Novel deep scarification and soil preparation combined machine

A combined working machine and subsoiling technology, applied in agricultural machinery and equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of unstable ploughing depth, insignificant drag reduction and energy saving, and poor surface leveling, and achieve stable ploughing depth, The effect of good surface flatness and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

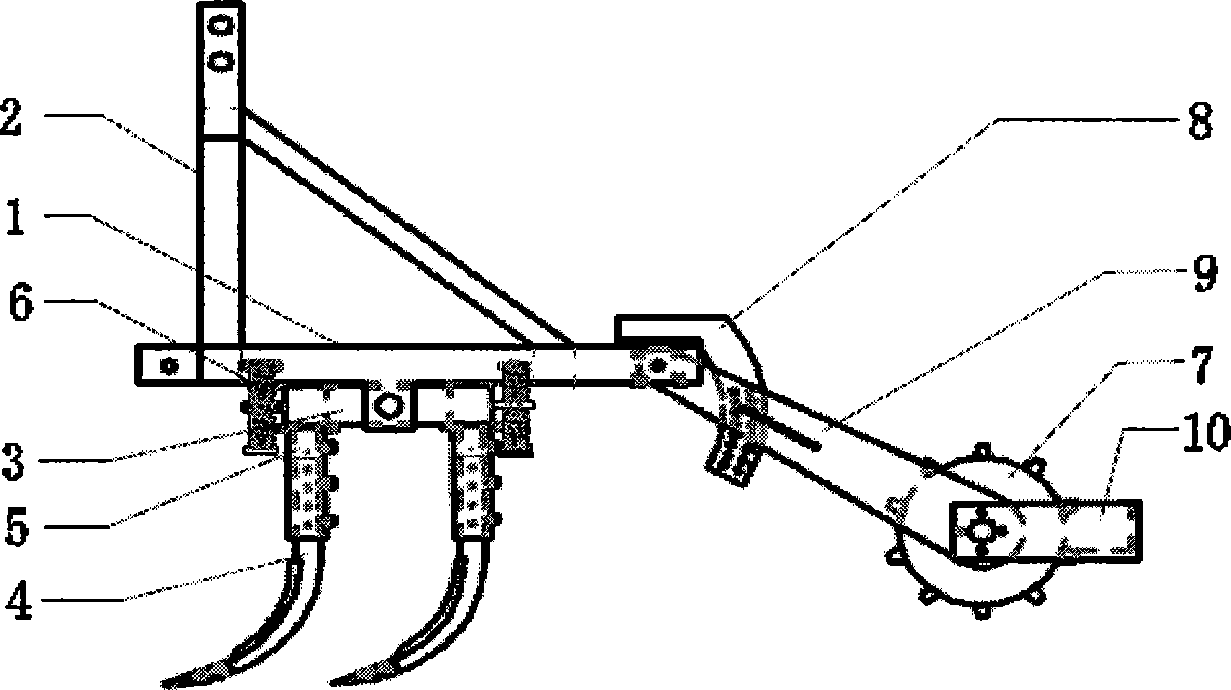

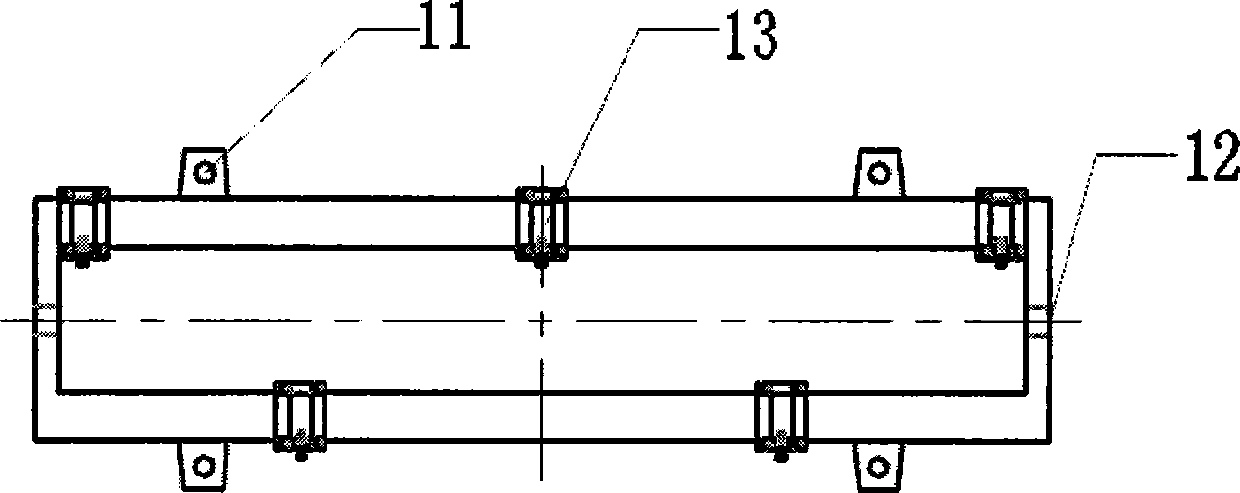

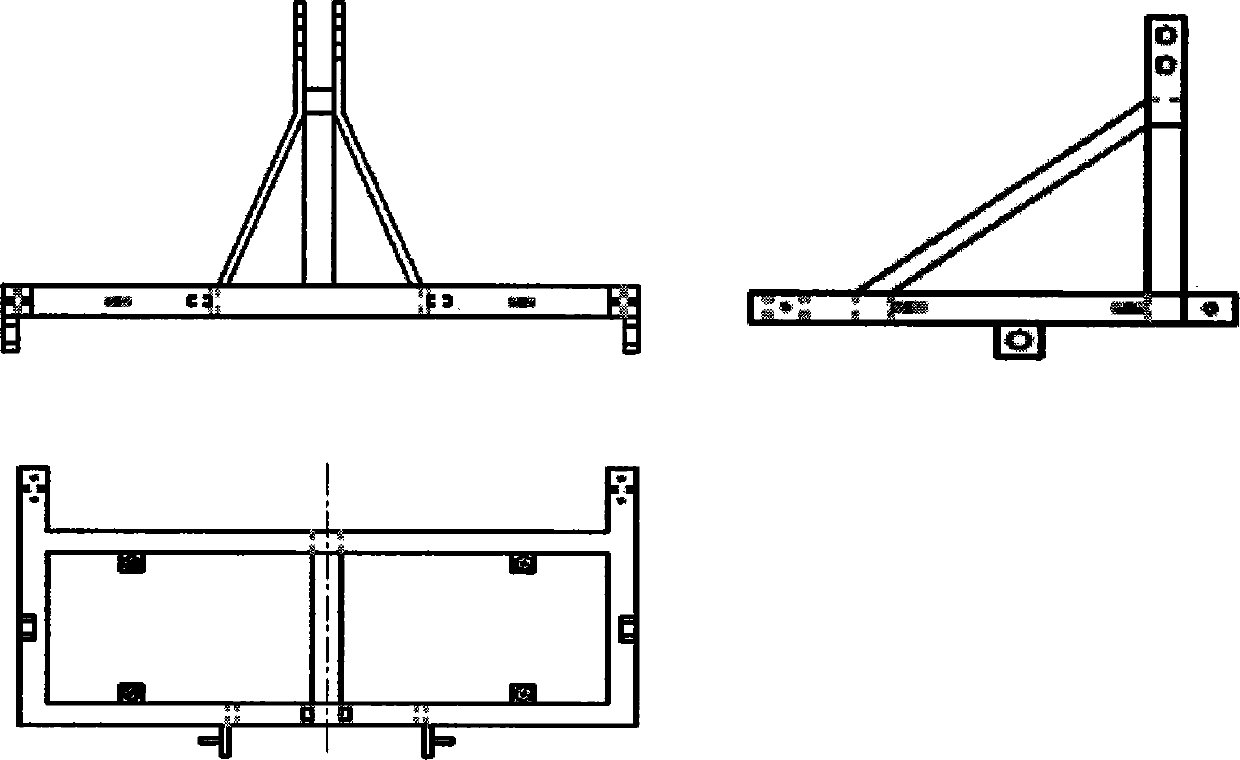

[0017] Such as figure 1 , 2 As shown in , 3, the subsoiling soil preparation combined operation machine includes a frame (1), the front end of the frame (1) is connected with a suspension frame (2), and the suspension frame is connected with a traction machine (such as a tractor) in a three-point suspension mode . The frame (1) and subsoiling shovel (3) are hinged with bearings through the lifting lugs fixedly connected under the side beam of the frame and the hinge hole (12) of the side beam of the shovel frame, and through the spring located between the upper and lower springs of the elastic component group. The spring seat (11) is connected. The two sets of subsoiling shovels (4) are installed at the shovel positions (13) on the front and rear two transverse arms of the subsoiling shovel frame (3) through the subsoiling shovel fixing element (5), adopting an inverted "V" arrangement, and at the same time The depth of tillage and blade distance can be adjusted by changing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com