Stereocomplex polylactic acid material or product with excellent melt stability and melt processability and preparation method thereof

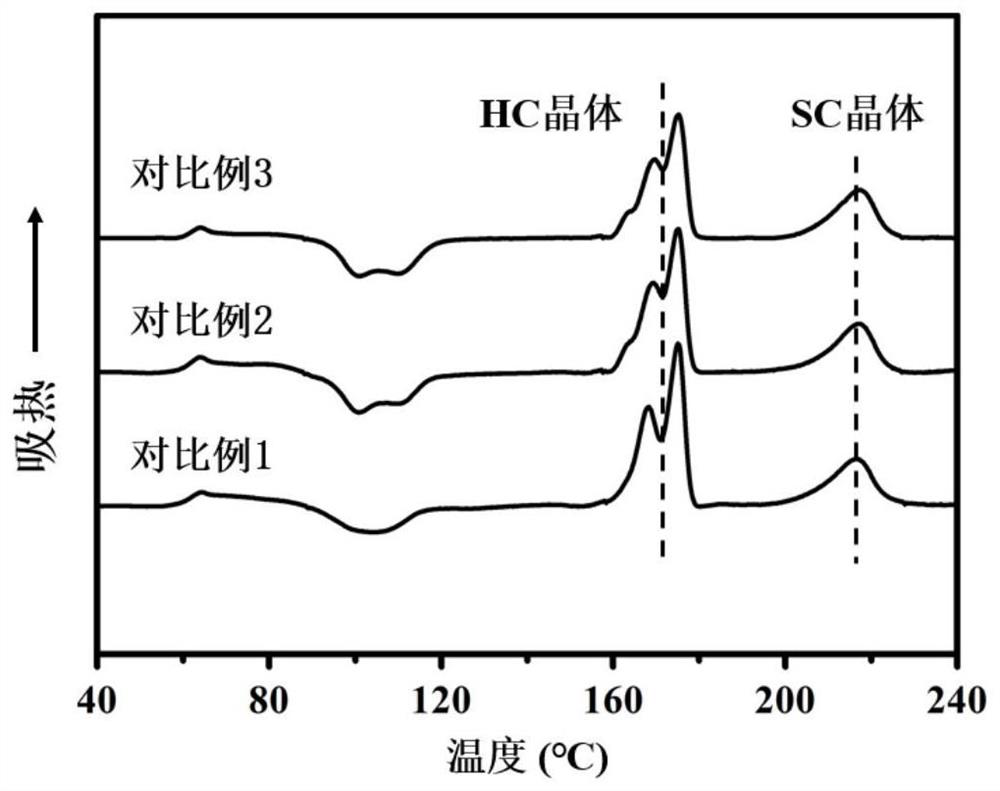

A melting stability and composite polylactic acid technology, applied in the field of stereocomposite polylactic acid materials or products and its preparation, can solve the problem of SC-PLA melt viscosity, low melt strength, difficulty in melt processing and interchain interaction Weaken and other problems, to achieve excellent melt processing performance, excellent melt stability, and the effect of inhibiting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

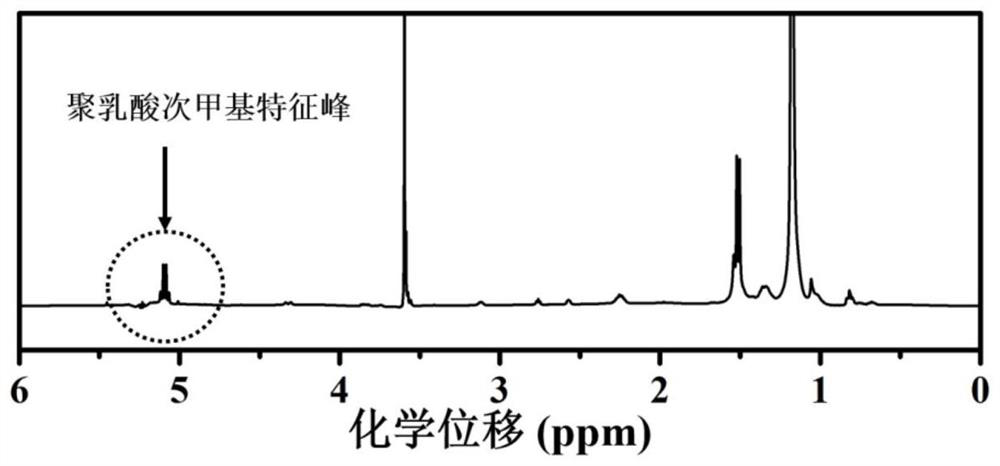

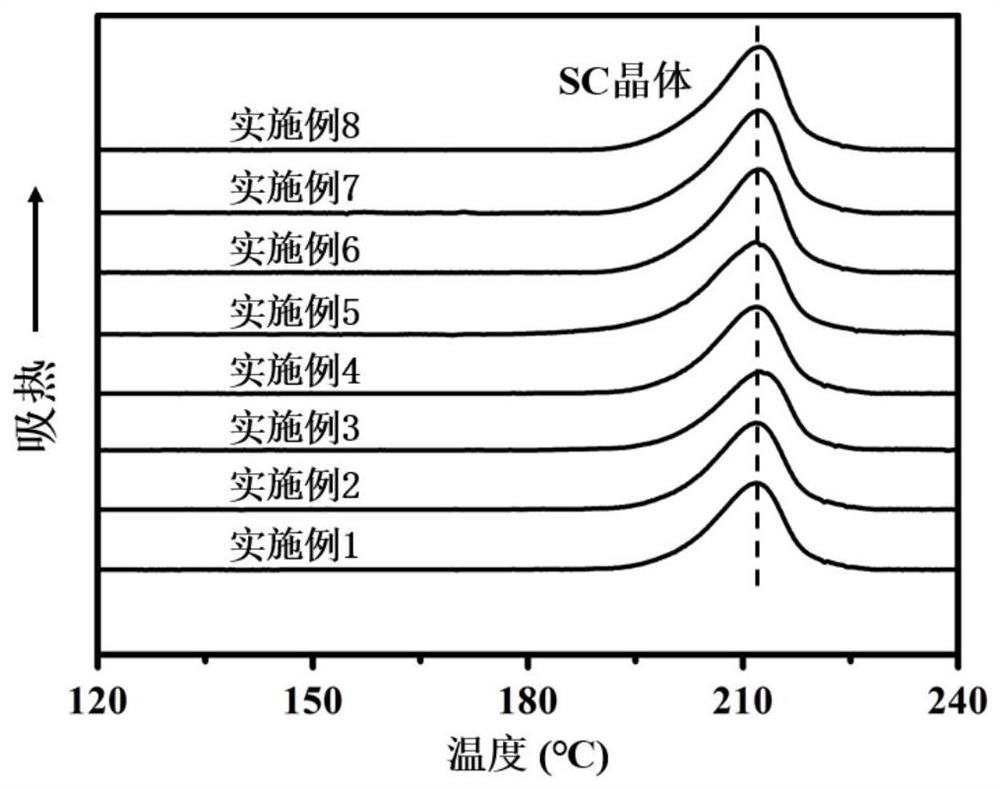

[0039] The weight average molecular weight was 5.0×10 5 g / mol and 3.7×10 5 PLLA and PDLA with g / mol and optical purity of 90% and 95% respectively were vacuum-dried at 60°C until the water content was lower than 200ppm under a vacuum degree of less than 900Pa; 0.1 part of ADR4300 grafting agent, 0.1 part of 14DMA catalyst, 50 1 part of PLLA and 50 parts of PDLA were stirred and mixed evenly; the mixed material was added to a torque rheometer, melted and blended at a temperature of 170 ° C for 3 minutes, and granulated to obtain SC-PLA pellets. The crystallinity of the obtained pellets was 30.7%, and the melting temperature was 210°C; at 240°C, the viscosity of the SC-PLA melt in the high-frequency region was 56Pa·s, and the melt index was 55.1g / 10min.

[0040] The Vicat softening temperature and heat distortion temperature of the product obtained by melting the above pellets at 240°C are 180°C and 166°C, respectively.

Embodiment 2

[0042] The weight average molecular weight was 3.2×10 5 g / mol and 1.0×10 5 PLLA and PDLA with g / mol and optical purity of 92% and 99% respectively were vacuum-dried at 60°C until the water content was lower than 200ppm under a vacuum degree of less than 900Pa; 0.2 parts of TTI grafting agent, 0.2 parts of 12DMA catalyst, 50 1 part of PLLA and 50 parts of PDLA were stirred and mixed evenly; the mixed material was added to a torque rheometer, melted and blended at a temperature of 210 ° C for 4 minutes, and granulated to obtain SC-PLA pellets. The crystallinity of the obtained pellets was 55.2%, and the melting temperature was 227°C; at 240°C, the viscosity of the SC-PLA melt in the high-frequency region was 116Pa·s, and the melt index was 26.3g / 10min.

[0043] The Vicat softening temperature and heat distortion temperature of the product obtained by melting the above pellets at 240°C are 205°C and 190°C, respectively.

Embodiment 3

[0045] The weight average molecular weight was 2.6×10 5 g / mol and 5.0×10 5 PLLA and PDLA with g / mol and optical purity of 95% and 99.5% respectively were vacuum-dried at 60°C until the water content was lower than 200ppm under a vacuum degree of less than 900Pa; 0.3 parts of L-lysine triisocyanate grafting agent, 0.3 parts of 18DMA catalyst, 50 parts of PLLA and 50 parts of PDLA were stirred and mixed evenly; the mixture was added to a torque rheometer, melted and blended at a temperature of 200°C for 7 minutes, and granulated to obtain SC-PLA pellets. The crystallinity of the obtained pellets was 53.1%, and the melting temperature was 222°C; at 240°C, the viscosity of the SC-PLA melt in the high-frequency region was 188Pa·s, and the melt index was 3.6g / 10min.

[0046] The Vicat softening temperature and heat distortion temperature of the product obtained by melting the above pellets at 240°C are 202°C and 189°C, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com