Icing wind tunnel pressure measurement test method

A test method and pressure measurement technology, which is applied in the field of wind tunnel tests, can solve the problems of test influence, inability to achieve fixed-point deicing, and damage to ice shape, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

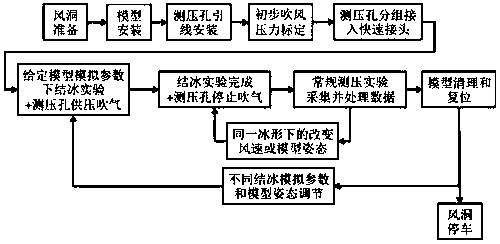

Method used

Image

Examples

Embodiment 1

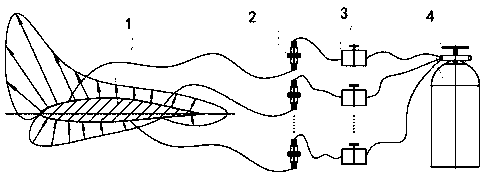

[0051] Such as figure 2 As shown, when ice blowing is required in an icing wind tunnel, a pressure regulating valve and an air source are connected through a joint at one end of the pressure measuring tube, and the pressure measuring tube is directly supplied with a high-pressure air source to make the measured The pressure measuring hole on the model is sprayed out of the model to prevent the sand contained in the blowing test from blocking the pressure measuring hole. In the icing and blowing test, the temperature in the wind tunnel is very low and contains a lot of moisture. Therefore, in order to avoid the freezing of water vapor in the pressure measuring hole, the high-pressure air source adopts a hot air flow with a certain temperature to carry out the pressure measuring hole. Spray to avoid freezing of the pressure tap.

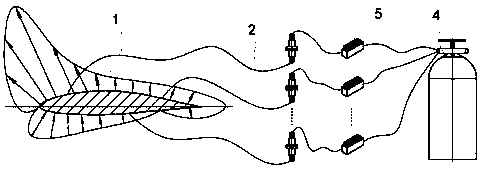

[0052] Such as image 3 As shown, when it is necessary to measure the ice shape on the surface of the tested model in an icy wind tunnel, quickly remov...

Embodiment 2

[0055] On the basis of the first embodiment, in order to improve the measurement accuracy in one step, a connector of the embodiment is designed as a quick connector. The quick connector has multiple input terminals, and the multiple input terminals can be switched and cut off. The scanning valve and the pressure regulating valve can be connected to the quick coupling at the same time through the quick coupling.

[0056] During the test, the high-pressure gas source and the scanning valve are switched in the pressure measurement pipeline by controlling the quick connector, reducing the state delay in the measurement process, and accurately realizing the real-time measurement of the state in the wind tunnel.

[0057] The above two embodiments are aimed at the pressure measurement during the icing process in the icing wind tunnel. For the conventional pressure distribution test and the conventional inlet pressure test, you can participate in the published document "Wang Xunnian et al....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com