A hydraulic double roll crusher

A double-roller crusher and crusher technology, applied in the direction of mechanical equipment, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problems of low adjustment accuracy, spring fatigue, time-consuming and labor-intensive, etc., to improve the response sensitivity , avoid the belt is too loose, the effect of high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

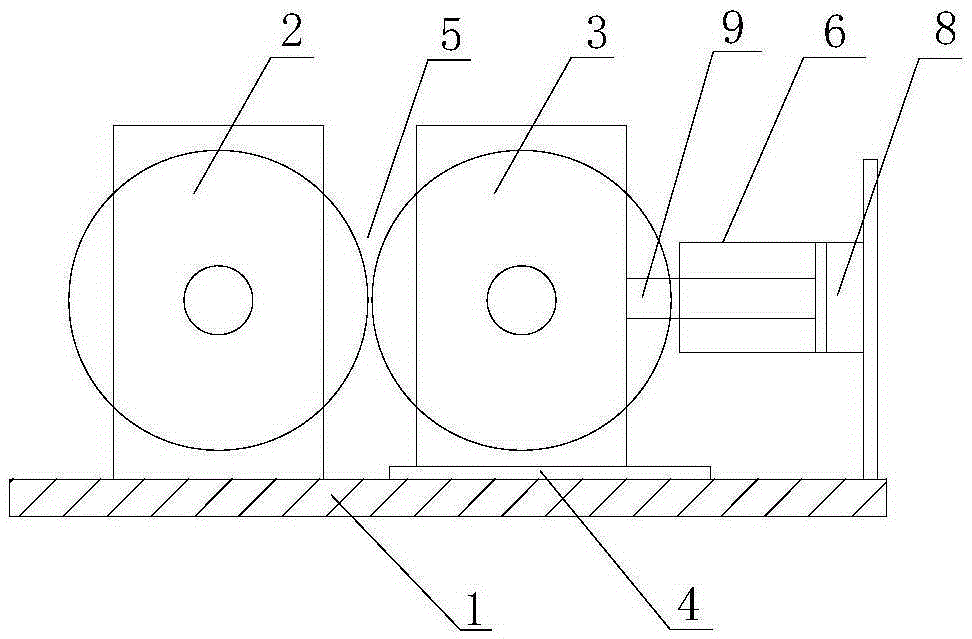

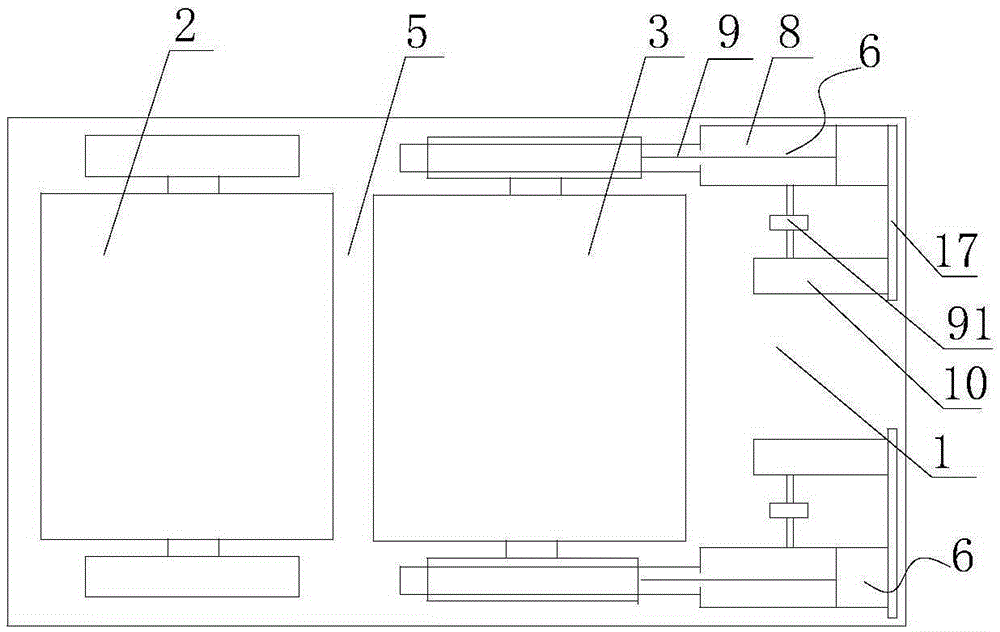

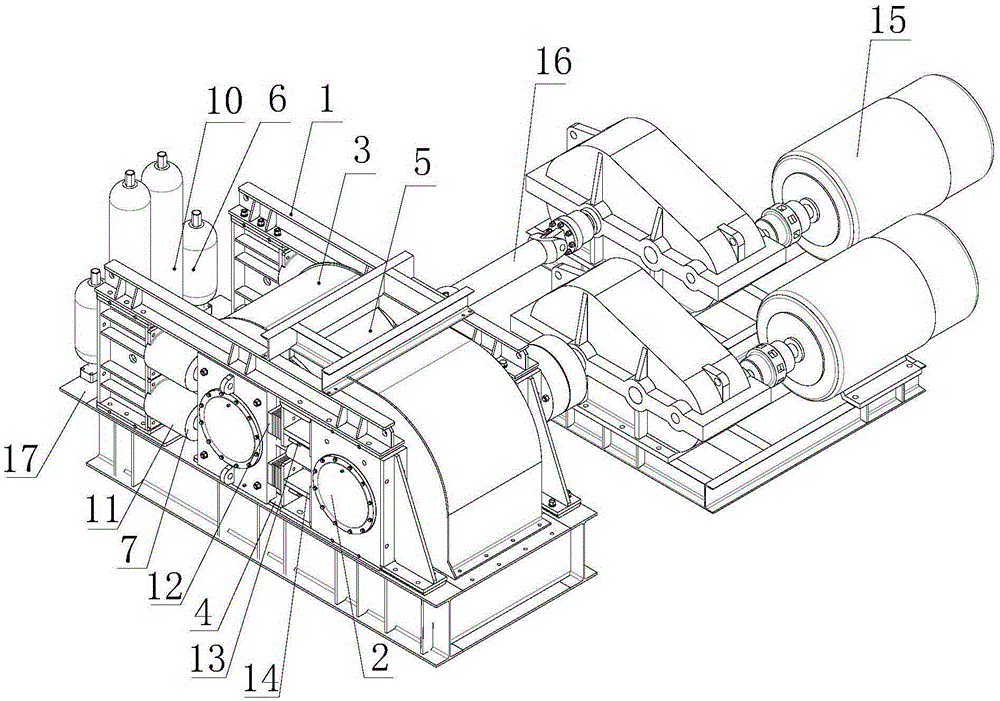

[0014] refer to figure 1 , figure 2 and image 3 , the hydraulic double-roller crusher of the present invention includes a crusher frame 1, a fixed roller group 2, a moving roller group 3, a power device and a hydraulic system, and the moving roller group 3 is fixed on the frame 1 through a slider 4. A crushing cavity 5 is formed between the fixed roller group 2 and the movable roller group 3, and the movable roller group 3 is provided with a protection actuator 6 and a discharge port adjustment mechanism 7, and the protection actuator 6 includes a hydraulic cylinder 8 and a piston rod 9. The piston rod 9 is installed in the hydraulic cylinder 8, the piston rod 9 is connected with the moving roller group 3, the hydraulic cylinder 8 is connected with the accumulator 10 through the overflow valve 91, and the discharge port adjustment mechanism 7 includes a small Oil cylinder 11 and spacer 12, described small oil cylinder 11 is connected with slide block 4, spacer 12 is set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com