Differential spirally-wound type mirror surface polishing process and polishing equipment for metal zipper

A metal zipper and mirror polishing technology, applied in the field of zipper, can solve the problems of high loss rate, insignificant polishing effect, low efficiency, etc., and achieve the effect of preventing fluff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

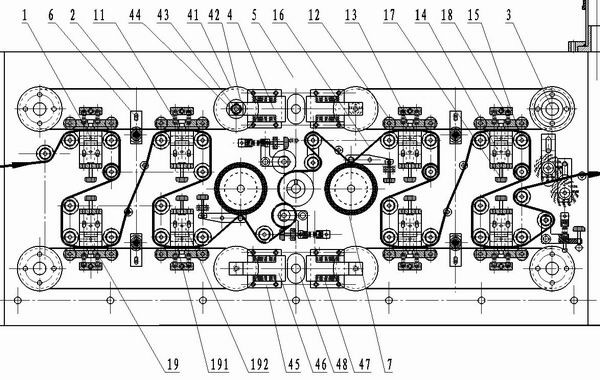

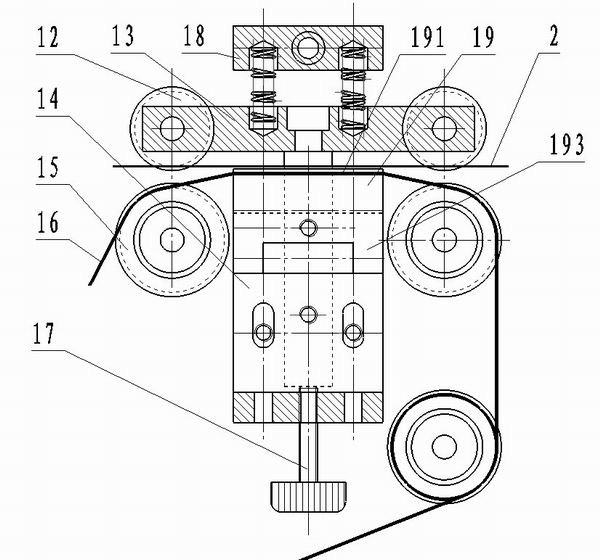

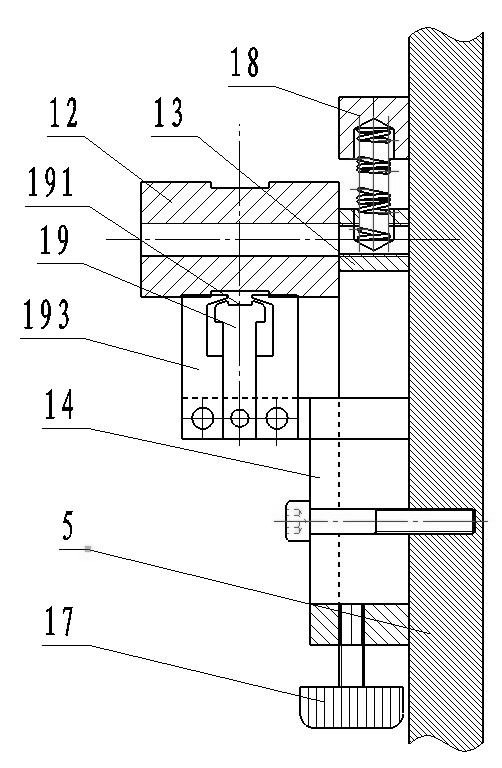

[0037] Differential belt-wound metal zipper mirror polishing process, the chain element surface of the metal zipper is in surface contact with the flexible abrasive belt, the surface of the flexible abrasive belt is attached with abrasive grains for cutting, the zipper and flexible abrasive belt travel at a constant or variable speed, Its traveling action is completed by the transmission assembly, and a forward speed difference is formed between the zipper and the flexible grinding belt. The zipper traveling speed is controlled at 900-2200 m / h, and the best is 1000-1500 m / h. The zipper and the flexible grinding belt The speed ratio of the zipper is 1:150-800, the best is 1:300-600, and the rough surface layer of the zipper is removed by cutting with a flexible grinding belt.

[0038] The polishing equipment for realizing this process is: composed of one or more groups of grinding belt polishing units 1, the structure of the grinding belt polishing unit 1 is: the grinding belt 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com