Aluminium pipe

An aluminum tube and inner layer technology is applied to the aluminum tube. It can solve the problems of reducing the service life of aluminum tubes, easy accumulation of scale on the inner wall, and limited strength of aluminum tubes, so as to achieve the effect of prolonging service life, increasing strength, and not easy to form scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

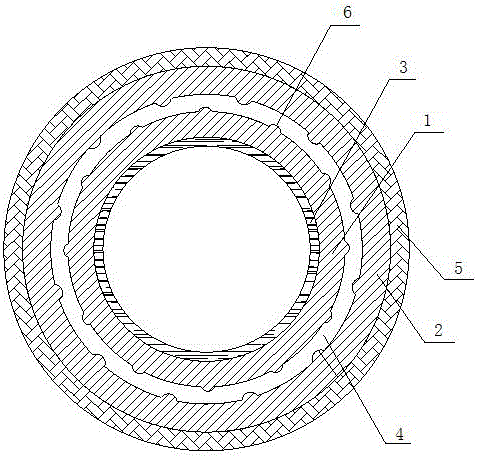

[0011] An aluminum tube, comprising an inner layer aluminum tube 1 and an outer layer aluminum tube 2. The inner layer of aluminum tube 1 is provided with a Teflon coating layer 3, which increases the strength and smoothness of the aluminum tube, and prevents liquid from flowing through. It will accumulate scale and can be used normally for a long time; there is a hollow layer 4 between the inner aluminum tube 1 and the outer aluminum tube 2 to prevent sound transmission and have the effect of silencing; the outer aluminum tube 2 is provided with a fluororesin anticorrosive layer 5 outside , To prevent the external medium of the aluminum tube from corroding the aluminum tube and prolong the service life of the aluminum tube; the outer surface of the inner aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com