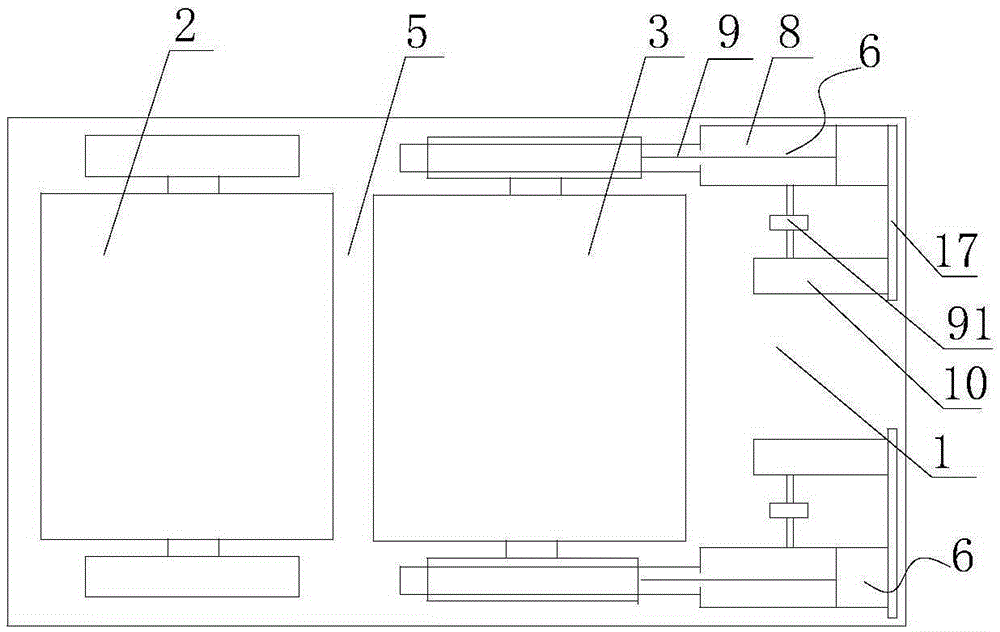

Agricultural film blow molding machine

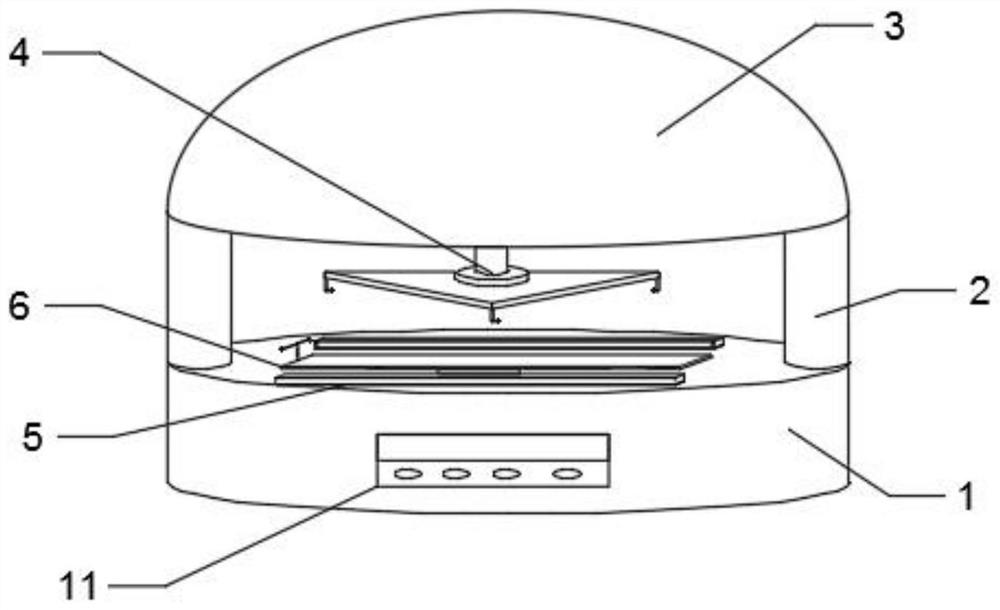

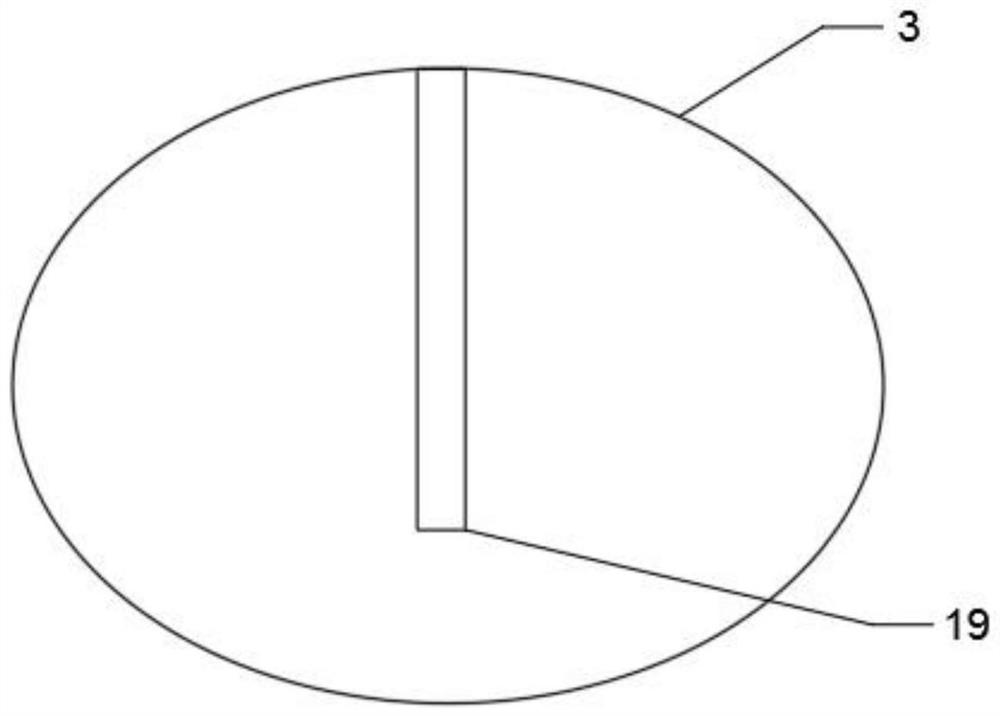

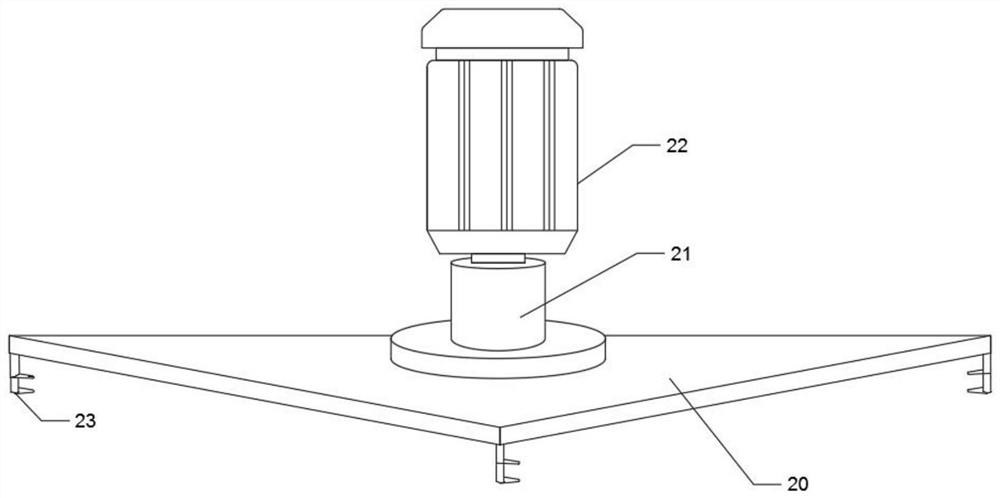

InactiveCN110723572AEasy to install and removeImprove convenienceDispersed particle filtrationWebs handlingElectric machineryAgricultural engineering

The invention discloses an agricultural film blow molding machine. The agricultural film blow molding machine comprises a fixed stand, an agricultural film winding mechanism and a raw material conveyor, wherein the agricultural film winding mechanism is located at one side of the fixed stand, the raw material conveyor is located at the bottom of the fixed stand, a supporting cross beam is fixedlyinstalled at the top position of the interior of the fixed stand, an agricultural film turning roller is movably installed at the rear portion of the supporting cross beam, a first motor is fixedly installed at the front portion of the supporting cross beam, a first supporting cross rod is fixedly installed at the top position of one side of the fixed stand, and one end of the first supporting cross rod is movably connected with a first steering roller. According to the agricultural film blow molding machine, the agricultural film roller can be conveniently disassembled and installed, the useconvenience is improved, meanwhile, the agricultural film roller can be subjected to pressure test in a self-adaption mode, the phenomenon that the density of the agricultural film roller is too largeis avoided, the blow molding air can be filtered, and dust and batt in the air are prevented from adhering to the outside of the agricultural film.

Owner:湖州耀农塑料有限公司

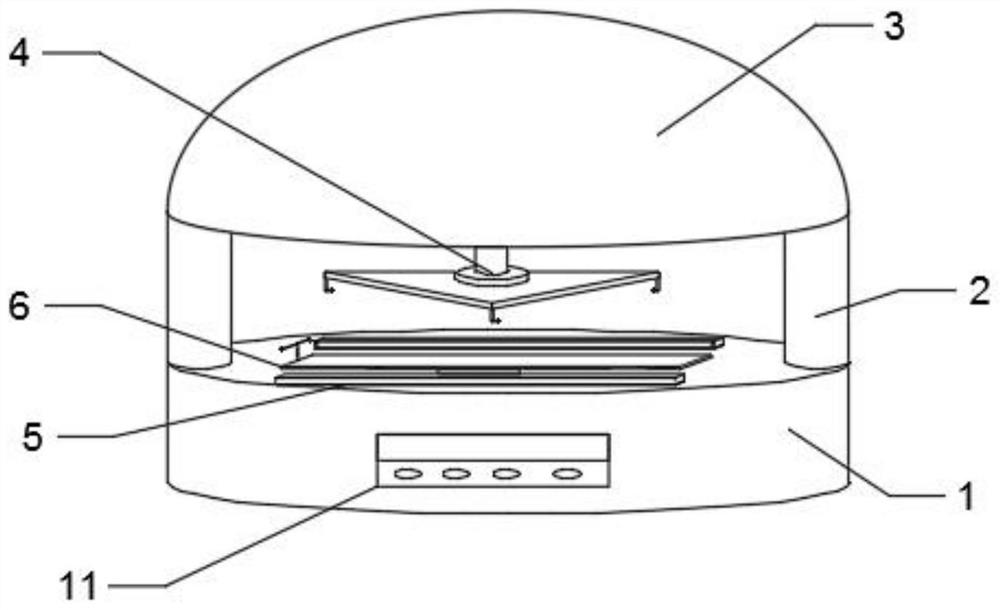

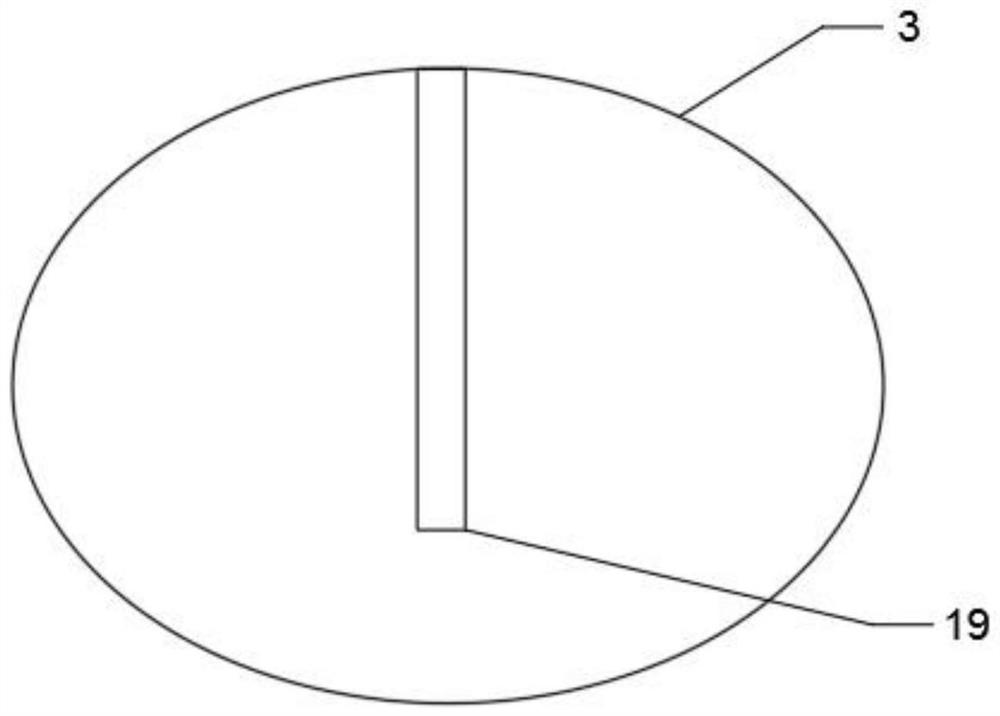

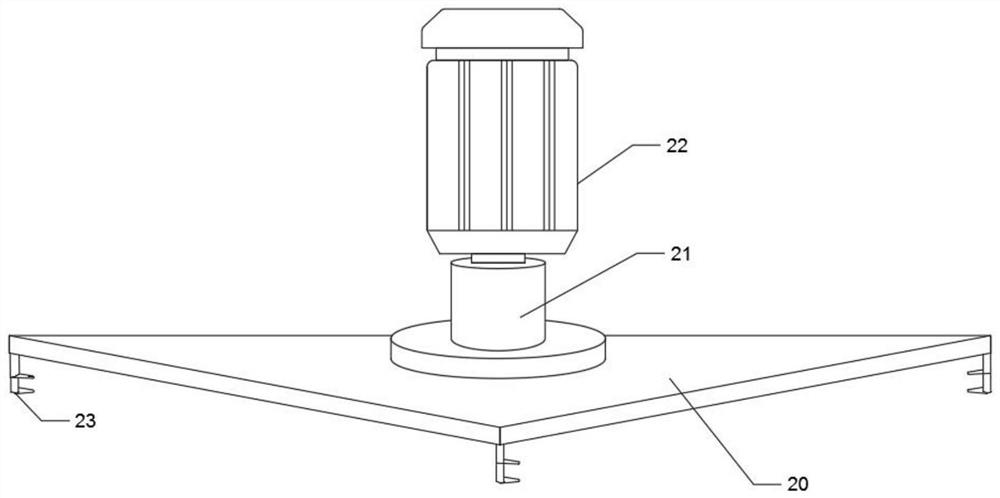

Dyeing device for sun umbrella cloth processing and application method thereof

InactiveCN112095251AAvoid loosenessIncrease rotational resistanceMechanical cleaningPressure cleaningStructural engineeringMechanical engineering

The invention discloses a dyeing device for sun umbrella cloth processing and an application method thereof. The dyeing device comprises a supporting frame, supporting legs are fixedly mounted at thebottom of the supporting frame, the number of the supporting legs is two, a connecting frame is fixedly connected between the two supporting legs, and a pigment barrel is placed on the upper portion of the connecting frame; and a discharging roller is movably mounted at one end of the supporting frame, a first steering roller is movably mounted at the position, located on one side of the discharging roller, of the inner side of the supporting frame, and a dyeing roller is movably mounted at the position, close to the lower portion, of the center of the interior of the pigment barrel. Accordingto the dyeing device for sun umbrella cloth processing, pigment can be stirred, the precipitation phenomenon is avoided, supporting of a power device is not needed, the discharging roller and a winding roller can be conveniently disassembled and assembled, the use convenience is improved, in addition, the impurity removal function is achieved, dust and impurities on the surface of umbrella clothand in holes of the umbrella cloth are prevented from polluting pigment, and the device is more beneficial to using.

Owner:NANJING XUYURUI MATERIAL TECH CO LTD

Night Puck

ActiveUS20160317875A1Predictable behaviorAvoid playingBall sportsRacket sportsCircular discThin membrane

The night puck has a median plane contiguous with a circumference thereof. The centroid of the puck is located at an intersection of the axis of rotation of the puck with the median plane. A cylindrical cavity extends therein along the natural axis of rotation. This cylindrical cavity has a thin membrane-like bottom wall. A series of holes extend radially along the median plane from the cylindrical cavity to the circumference of the puck. An electronic module is mounted in the cylindrical cavity. This electronic module comprises a battery and has a center of gravity that is located on the centroid of the puck. A push-button switch is held against the membrane-like bottom wall for operation of the switch by a depression of the membrane-like bottom wall. A series of diodes are mounted in the radial holes and are connected to the electronic module, for illuminating rays of lights around the puck.

Owner:NIGHT PUCK TECH INC

Combustion-supporting desulfurization straw biomass combustion rod and preparation method thereof

The invention discloses a combustion-supporting desulfurization straw biomass combustion rod and a preparation method thereof. The combustion-supporting desulfurization straw biomass combustion rod is characterized by comprising in parts by weight, 2-3 parts of solid ethyl alcohol, 5-10 parts of sludge, 1-2 parts of yeast, 1-2 parts of bagasse, 5-10 parts of pulverized coal, 2-3 parts of polyvinyl alcohol, 3-6 parts of paraffin, 10-20 parts of yellow mud, 10-20 parts of straws, 1-2 parts of cement, 5-10 parts of rice straws, 5-10 parts of bamboo materials, 3-5 parts of branches, 4-8 parts of ferric oxide, 0.1-0.4 part of zirconium dioxide and an appropriate amount of water. The straws and the pulverized coal are matched to prepare the combustion rod, resources are sufficiently used, emission of poisonous gases such as sulfur dioxide is effectively decreased, environmental protection and human body health are facilitated, the solid ethyl alcohol is added into the combustion rod, so that fuel is easily ignited, and energy resources are saved.

Owner:太湖县享有新能源有限责任公司

A rapier loom

ActiveCN106048864BFinished product quality impactAccurate and fast resetLoomsAuxillary apparatusPush and pullDrive shaft

The invention provides a rapier loom which comprises a workbench, a warp let-off mechanism, a weft let-off mechanism, a slitter edge cutting mechanism and a rolling mechanism. The slitter edge cutting mechanism comprises a cutter rest, a fixed cutter body and a movable cutter body, the fixed cutter body is provided with a first blade, the movable cutter body is provided with a second blade, the fixed cutter body is fixed to the cutter rest in a height-adjustable mode, the movable cutter body is hinged to the fixed cutter body, and the first blade and the second blade abut against each other to form a cutting opening; the slitter edge cutting mechanism further comprises a motor driving the movable cutter body to rotate, a transmission shaft and a rotating disc, and the transmission shaft is controlled by the motor and fixedly connected to the center of the rotating disc; the cutter rest is provided with a longitudinal sliding groove, a sliding block is arranged in the sliding groove, a first connecting rod used for driving the sliding block to rise and fall is arranged between the sliding block and the rotating disc, a second connecting rod used for pushing and pulling the movable cutter body is arranged between the sliding block and the movable cutter body, one side of the sliding block is fixedly connected with the second connecting rod, and the second connecting rod is hinged to the movable cutter body; the other side of the sliding block is hinged to the first connecting rod, and the first connecting rod is hinged to the eccentric position of the rotating disc.

Owner:LANGXI YUANHUA TEXTILE

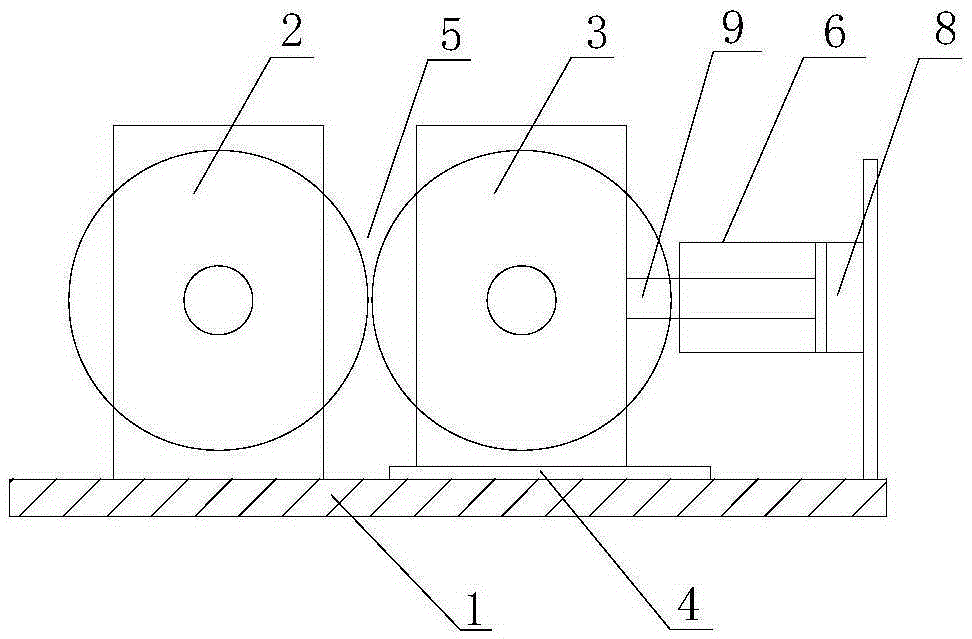

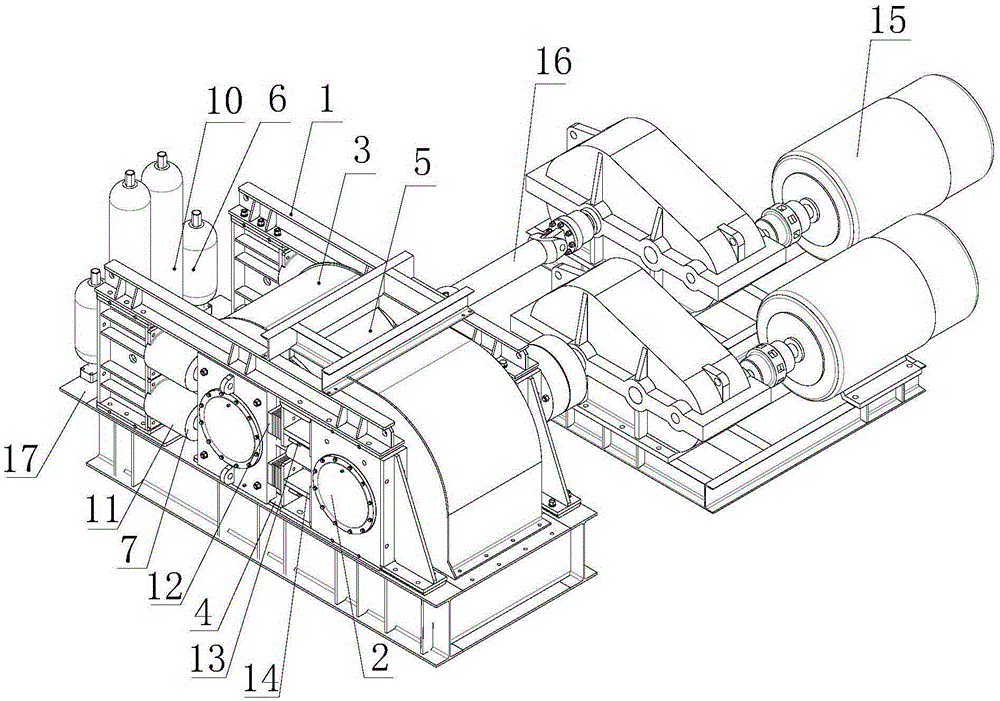

A hydraulic double roll crusher

ActiveCN103657775BAvoid offsetImprove securityServomotor componentsServomotorsHydraulic cylinderPulp and paper industry

The invention discloses a hydraulic double-roll crusher and a hydraulic system thereof. The hydraulic double-roll crusher comprises a crusher frame, a fixed roller set, a movable roller set, a power device and a hydraulic system, wherein a protective executing mechanism and a discharge hole adjusting mechanism are arranged on the movable roller set; the protective executing mechanism comprises a hydraulic cylinder and a piston rod; the piston rod is connected with the movable roller set; the discharge hole adjusting mechanism comprises a small cylinder and a cushion block; and the small cylinder is connected with a slide block. The hydraulic cylinder with the piston rod is arranged on the movable roller set, so that the unreasonable structure that the spring serves as the protective executing mechanism in the past is changed, deviation of the movable roller set is prevented, the crusher has high safety and use performances and long service life, and the reaction sensitivity through iron is improved. Due to arrangement of the small cylinder, the size of the discharge hole is controlled in a hydraulic adjusting manner. Compared with the traditional spring adjustment, the hydraulic double-roll crusher has the advantages of high accuracy, convenience and the like.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

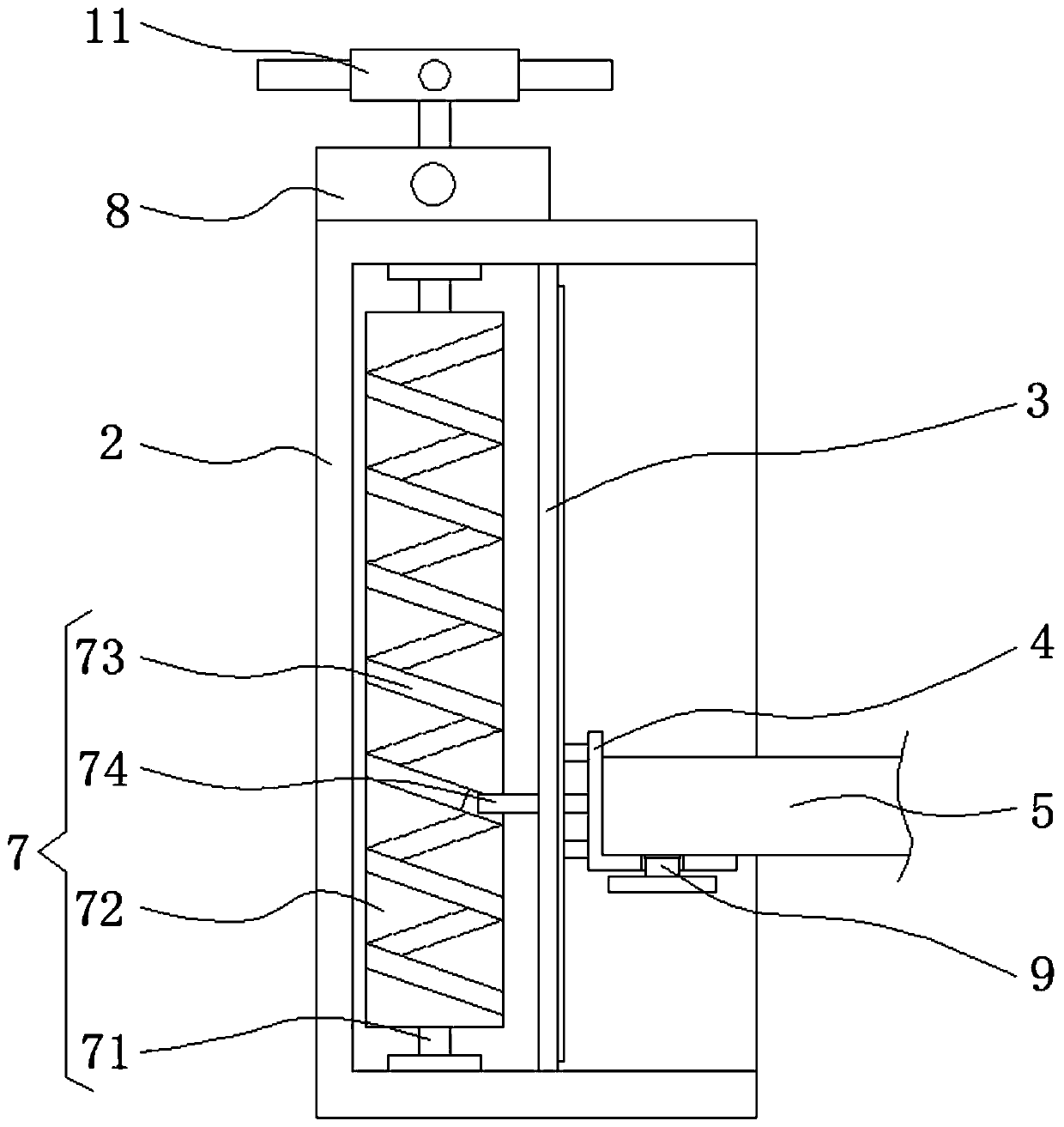

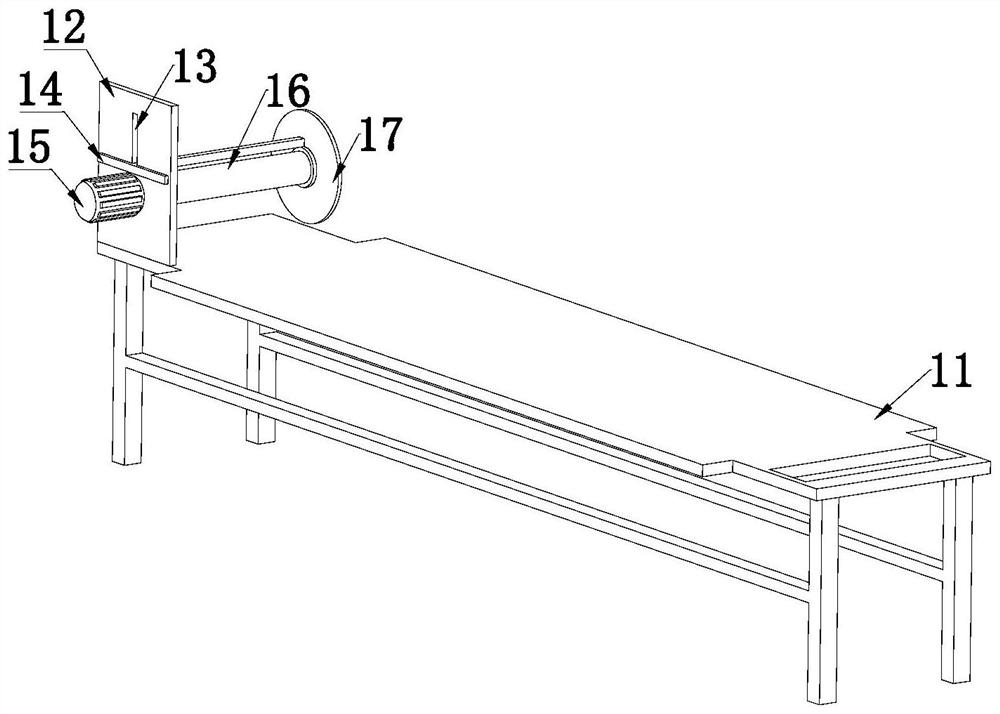

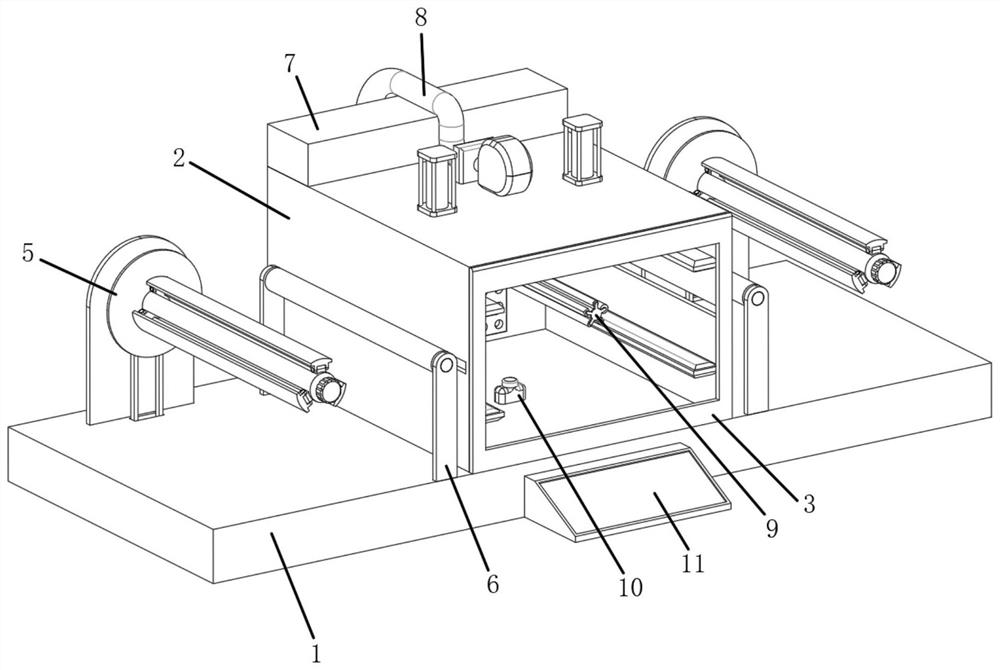

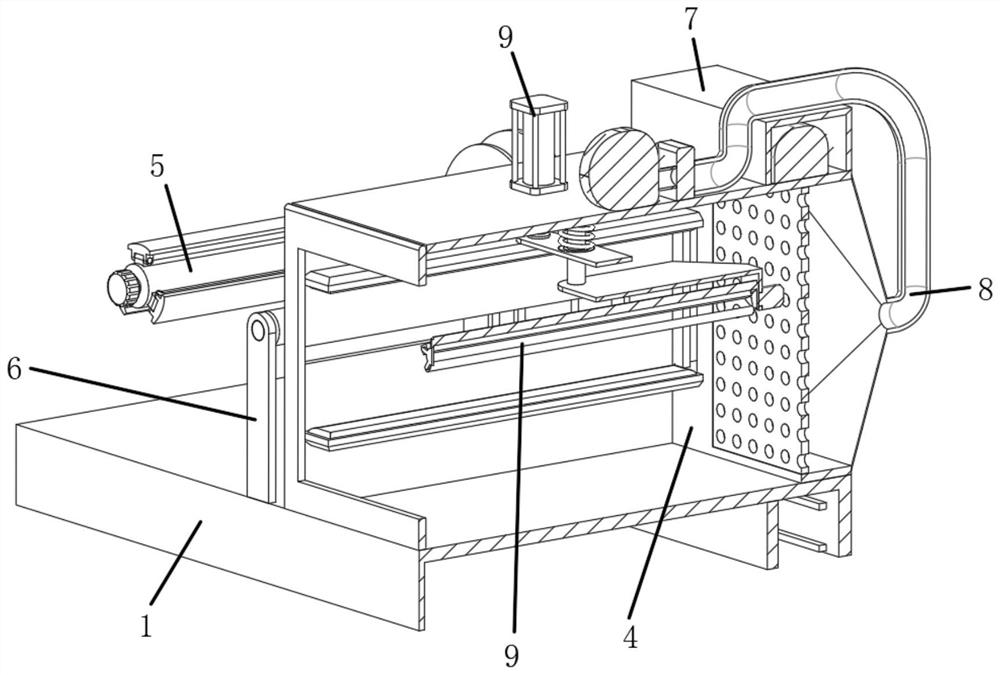

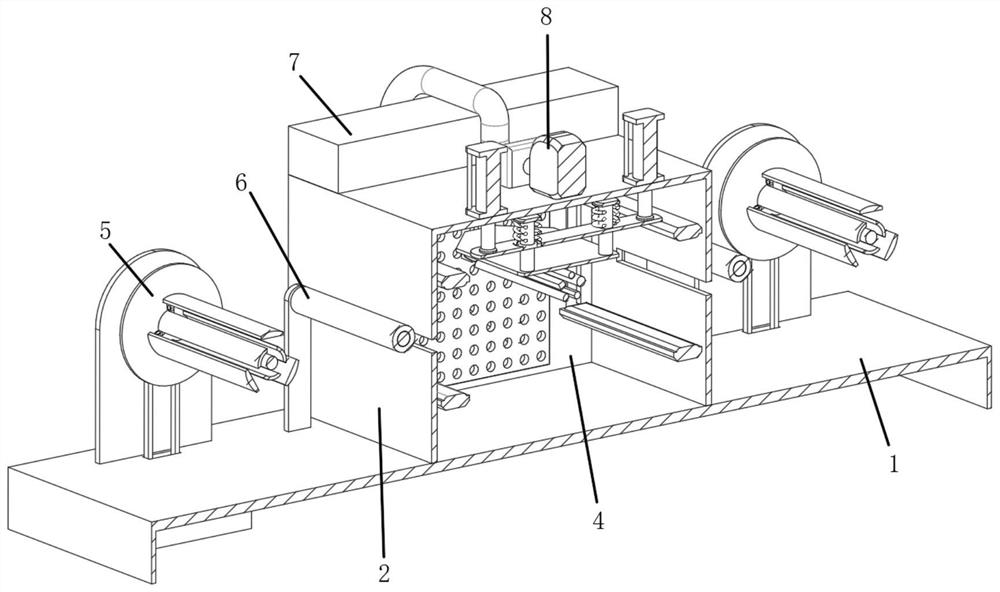

Sand coating equipment for abrasive paper production and sand coating process thereof

InactiveCN114434347AAvoid displacementAvoid loosenessAbrasion apparatusSand blastingPaper production

The invention discloses sand coating equipment for abrasive paper production and a sand coating process of the sand coating equipment, and belongs to the technical field of abrasive paper production. The sand coating equipment comprises an unwinding device, a power assisting device, a winding device, a gluing device, a sand blasting device, a trowelling device and a drying device, the unwinding device is vertically arranged on the ground, and the power assisting device is arranged at the bottom of the unwinding device; the winding device is arranged at the top of the unwinding device, the gluing device is arranged at the top of the unwinding device, the sand blasting device is arranged at the top of the unwinding device, the trowelling device is arranged at the top of the unwinding device, and the drying device is arranged at the top of the unwinding device. Paper to be coated with sand is unwound through the unwinding device, sand paper coated with sand is wound through the winding device, and the sand paper coated with sand is rapidly glued and coated with sand through the gluing device and the sand blasting device.

Owner:惠州市瑞丰研磨材料有限公司

Inflammable desulfurated straw biomass burning rod and preparation method thereof

The invention discloses an inflammable desulfurated straw biomass burning rod and a preparation method thereof. The burning rod is characterized by being prepared from, by weight, 1-2 parts of urea, 5-10 parts of sludge, 1-2 parts of yeast, 1-2 parts of sphaeropsis clostridia, 5-10 parts of pulverized coal, 2-3 parts of polyvinyl alcohol, 3-6 parts of paraffin, 10-20 parts of yellow mud, 10-20 parts of wheat straw, 1-2 parts of calcium stearate, 5-10 parts of rice straw, 5-10 parts of bamboo wood, 3-5 parts of branches, 4-8 parts of ferric oxide, 0.1-0.4 part of zirconium dioxide and a proper amount of water. The straw and the pulverized coal cooperate to be prepared into the burning rod, full utilization of resources is realized, emission of sulfur dioxide and other poisonous gases is effectively reduced, and the burning rod is beneficial for environmental protection and human health; urea is added in a matched mode, and the combustion supporting effect is achieved.

Owner:太湖县享有新能源有限责任公司

Oxygen combustion-supporting and desulfurization straw biomass combustion rod and preparation method thereof

The invention discloses an oxygen combustion-supporting and desulfurization straw biomass combustion rod and a preparation method thereof. The combustion rod is characterized in that the combustion rod is prepared from the following raw materials in parts by weight: 2 to 4 parts of potassium permanganate, 5 to 10 parts of sludge, 1 to 2 parts of yeasts, 1 to 3 parts of waste paper pulp, 5 to 10 parts of coal dust, 2 to 3 parts of polyvinyl alcohol, 3 to 6 parts of paraffin, 10 to 20 parts of yellow mud, 10 to 20 parts of wheat straws, 1 to 2 parts of urea formaldehyde resin, 5 to 10 parts of rice straws, 5 to 10 parts of a bamboo material, 3 to 5 parts of branches, 4 to 8 parts of iron sesquioxide, 0.1 to 0.4 part of zirconium dioxide and a proper amount of water. According to the combustion rod and the preparation method thereof, the combustion rod is prepared by matching the straws and the coal dust, so that resources are fully utilized, emissions of toxic gas such as sulfur dioxide are also effectively reduced, and the combustion rod is favorable for environmental protection and human health; the added potassium permanganate can be decomposed to release oxygen, so that a fuel can be combusted more easily and completely.

Owner:太湖县享有新能源有限责任公司

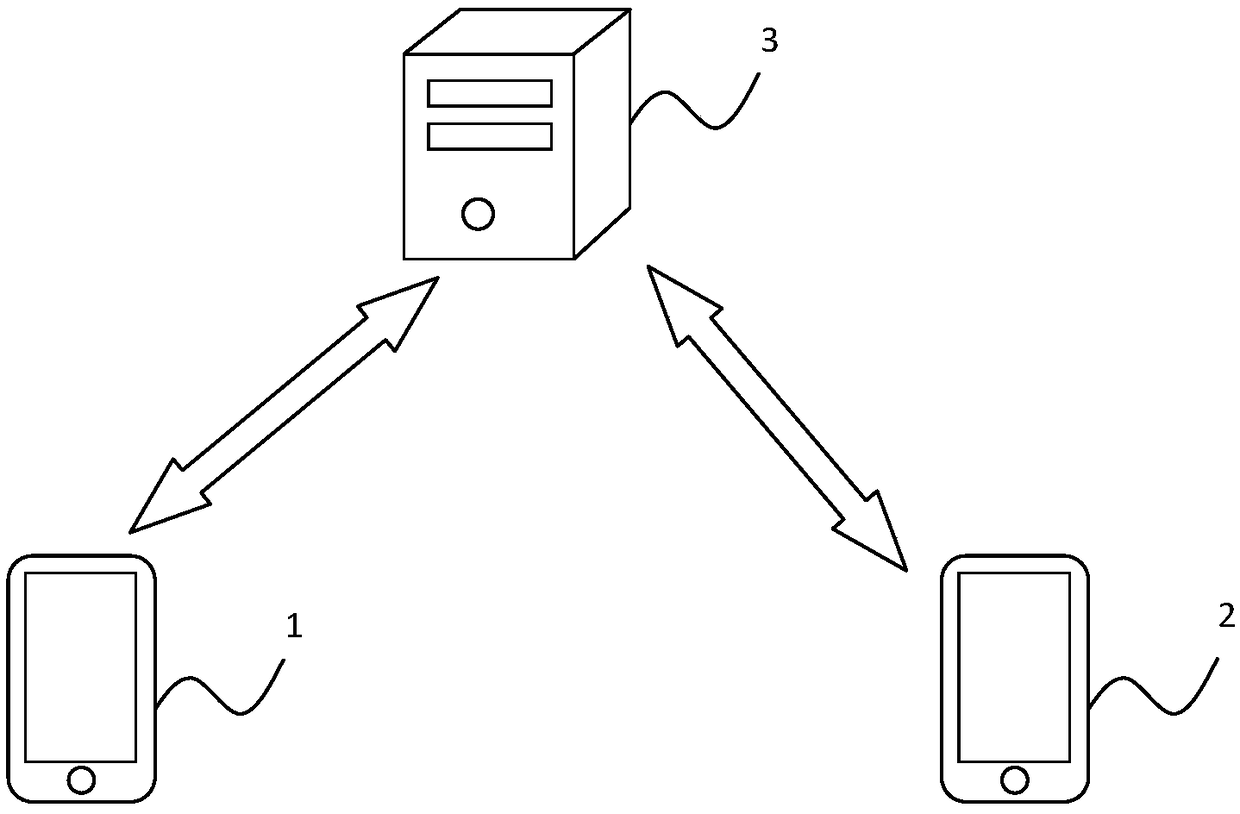

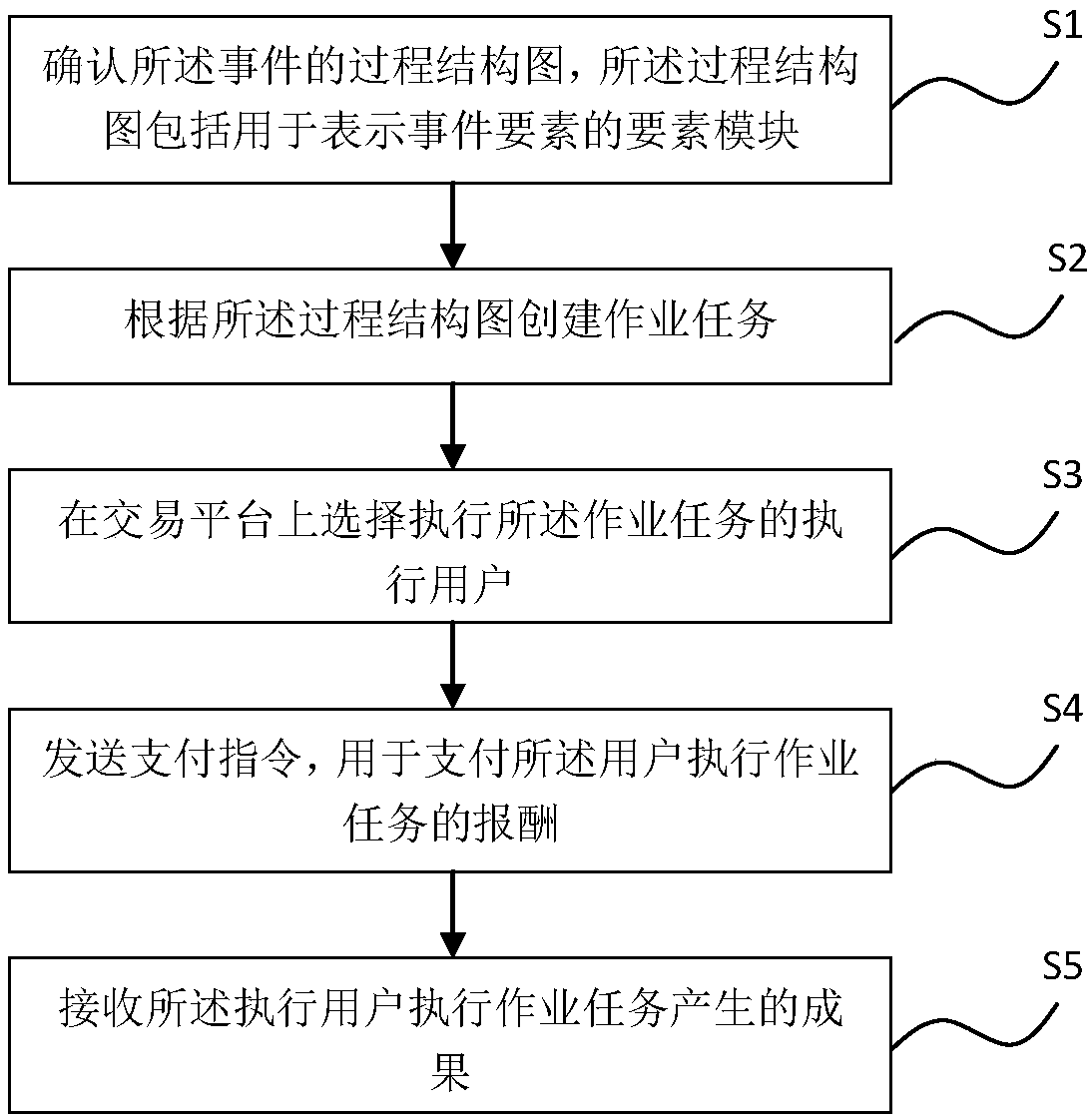

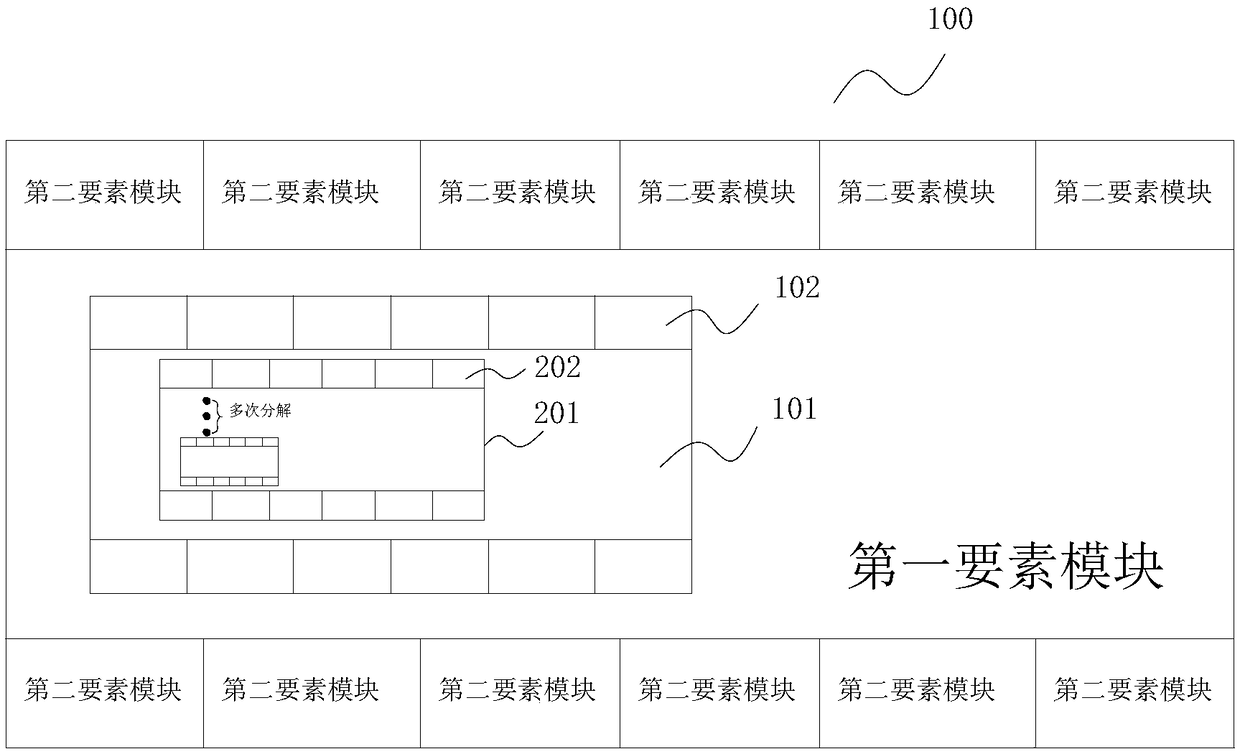

Event implementation method and apparatus

ActiveCN108876173AAvoid looseness and randomnessImprove efficiency and qualityOffice automationResourcesOperating systemPayment

The invention discloses an event implementation method, the method comprising: confirming a process structure diagram for an event, the process structure diagram comprising an element module for representing an event element; creating an operation task according to the process structure diagram; selecting an execution user executing the operation task on a transaction platform; sending a payment instruction used for payment of the user to execute the operation task; and receiving a result generated by executing the job task by the execution user. When the execution user executes the task, according to the modular information in the process structure diagram, a route to complete the task can be clearly grasped. An event implementation platform built according to the process structure diagram enables all users involved in the execution of the task to execute the task and record information according to the process structure diagram, and all events can be implemented and recorded in a rigorous and standard process, thereby avoiding the looseness and randomness of the existing crowdsourcing platform, and improving the quality and efficiency to complete the task.

Owner:魏代利

Touch screen glass positioning equipment and positioning method

ActiveCN111620121AGuaranteed timelinessGuaranteed accuracyWork holdersCharge manipulationComputer sciencePositioning equipment

The invention discloses touch screen glass positioning equipment and a positioning method, and belongs to the technical field of touch screen glass positioning equipment. The touch screen glass positioning equipment comprises a base and a placement frame installed at the top of the base, wherein adjusting frames are installed on two sides of the placement frame, a T-shaped support frame is fixedlyinstalled at one end of the placement frame, gradienters are installed at two ends of the T-shaped support frame correspondingly, adjusting frames are installed at the two ends of the placement framecorrespondingly, second motors are arranged inside the adjusting frames, the two output ends of the second motors are connected with adjusting boxes through first telescopic rods, first motors are arranged inside the adjusting boxes, and the output ends of the first motors are connected with telescopic strips. According to the touch screen glass positioning equipment and the positioning method, the adjusting frames and a moving frame match with each other, so that positioning is more accurate, the gradienters and cameras are arranged so that the position of the touch screen glass can be subjected to image acquisition in real time, and timeliness and accuracy of position information of the touch screen glass are guaranteed.

Owner:宿州市迎盛科技有限公司

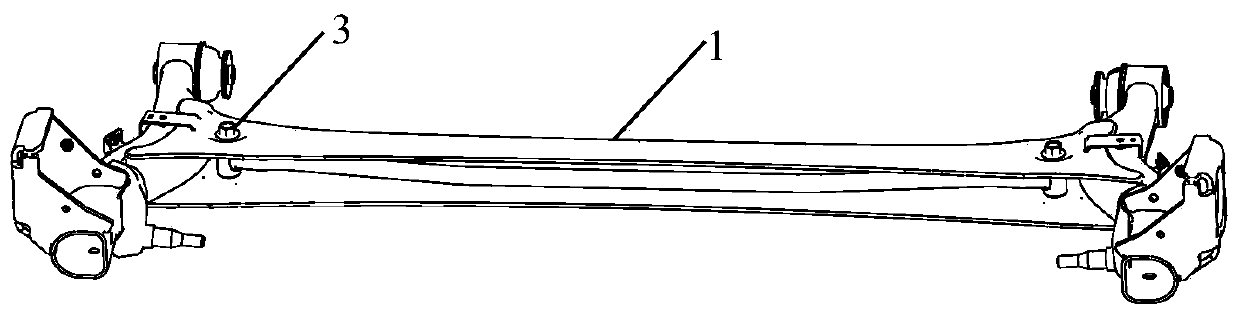

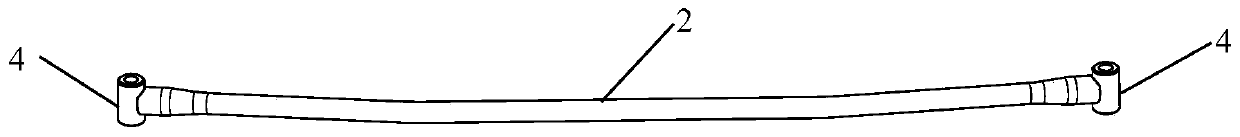

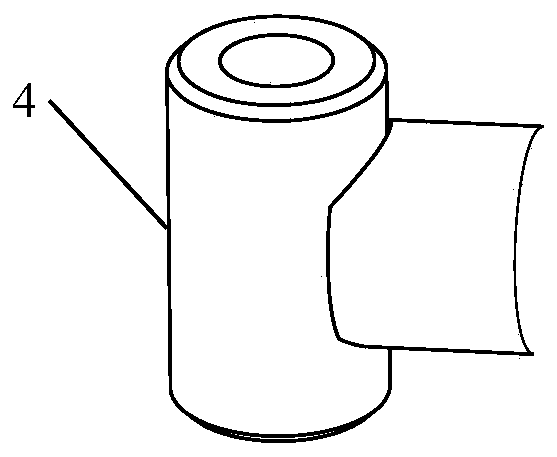

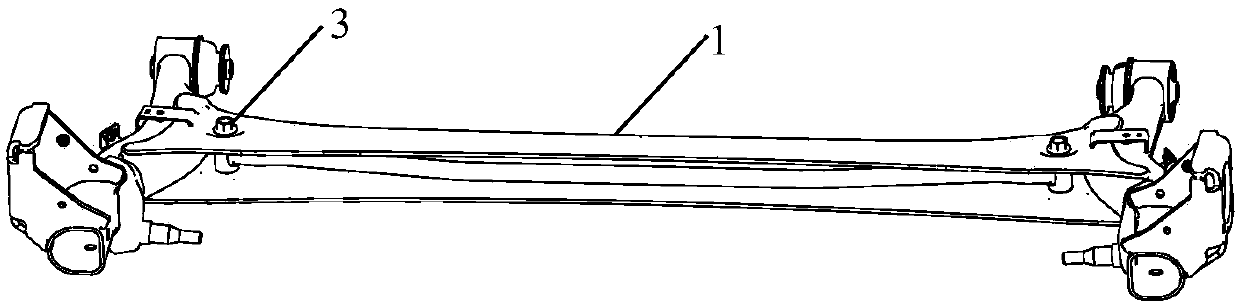

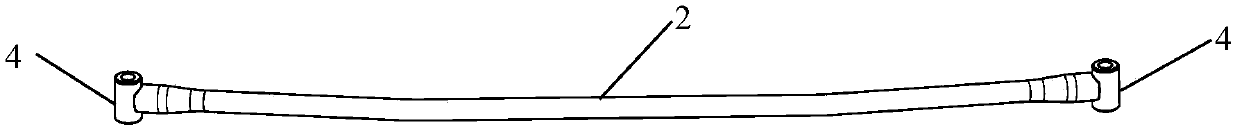

Anti-loosening and anti-abnormal noise structure for rear axle stabilizer bar

ActiveCN107901723BSimple structureIncrease coefficient of frictionInterconnection systemsEngineeringTooth root

The invention discloses a structure for preventing a rear axle stabilizer rod from loosening and having abnormal sound. The structure comprises a rear axle stabilizer rod, wherein stabilizer rod sleeve barrels are respectively and fixedly connected to two ends of the rear axle stabilizer rod; each stabilizer rod sleeve barrel is provided with a barrel top surface and a barrel bottom surface; eachbarrel top surface comprises a first annular plane and a second annular plane; the height between each second annular plane and the corresponding barrel bottom surface is greater than that between thecorresponding first annular plane and the corresponding barrel bottom surface; loosening preventing teeth are arranged on each first annular plane, and each loosening preventing tooth is provided with a tooth top and a tooth root; and the height between each tooth top and the corresponding tooth root is greater than that between each first annular plane and the corresponding second annular plane.The structure disclosed by the invention is simple in structure, low in cost, and high in reliability; the problems that the torque of a relevant part is loosened, and a chassis at the relevant parthas abnormal sound can be solved; and the driving quality and the appearance quality can be improved.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

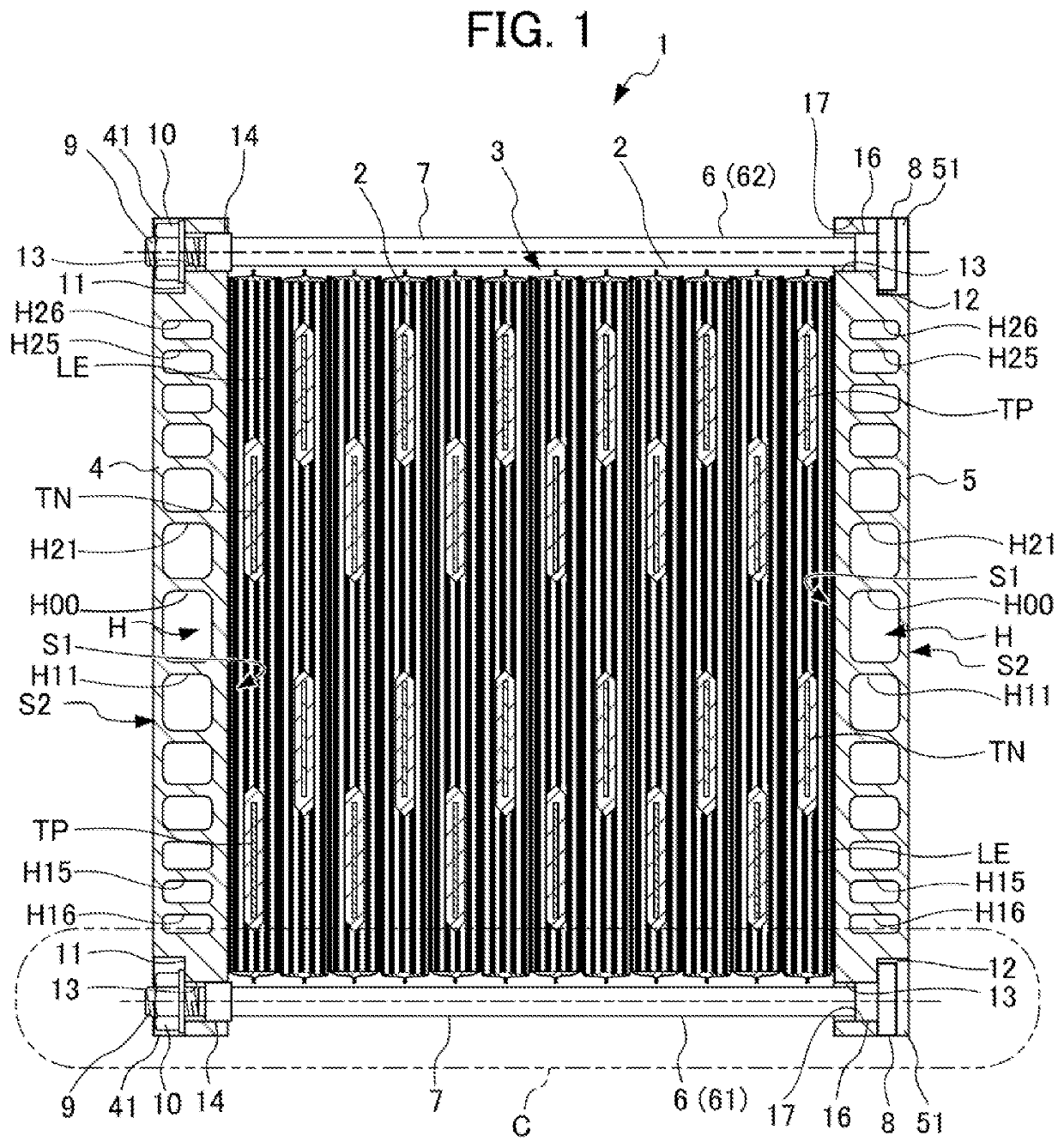

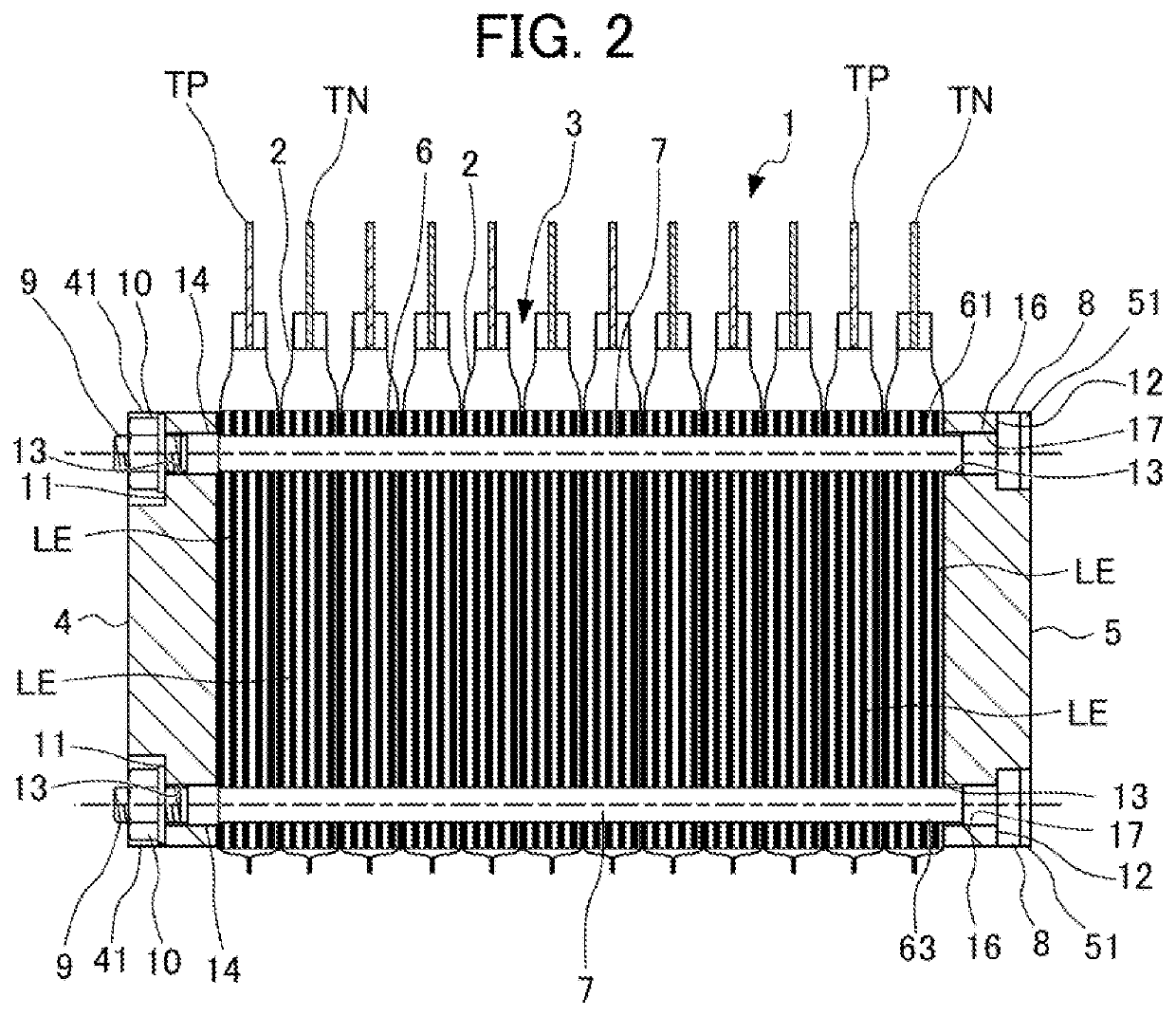

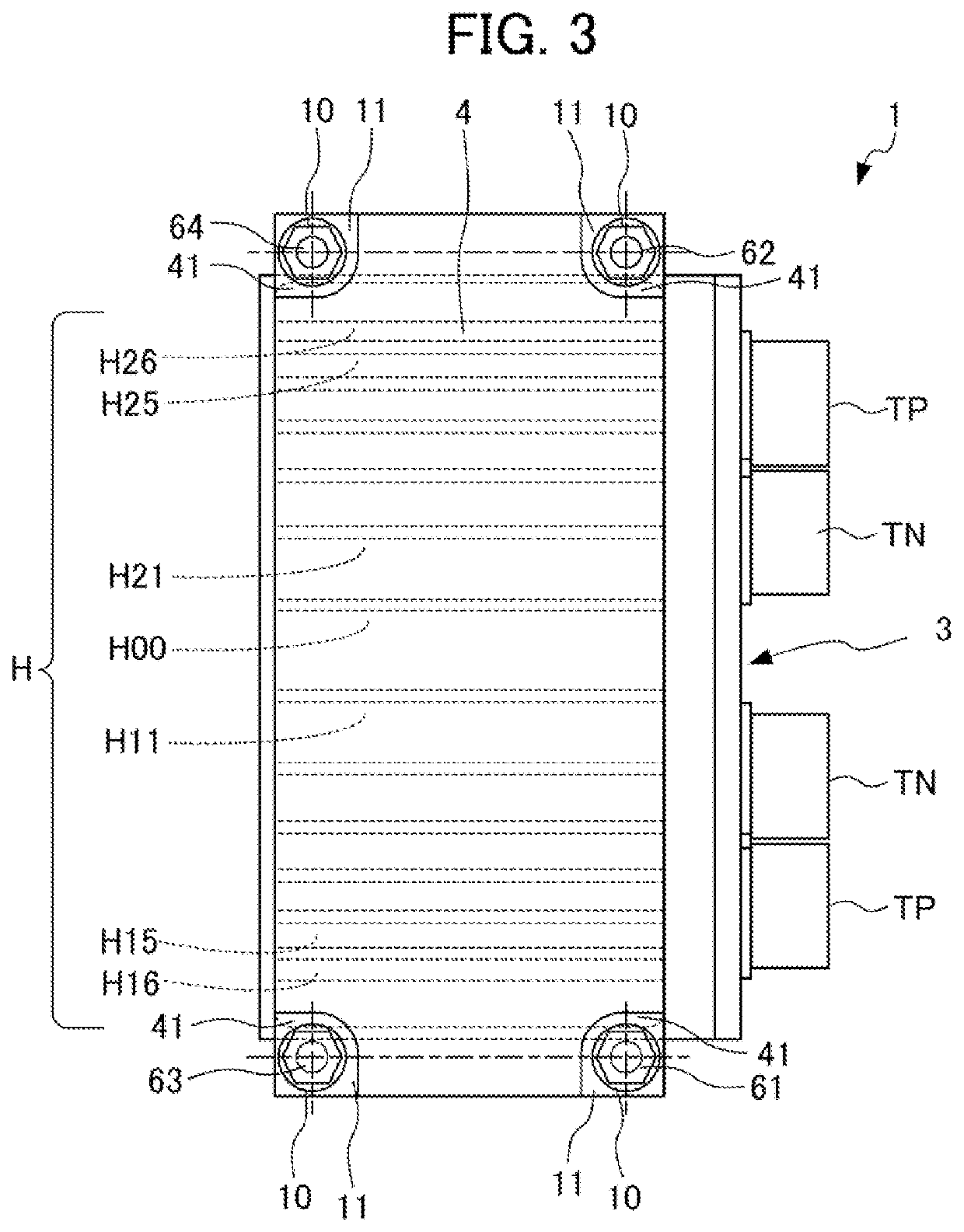

Battery module

PendingUS20220271383A1Avoid loosenessWorkability is deterioratedSecondary cells manufactureCell component detailsStructural engineeringMechanical engineering

Provided is a battery module in which torsion residual stress in a rod-shaped connecting member that fastens end plates is minimized so that looseness of the end plate fastening member can be prevented during use. A battery module in which a stacked body of a plurality of battery cells is pinched and held by two end plates from both end sides in a stacking direction, includes a rod-shaped connecting member. The rod-shaped connecting member applies tension in directions opposite to each other to the two end plates on both the end sides. The rod-shaped connecting member includes fastening portions adjacent to one end plate, and includes a detent mechanism part in the vicinity of the fastening portions.

Owner:HONDA MOTOR CO LTD

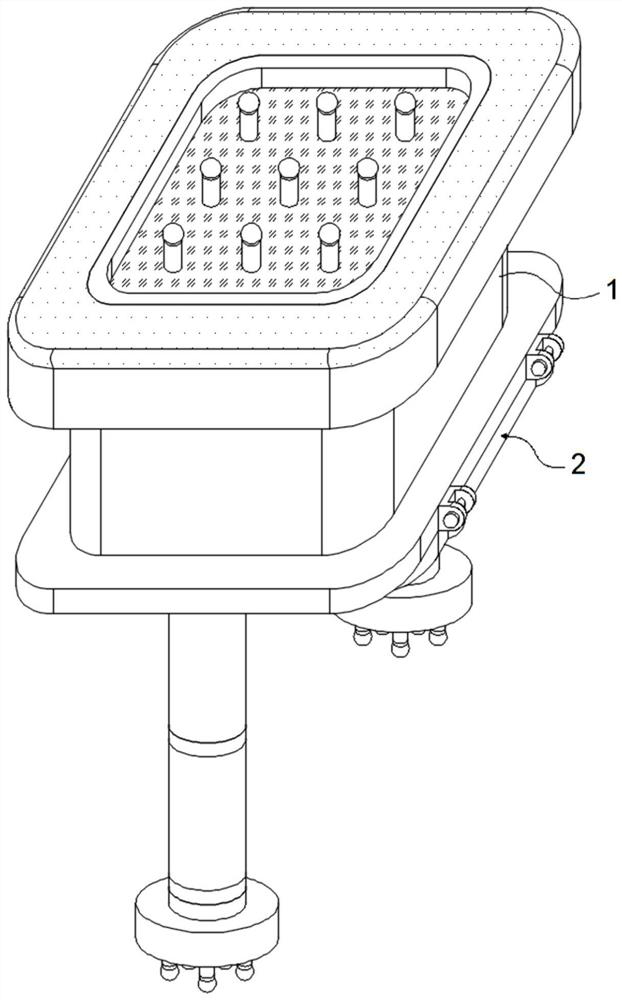

Intelligent textile joint performance detection device

PendingCN114878342AEasy to fixAvoid loosenessMaterial strength using tensile/compressive forcesManufacturing computing systemsStructural engineeringMechanical engineering

The invention discloses an intelligent textile seam performance detection device, and belongs to the technical field of textiles, the intelligent textile seam performance detection device comprises a mounting table, guide roller assemblies are arranged on the two sides of the upper surface of the mounting table, and the guide roller assemblies are used for guiding cloth; the mounting box is arranged in the mounting table, a partition plate is arranged in the mounting box, and the front side of the mounting box is rotationally connected with a box door through a rotating shaft; the rolling assembly is used for rolling the cloth, and the rolling assembly is arranged on the upper surface of the mounting table; the clamping assemblies and the detection assembly are arranged in the mounting box, and the detection assembly is located between the clamping assemblies. Therefore, performance detection under different conditions can be simulated according to needs, and the diversity and accuracy of detection are improved.

Owner:SUZHOU FIBER EXAMINATION INST

A touch screen glass positioning device and positioning method

ActiveCN111620121BGuaranteed timelinessGuaranteed accuracyWork holdersCharge manipulationComputer sciencePositioning equipment

Owner:宿州市迎盛科技有限公司

Chip connector

PendingCN114122770AAvoid loosenessAvoid disorderCoupling contact membersCoupling parts mountingEmbedded systemEngineering

A chip connector disclosed by the present invention comprises a connector mechanism, the connector mechanism comprises an insertion assembly and two supporting assemblies, the two supporting assemblies are in threaded connection to the two sides of the bottom end of the insertion assembly respectively, and a locking cavity shell is slidably nested outside the insertion assembly. The mounting plate is fixed at the bottom of the connecting plug, and a chip base communicated with the battery cell is arranged in the middle of the mounting plate. According to the invention, by adopting the connector structure of a mutual sliding nesting structure of the locking cavity shell and the insertion assembly, on one hand, the insertion stability of the device on the circuit board can be enhanced, and on the other hand, the circuit board or the connector is effectively prevented from being loosened, unstable, poor in contact and the like due to repeated insertion and extraction of the connector; meanwhile, the supporting assembly not only can support and connect a plurality of circuit boards for chip burning or data collecting and recording, avoids disorder caused by mixing and intertwining of a plurality of connecting lines, but also can play a role in branch connection, and reduces the load degree of the same connector.

Owner:武汉烽唐科技有限公司

Structure for preventing rear axle stabilizer rod from loosening and having abnormal sound

ActiveCN107901723ASimple structureIncrease coefficient of frictionInterconnection systemsEngineeringTooth root

The invention discloses a structure for preventing a rear axle stabilizer rod from loosening and having abnormal sound. The structure comprises a rear axle stabilizer rod, wherein stabilizer rod sleeve barrels are respectively and fixedly connected to two ends of the rear axle stabilizer rod; each stabilizer rod sleeve barrel is provided with a barrel top surface and a barrel bottom surface; eachbarrel top surface comprises a first annular plane and a second annular plane; the height between each second annular plane and the corresponding barrel bottom surface is greater than that between thecorresponding first annular plane and the corresponding barrel bottom surface; loosening preventing teeth are arranged on each first annular plane, and each loosening preventing tooth is provided with a tooth top and a tooth root; and the height between each tooth top and the corresponding tooth root is greater than that between each first annular plane and the corresponding second annular plane.The structure disclosed by the invention is simple in structure, low in cost, and high in reliability; the problems that the torque of a relevant part is loosened, and a chassis at the relevant parthas abnormal sound can be solved; and the driving quality and the appearance quality can be improved.

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

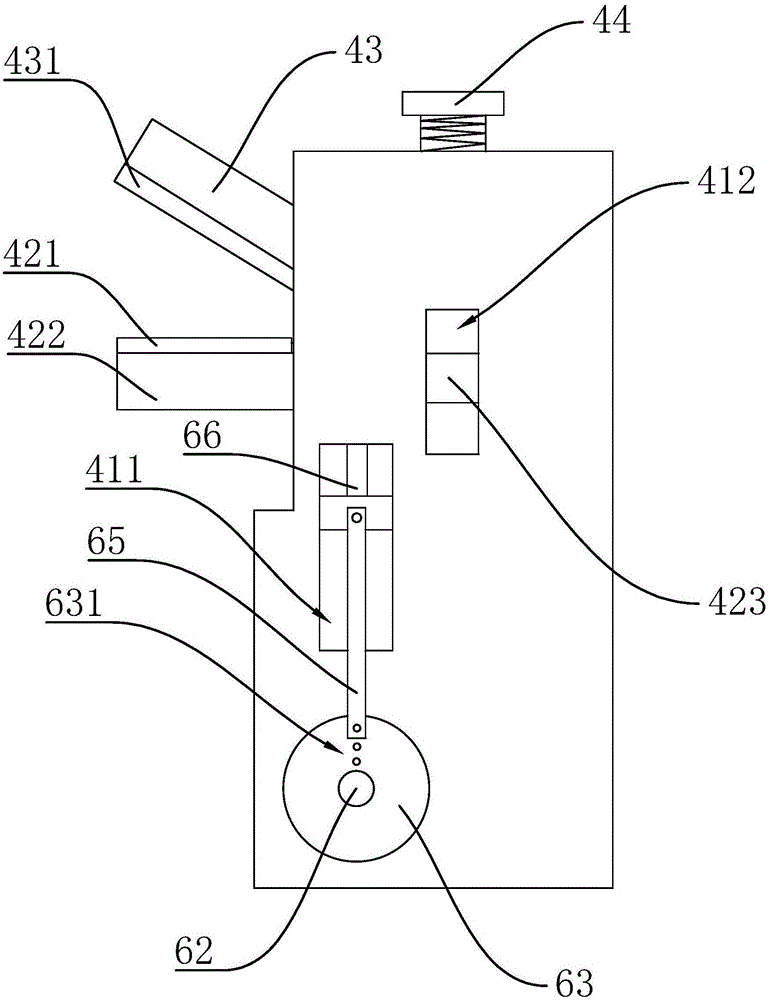

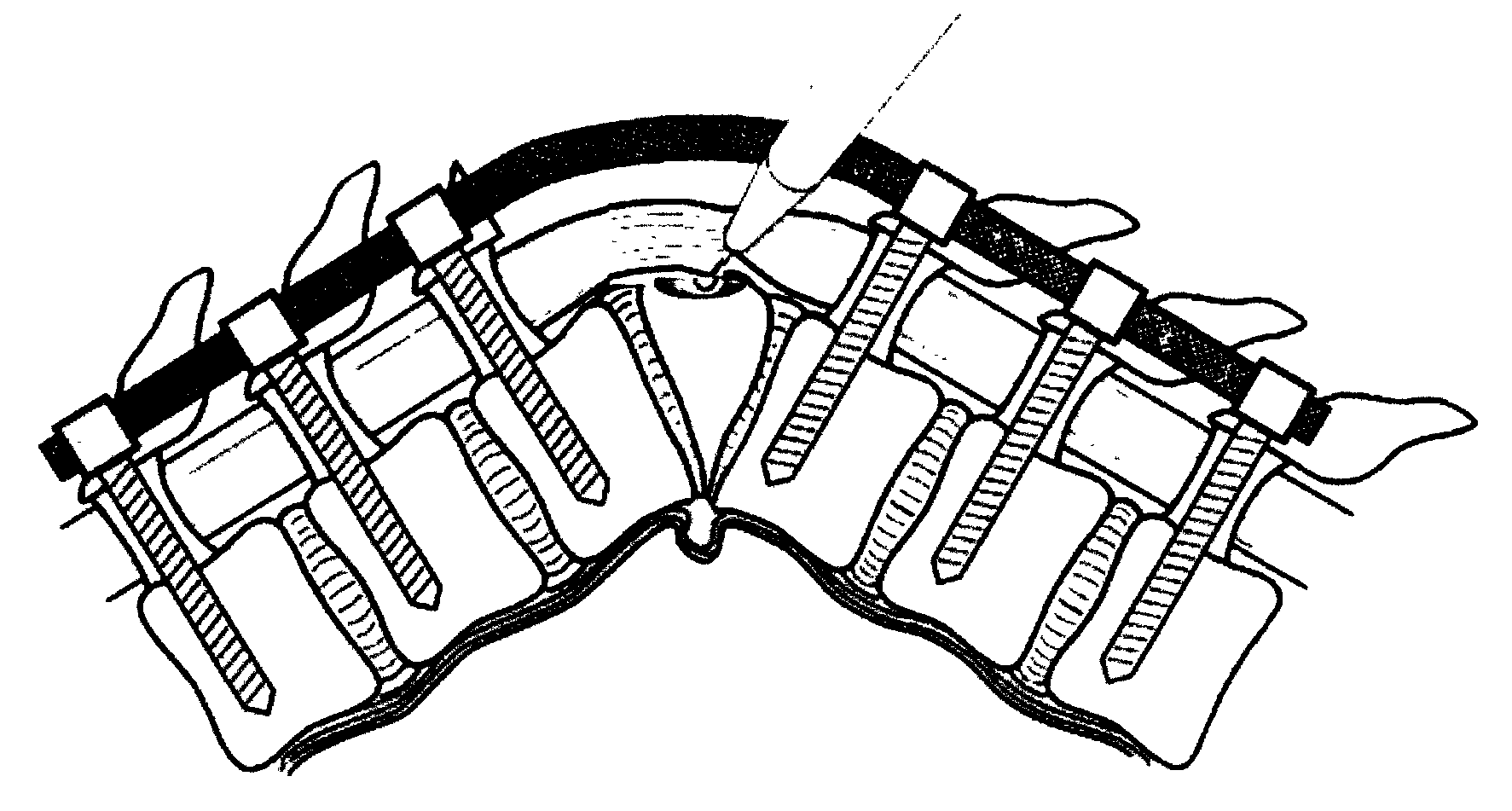

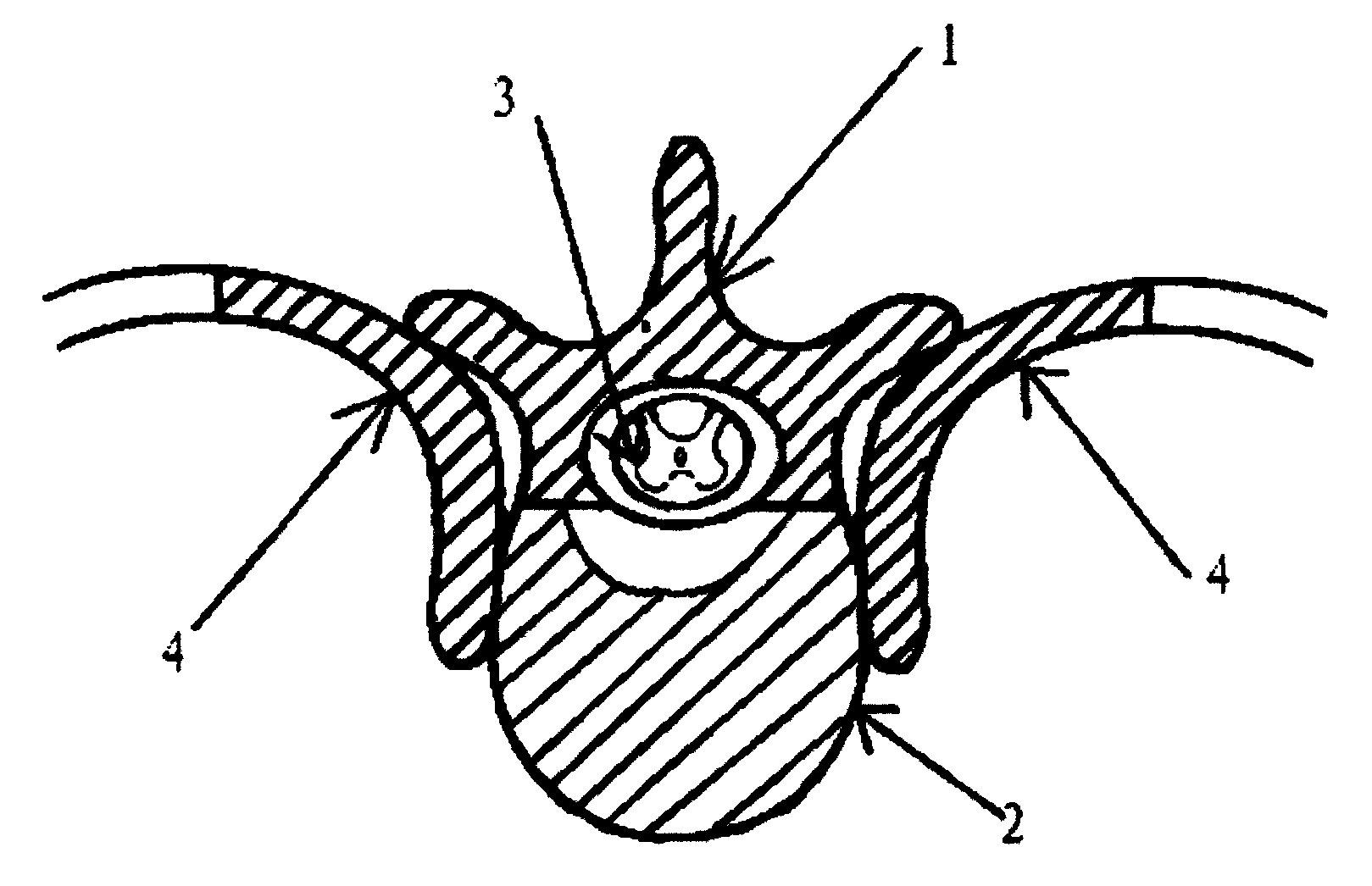

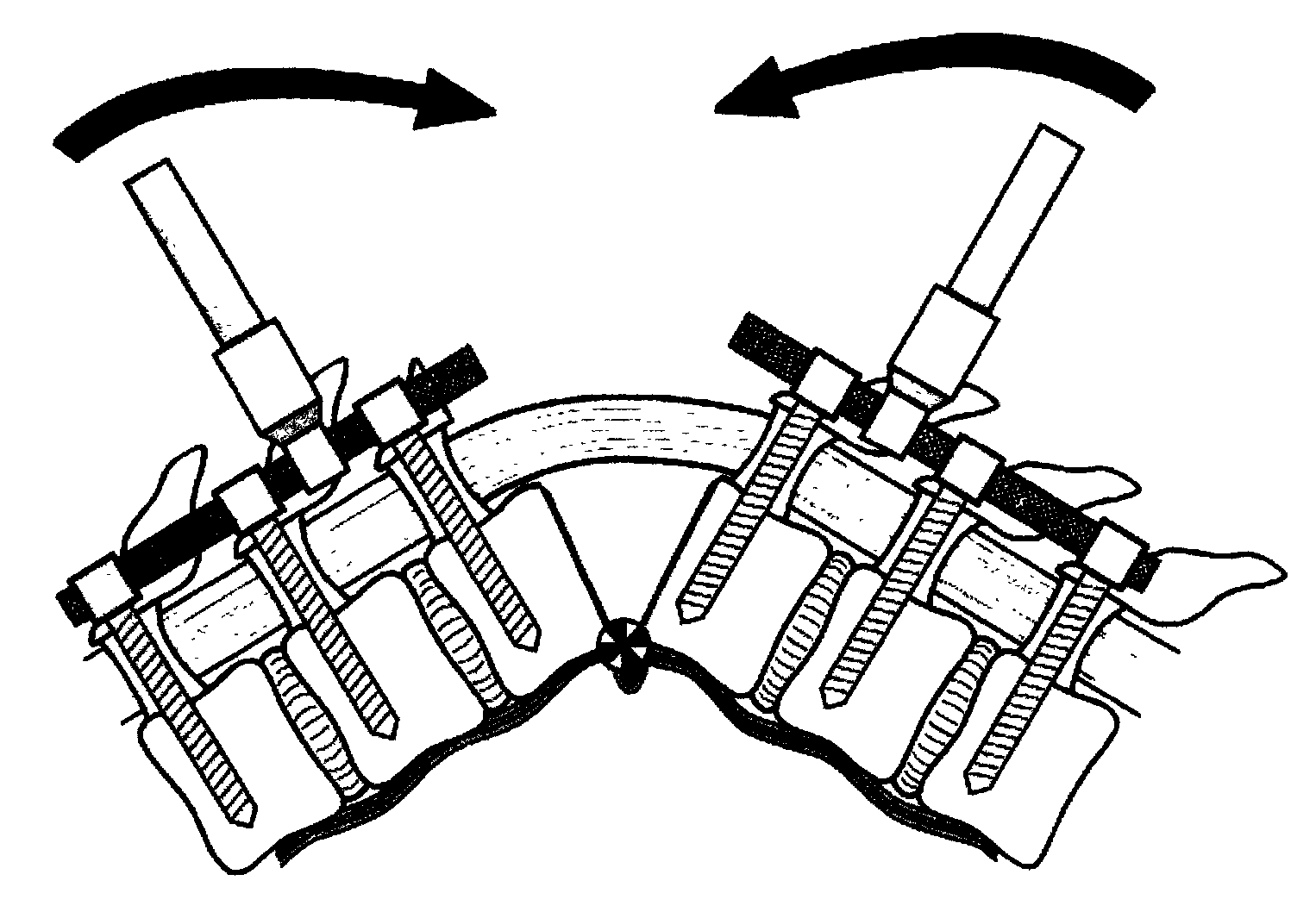

Spine osteotomy bone knife

The invention provides a spine osteotomy bone knife which comprises a cutter head, a cutter rod and a cutter handle, wherein the cutter head is arranged at the end part of the cutter rod; the cutter head is provided with a first end part and a second end part; the cutter rod and the first end part are L-shaped; the blade is arranged on the edge of the first end part; the cutter rod and the cutter handle are of an integrated structure in a filling-casting manner. According to the spine osteotomy bone knife, the cutter rod and the first end part are L-shaped, the first end part and the second end part are L-shaped, the first end part is used for cutting the bone across the spinal cord of the spine, the first end part and the second end part are clamped in the bone cutting position of the spine bone, and the stability of the spine osteotomy bone knife in the surgery process is improved; on the other hand, the cutter rod and the cutter handle are of the integrated structure in the filling-casting manner, the loose of the spine osteotomy bone knife after being used for a too long time is avoided, and the security of the spine osteotomy bone knife in surgery is further improved.

Owner:陶惠人 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com