Cable structure with middle reinforcing rib

A technology of cable structure and ribs, which is applied in the field of cable structures with intermediate ribs, can solve the problems of cable breakage, cable waste, poor toughness and ductility, etc., and achieve improved fastening, improved tensile performance, and not easy to break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

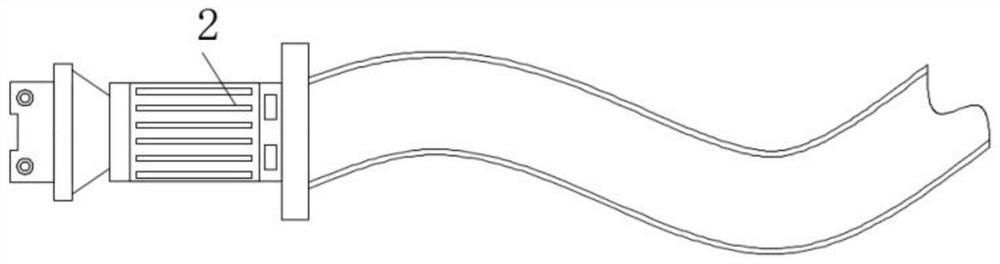

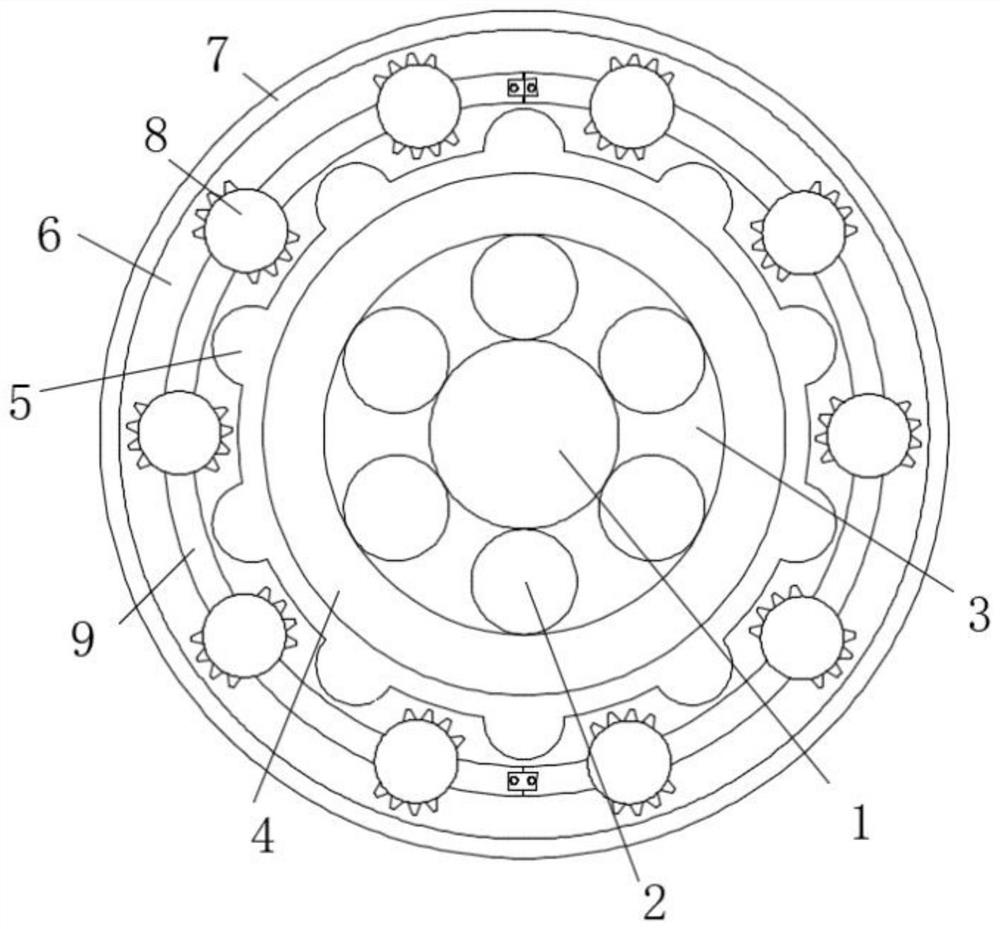

[0025] refer to Figure 1-5 , a cable structure with intermediate ribs, including a cable body, one end of the cable body is fixedly connected with a conductor 2, the cable body includes a center line 1, and a plurality of conductors 2 are fixedly attached to the outside of the center line 1, and the conductor 2 An insulating layer is provided on the outer side, fillers 3 are filled between multiple conductors 2, the outer side of the filler 3 is fixedly wrapped with a shielding layer 4, the outer side of the shielding layer 4 is fixedly wrapped with a heat insulating layer 5, and the outer side of the heat insulating layer 5 is fixedly wrapped with The reinforcement layer 6, the outer side of the reinforcement layer 6 is fixedly wrapped with a rubber layer 7, and the reinforcement layer 6 is fixedly equipped with a plurality of equidistantly arranged reinforcing ribs 8, and the outer sides of the plurality of equidistantly arranged reinforcing ribs 8 are sleeved There are a p...

Embodiment 2

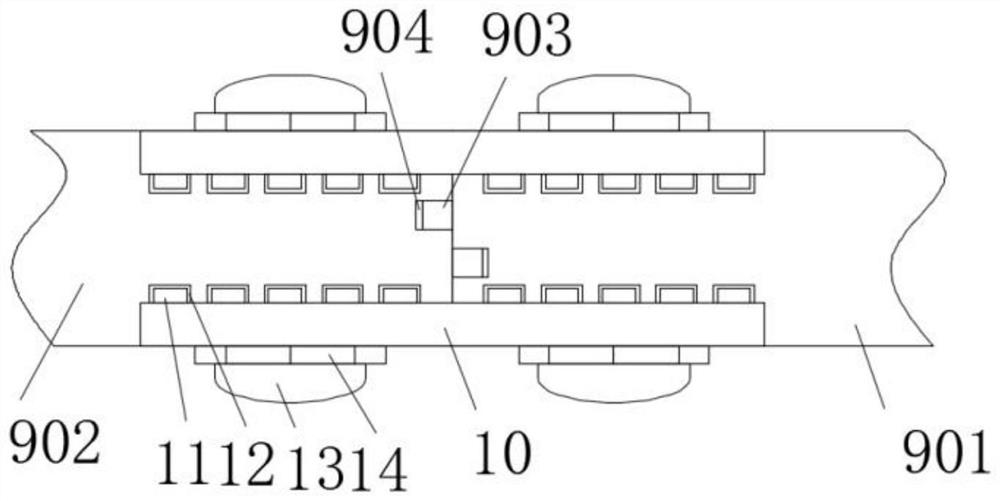

[0027] Further improvement on the basis of Embodiment 1: the number of reinforcing ribs 8 is six to ten, and the six to ten reinforcing ribs 8 are arranged in a circular equidistant manner in the reinforcing layer 6, and the use of reinforcing ribs 8 can greatly improve the cable The tensile strength used by the body, the fastening ring 9 includes a first fixing ring 901 and a second fixing ring 902, the first fixing ring 901 and the second fixing ring 902 pass through a plurality of reinforcing ribs 8, and the first fixing ring 901 and the second fixing ring 901 The sides of the two fixed rings 902 are fitted with clamping blocks 903, the sides of the first fixed ring 901 and the second fixed ring 902 are fitted with slots 904, and one end of the clamping blocks 903 extends to In the corresponding card slot 904 and locked with the card slot 904, a locking assembly is provided at the joint between the first fixing ring 901 and the second fixing ring 902, so that the first fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com