A thin-walled high-strength inlaid drip irrigation belt and its high-speed production method

A high-strength, drip irrigation belt technology, applied in the field of polymer material processing, can solve the problems of low pressure resistance, low melt strength, easy pipe breakage, etc., to improve the processing speed and pressure resistance, the best dispersion effect, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

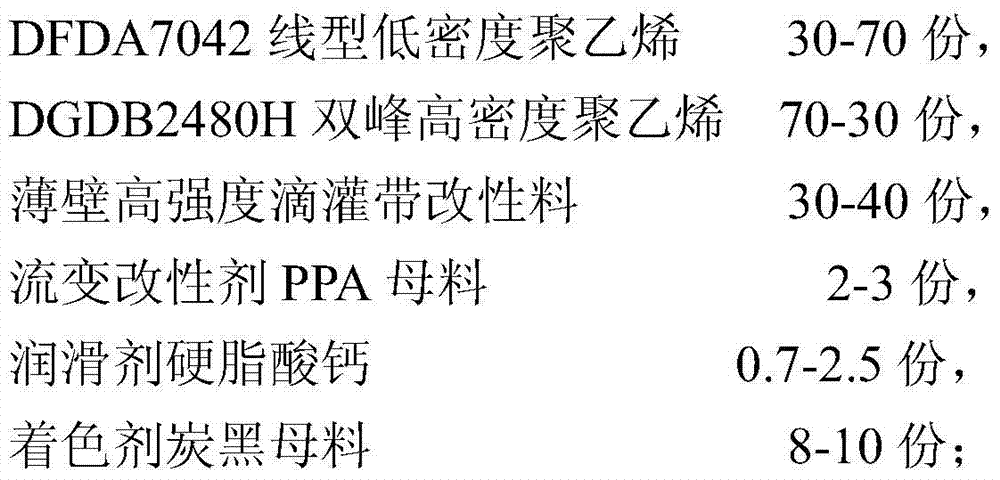

[0028] Embodiment 1 A kind of high-speed production method of thin-walled high-strength inlaid drip irrigation belt, through the preparation of thin-walled high-strength drip irrigation belt modified material, three steps of blending and extrusion stretching, each step is described as follows:

[0029] Ⅰ. Preparation of modified material for thin-walled high-strength drip irrigation tape

[0030] First, place nylon 6 in the modified material of thin-walled high-strength drip irrigation tape in a vacuum oven at 80°C for 12 hours, and take 70 parts of DGDB2480H bimodal high-density polyethylene, 15 parts of dried nylon 6, and 15 parts of HDPE-g - The MAH compatibilizer is evenly dispersed in the mixer and then granulated by a twin-screw extruder. The temperature of the extruder is controlled from the feeding port to the machine head: the first zone of the feeding section is 145±3°C, and the second zone is 180±3°C. In the mixing section, the first zone is 200±3℃, the second zone ...

Embodiment 2

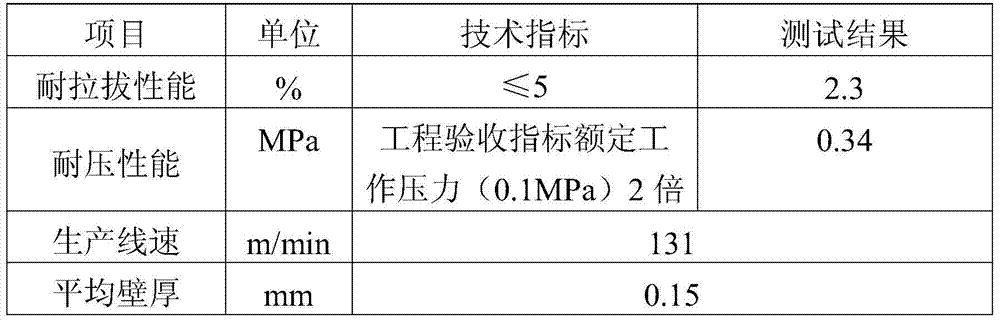

[0038] Step I in Example 2 is the same as Step I in Example 1, and Step II is: take 50 parts of DFDA7042 linear low-density polyethylene, 50 parts of DGDB2480H bimodal high-density polyethylene, and 35 parts of step Ⅰ The prepared thin-walled high-strength drip irrigation belt modified material, 2.5 parts of rheology modifier PPA masterbatch, 1.5 parts of lubricant calcium stearate, and 9 parts of colorant carbon black masterbatch were put into a high-speed mixer for Mix and stir evenly to form a mixture; then obtain a thin-walled high-strength inlaid drip irrigation belt according to step III in Example 1.

[0039] The production line speed and performance test results of the thin-walled high-strength inlaid drip irrigation belt obtained in Example 2 are shown in Table 2.

[0040] Product line speed and performance test result of table 2 embodiment 2

[0041]

Embodiment 3

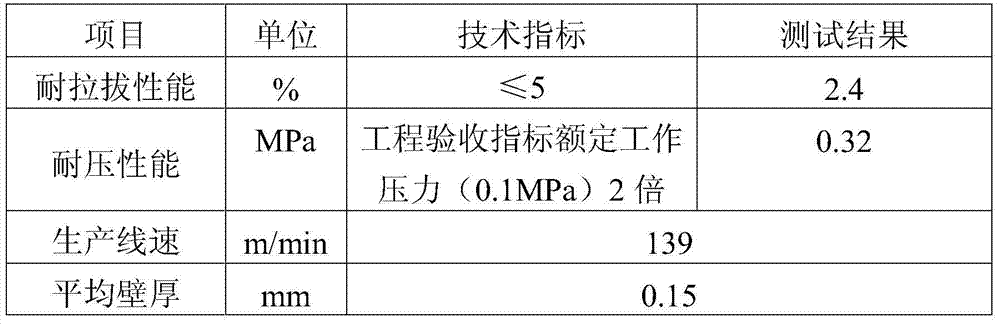

[0043] Step I in Example 3 is the same as Step I in Example 1, and Step II is as follows: 65 parts of DFDA7042 linear low-density polyethylene, 40 parts of DGDB2480H bimodal high-density polyethylene, and 39 parts of step Ⅰ The prepared thin-walled high-strength drip irrigation belt modified material, 2.9 parts of rheology modifier PPA masterbatch, 2.0 parts of lubricant calcium stearate, and 9.5 parts of colorant carbon black masterbatch were put into a high-speed mixer for Mix and stir evenly to form a mixture; then obtain a thin-walled high-strength inlaid drip irrigation belt according to step III in Example 1.

[0044] The production line speed and performance test results of the thin-walled high-strength inlaid drip irrigation belt obtained in Example 3 are shown in Table 3.

[0045] Product production line speed and performance test result of table 3 embodiment 3

[0046]

[0047] See Table 4 for the comparison of the production line speed and performance of the dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com