Heat shrink film

A heat-shrinkable film and base layer technology, applied in the field of packaging materials, can solve the problems of poor material rheology or melt fluidity, difficult to control the sealing anti-pollution ability, and poor heat-sealing properties of materials, etc., to achieve excellent resistance to environmental stress Crack resistance, strong sealing anti-pollution ability, and strong comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

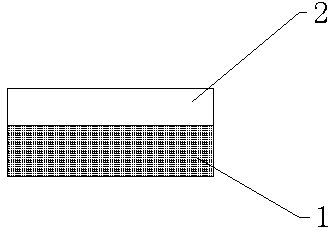

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0012] A heat-shrinkable film, comprising a base layer 1 and a buffer layer 2, the base layer 1 is a composite material of LLDPE and OPS, the mass ratio of the LLDPE and OPS is 2.5-3.5:1, and the buffer layer 2 is a POF material Compounded with UV anti-ultraviolet agent, LDPE is applied to heat shrinkable film to enhance the properties of tensile resistance, penetration resistance, impact resistance and tear resistance, making LLDPE suitable for film. Its excellent resistance to environmental stress cracking, resistance to Low-temperature impact and warpage resistance make LLDPE attractive for pipe, sheet extrusion and all molding applications. At the same time, it has good heat-sealability, easy processing, and strong anti-pollution ability for se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com