Flattening and dust-removing composite cloth roll

A technology of composite cloth and cloth roller, which is applied in the direction of electrostatic cleaning, winding strips, cleaning methods and utensils, and can solve the problems of inability to remove impurities on the surface of textiles, non-existence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

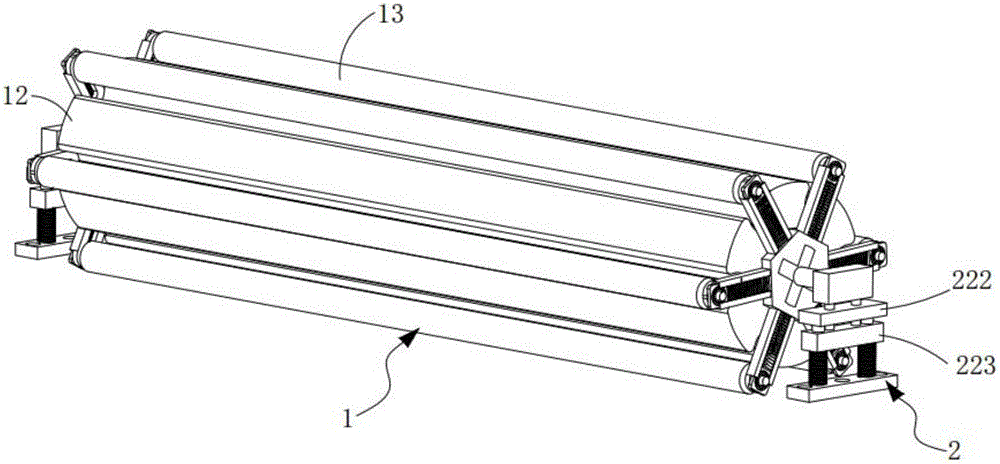

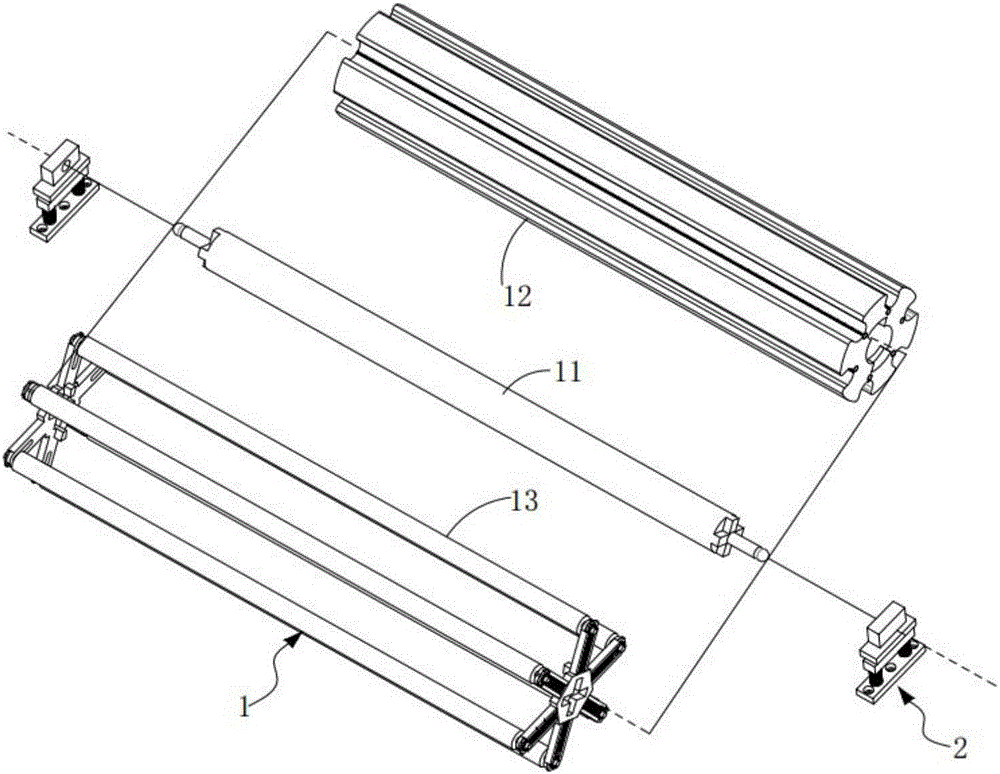

[0060] Such as figure 1 , figure 2 and image 3 As shown, this embodiment provides a flat and dust-removing composite cloth roller, including:

[0061] Roller body 1, the roller body 1 includes a main shaft unit 11, a rolling cloth roller unit 12, a telescopic cloth roller unit 13 and a brush roller unit 14, the outer side of the main shaft unit 11 is provided with a rolling cloth roller unit 12. The cloth roller unit 13 is located outside the rolling cloth roller unit 12; the two ends of the telescopic cloth roller unit 13 and the two ends of the main shaft unit 11 are fixedly connected by splicing, and the two realize synchronous rotation; The brush roller unit 14 is arranged on the outer wall of the rolling cloth roller unit 12, which is set corresponding to the telescopic cloth roller unit 13; when cleaning the brush roller unit, the rolling cloth roller unit 12 can be opposite to the The main shaft unit 11 reversely rotates, so that the rolling cloth roller unit 12 is...

Embodiment approach

[0077] Such as Figure 10 As shown, as a preferred implementation manner, the telescopic assembly 135 includes:

[0078] Slide the slider 1351 arranged in the chute 1331, the slider 1351 is embedded with a ball bearing 1352, and the slider 1351 is symmetrically sleeved on both ends of the telescopic cloth roller 134 through the ball bearing 1352 ;as well as

[0079] A telescopic spring 1353 , the telescopic spring 1353 is arranged in the sliding slot 1331 , one end of which is fixedly connected to the inner end surface of the slider 1351 , and the other end is fixedly connected to the base 131 .

[0080] It should be noted that when the rolling cloth roller unit 12 is in operation, the installation arms 133 of the telescopic cloth roller unit 13 are symmetrically arranged at both ends of the arc-shaped groove 1211, and the center line of the installation arm 133 is aligned with the center line of the arc-shaped groove 1211. Overlapping, the rolling cloth roller unit 12 and t...

Embodiment 2

[0082] image 3 , Figure 5 , Figure 9 and Figure 10 It is a structural schematic diagram of Embodiment 2 of a flat and dust-removing composite cloth roller of the present invention; Figure 9 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment two and embodiment one is:

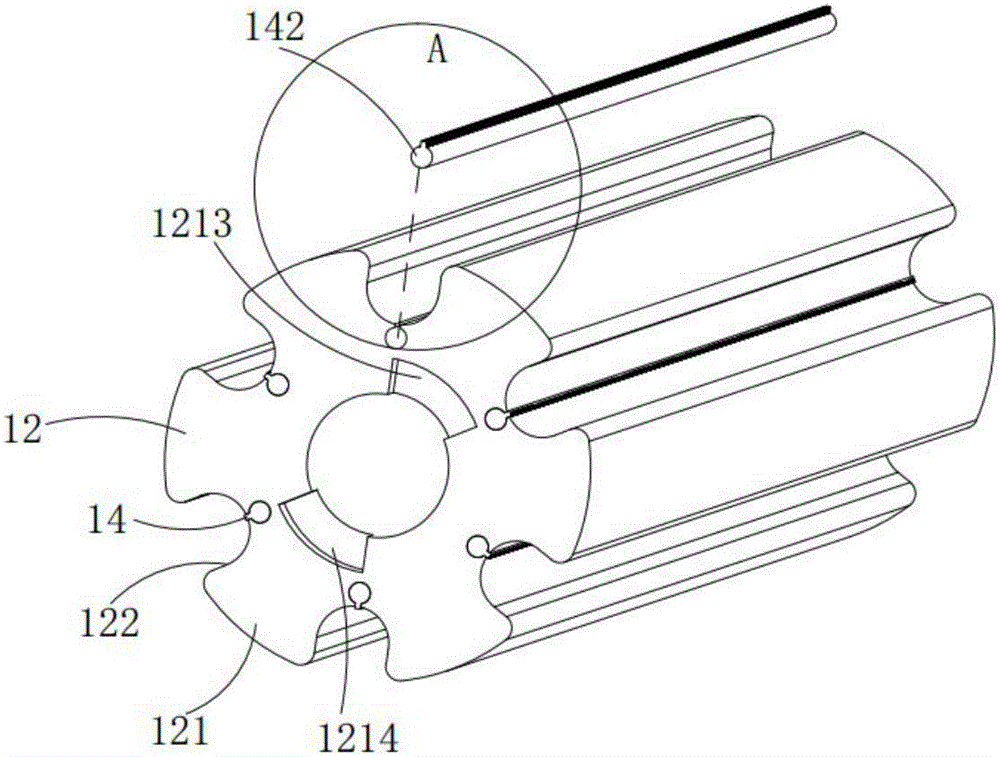

[0083] Such as image 3 shown, also includes:

[0084] Both ends of the rolling cloth roller 121 are provided with fan-shaped slots a1213 and fan-shaped slots b1214, and the fan-shaped slots a1213 and fan-shaped slots b1214 are arranged symmetrically, and the fan-shaped slots a1213 and fan-shaped slots b1214 are both arranged on opposite sides. Between two arc-shaped slots 1211 , extension lines of both sides of the fan-shaped slot a1213 and the fan-shaped slot b1214 pass through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com