A kind of preparation method of selective emitter solar cell

A solar cell and selective technology, applied in the field of solar cells, can solve problems such as cell pollution, secondary pollution, and low battery processing efficiency, and achieve the effects of improving efficiency, easy cleaning, and realizing large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

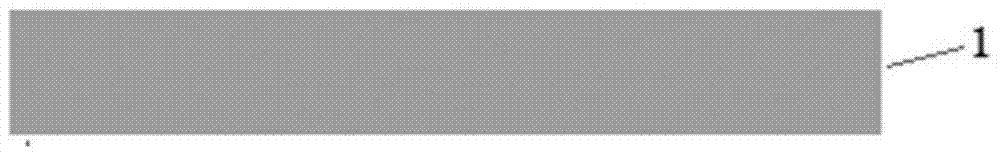

[0043] 1. If figure 1 As shown, take a P-type silicon wafer 1 with good performance, high purity, and a resistivity of 10 ohm / cm, and perform KOH alkaline polishing to remove scratches and uneven areas on the surface of the bare silicon wafer.

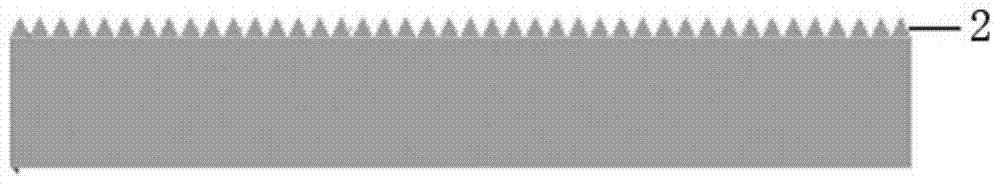

[0044] 2. If figure 2 As shown, the silicon wafer is placed in an alkaline solution to react to form an inverted pyramid suede structure 2, and then acid cleaning is performed to remove the scratch damage layer, organic matter and metal ions on the surface of the silicon wafer.

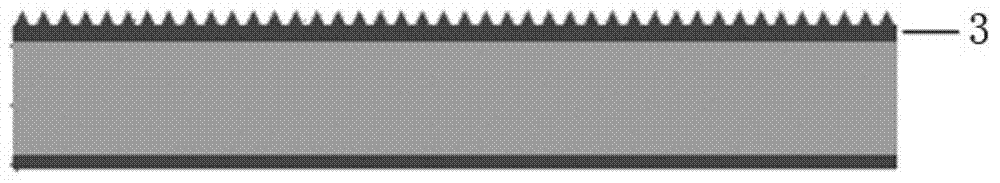

[0045] 3. If image 3 As shown, the silicon wafer is placed in a diffusion furnace for diffusion, using liquid POCl 3 As a diffusion source, diffusion is carried out at 850°C to form n on the surface 3 of the silicon wafer + layer, the square resistance is 20ohm / sq, after diffusion, use hydrofluoric acid to remove the surface phosphosilicate glass.

[0046] 4. If Figure 4As shown, the screen printing barrier ink paste 4RSTINK SCR CLEAR (purchased from S...

Embodiment 2

[0053] 1. If figure 1 As shown, take a P-type silicon wafer 1 with good performance, high purity, and a resistivity of 3 ohm / cm, and perform KOH alkaline polishing to remove scratches and uneven areas on the surface of the bare silicon wafer.

[0054] 2. If figure 2 As shown, the silicon wafer is placed in an alkaline solution to react to form an inverted pyramid suede structure 2, and then acid cleaning is performed to remove the scratch damage layer, organic matter and metal ions on the surface of the silicon wafer.

[0055] 3. If image 3 As shown, the silicon wafer is placed in a diffusion furnace for diffusion, using liquid POCl 3 As a diffusion source, diffusion is carried out at 850°C to form n on the surface 3 of the silicon wafer + layer, the square resistance is 20ohm / sq, after diffusion, use hydrofluoric acid to remove the surface phosphosilicate glass.

[0056] 4. If Figure 4 As shown, the screen printing resist ink paste 4Resist Ink (purchased from PVGS com...

Embodiment 3

[0063] 1. If figure 1 As shown, take a P-type silicon wafer 1 with good performance, high purity, and a resistivity of 5 ohm / cm, and perform KOH alkaline polishing to remove scratches and uneven areas on the surface of the bare silicon wafer.

[0064] 2. If figure 2 As shown, the silicon wafer is placed in an alkaline solution to react to form an inverted pyramid suede structure 2, and then acid cleaning is performed to remove the scratch damage layer, organic matter and metal ions on the surface of the silicon wafer.

[0065] 3. If image 3 As shown, the silicon wafer is placed in a diffusion furnace for diffusion, using liquid POCl 3 As a diffusion source, diffusion is carried out at 850°C to form n on the surface 3 of the silicon wafer + layer, the square resistance is 20ohm / sq, after diffusion, use hydrofluoric acid to remove the surface phosphosilicate glass.

[0066] 4. If Figure 4 As shown, the screen printing resist ink paste 4Resist Ink (purchased from PVGS com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com