A kind of ABS/polyester alloy material and its preparation method and application

A technology of polyester alloy and polyester resin, which is applied in the field of ABS/polyester alloy materials and their preparation, can solve problems such as limiting the use range of materials and material cracking, achieve excellent environmental stress cracking resistance, solve water leakage and cracking, Significant technical and market value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

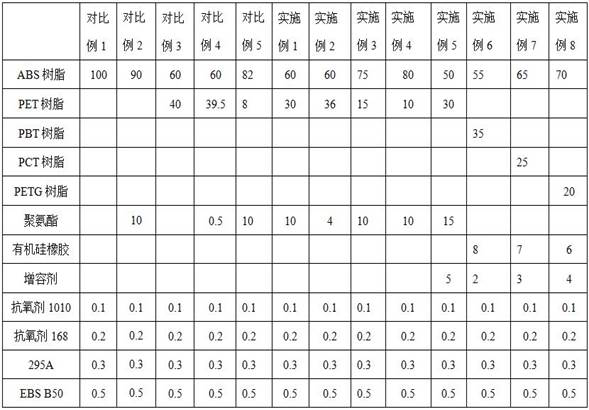

Embodiment 1-8 and comparative example 1-5

[0046] Mix the components uniformly according to the ratio in Table 1, melt and blend and extrude in a twin-screw extruder, and obtain an ABS / polyester alloy material after underwater pelletizing and drying. The performance test results are shown in Table 2; Among them, the temperature of the first to second zones of the twin-screw extruder is 120°C to 190°C, the temperature of the third to fifth zones is 200°C to 280°C, the temperature of the fifth to tenth zones is 200°C to 240°C, and the screw speed is 350 rpm to 450rpm.

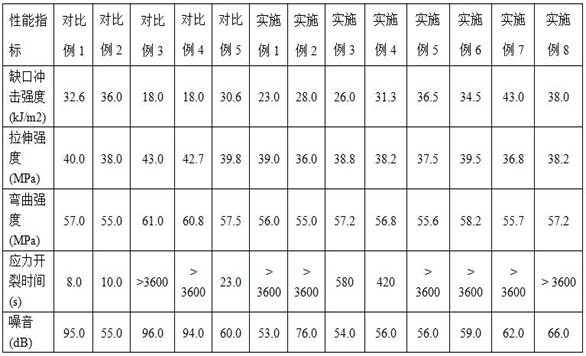

[0047] The notched impact strength is tested according to the ISO 180 standard, and the notch type is type A;

[0048] The tensile strength is tested according to the ISO 527 standard, and the tensile speed is 50 mm / min;

[0049] The bending strength is tested according to the ISO 178 standard, and the bending rate is 2 mm / min;

[0050] Stress cracking time: The test solvent is glacial acetic acid (>99%), and the deflection of the test fixture is 2.54cm;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com