Anti-fold cloth feeding device for cloth spreading machine

A cloth feeding device and anti-wrinkle technology, applied in the direction of spreading thin soft materials, transportation and packaging, winding strips, etc., can solve the problem of inaccurate laying position and length of cloth, influence of cutting quality, rising defective rate, etc. problem, to achieve the effect of flatness, simple structure, and elimination of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

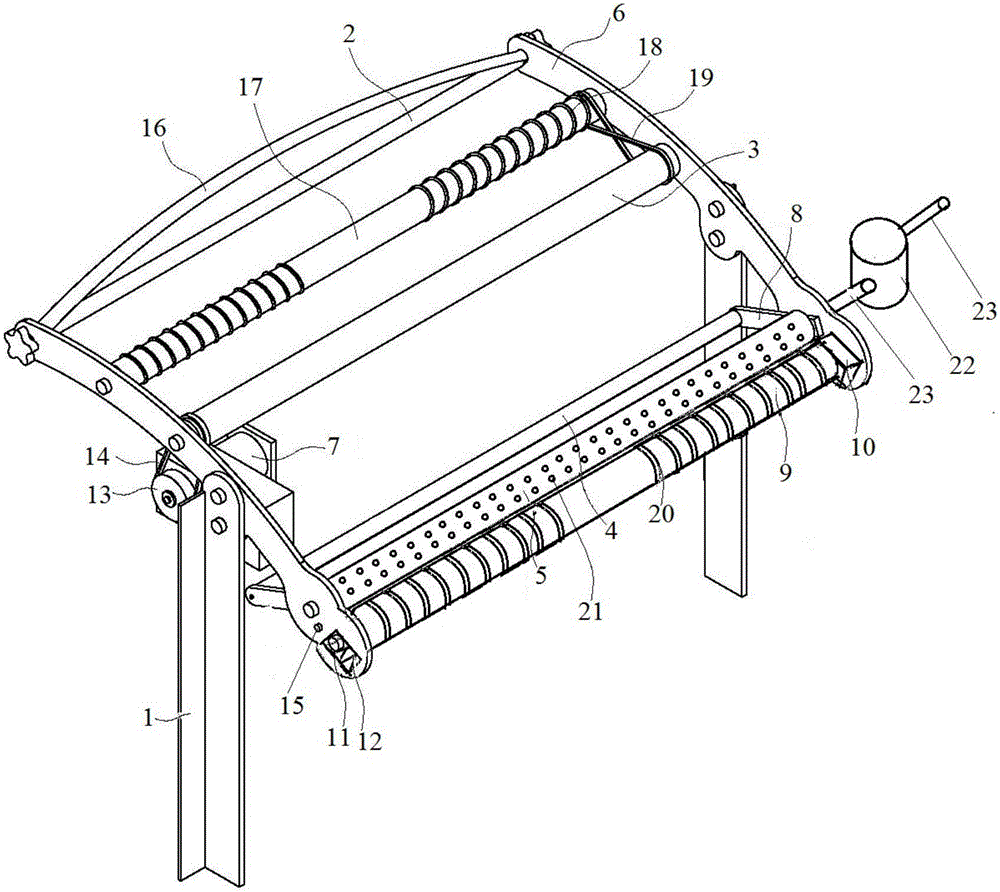

[0022] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0023] as attached figure 1 Shown: the present invention is a cloth arrangement device of a cloth spreading machine, the device includes a frame 1 and a cloth feeding unit arranged on the frame 1, the cloth feeding unit includes a cloth guide roller 2, a cloth feeding unit Roller 3, tension roller 4 and cloth discharge roller 5, the cloth guide roller 2, cloth feed roller 3 and cloth discharge roller 4 are parallel and sequentially arranged on the cross bar 6 of the frame 1, the cloth feed roller 3 consists of a The motor 7 is driven to rotate, and the two ends of the tension roller 4 are pivotally connected to the two ends of the cloth disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com