Welding shielding gas device and pipe fitting connecting piece thereof

A technology of shielding gas and connectors, applied in the direction of pipes/pipe joints/fittings, auxiliary devices, welding equipment, etc., can solve problems such as small and difficult installation, welding failure, welding pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

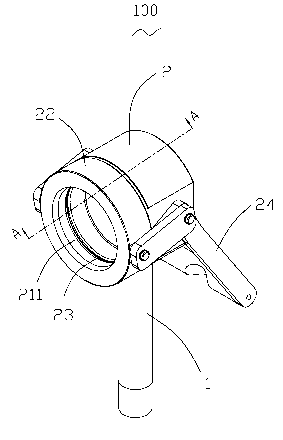

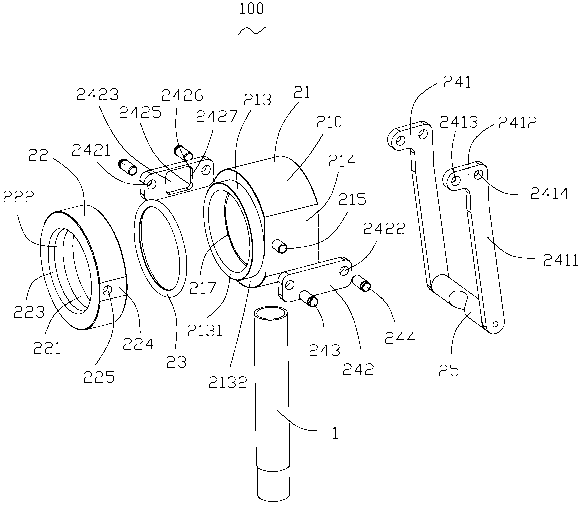

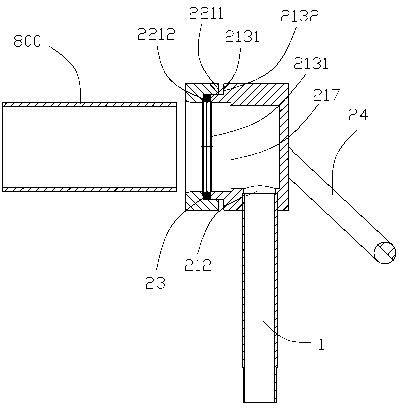

[0030] Please refer to figure 1 Shown is a specific embodiment of the welding shielding gas device 100 of the present invention. Please combine figure 2 and image 3 As shown, the welding shielding gas device 100 includes: a clean gas pipe base (not shown) provided with a clean gas pipe 1 for conveying shielding gas, and a pipe fitting connection fixed at the outlet end of the clean gas pipe 1 to connect a welding pipe 800 piece 2. The pipe connector 2 includes a base 21 connected to the clean air pipe 1, a collar 22 movably positioned at one end of the base 21, a sealing ring 23 embedded between the base 21 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com