Nitrogen spring with self-induction monitoring function and pressure monitoring system thereof

A nitrogen gas spring, functional technology, used in springs, springs/shock absorbers, gas shock absorbers, etc., can solve the problems of large space occupation, difficulty in finding faults in time, and inability to install in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

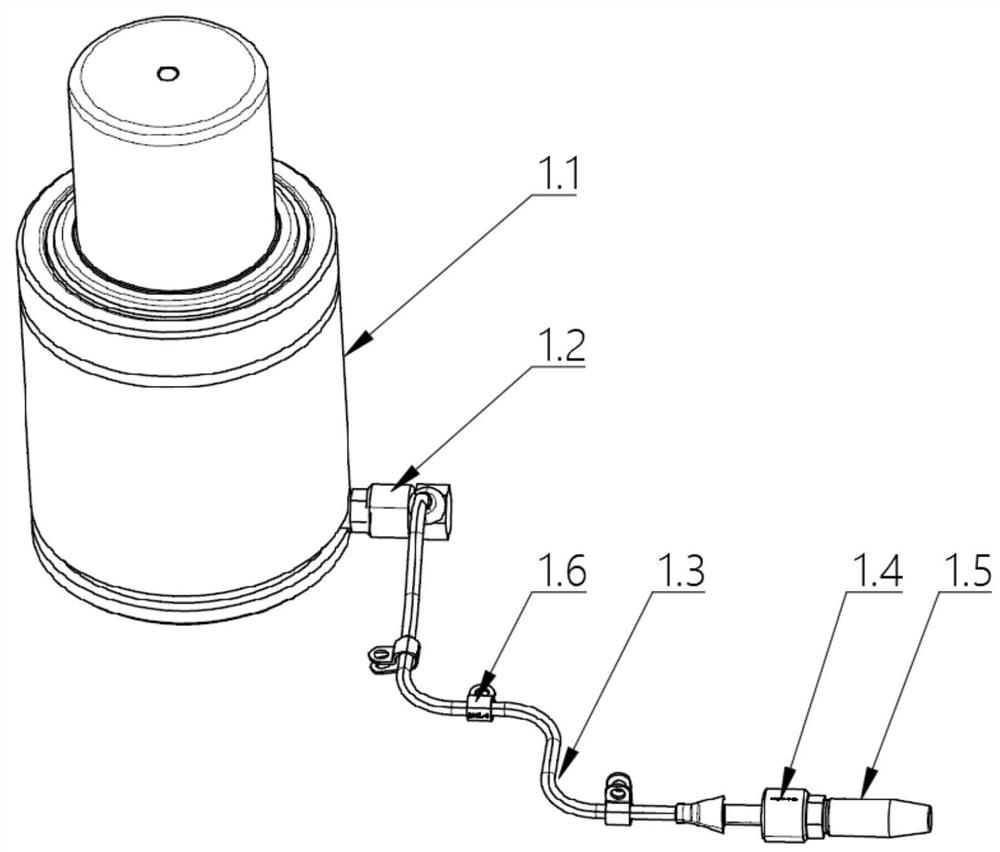

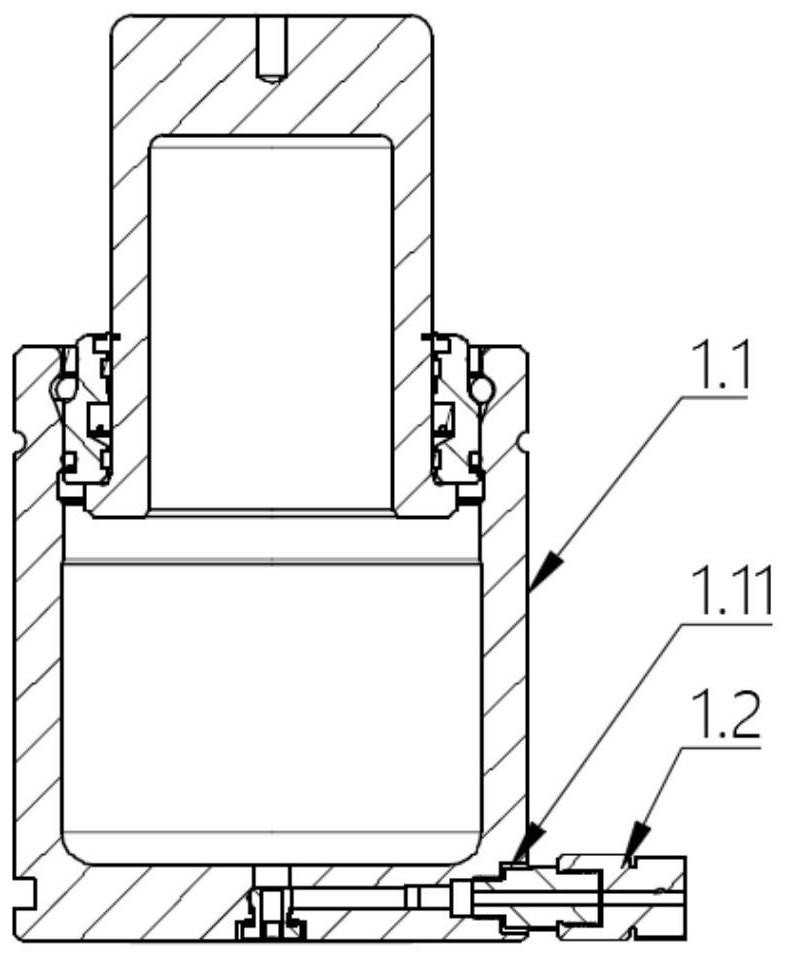

[0022] like Figure 1~4 As shown, the nitrogen gas spring with self-induction monitoring function designed in this embodiment includes the nitrogen gas spring body 1.1 (equivalent to the nitrogen gas spring before improvement) and the self-induction component. in:

[0023] The nitrogen gas spring body 1.1 is provided with an inflation interface 1.11.

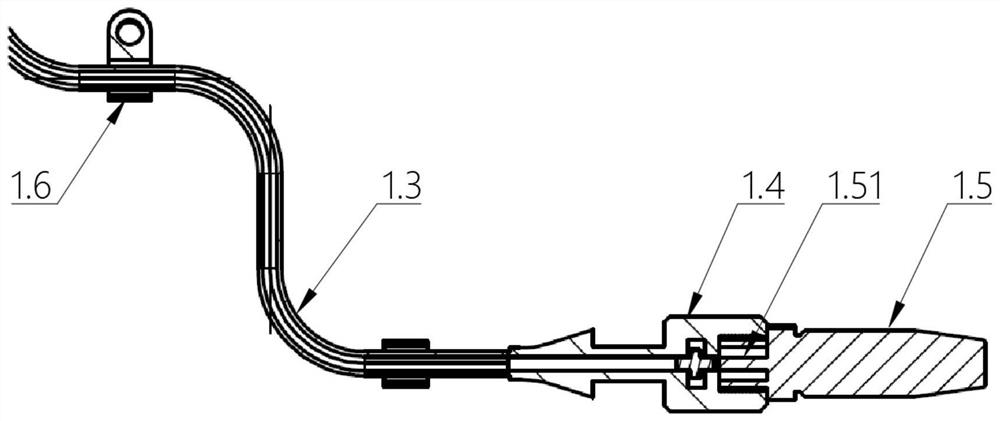

[0024] The self-sensing assembly includes an adapter 1.2, a hose 1.3, an inflation check valve 1.4 and a wireless pressure sensor 1.5 with a wireless signal transmitter (a WiFi module is used in the embodiment).

[0025] One end of the adapter 1.2 is threadedly connected with the inflation interface 1.11 of the nitrogen gas spring body 1.1, and the other end is connected with one end of the hose 1.3.

[0026] The other end of flexible pipe 1.3 links to each other with the air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com