Double-layer alkali-resisting separation membrane support material and preparing method thereof

A technology for supporting materials and separation membranes, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of poor alkali resistance, poor flexibility, and low strength of separation membrane supports, and improve physical and mechanical properties. and structural stability, reducing resistance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

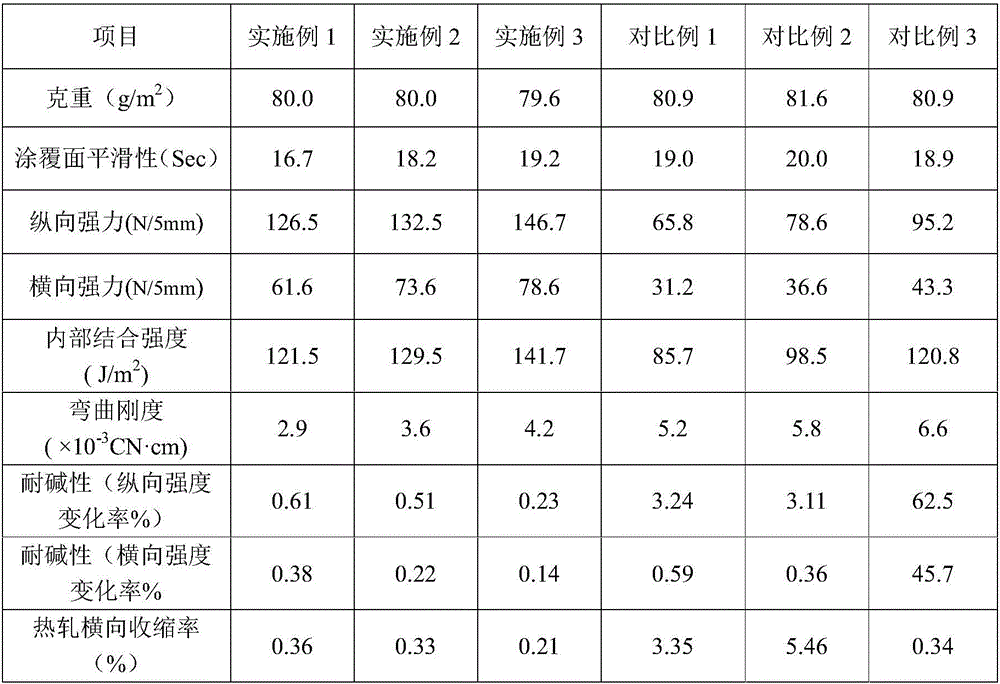

Embodiment 1

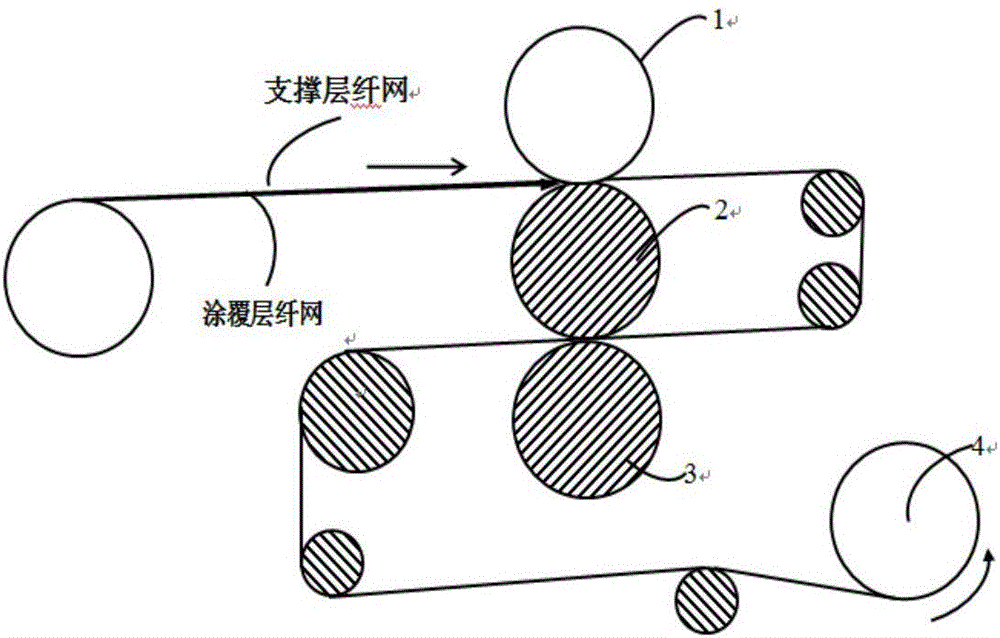

[0032] The preparation of the double-layer wet spunlace separation membrane support mainly includes the following steps:

[0033] 1. Blending pulp

[0034] Disperse polypropylene fiber (fiber diameter 6.3 μm, fiber length 5 mm) and ES fiber (3.2 μm, fiber length 5 mm) in water at a mixing ratio of 60:40, control the fiber concentration to 2%, defrost for 40 minutes, and put it into the slurry Pool, add water and polyacrylamide dispersant and stir evenly to make the concentration 0.03%, viscosity 60 seconds, and make coating layer slurry;

[0035] Disperse polypropylene fiber (fiber diameter 14.5 μm, fiber length 5 mm) and ES fiber (10.2 μm, fiber length 5 mm) in water at a mixing ratio of 60:40, control the fiber concentration to 2%, defrost for 40 minutes, and put it into the slurry Pool, add water and polyacrylamide dispersant and stir evenly, so that the concentration is 0.04%, the viscosity is 65 seconds, and it is made into a support layer slurry;

[0036] 2. Web format...

Embodiment 2

[0041] The preparation of the double-layer wet spunlace separation membrane support mainly includes the following steps:

[0042] 1. Blending pulp

[0043] Disperse polypropylene fibers (fiber diameter 7.2 μm, fiber length 5 mm) and PE fibers (melting point 130 ° C, 4.3 μm, fiber length 5 mm) in water at a mixing ratio of 60:40, control the fiber concentration to 2%, and disperse for 40 minutes. Put it into the slurry mixing tank, add water and polyacrylamide dispersant and stir evenly, so that the concentration is 0.03%, the viscosity is 60 seconds, and it is made into a coating layer slurry;

[0044] Disperse polypropylene fibers (fiber diameter 13.8 μm, fiber length 5 mm) and PE fibers (melting point 130 ° C, 12.6 μm, fiber length 5 mm) in water at a mixing ratio of 60:40, control the fiber concentration to 2%, and disperse for 40 minutes. Put it into the slurry mixing tank, add water and polyacrylamide dispersant and stir evenly, so that the concentration is 0.04%, the vi...

Embodiment 3

[0050] Using the same process conditions and processing methods as in Example 2, the difference is that the pressure of the spunlace main thorn is adjusted to 55bar, and the quantitative 79.6g / m 2 Double layer wet spunlace separation membrane support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com