Special-purpose low temperature solidification silver migration resistance laser etching conductive silver paste for handset touch screen and preparation method thereof

A technology of conductive silver paste and laser etching, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as device short circuit, open circuit failure, and complete machine failure, and achieve improved contact Effects of denaturation, reduced dosage, and enhanced binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

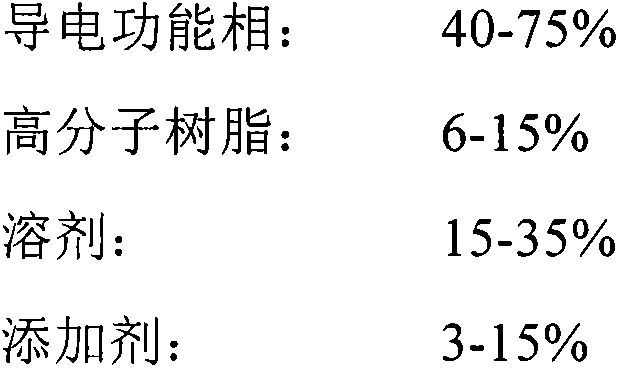

Method used

Image

Examples

example 1

[0028] The silver paste is prepared through three process steps of preparation of polymer resin carrier, preparation of conductive silver paste and post-treatment of conductive silver paste.

[0029] Step 1, preparation of polymer resin carrier.

[0030] First by weighing 40% low-molecular-weight polyester resin (relative molecular mass is 15000) by mass percentage and mixes with 60% diethylene glycol ether acetate and diethylene glycol butyl ether acetate mixed solvent, and at 70 ℃ Dissolve completely under; Then take 20% high molecular weight polyester resin (relative molecular mass is 35000) and mix with 80% ethylene glycol ethyl ether according to mass percentage, and dissolve completely at 70 ℃. Finally, the two carriers were weighed and mixed with a mass ratio of 4:1. They were mixed and stirred evenly at 70° C., and the obtained carrier had a viscosity of 6000-7000 cps. The carrier is then filtered to remove impurities on a 600-mesh stainless steel screen to obtain the...

example 2

[0037]The silver paste is prepared through three process steps of preparation of polymer resin carrier, preparation of conductive silver paste and post-treatment of conductive silver paste.

[0038] Step 1, preparation of polymer resin carrier

[0039] First by weighing 40% low molecular weight polyester resin (relative molecular mass is 15000) mixed with 60% diethylene glycol butyl ether acetate by mass percentage, and dissolve completely at 70 ℃; Then weigh according to mass percentage 40% of high molecular weight polyester resin (relative molecular mass is 35,000) is mixed with 60% of ethylene glycol ether acetate, and dissolved completely at 70°C. Finally, the two carriers were weighed and mixed with a mass ratio of 3:16, mixed and stirred evenly at 70°C, and the viscosity of the obtained carrier was 13000-15000cps, and then the carrier was filtered on a 400-mesh stainless steel screen to obtain the final Polymer resin carrier.

[0040] Step 2, preparation of conductive ...

example 3

[0046] The slurry preparation method is similar to example one and two.

[0047] The proportion of each component is: high molecular weight resin-5.26%, low molecular weight resin content-4.06%, ethylene glycol ethyl ether acetate-4.12%, diethylene glycol butyl ether acetate-2.95%, DBE-7.5%, hydroxyethyl ether Base Cellulose-1.5%, Polyamide Wax-0.5%, Dibutyl Phthalate-1%, BYK-R605-0.5%, Benzyl Glycidyl Ether-2.5%, Silicone Oil-1%, Acrylate Flow Leveling agent-0.5%, sodium dodecylsulfonate-1%, fluorine-modified surfactant-0.5%, dodecanoic acid-1.5%, and the remaining components are mixed conductive powder.

[0048] The composition ratio of the mixed silver powder and the conductive carbon black is: micron flake silver powder-75.02%, nanometer anti-silver migration spherical silver powder-18.74%, and nanometer conductive carbon black-6.24%.

[0049] Using Brookfield DV-II viscometer, using No. 28 spindle to measure at 50 rpm, the viscosity is 50000-60000cps. After printing, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com