Double-deck plastic bag blow-molding processing technology

A processing technology and technology for plastic bags, applied in the field of plastics, can solve the problems of pollution, waste of materials, and complicated processing, and achieve the effects of avoiding environmental pollution, excellent performance, and enhanced rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

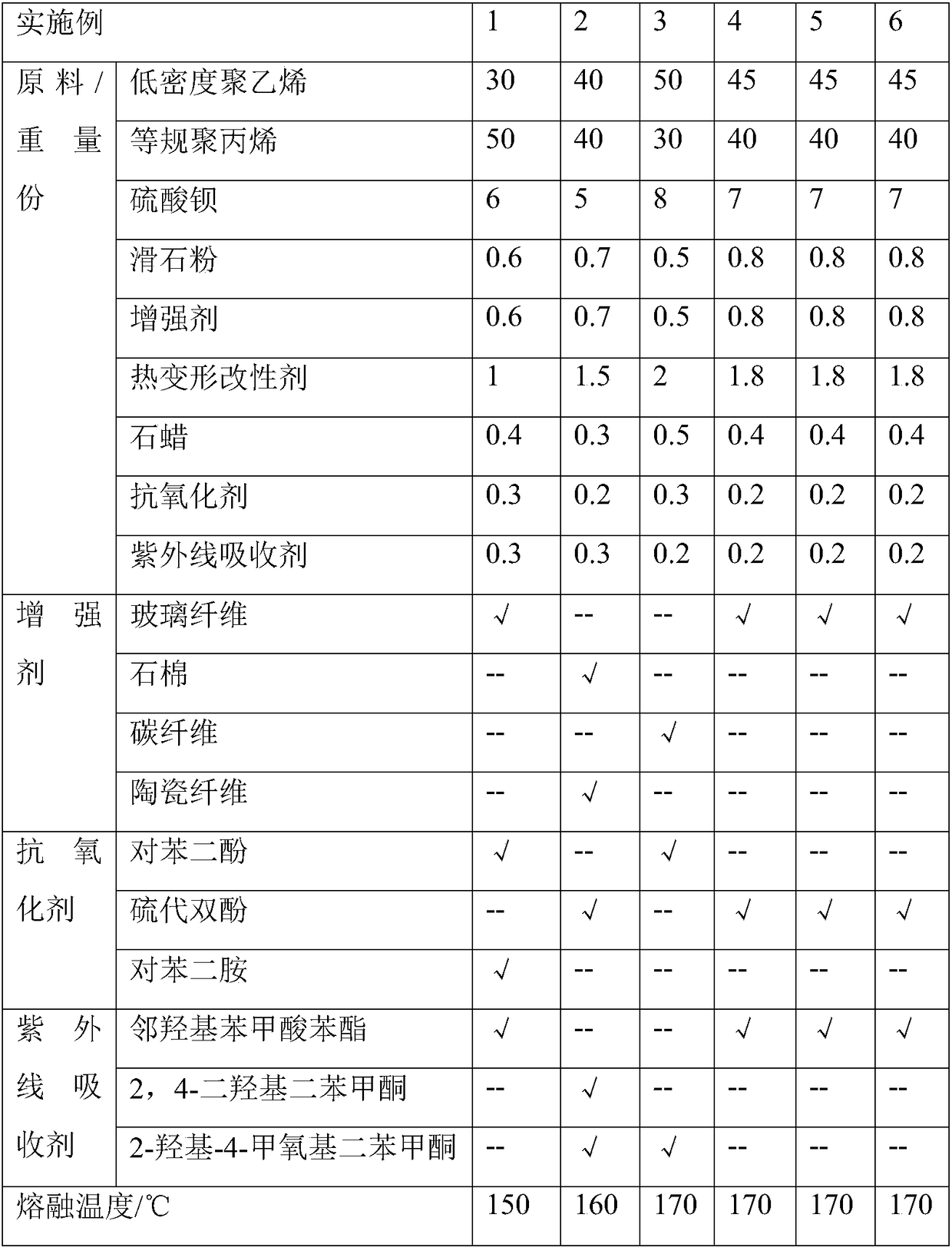

[0040] The specific implementation of embodiment 1-embodiment 6 is as shown in table 1, and wherein embodiment 1-embodiment 4 is the technical parameter defined in the present invention, does not contain polypropylene in embodiment 5, is single in embodiment 6 Layer plastic bag, wherein embodiment 5-embodiment 6 is the technical parameter defined in the present invention.

[0041]

[0042] Table 1

[0043] The performance parameter of embodiment 1-embodiment 6 is as shown in table 2, and wherein embodiment 1-embodiment 4 is the technical parameter defined in the present invention, does not contain polypropylene in embodiment 5, is monolayer in embodiment 6 Plastic bag, wherein embodiment 5-embodiment 6 is the technical parameter defined in the present invention.

[0044] Example

[0045] Table 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com